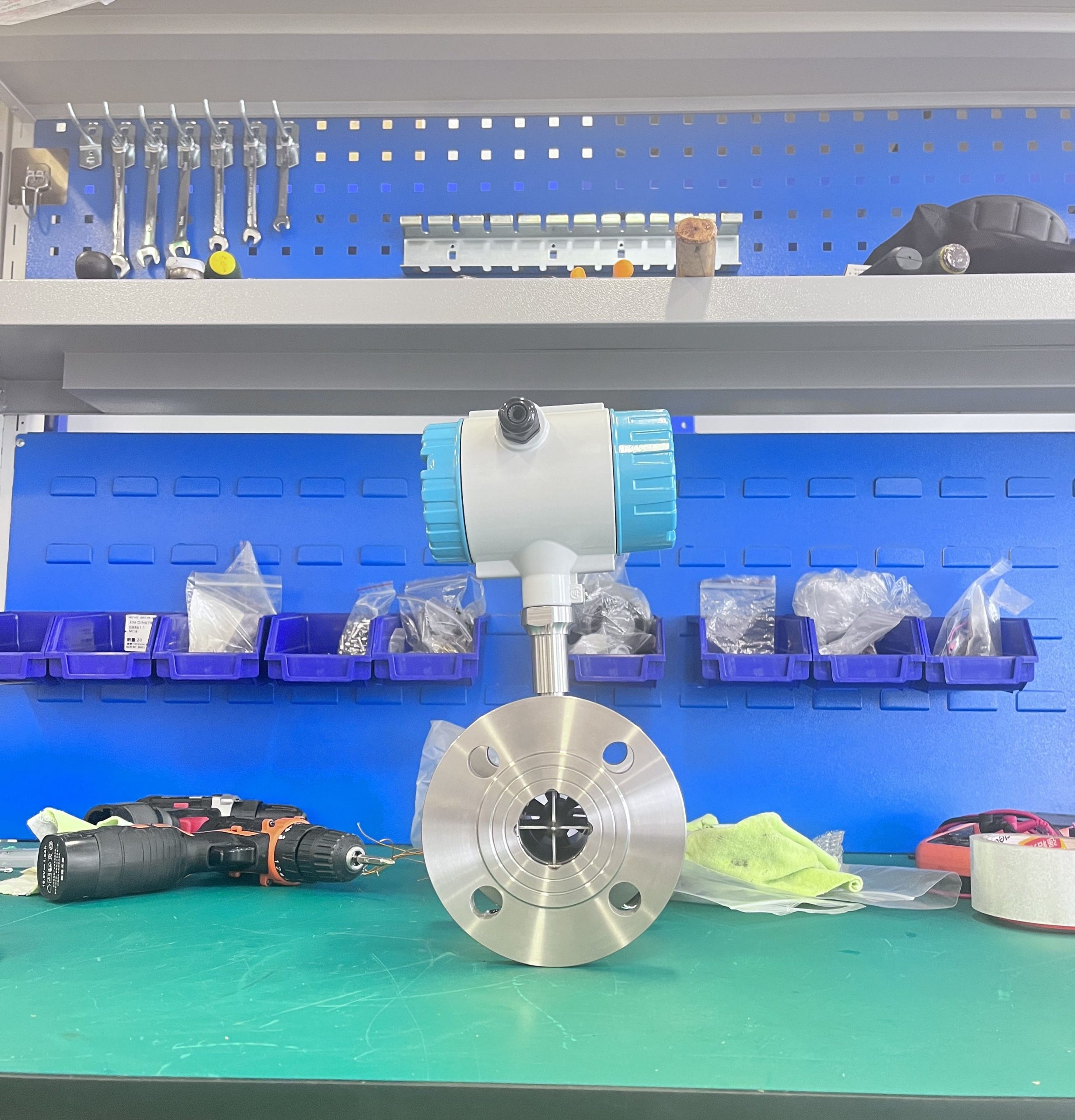

The selection principle of turbine flow meter and the implementation of selection parameters

In the case that the type of flow sensor has been selected, the selection of the flow sensor specification and its supporting components is very important. In a word, choose well to use well. Therefore, two basic principles should be grasped in the selection process of turbine flowmeter; To wit:

First, we must ensure the accuracy of use, and second, we must ensure production safety. To do this, it is necessary to implement three selection parameters, namely, the large, small and commonly used instantaneous flow in the near and long term, the design pressure of the measured medium, and the working pressure.

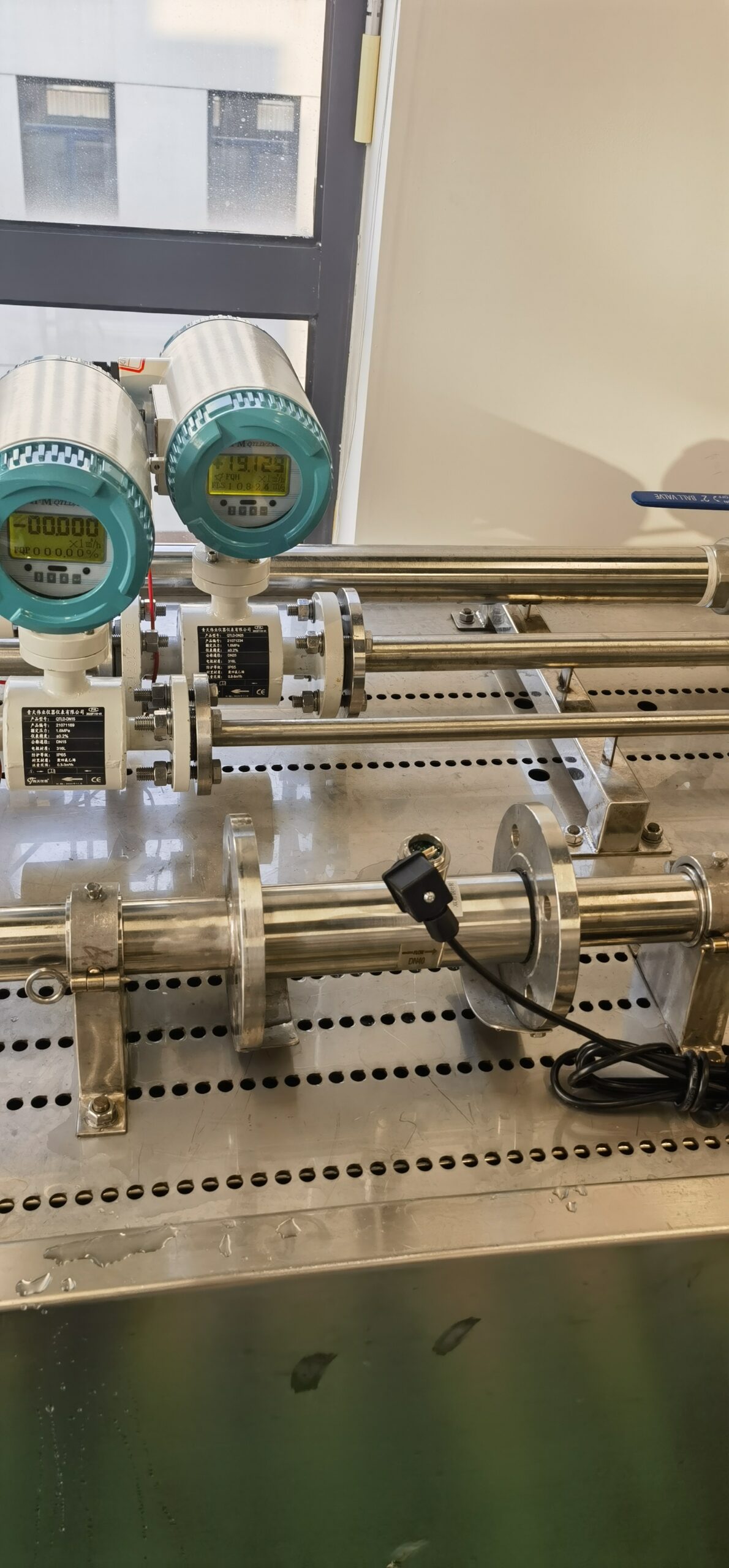

1. Calibration before use

On the one hand, considering that there are still some difficulties in the field verification of this kind of flow sensor. In addition, if the intention of the purchase is to prepare the flow sensor to be used in more important measurement occasions, such as large flow of trade measurement or measurement disputes more prominent measurement points, and the use of the site does not have the flow online calibration conditions, then in this case, It is too early to easily determine the full performance of the flow sensor based on a factory qualification certificate provided by the manufacturer at the time of purchase. Therefore, in order to ensure the reliability and accuracy of the measurement results of the flow sensor in the future work process, it is necessary to send the flow sensor to the department with this verification ability and qualification for a system verification within the full flow range before the formal installation

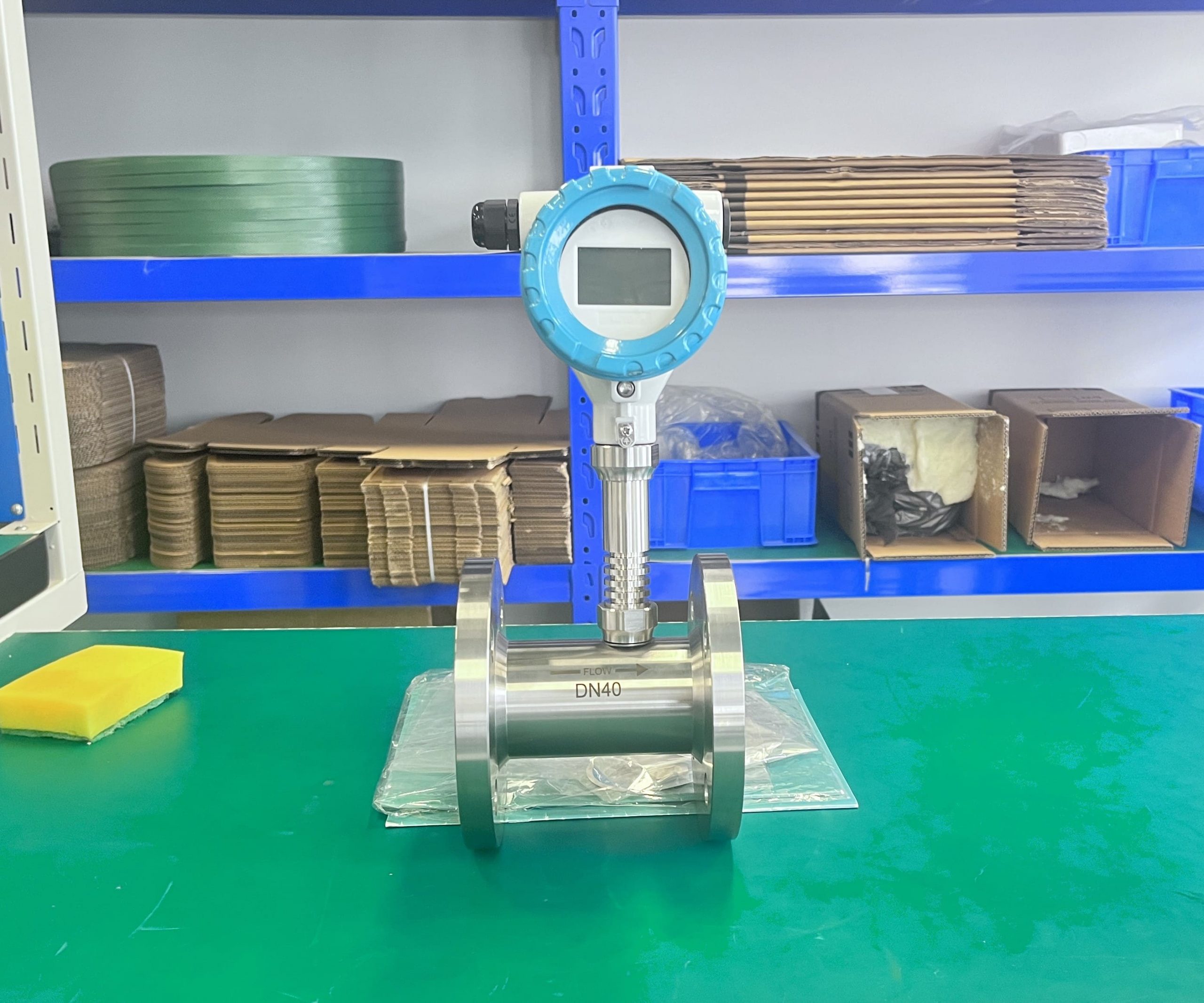

2. Do a good job of process installation

Although this kind of flow sensor does not have too many special requirements for the process installation and use environment, any kind of flow measuring instrument has such a common feature, that is, to avoid vibration and high temperature environment with off-flow interference elements, to keep the inner wall of the front and back straight pipe of the flow sensor smooth and straight, and to ensure that the measured medium is a clean single-phase fluid.

3. Strengthen post-management

Although this kind of flow sensor has a variety of automatic handling functions and micro-power consumption characteristics, it still needs to strengthen management after operation. For example, in order to ensure the accuracy and reliability of the long-term work of the flow sensor, the system calibration should be regularly carried out, the head data should be copied, the media parameters should be replaced, and the battery condition should be checked from time to time, the flow sensor coefficient and the lead seal should be checked.

4. Pay attention to internal maintenance

If the measurement chamber of the flow sensor and its components need to be regularly inspected or cleaned due to temperament dirt or other reasons, special attention must be paid to: for the turbine flow meter of the same specification, the core components such as the vortex generator and the flow guide body cannot be exchanged, otherwise, the measurement coefficient of the instrument must be re-calibrated and the temperature and pressure sensor equipped with the system correction.