Tips for proper use of vortex flowmeters

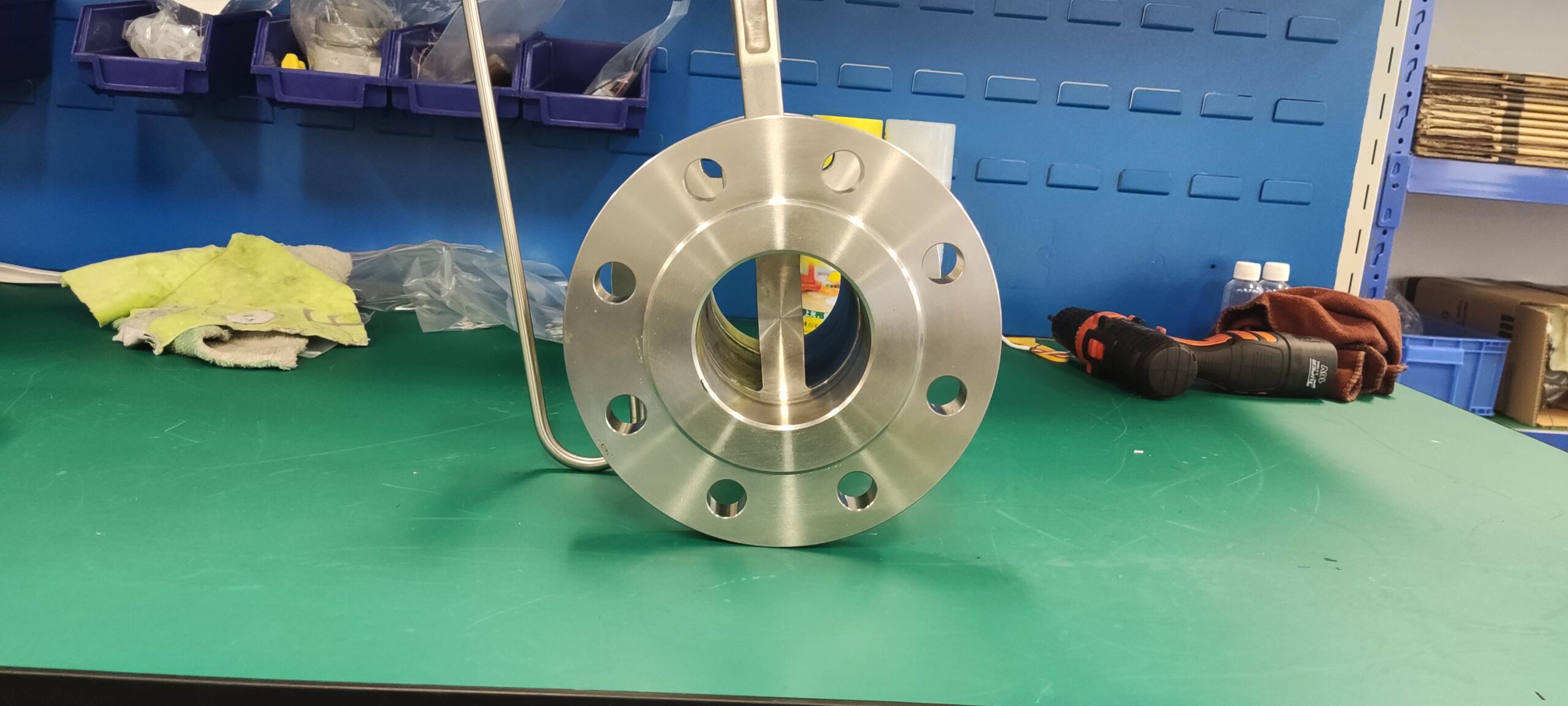

Vortex flowmeter is also known as Karman vortex flowmeter. It is a separation flowmeter made of the principle of natural oscillation of fluid. When a fluid flows at a sufficiently large velocity through an object perpendicular to the direction of the fluid, if the object is of appropriate size, it will produce a neatly aligned and reversed vortex train behind the object along two parallel lines.

Among them, S is the Stroha number, V is the average flow rate in the pipeline, and d is the width of the cylindroid facing surface. Therefore, by measuring the frequency of the vortex, the flow rate of the fluid can be known and the flow rate of the fluid can be measured.

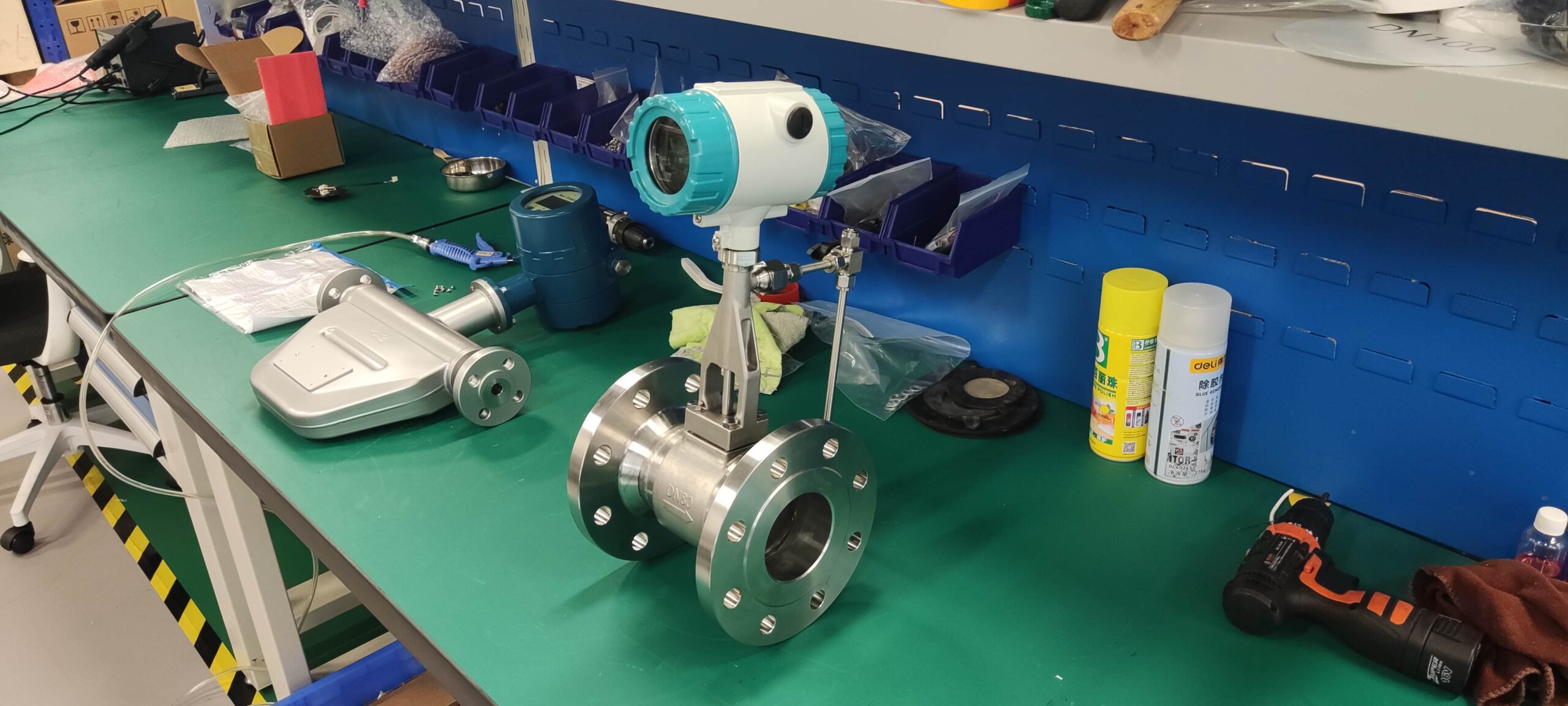

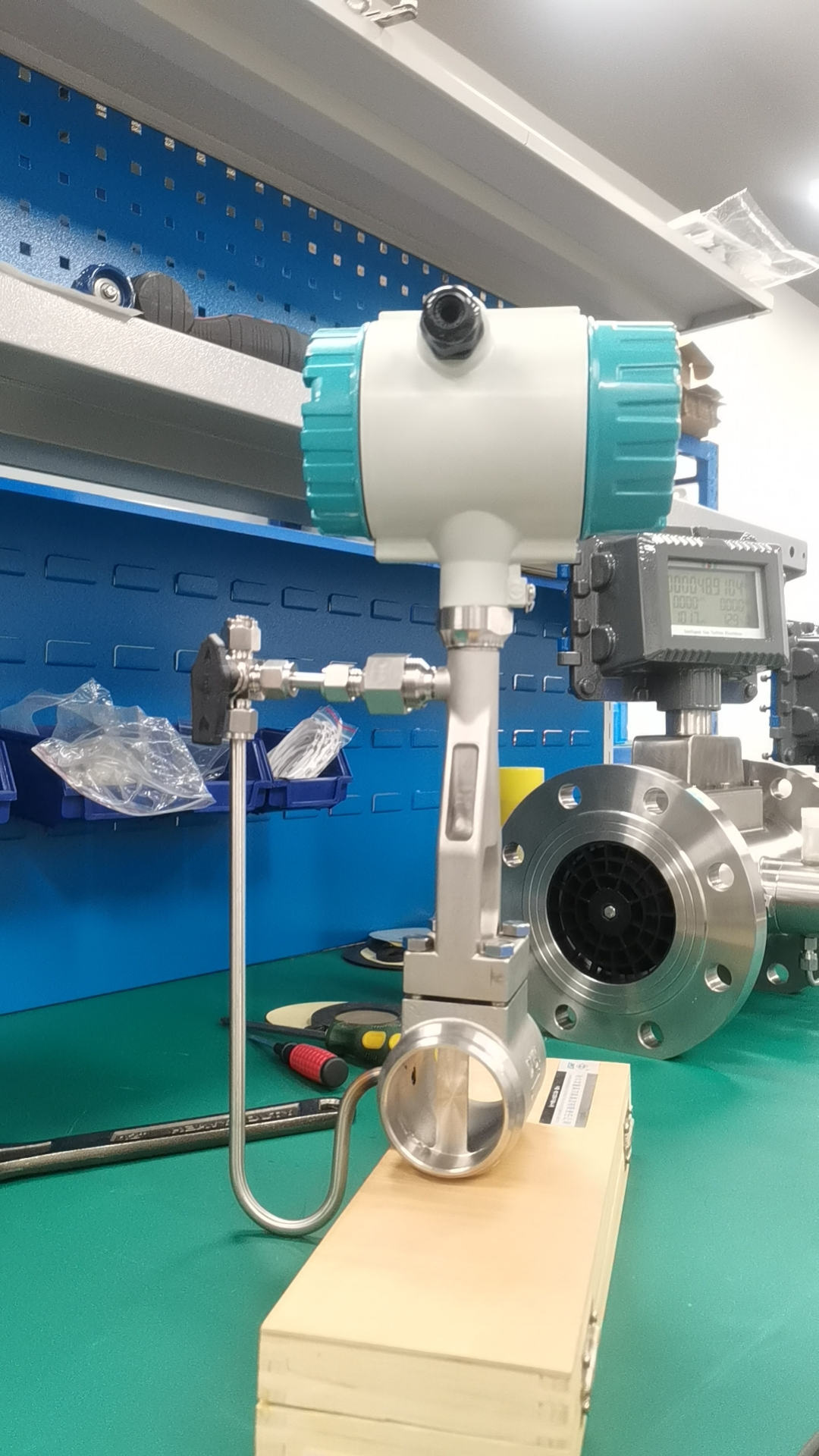

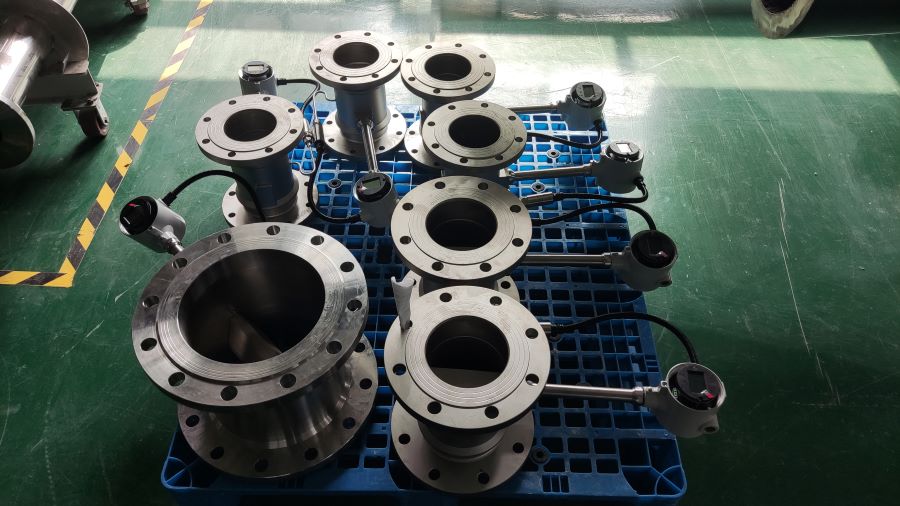

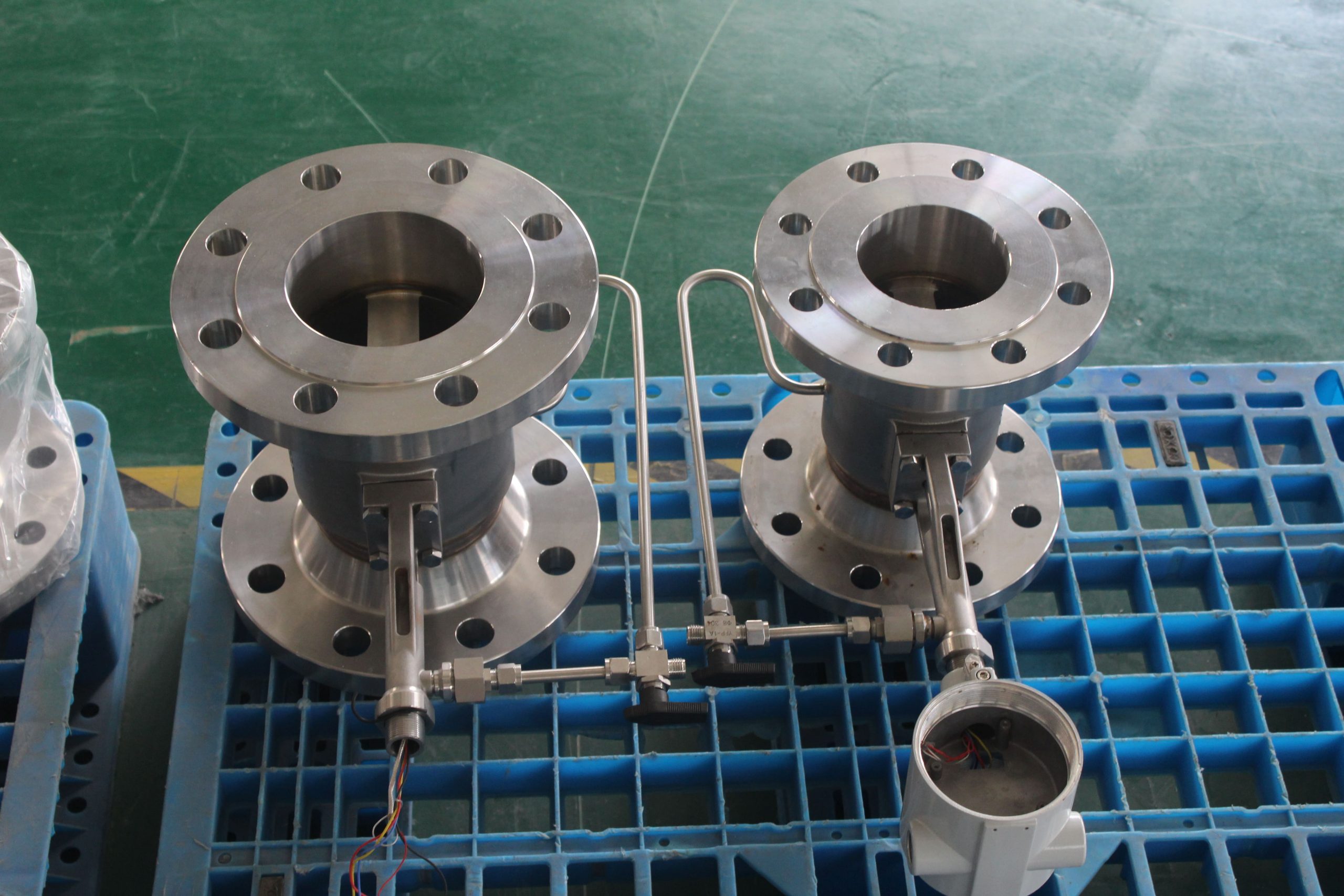

Precautions for installing sensors

(1) The sensor shall be mounted horizontally or vertically (the flow of fluid shall be bottom-up) on a pipe corresponding to the nominal diameter.

(2) When the vortex flowmeter is used for flow regulation, special attention should be paid to the flow regulator installed behind the sensor, otherwise it is easy to produce jet flow at a small flow rate, resulting in a fault phenomenon that the medium flow is inversely proportional to the opening of the valve when the flow is regulated.

(3) When the flow meter is installed, its upstream and downstream should be configured with a certain length of straight pipe section.

(4) The flowmeter can not be installed on the pipeline with strong vibration, so as not to affect the measurement accuracy.

Precautions for use

(1) In the water supply system, the flow meter is generally installed in the instrument well, in order to prevent damage to the instrument in the rainy season, the instrument should be moved out of the instrument well as far as possible, or the separation sensor should be selected.

(2) When there is a high-power motor near the flow meter, in order to avoid power frequency interference, in addition to increasing the shielding of the signal transmission cable, the signal transmission mode should be as far as possible to use DC signal.

(3) The technical parameters of the flow meter should do a good job of file record management, such as the KQ coefficient of the flow meter, full frequency, etc., the loss of these data will cause great difficulties for the maintenance of the meter in the future.

(4) When the flameproof flow sensor is used, the instrument enclosure must not be opened on the spot in the energized state, and attention should be paid to protecting the enclosure during maintenance, especially the flameproof joint surface can not be damaged.

(5) The detection element should be removed from the pipeline regularly and cleaned with alcohol or gasoline.