Transit Time Ultrasonic Flow Meter for Clean Liquids with Snap-Clamp on Pipe

Measuring range ±0.03 ft/s ~ ±40 ft/s (±0.01 m/s~ ±12 m/s)

Accuracy ±1%

Diameter range 1″~48″(25mm~1200mm)

Measuring medium Single conducting liquid medium

Measurable pipe Carbon steel, stainless steel, PVC pipe or other dense sound conductive pipe

Output Analog output: 4~20mA, maximum load 750Ω, Modbus: RS485

SD card storage 16G

Set the storage interval 1 ~ 99999 s

Keyboard Digital film keying

Display screen 240*128 LCD display (with backlight)

Power source Rechargeable lithium battery with 3000mAh battery capacity. Under normal use, a full charge can be used for 16 hours.

Operating temperature Transmitter: -40℃~ 60 ℃, sensor: -40℃~80℃, standard type; The range from -40 ° C to 130 ° C is optional

Measure the ambient relative humidity 0-99%

Protection class Transmitter IP65, sensor IP68

Cable Twisted pair shielded cable, standard length of 5 meters

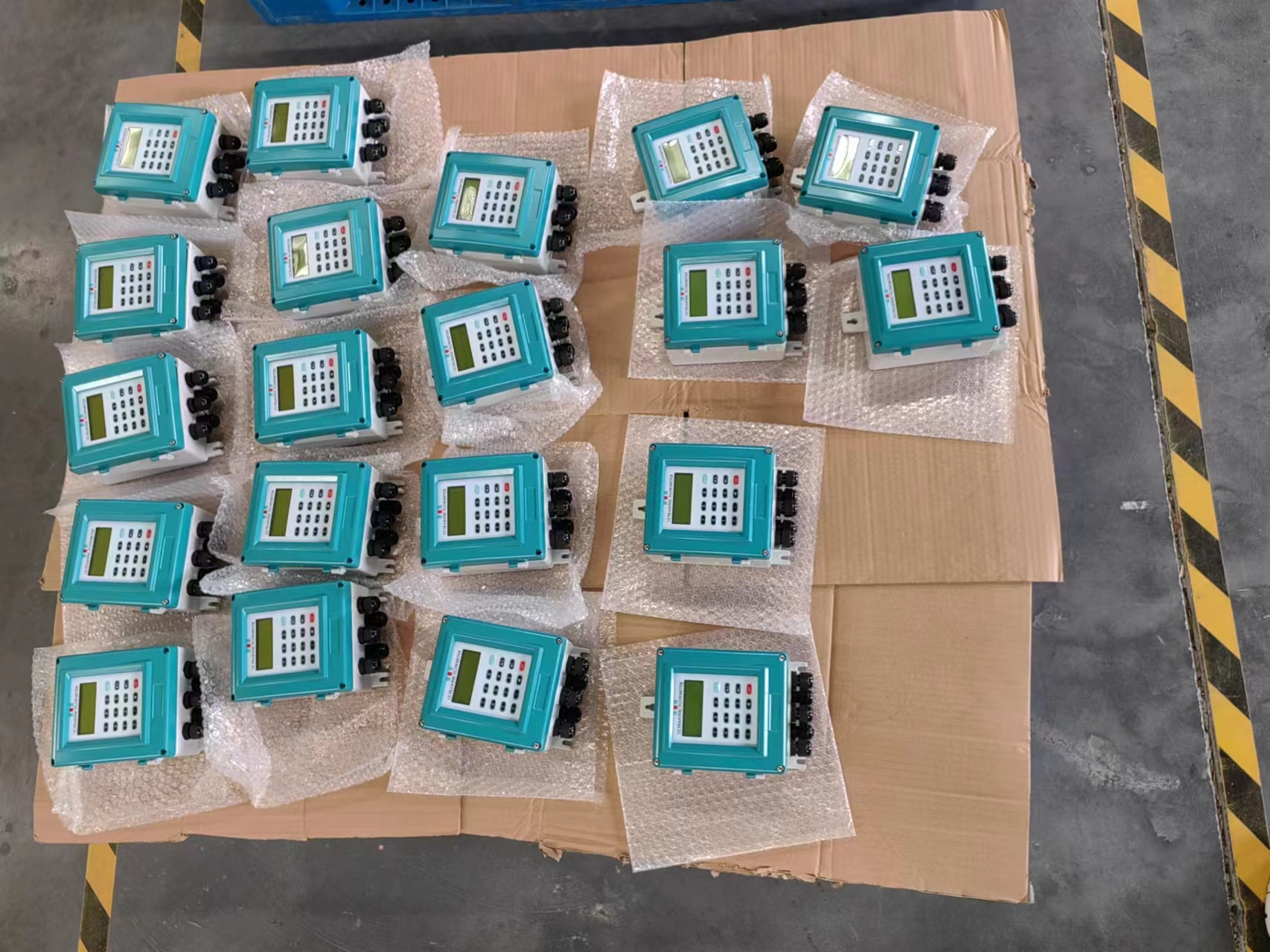

Handheld (portable) ultrasonic flowmeter with external clip-on sensing to measure liquid flow. The installation process is extremely simple, and the all-Chinese man-machine interface makes it easier to operate. The measurement process does not need to destroy the pipeline, do not need to stop production, the sensor does not contact with the measured medium, no pressure loss, and at the same time has the characteristics of battery power, small size, light weight, easy to carry. It can be said that the real sense of mobile measurement flow, online detection.

Ultrasonic time difference measurement method refers to the measurement method of fluid flow along the flow direction of the fluid average velocity by using the time difference of two ultrasonic signals propagating in the same stroke of the flowing fluid.

On the basis of the original flow meter, temperature sensor and temperature integrated module are installed. The matched temperature sensor is installed in the inlet and outlet positions of the cold (hot) quantity exchange loop respectively, which is used to collect the temperature signal of the inlet and outlet. The temperature difference is calculated by the integrated calculation module to obtain the value of the cold (heat) energy released or absorbed by the heat carrying or cooling medium from the inlet to the outlet.

Ultrasonic heat and cold meters are mostly used to measure the heat released or absorbed by the heat exchange system with water as the medium, which can be used for heating supply and can also be used in air conditioning refrigeration systems.