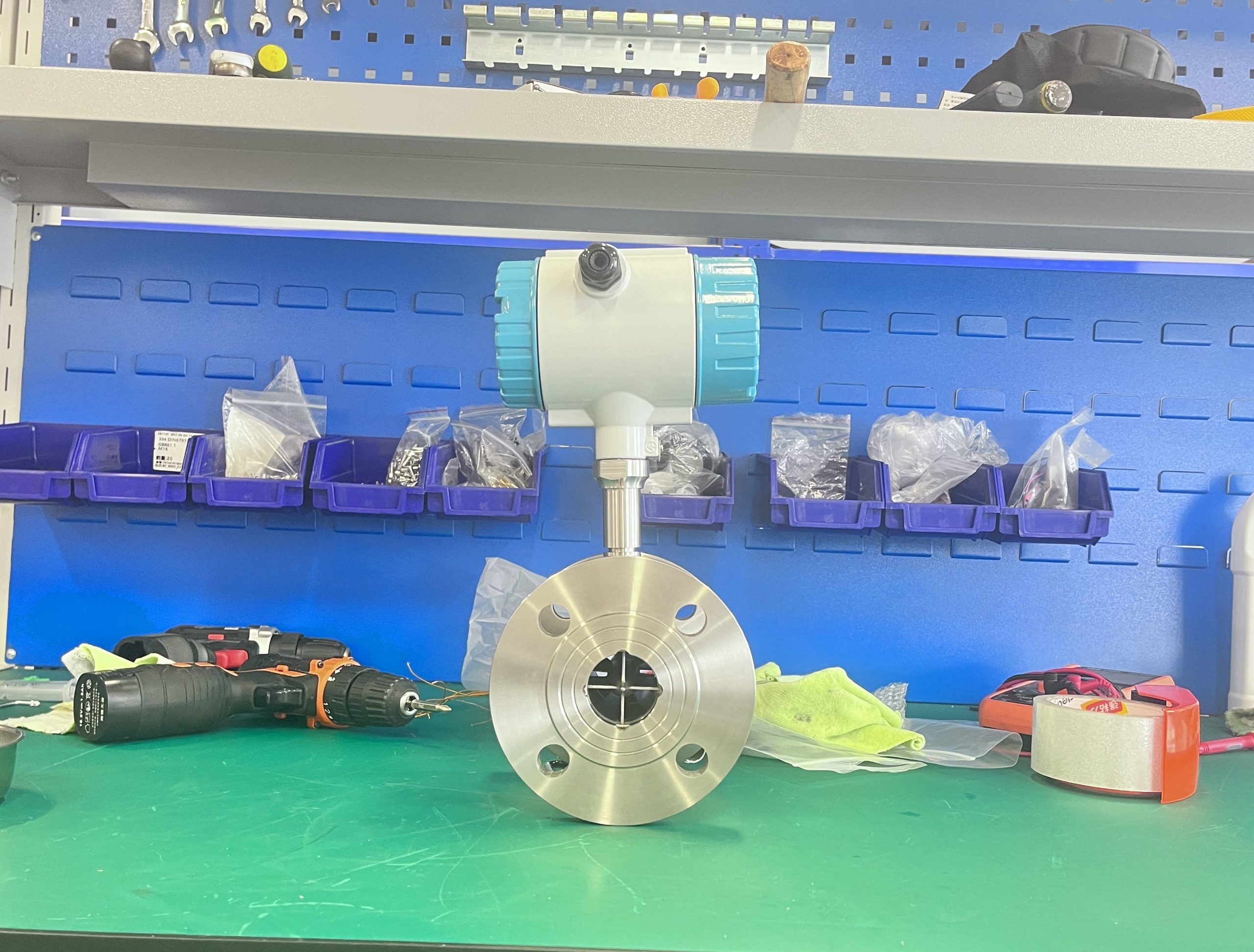

Turbine flow meter sensor maintenance

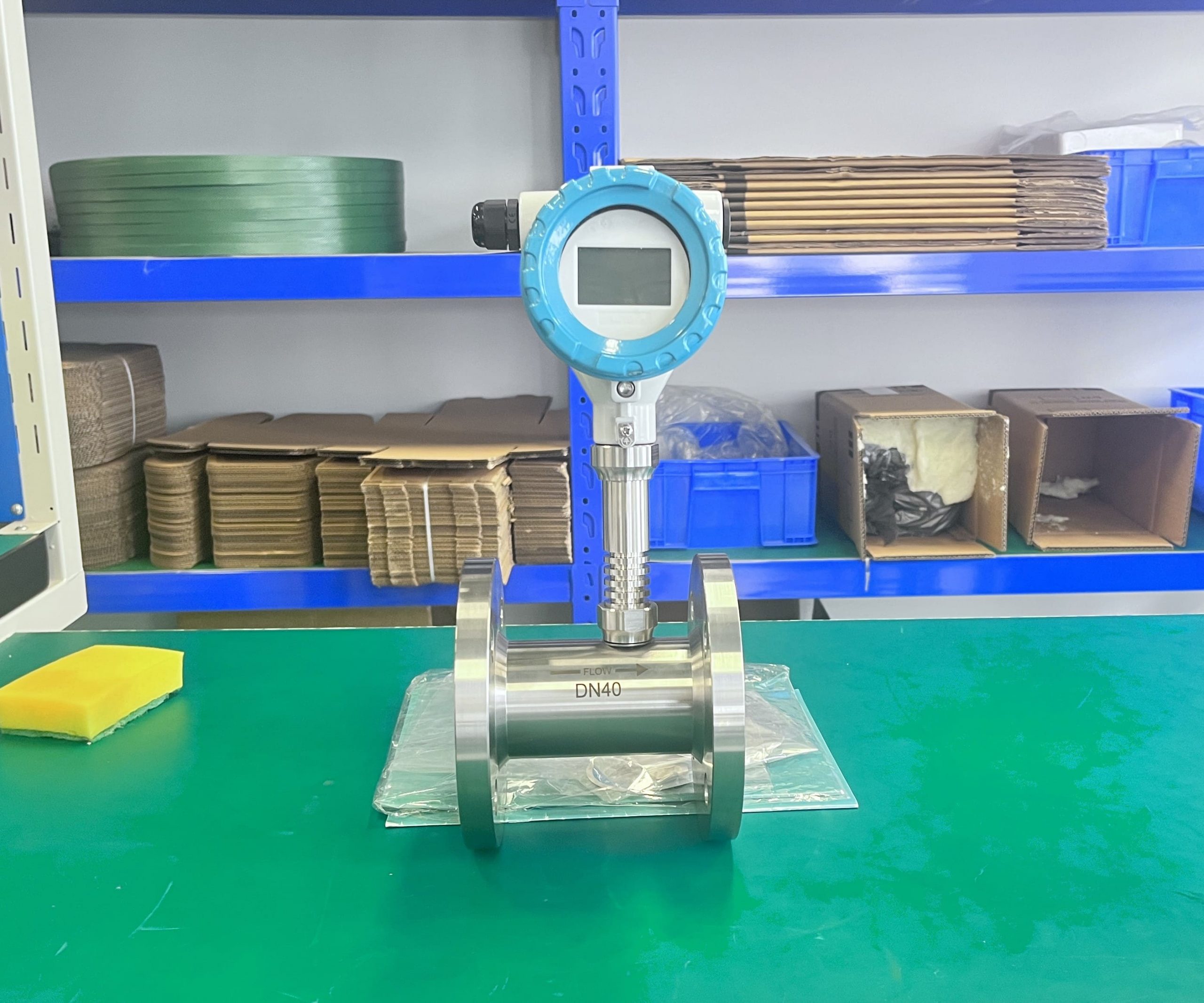

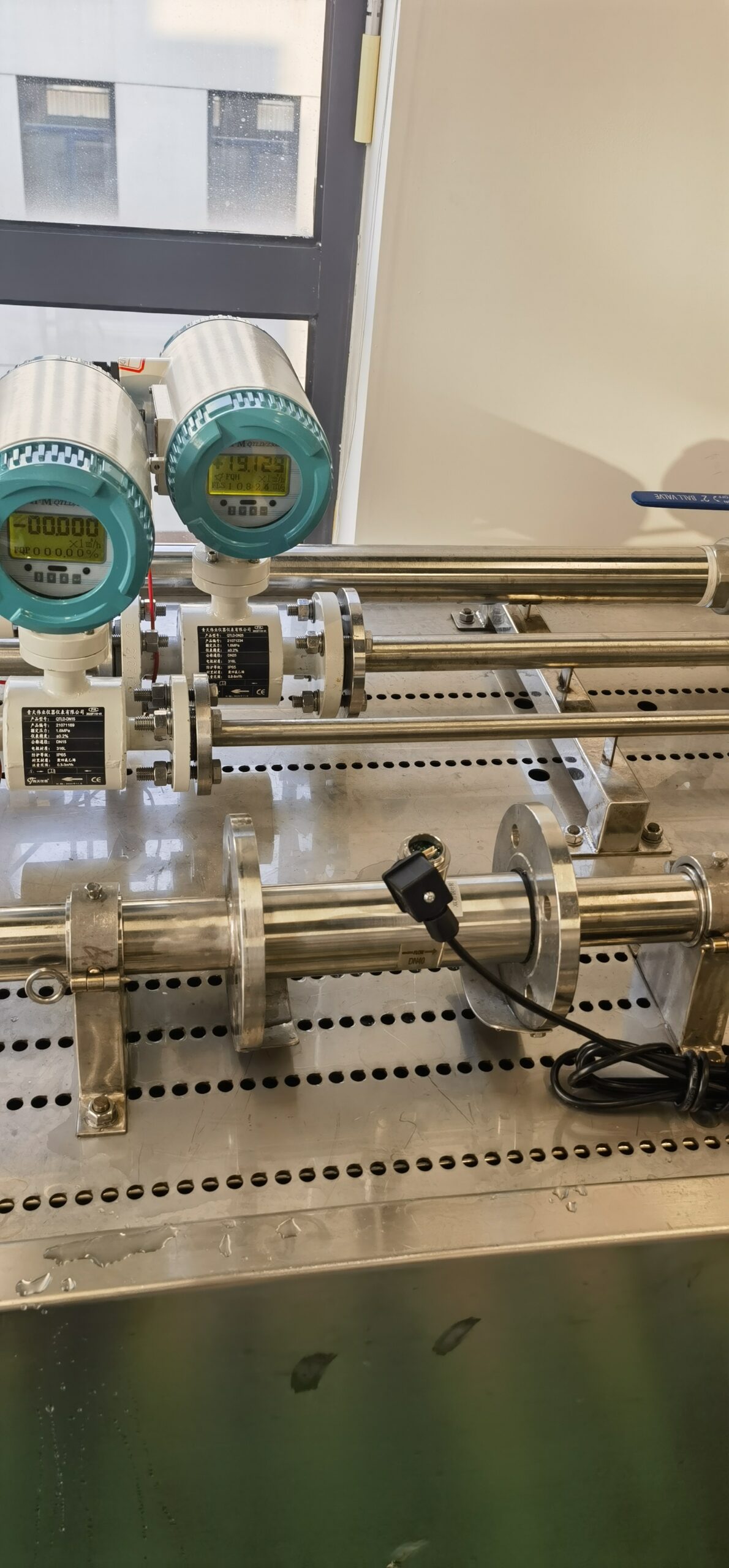

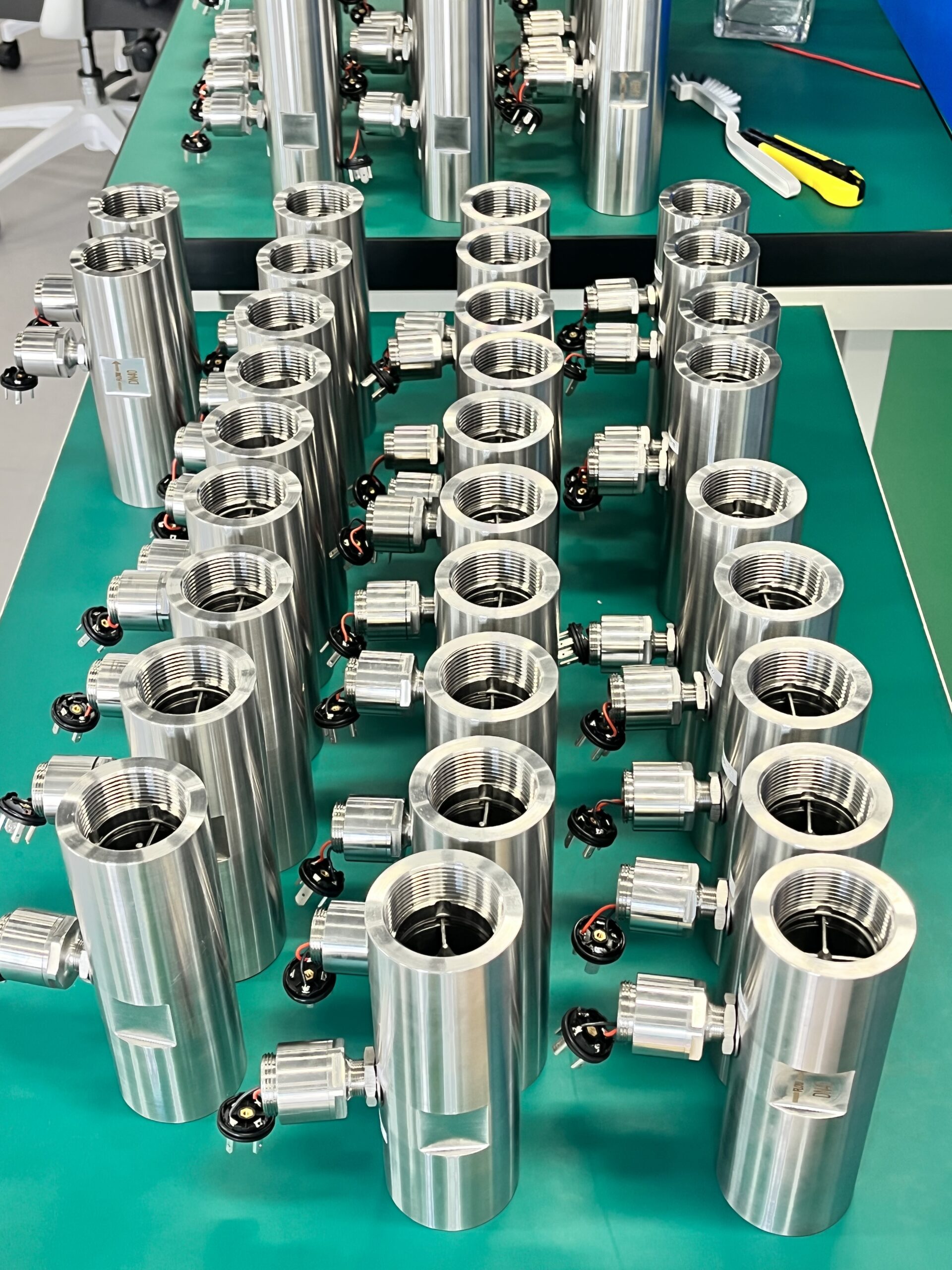

Turbine flowmeter is a kind of precision flow measuring instrument, which can be used to measure the flow and total amount of liquid with the corresponding flow integrating instrument. Widely used in petroleum, chemical industry, metallurgy, scientific research and other fields of measurement, control system. Turbine flow meter sensors equipped with sanitary connectors can be used in pharmaceutical, food and other industries.

The maintenance of the turbine flow meter sensor part should pay attention to the following points:

1. When used, the measured medium should be kept clean and free of impurities such as fibers and particles.

2. When the turbine flow sensor is used, it should be slowly filled with media in the sensor first, and then open the outlet valve (the valve should be installed at the back end of the flow meter), and it is strictly prohibited for the sensor to be affected by high-speed fluid when it is in a mediumless state.

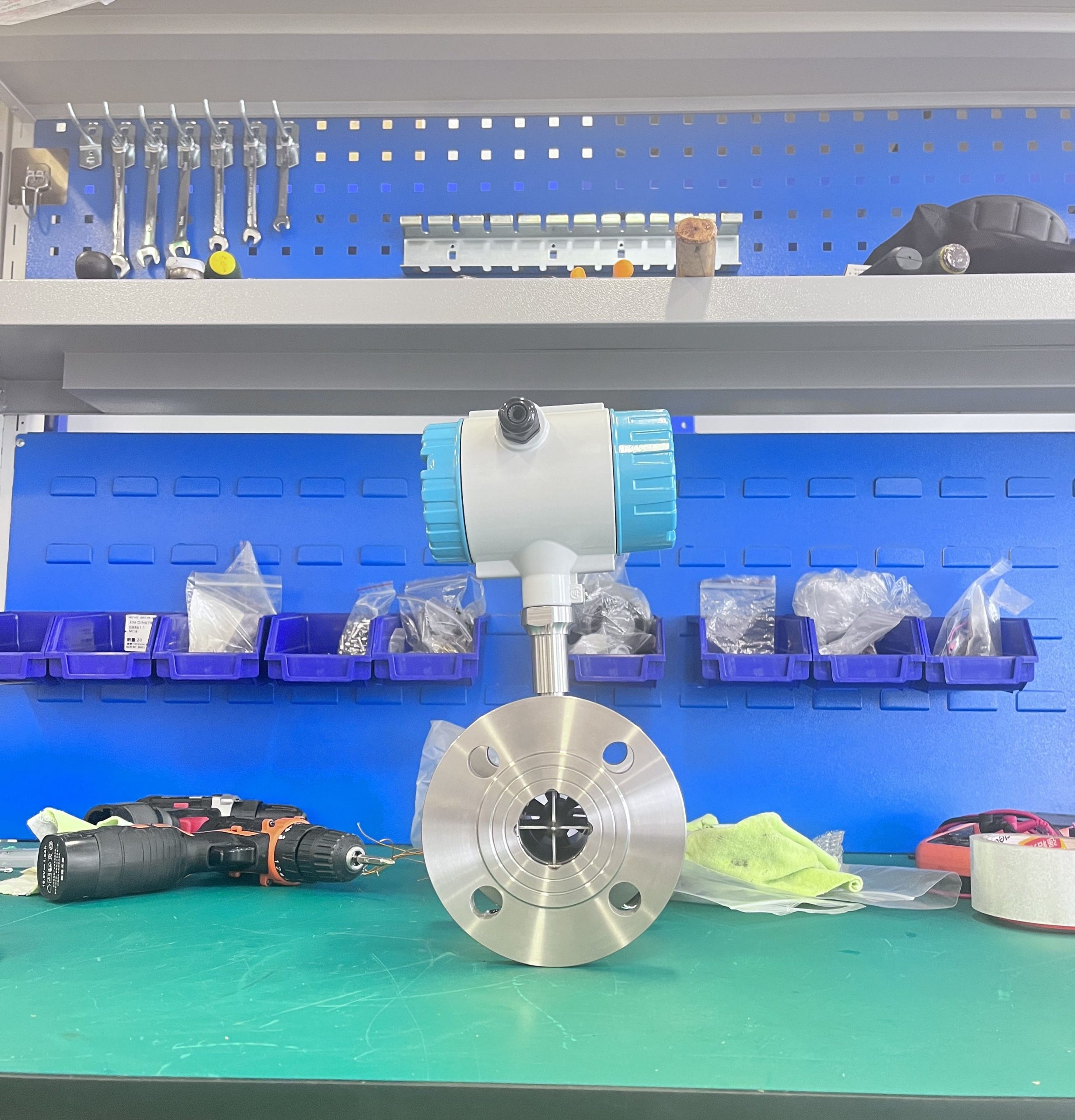

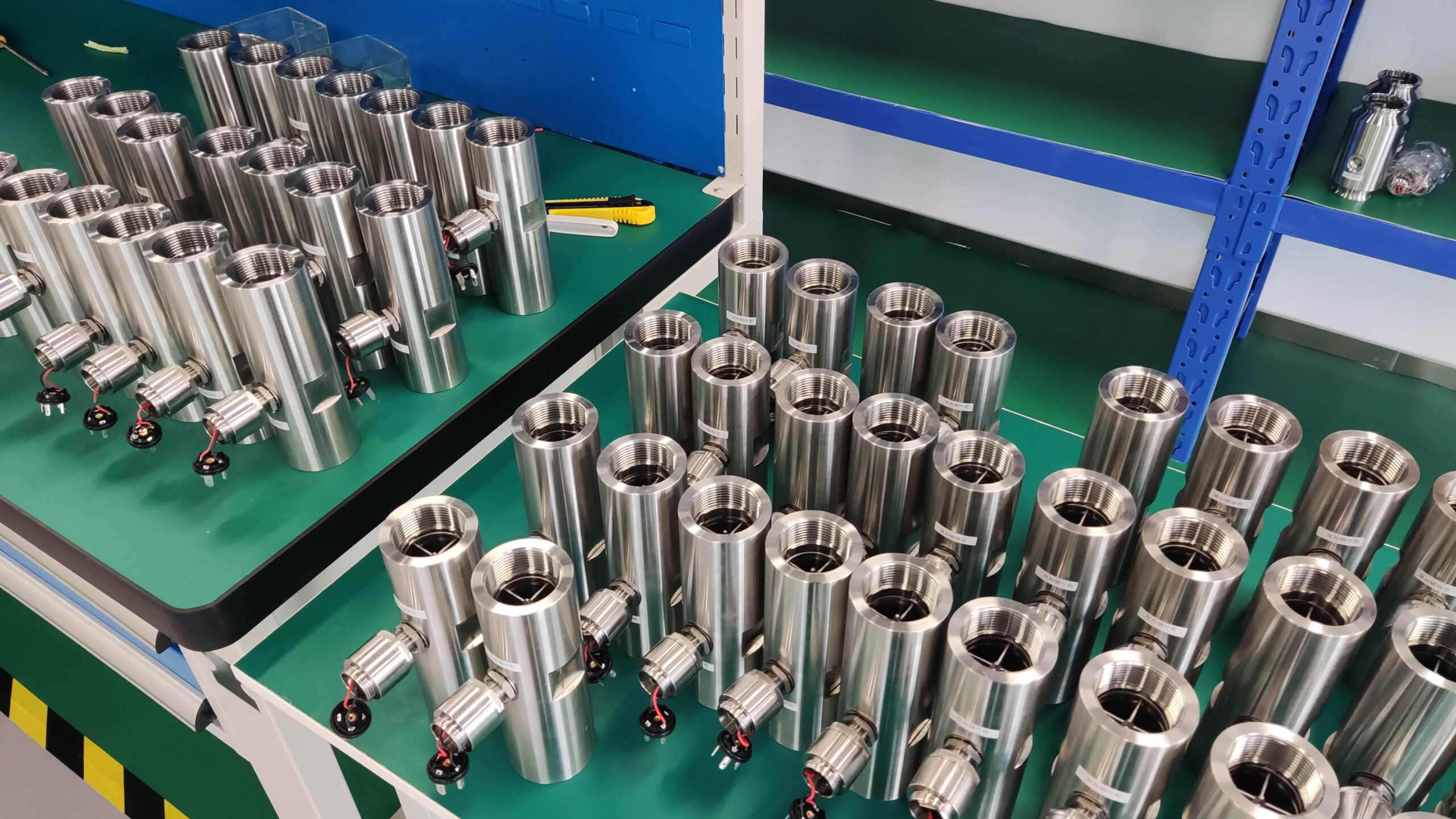

3. The maintenance period of the turbine flow sensor is generally half a year. When repairing and cleaning, please be careful not to damage the parts in the measuring chamber, especially the impeller. When assembling, please look at the position relationship between guide and impeller.

4. When the turbine flow sensor is not in use, the internal medium should be cleaned, and after drying, protective covers should be placed on both ends of the sensor to prevent dirt from entering, and then stored in a dry place.

5. The filter should be cleaned regularly, and the internal medium should be cleaned when not in use. Like the sensor, add dust jacket and store in a dry place.

6. Before the sensor is installed, blow the impeller by mouth or hand to make it rotate quickly to see if there is a display, and then install the sensor when there is a display. If none is displayed, check the relevant parts and troubleshoot the fault.