Thermal Mass Flow Meters are based on the principle of thermal dispersion

Due to the continuous development of thermal gas mass flow meter is based on the principle of thermal diffusion, that is, the use of fluid flow through the heated object, the heated object of the heat dissipation of how much with the fluid flow rate into a certain proportional relationship. Specifically, the flow meter’s sensor has two standard and the RTD, has been used as a heat source, has been used to measure the fluid temperature, the fluid flows through, the heat loss of the heat source and the size of the flow into a non-linear relationship, the thermal gas mass flowmeter can be converted into a measurement of this relationship to measure the flow rate of the signal of the linear output.

The advantages of the development of flow meters are becoming more and more obvious, in many large-scale industrial production sites, the use of measuring instruments is becoming more and more widespread.

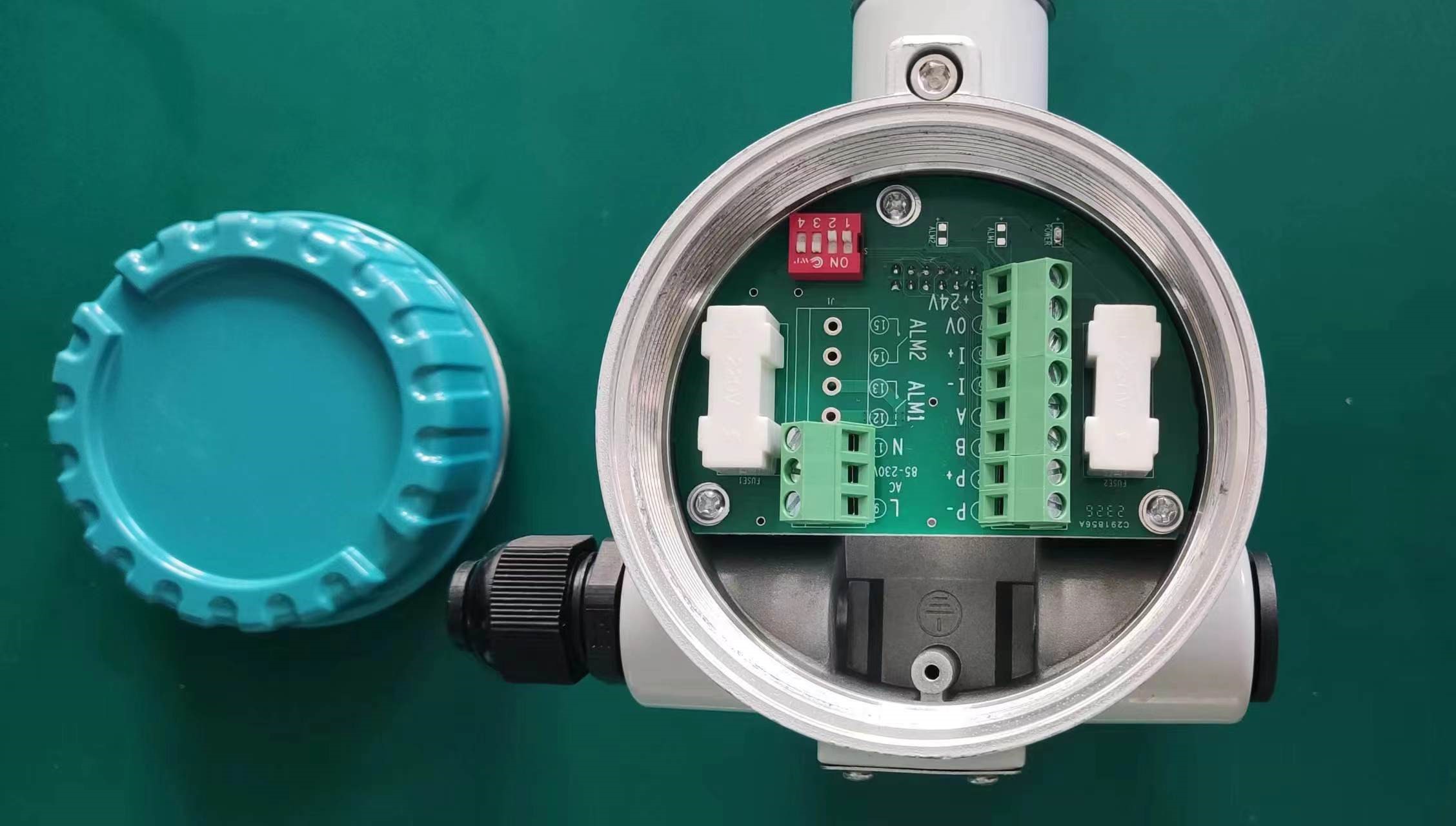

Therefore, thermal gas mass flow meter is widely used in petroleum, chemical, semiconductor, medical instruments, biological engineering, combustion control, measurement, food, metallurgy, aerospace and aviation, etc., for precision measurement and automation control of gas mass flow, it can be a standard input and output signals, you can realize the computer in the control.

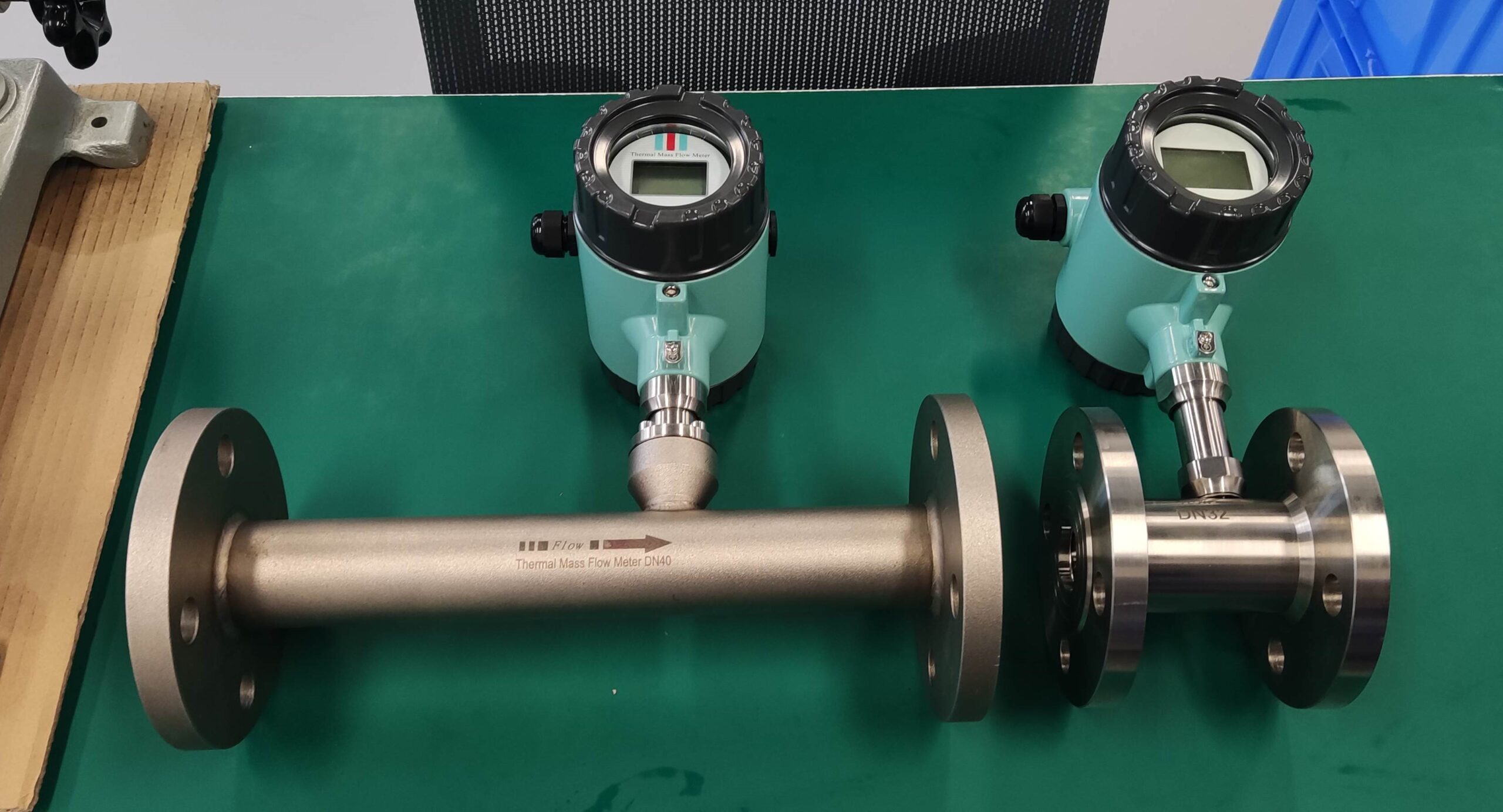

Thermal mass flow meter features: small range range of sensitive, affected by temperature, pressure, direct measurement of gas quality, pressure loss can be ignored, can be realized in large caliber and small flow rate of high-precision measurement.

Thermal mass flow meter principle: it is based on the principle of thermal diffusion flow meter. In layman’s terms, the heat source in the fluid, in the fluid through it, the heat source itself will lose heat, the greater the mass flow of the fluid, the greater the heat loss of the heat source. The greater the mass flow rate of the fluid, the greater the heat lost by the heat source. Thus the flow rate of the fluid and the heat lost by the heat source should ideally be equal. Therefore, we know the size of the heat, we can derive the fluid flow.

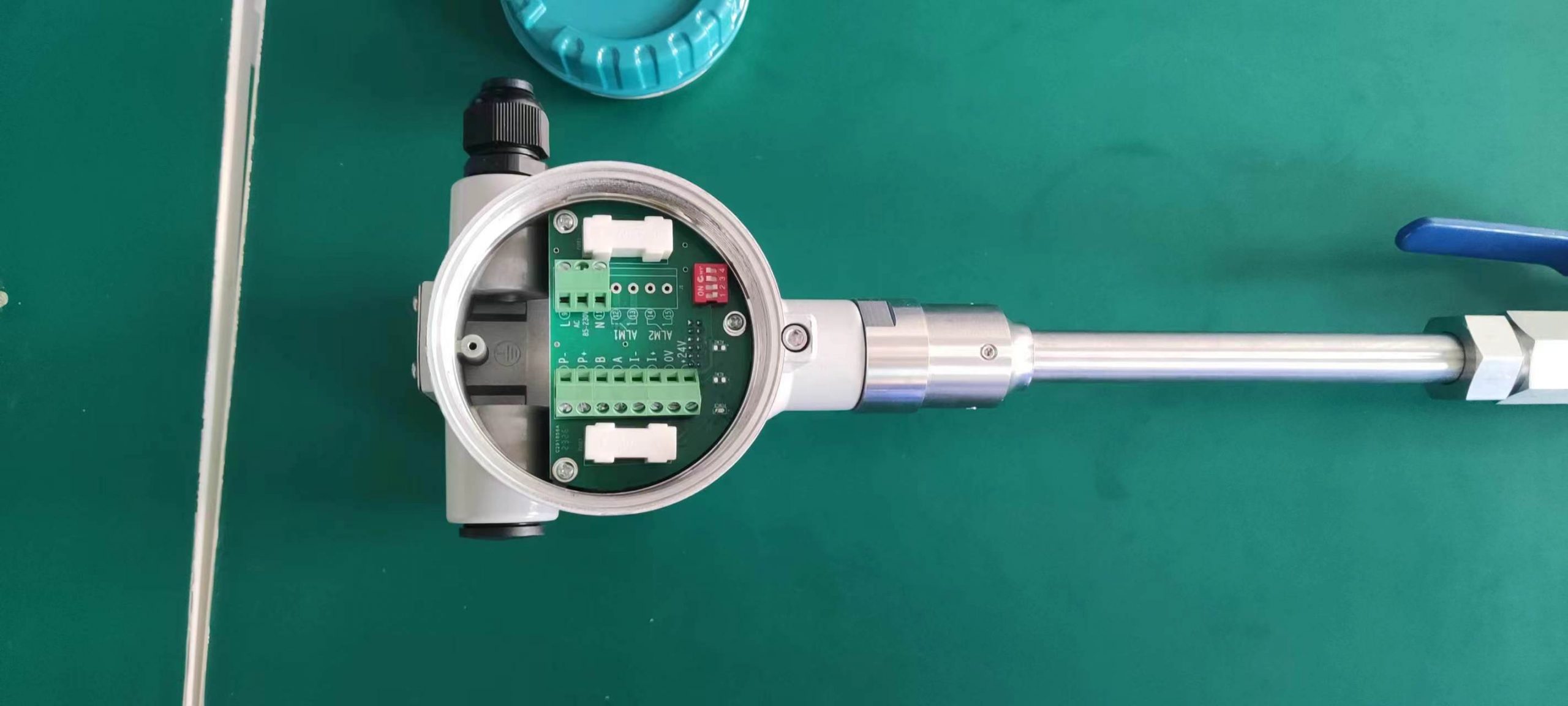

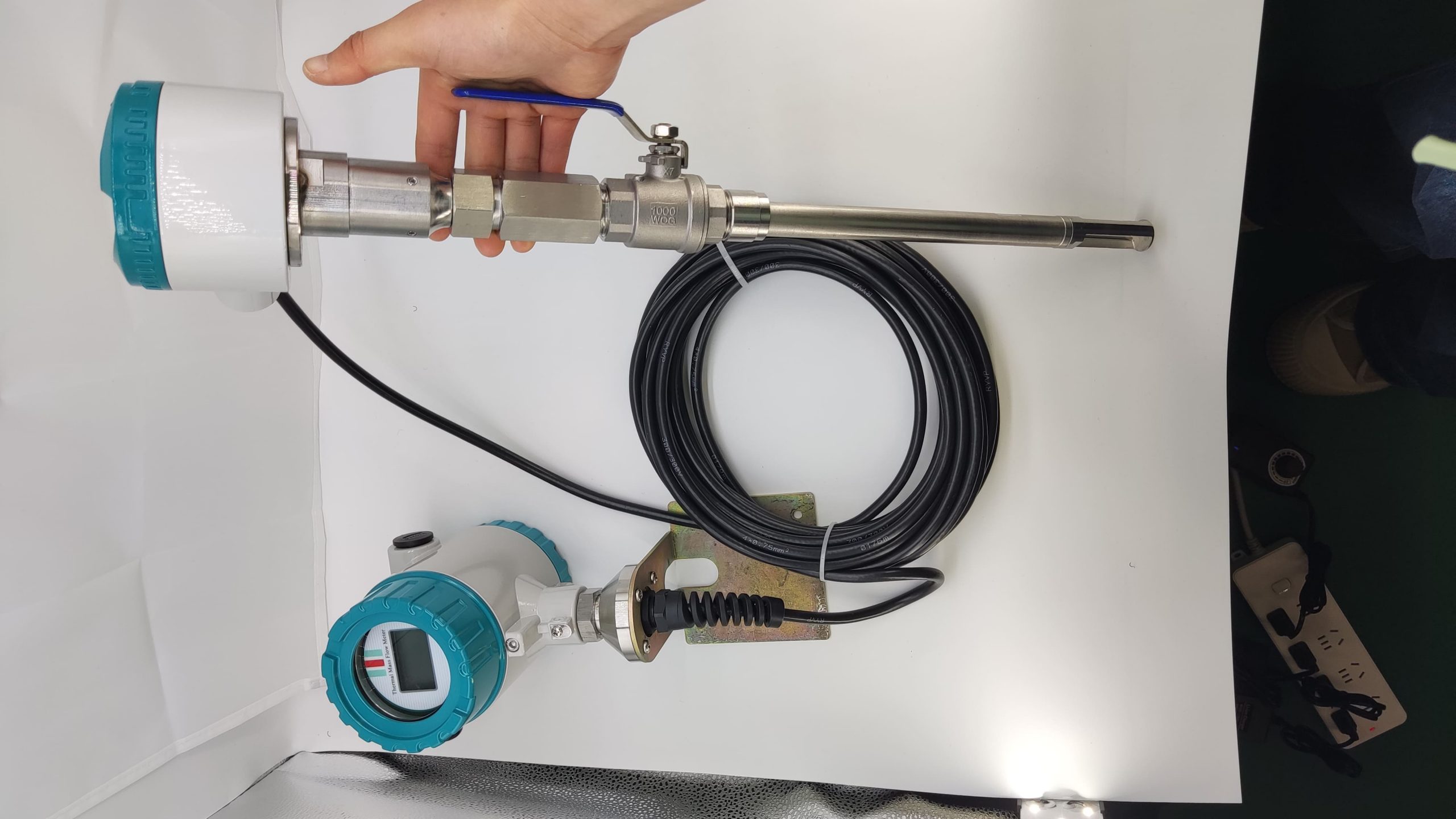

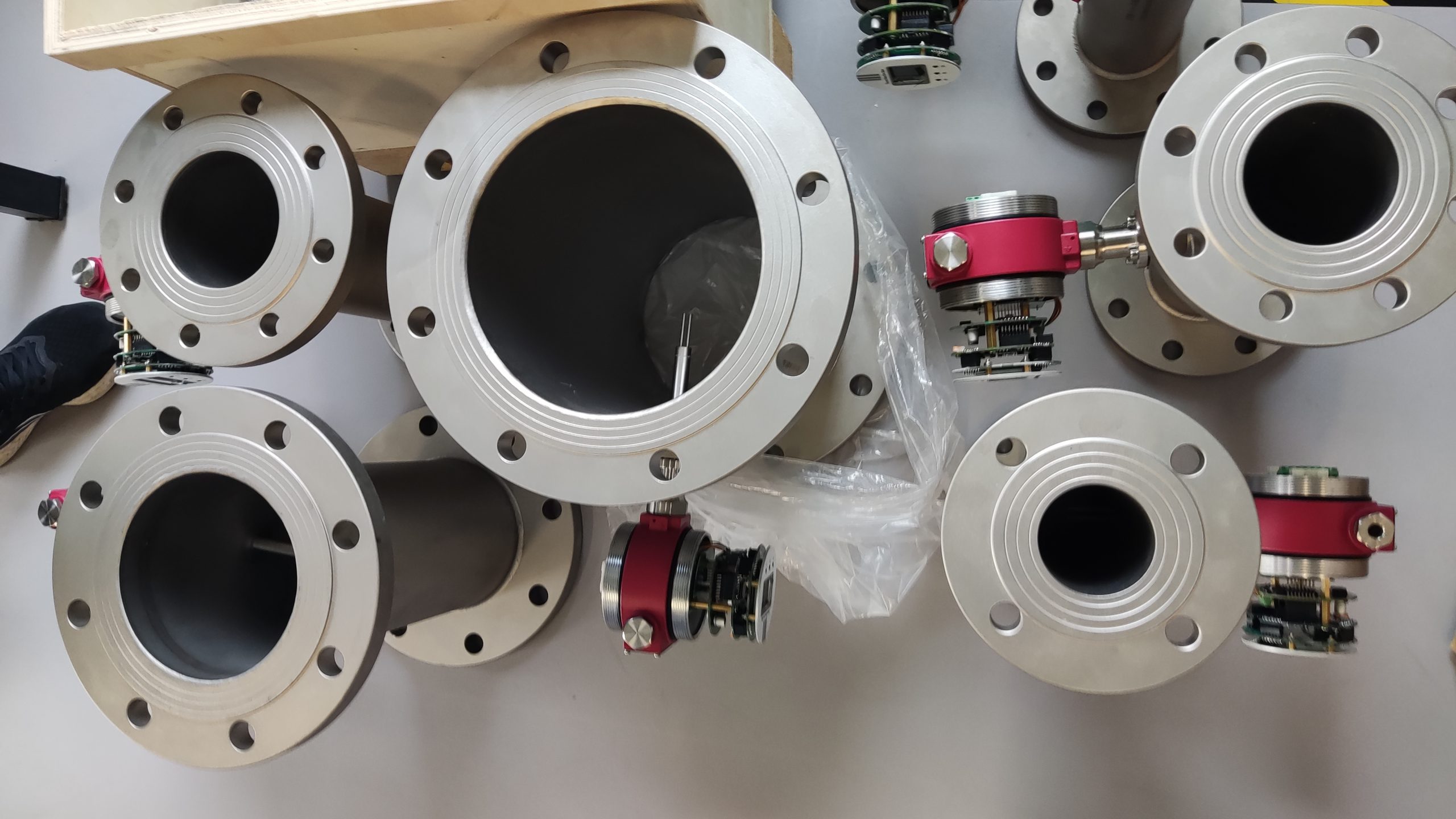

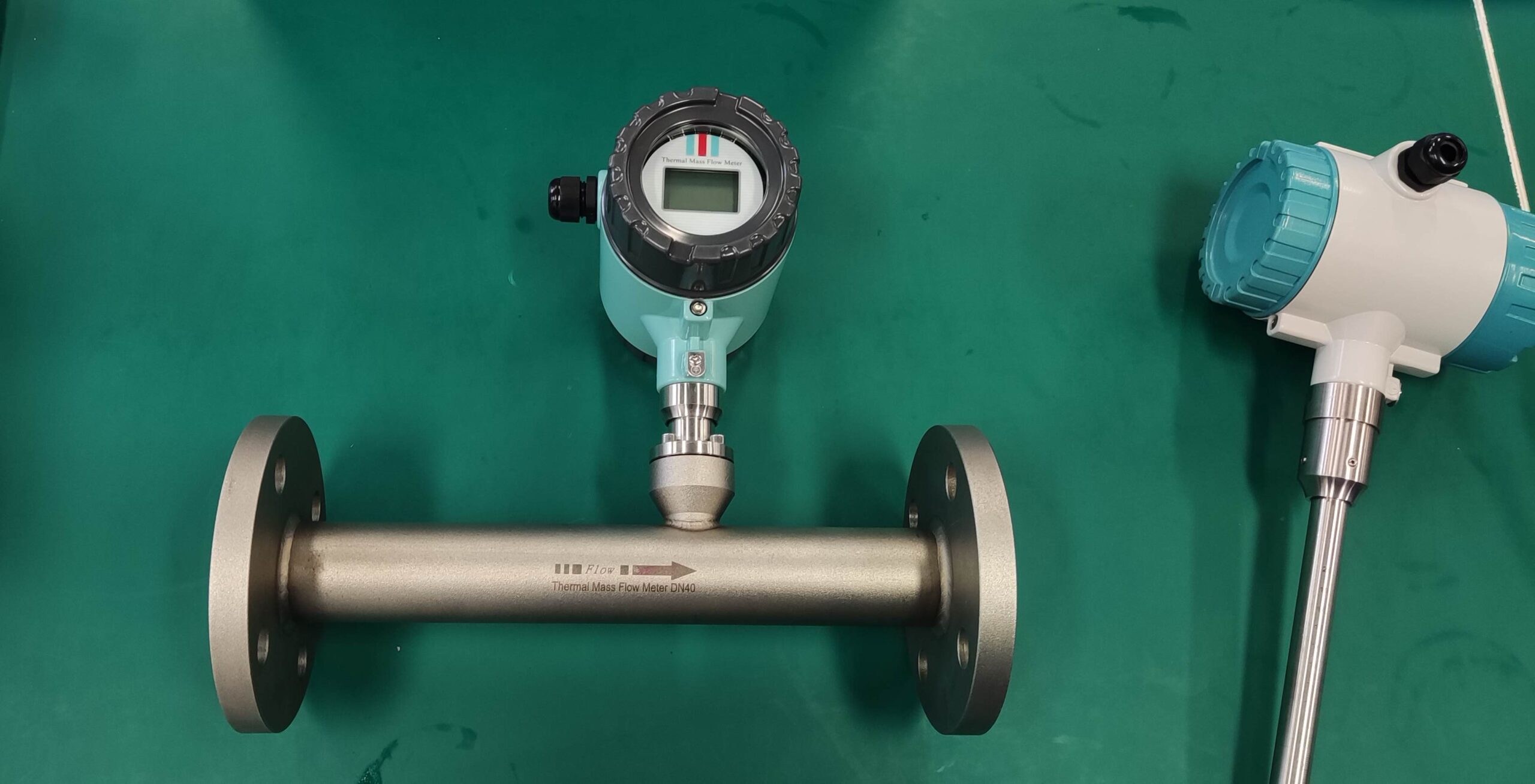

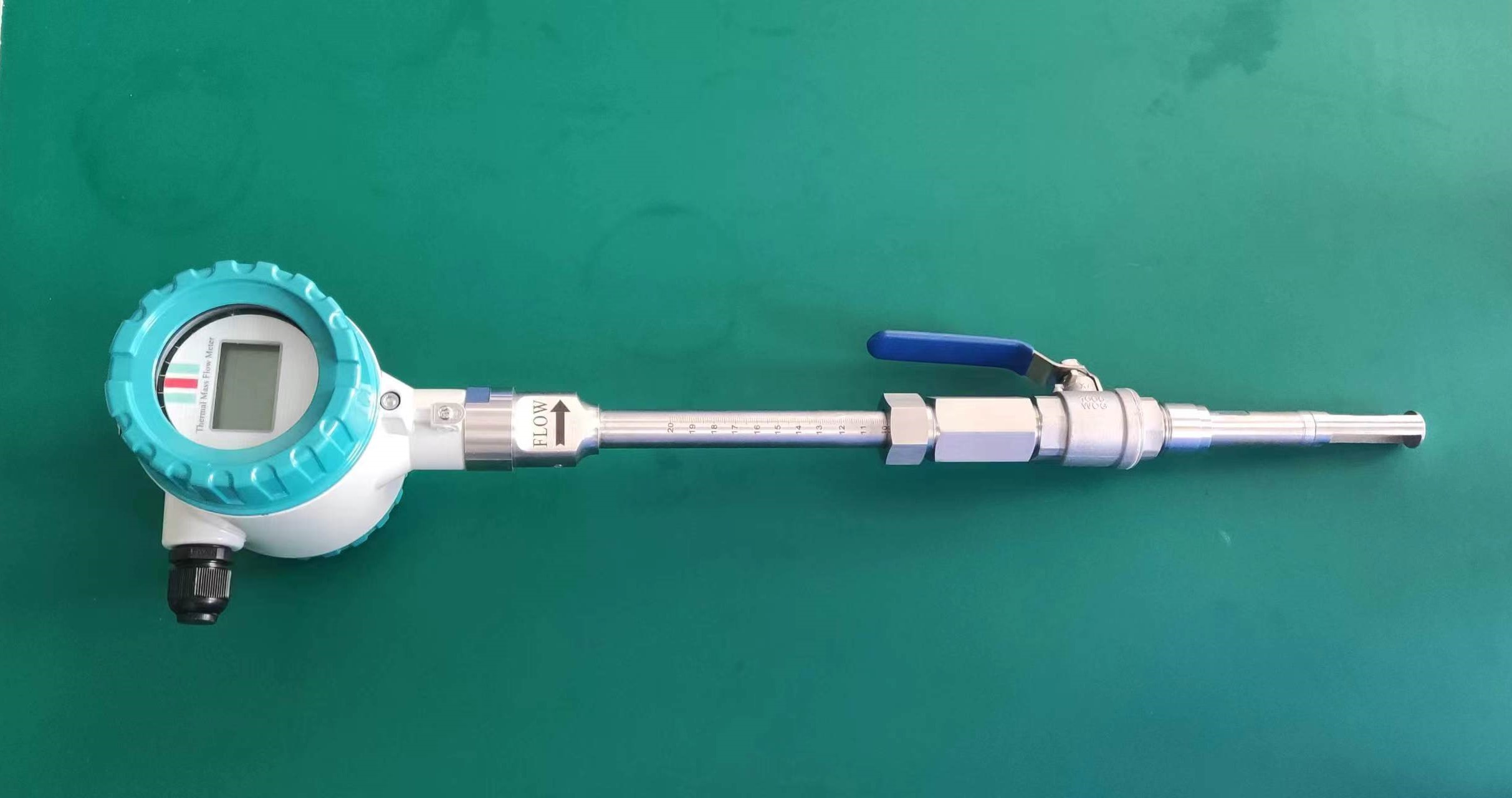

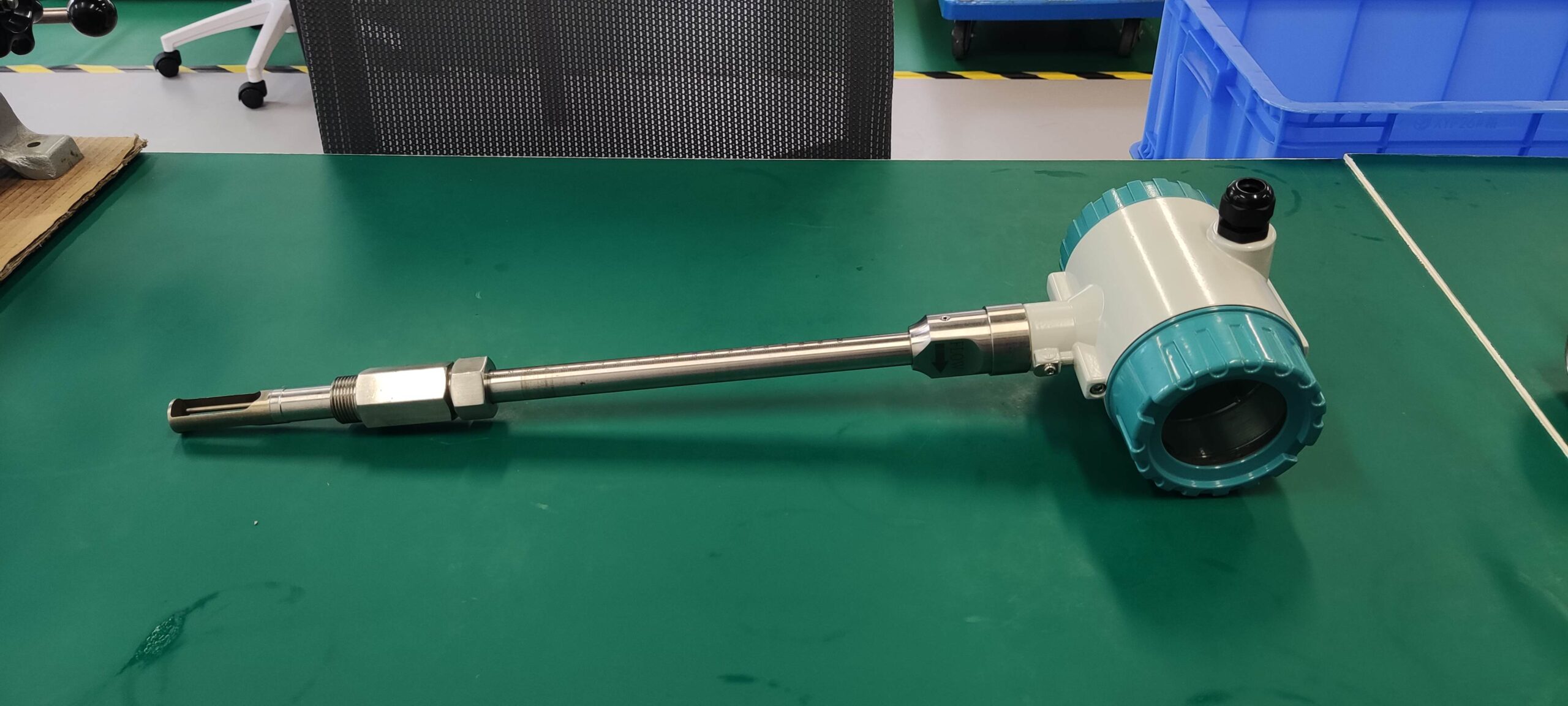

Specifically for the realization of thermal gas mass flow meter, that is: thermal flow meter probe has two probes, one of which is a reference point, used to measure the temperature of the fluid; the other is a heating source, used to act as a heat source.

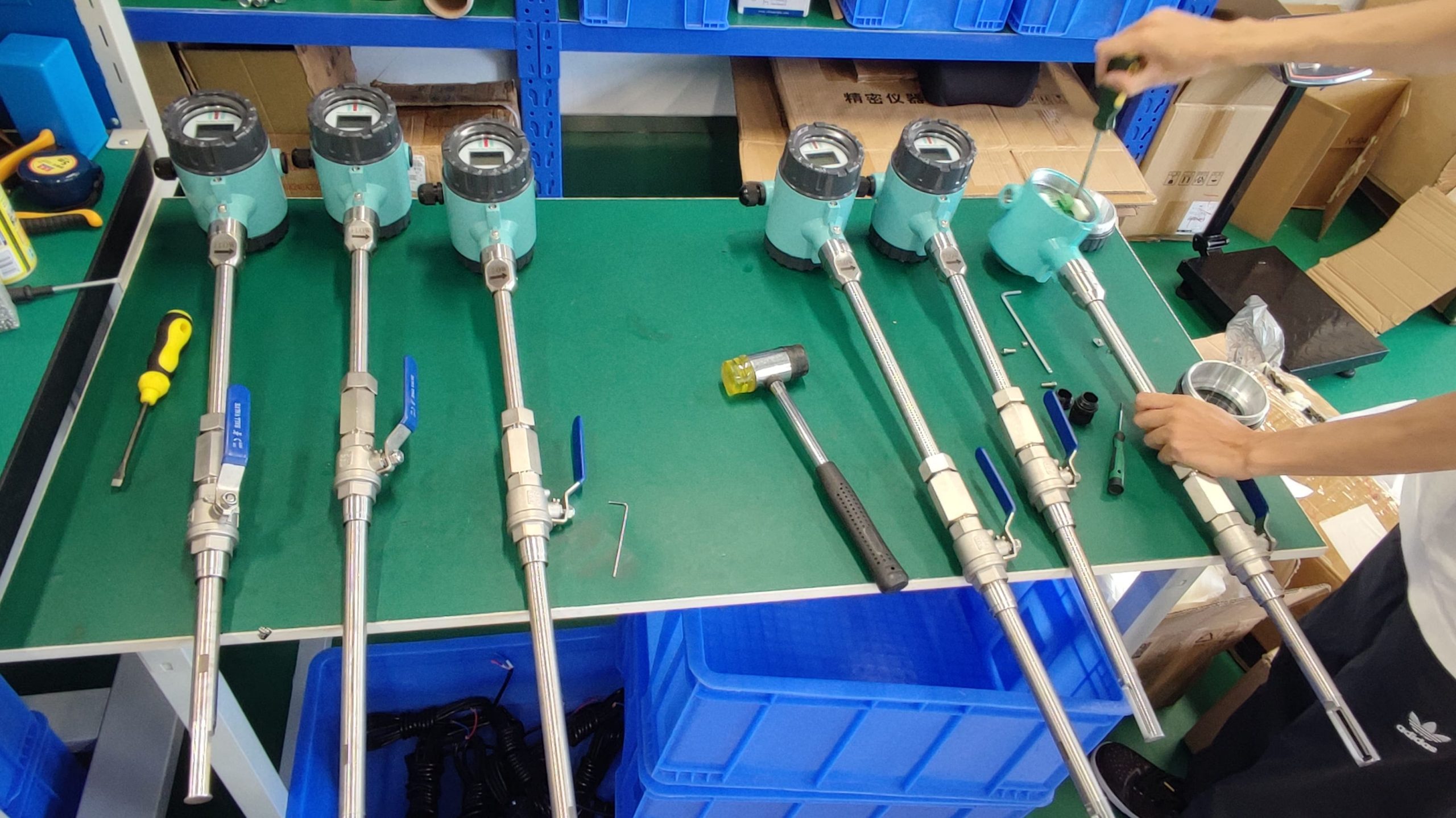

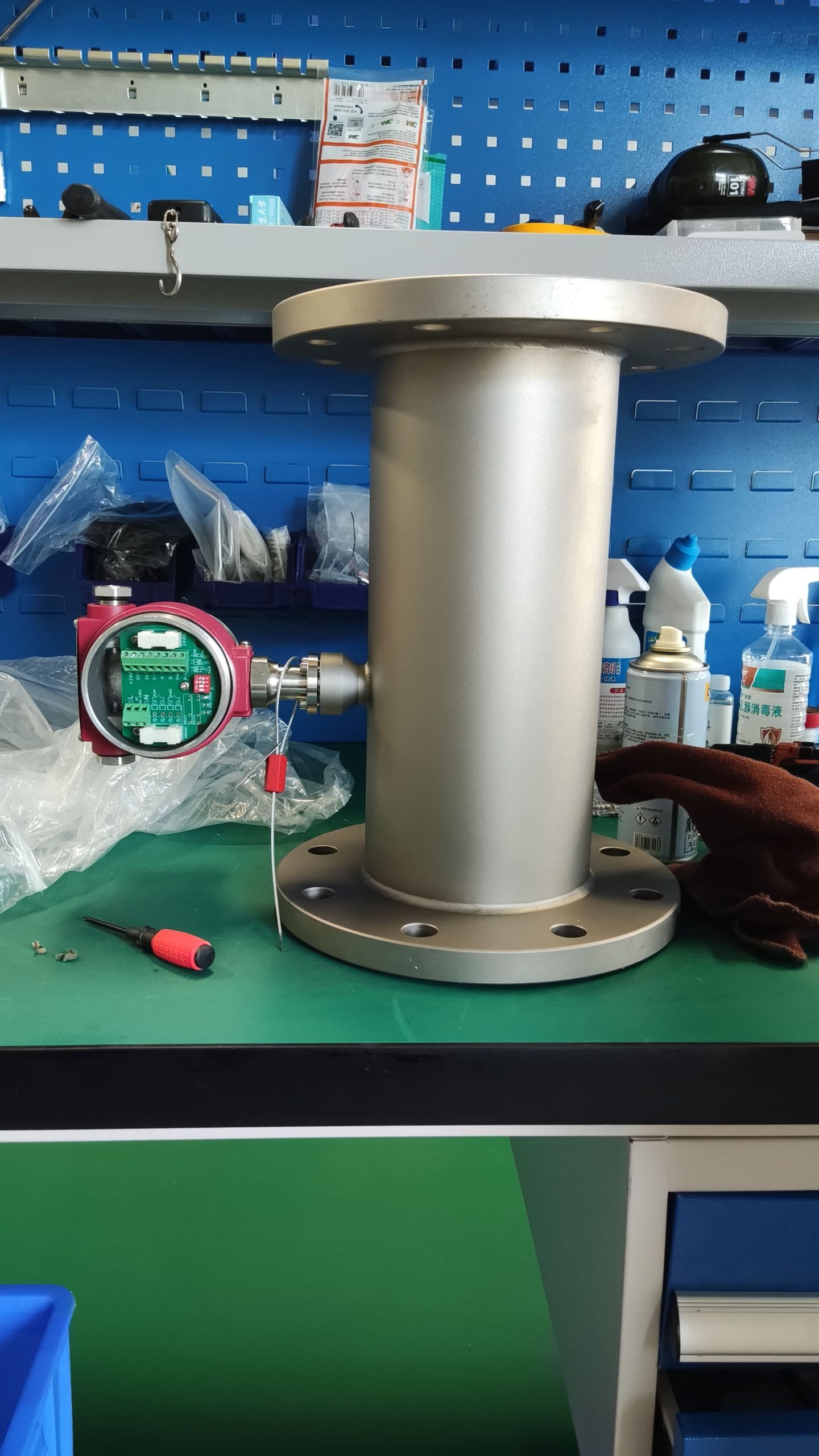

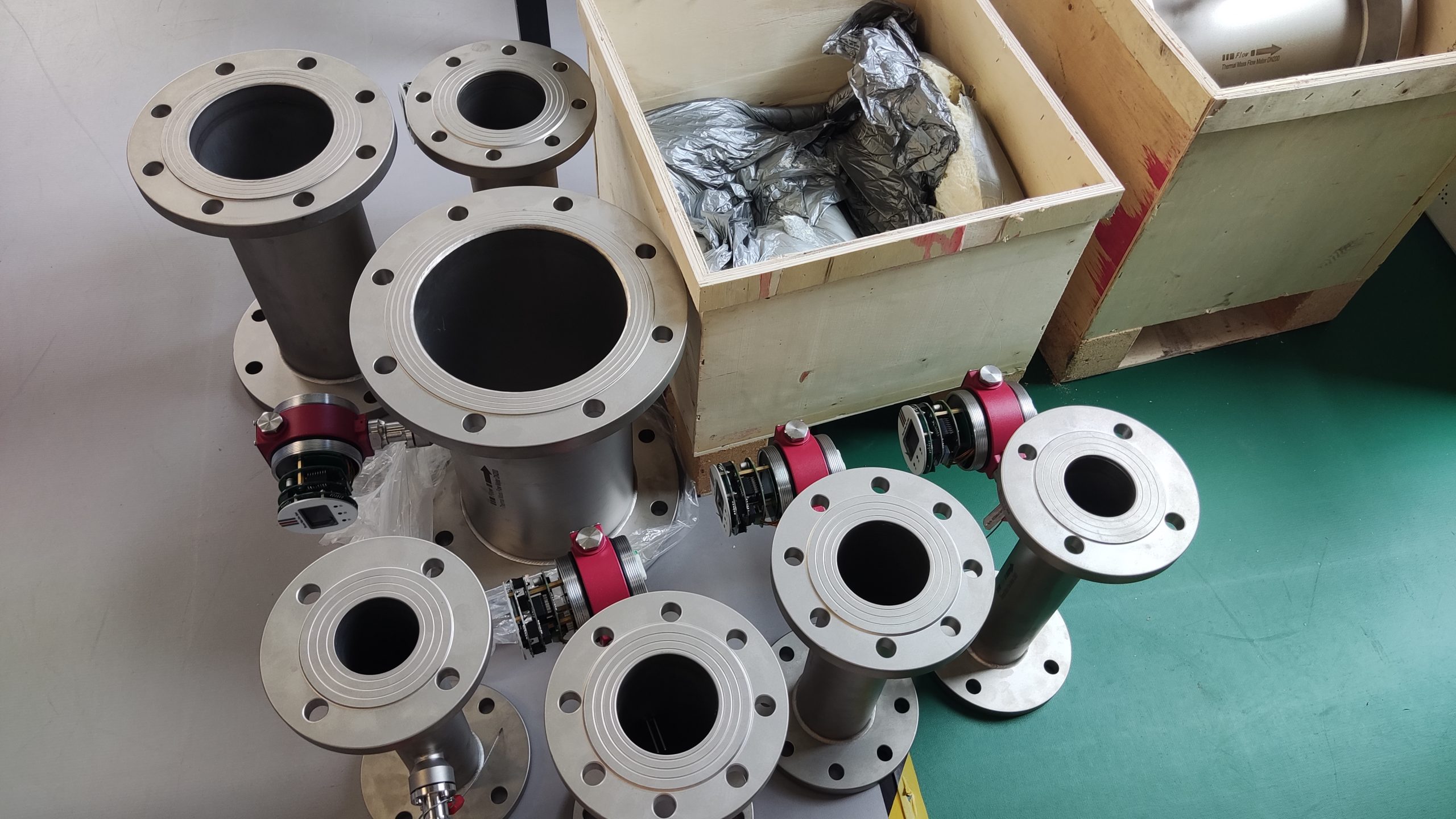

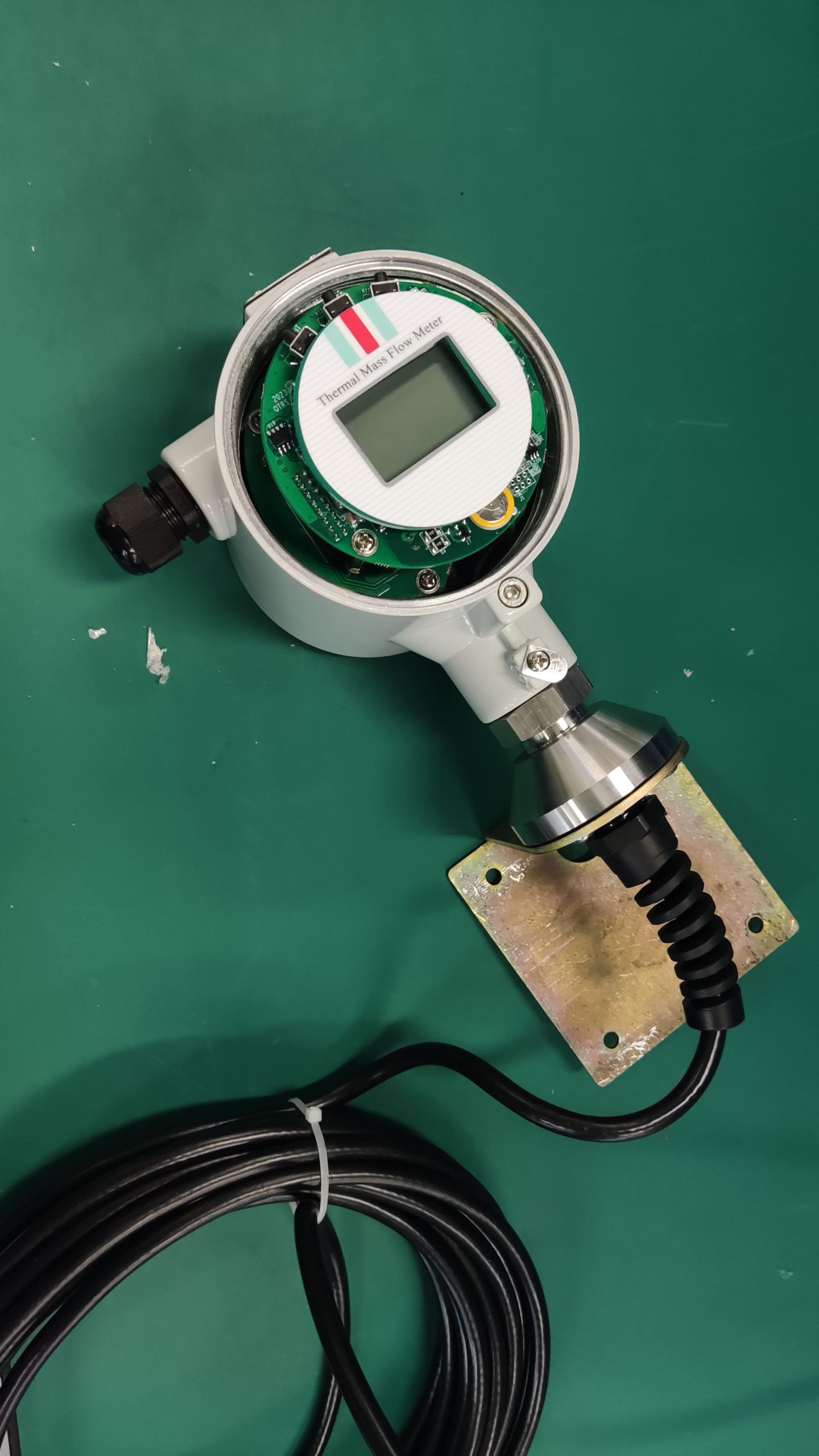

Thermal mass flow meter is easier to use, installation, it has two forms of insertion type, pipeline type. Whether it is inserted or pipeline type, maintenance, operation is extremely simple, the installation should pay attention to the direction of the fluid should be the same as the direction of the thermal flow meter instructions.

The disadvantages of thermal mass flow meter: not suitable for installation in the viscosity of the environment installation; not suitable for installation in the water bead content of more than 40% of the place.