Thermal gas mass flowmeter function advantages, installation and maintenance

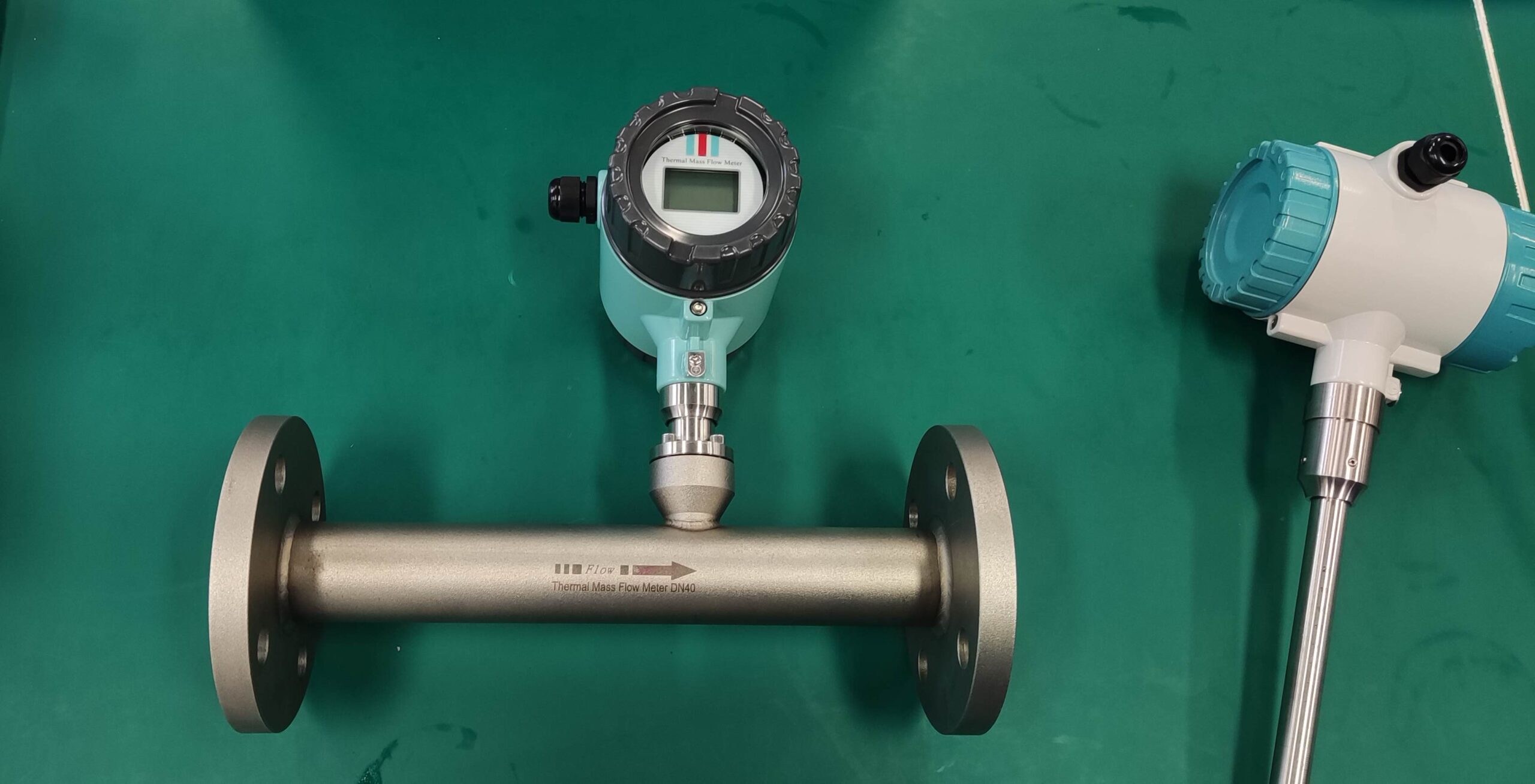

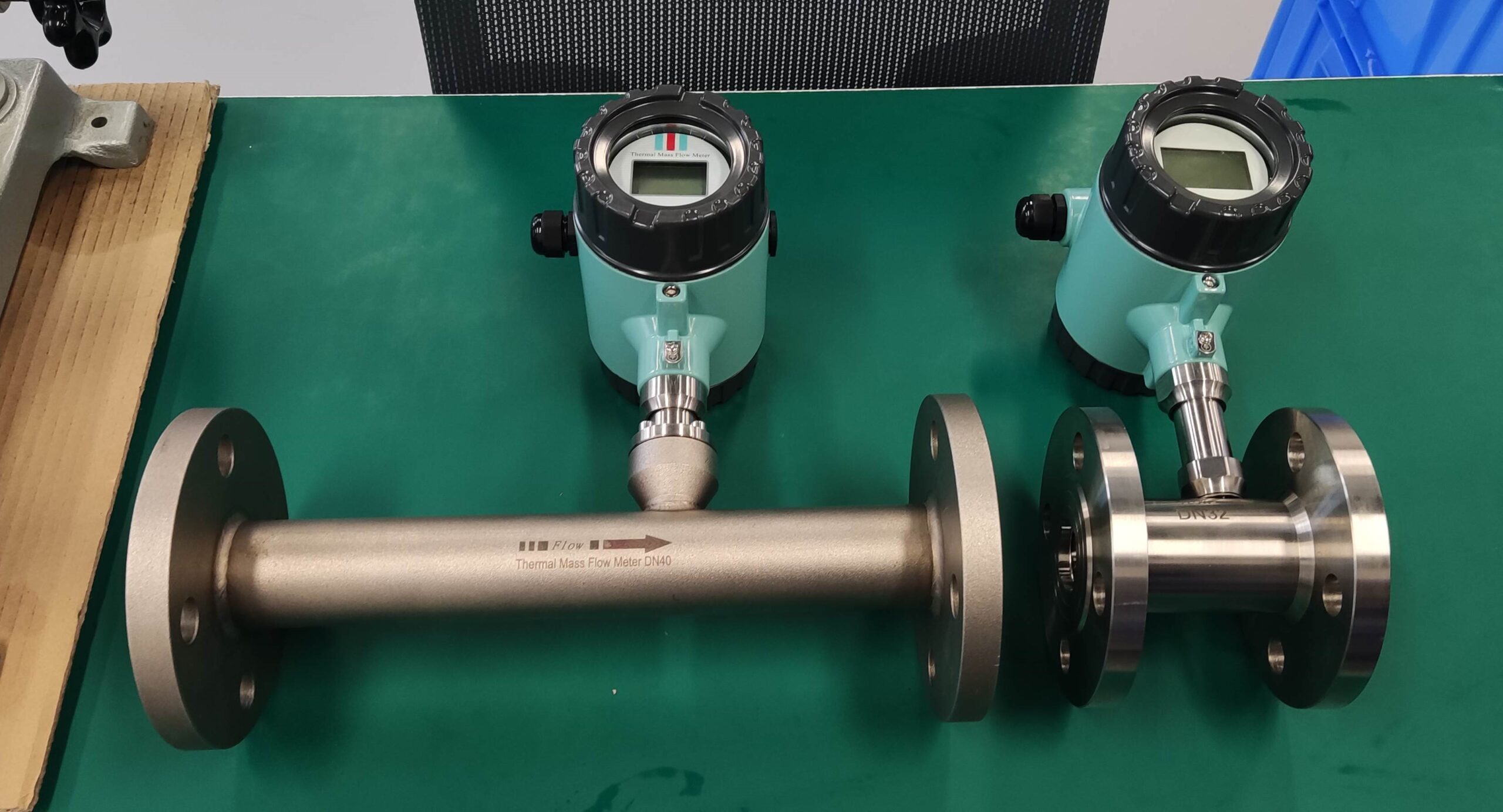

The thermal gas mass flowmeter is an instrument that uses the principle of heat conduction to measure fluid flow. The instrument uses the constant temperature difference method to measure the gas flow accurately. It has the advantages of small size, high digitization, easy installation and accurate measurement.

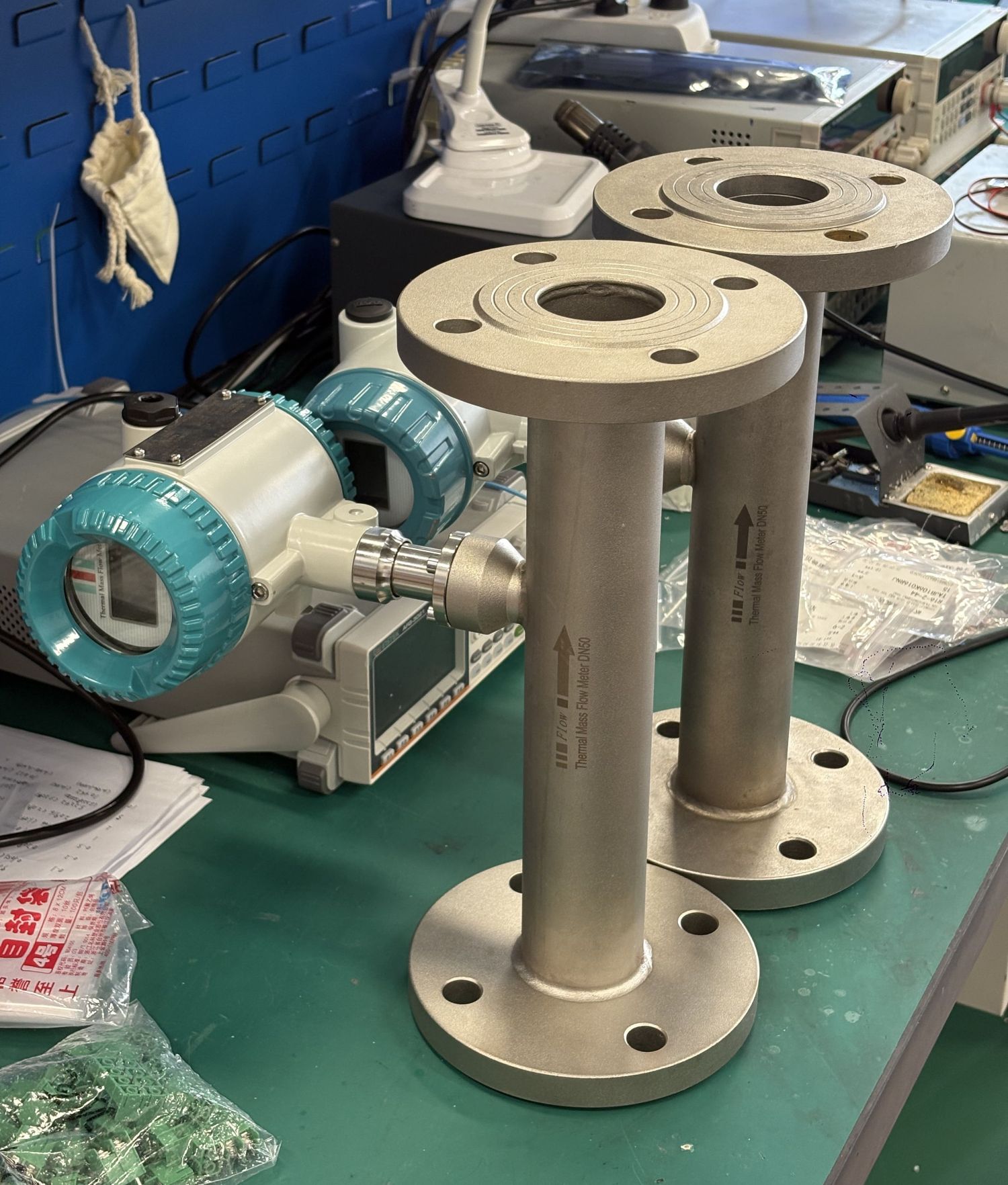

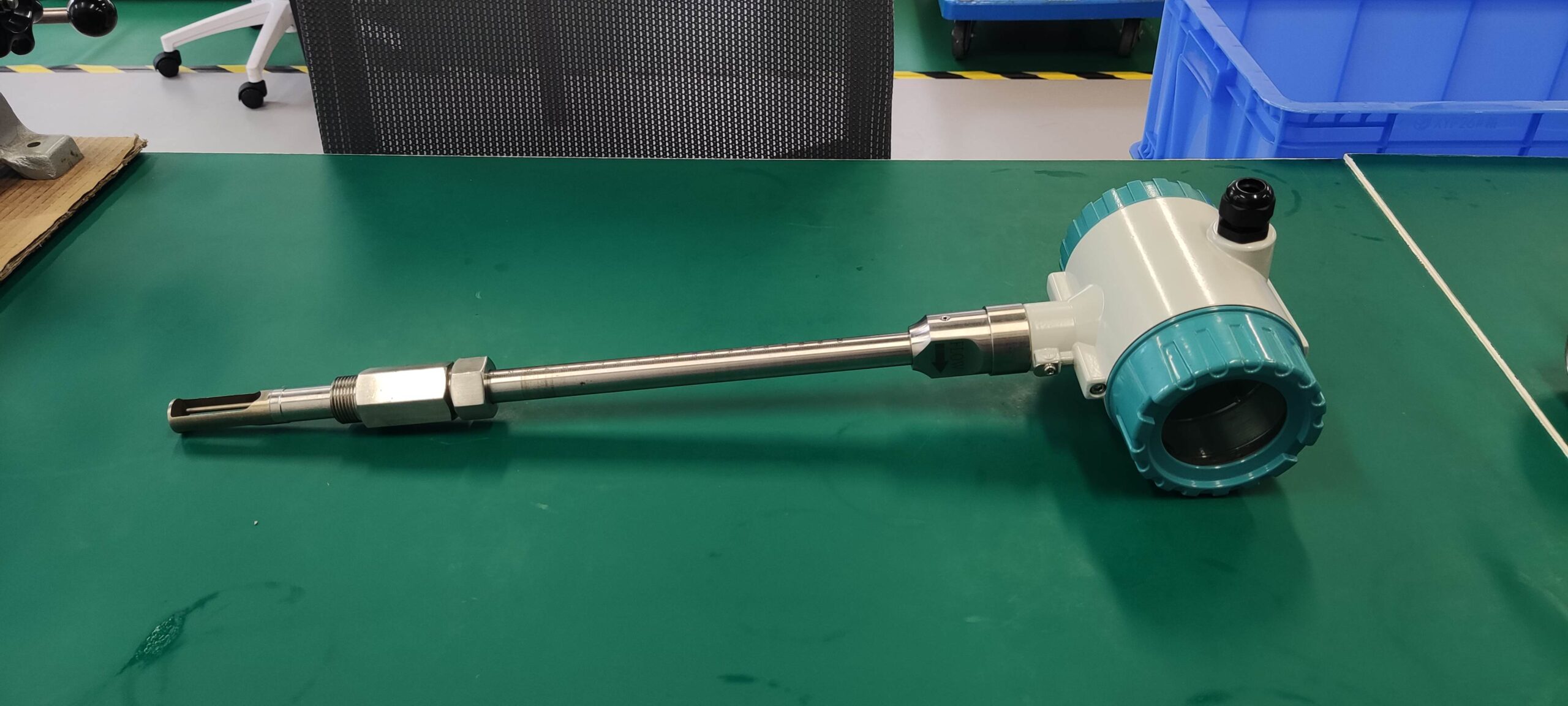

The thermal gas mass flowmeter is an instrument that uses the principle of heat conduction to measure fluid flow. The instrument uses the constant temperature difference method to measure the gas flow accurately. It has the advantages of small size, high digitization, easy installation and accurate measurement. The sensor part consists of two reference platinum resistance temperature sensors. Using a bridge loop, one sensor measures the fluid temperature and the other maintains a constant temperature difference above the fluid temperature, allowing flow measurement under high temperature and pressure conditions.

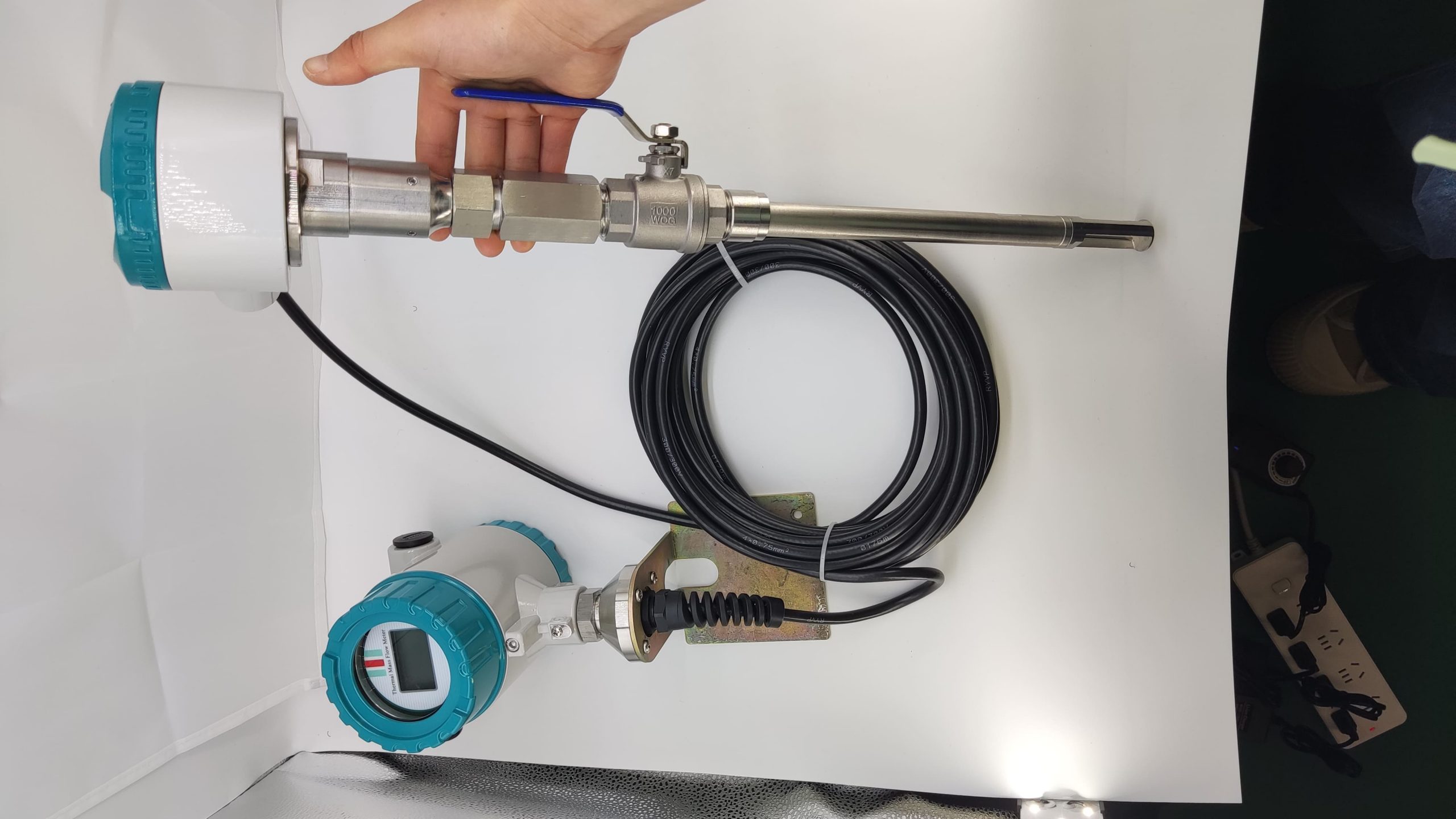

The advantages of thermal gas mass flowmeter: The real mass flowmeter, no temperature and pressure compensation for gas flow measurement, convenient and accurate measurement. The mass flow rate or standard volume flow rate of the gas can be obtained. Wide range ratio, can measure gas flow rates up to 100Nm/s bottom to 0.5Nm/s, can be used for gas leak detection. Good seismic performance and long service life. The sensor has no moving parts and pressure sensing parts, and is not affected by vibration on the measurement accuracy. Easy to install and maintain. If site conditions permit, it can be installed and maintained without stopping production. Digital design. Overall digital circuit measurement, accurate measurement, easy maintenance. Using RS-485 communication, factory automation and integration can be realized.

Installation and connection of thermal gas mass flowmeter

One type installation and connection requirements

1. If the flow meter is installed outdoors, do some protection to avoid the flow meter is often damaged by natural conditions.

2. Do not install in strong vibration occasions, do not install in a large number of corrosive gas environment.

3. Do not share an AC power supply with the equipment that pollutes the power supply such as frequency converter and welding machine. If necessary, install a purified power supply for the converter.

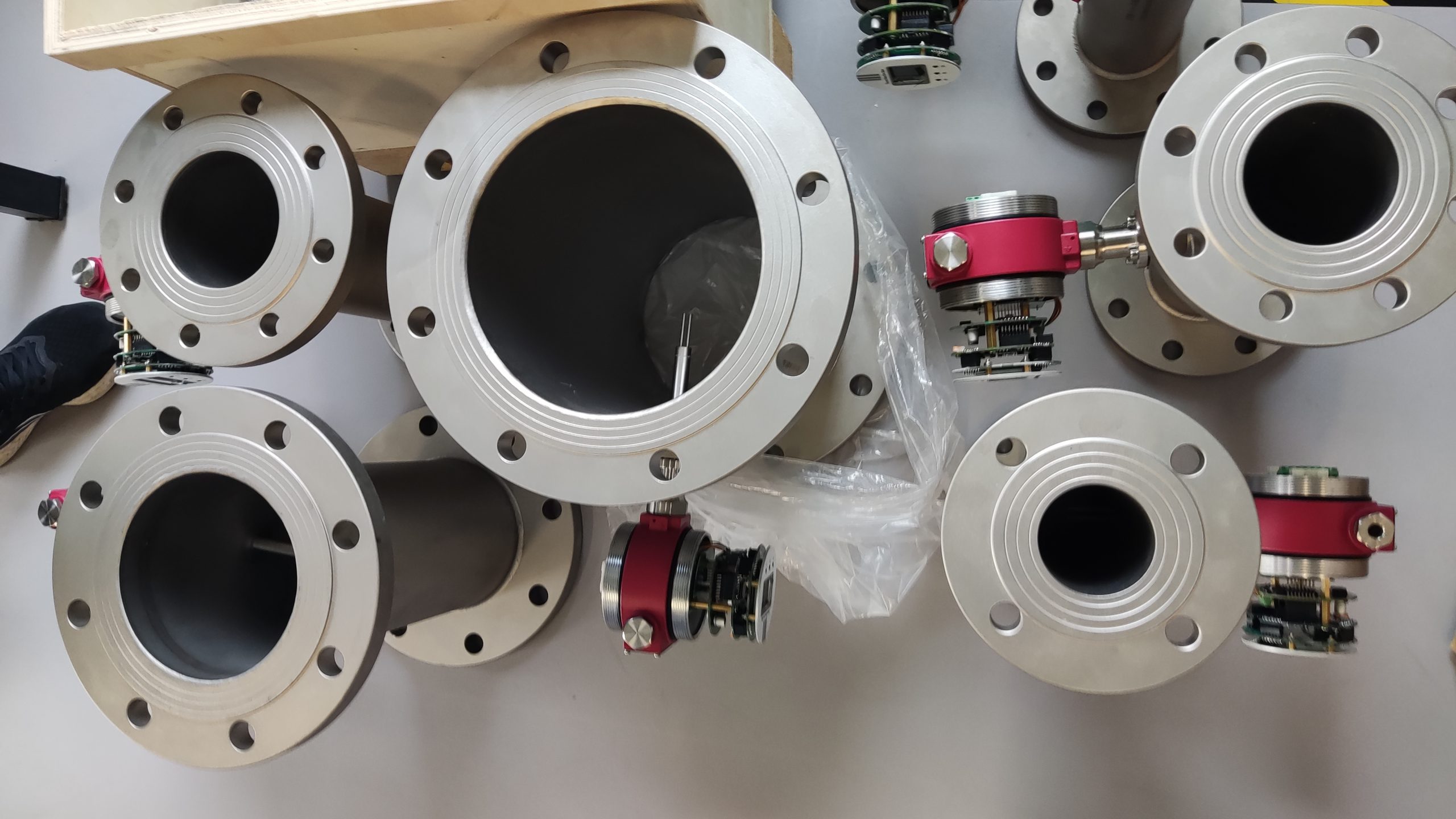

4. Pipe segment installation should select the corresponding standard flange and connect it.

5. The one-type insert type should be inserted into the axis of the pipeline under test, so the length of the measuring rod depends on the diameter of the pipe under test.

6. When installing, it should be noted that the “medium flow mark” marked on the instrument should be the same as the actual flow direction of the gas.

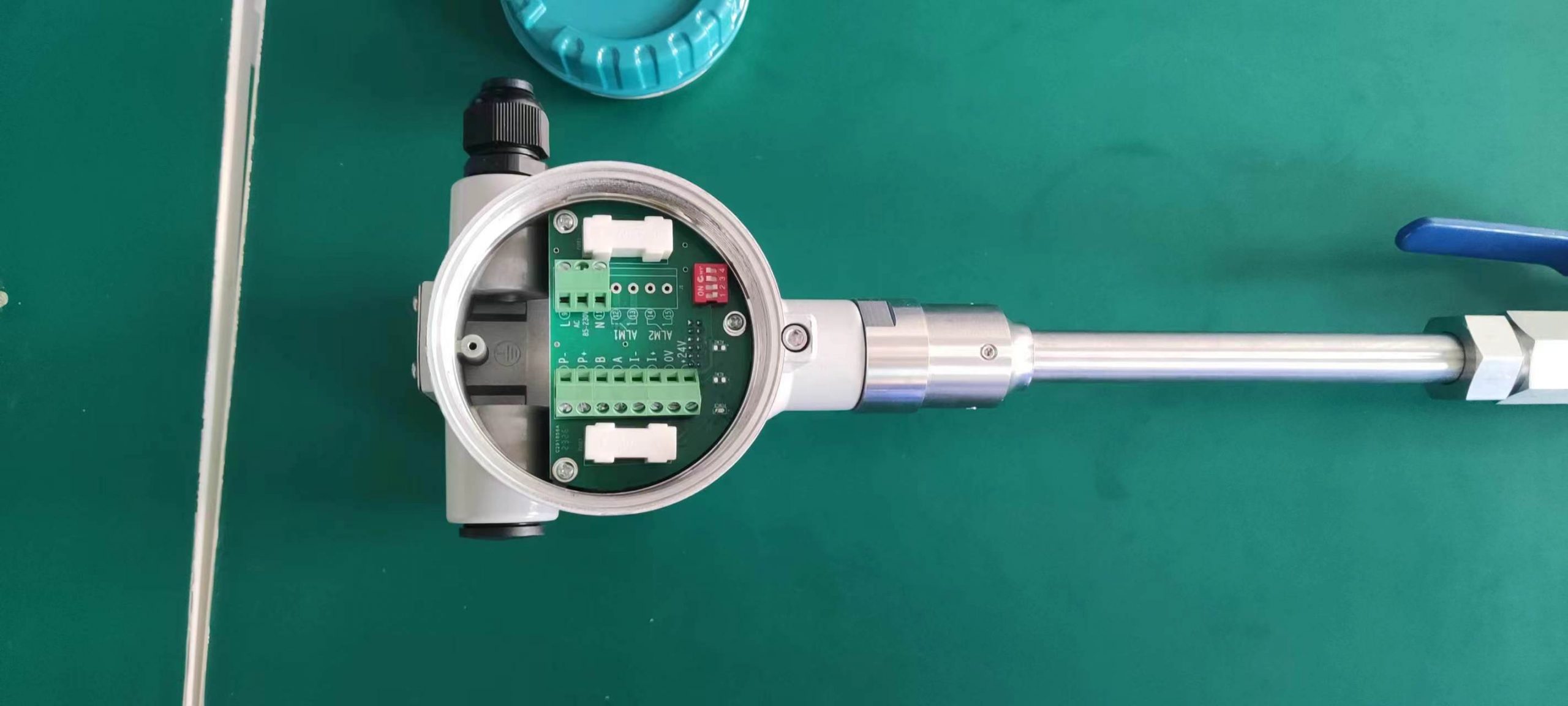

Thermal gas mass flow meter maintenance

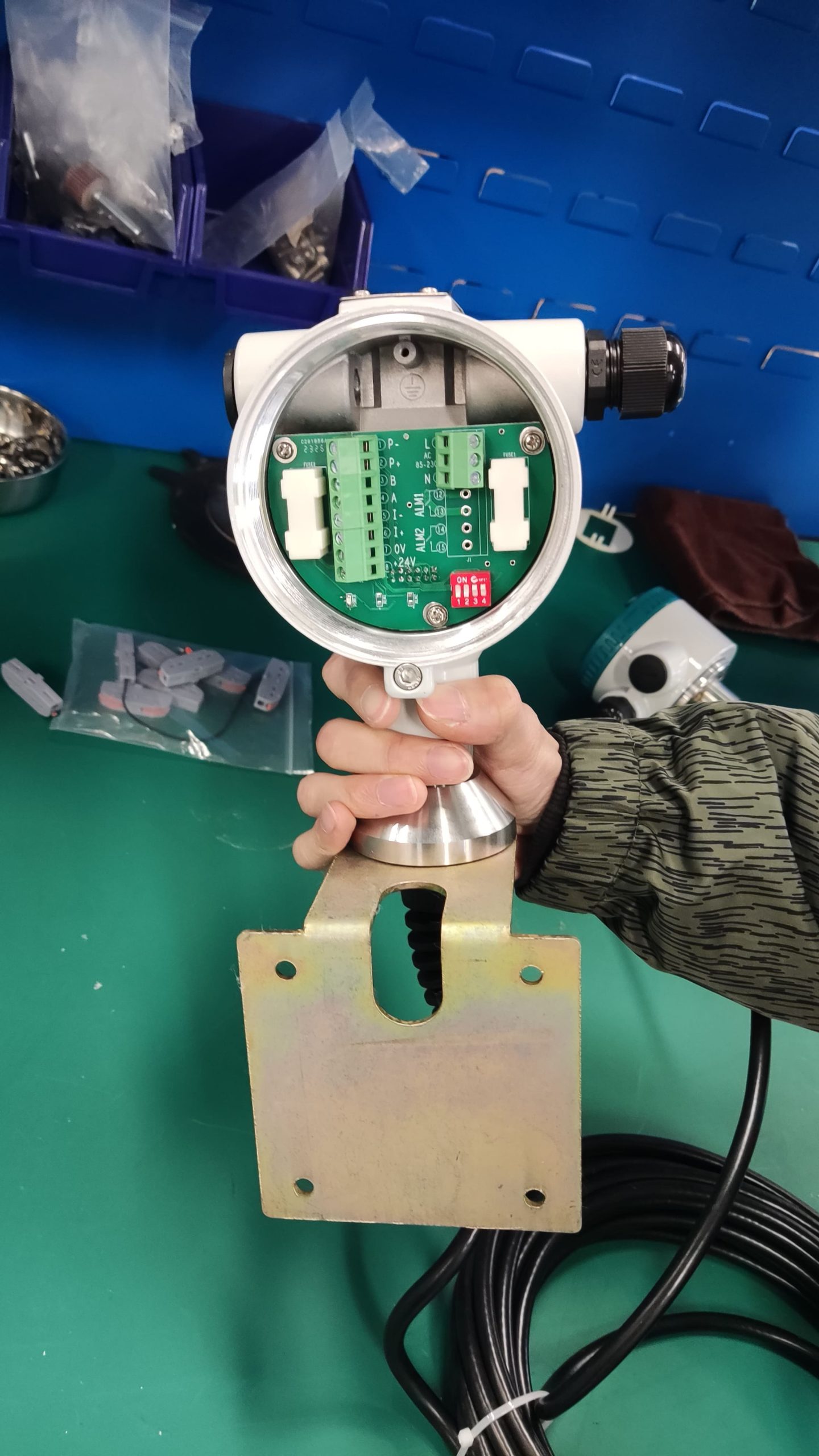

1. When opening the case, be sure to power off first.

2. When removing the sensor, pay attention to the non-toxic pipeline pressure, temperature or gas, and be sure to take protective measures to avoid injury to the operator.

3. The sensor is not sensitive to a small amount of dirt, but it should also be cleaned regularly when used in a dirty environment. Otherwise, the measurement accuracy will be affected.