The main points that should be paid attention to when installing the precession vortex flowmeter

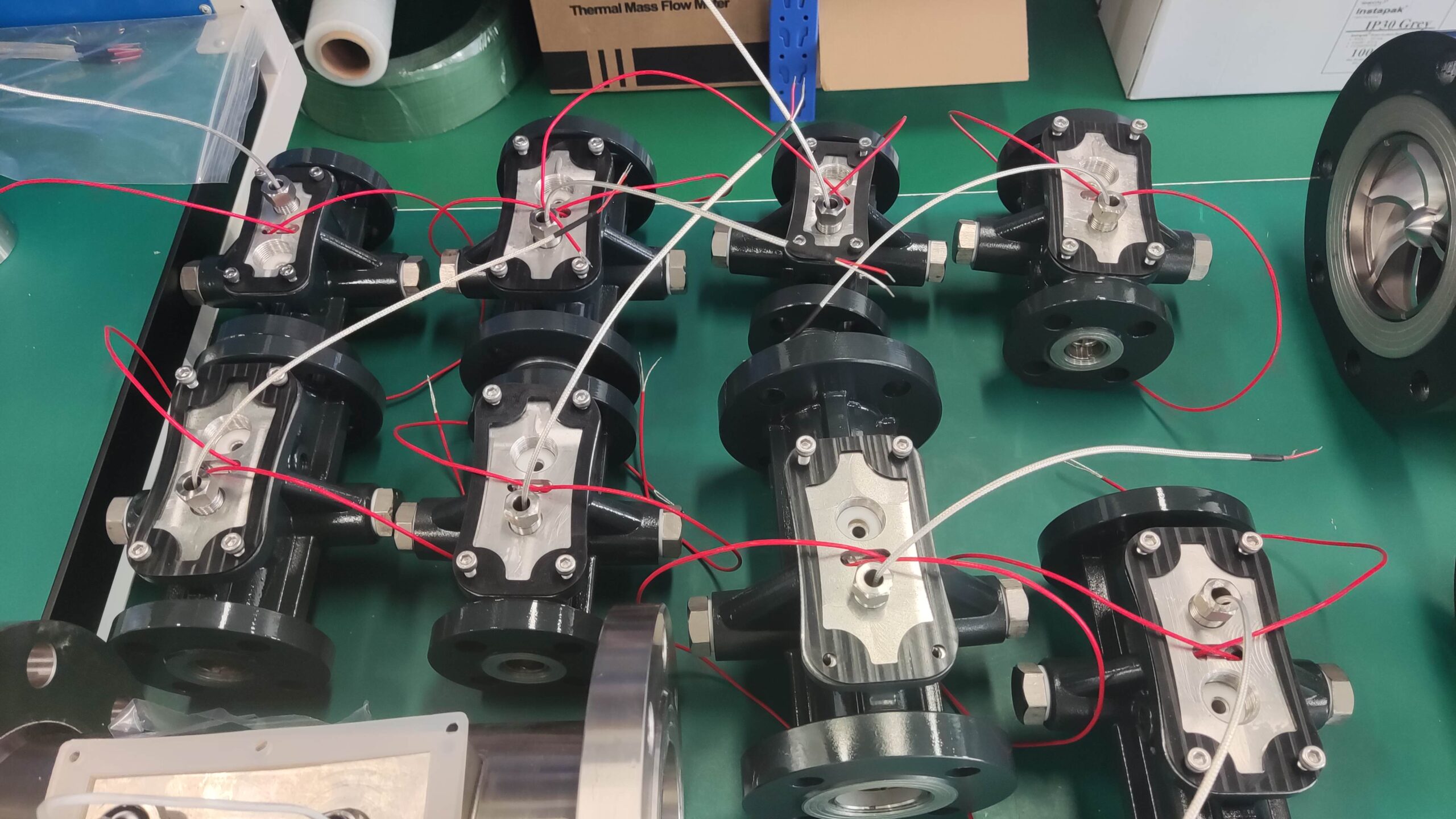

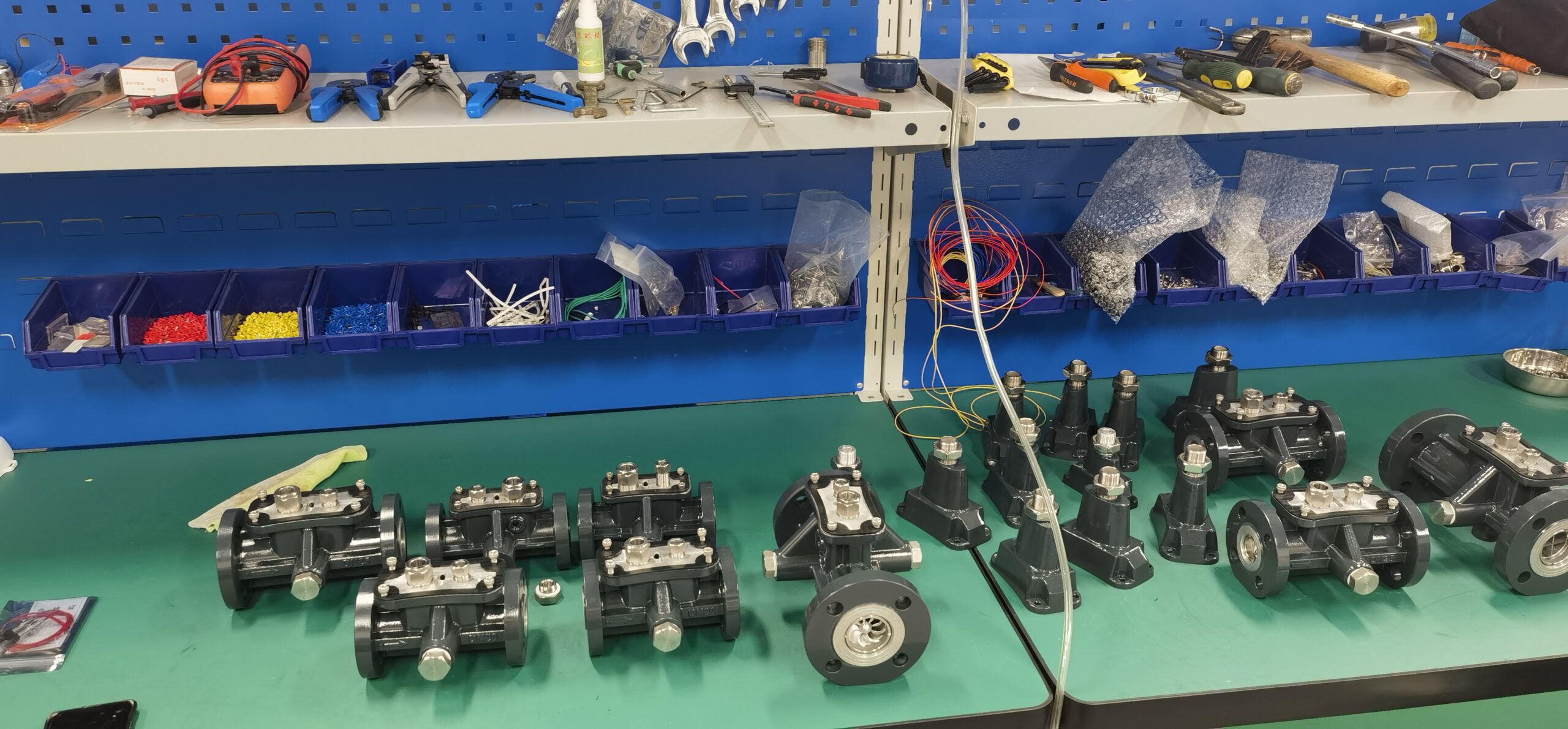

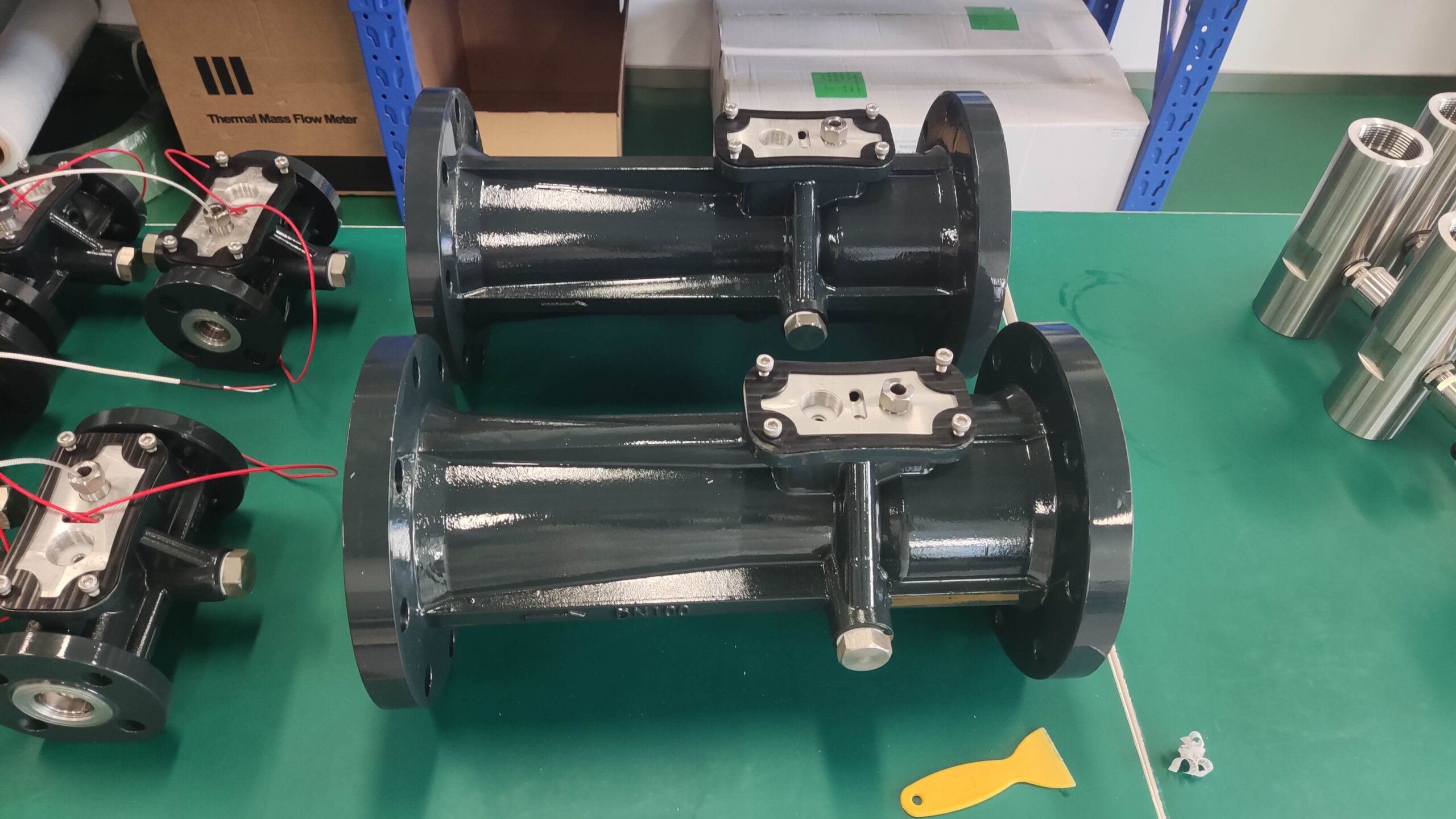

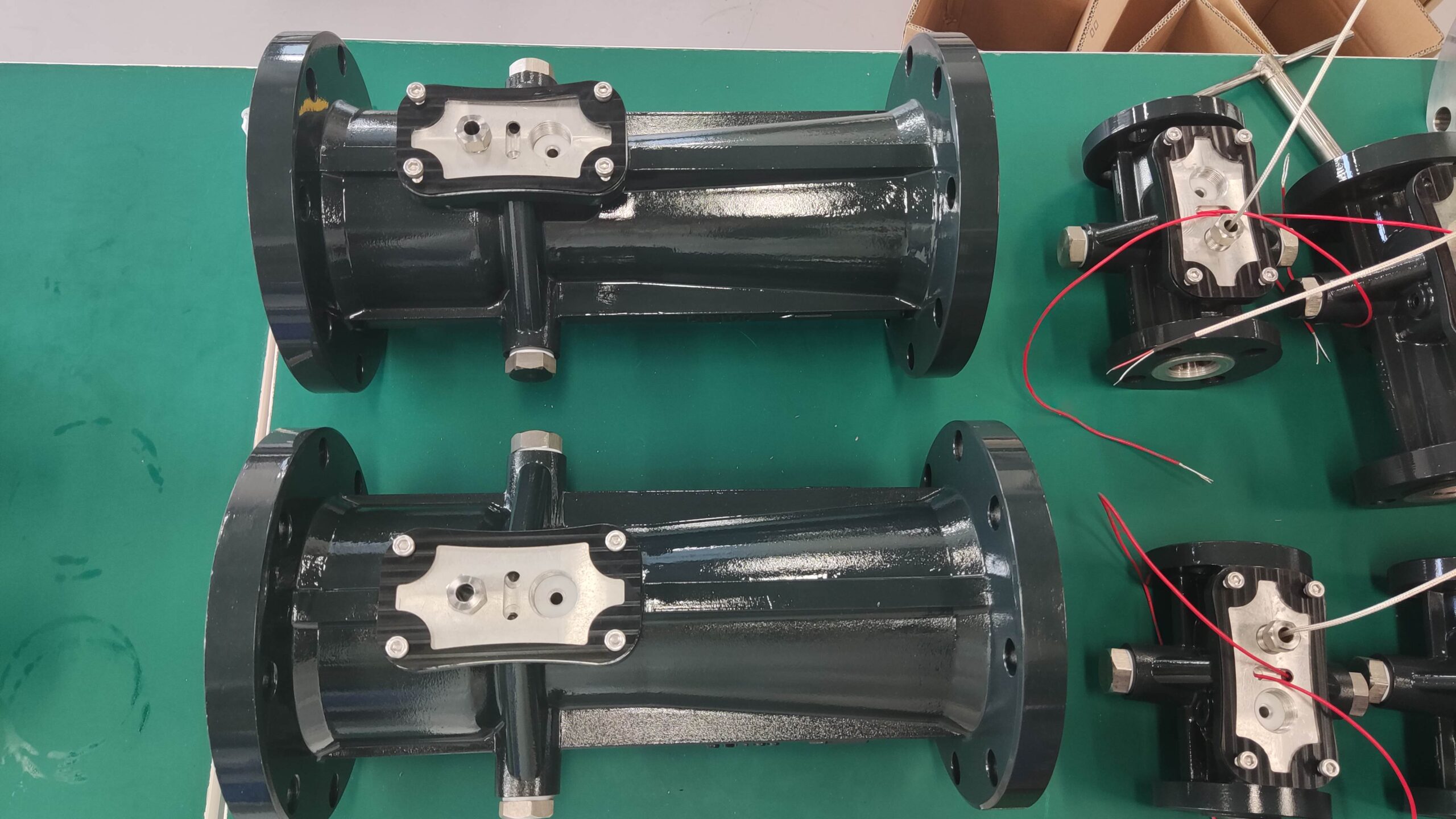

The precession vortex flowmeter adopts the new micro processing technology, which has the advantages of strong function, wide flow range, simple operation and maintenance, convenient installation and use. Widely used in petroleum, chemical, electric power, metallurgy, coal and other industries of various gas measurement.

Several points should be noted when installing the precession vortex flowmeter:

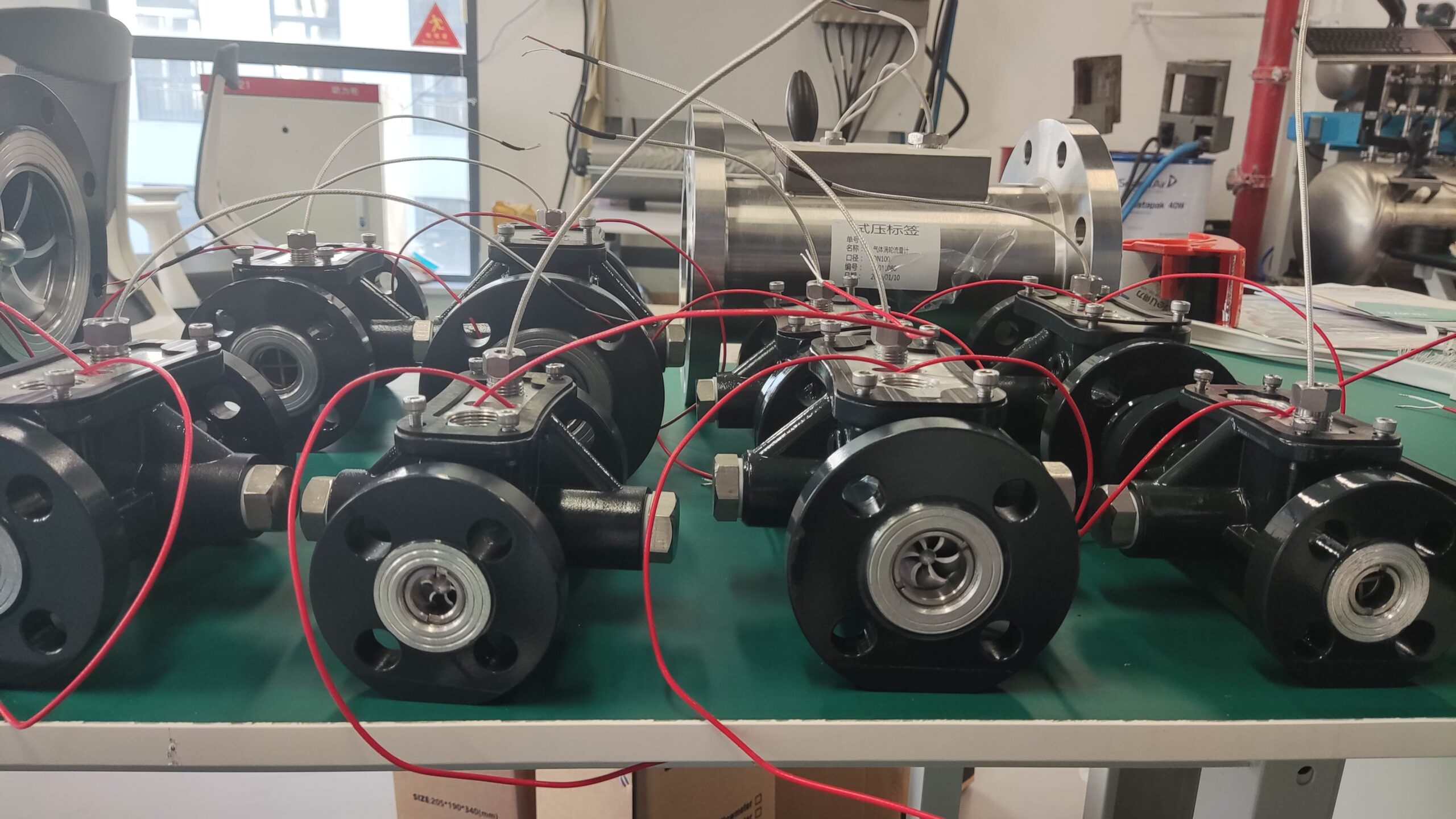

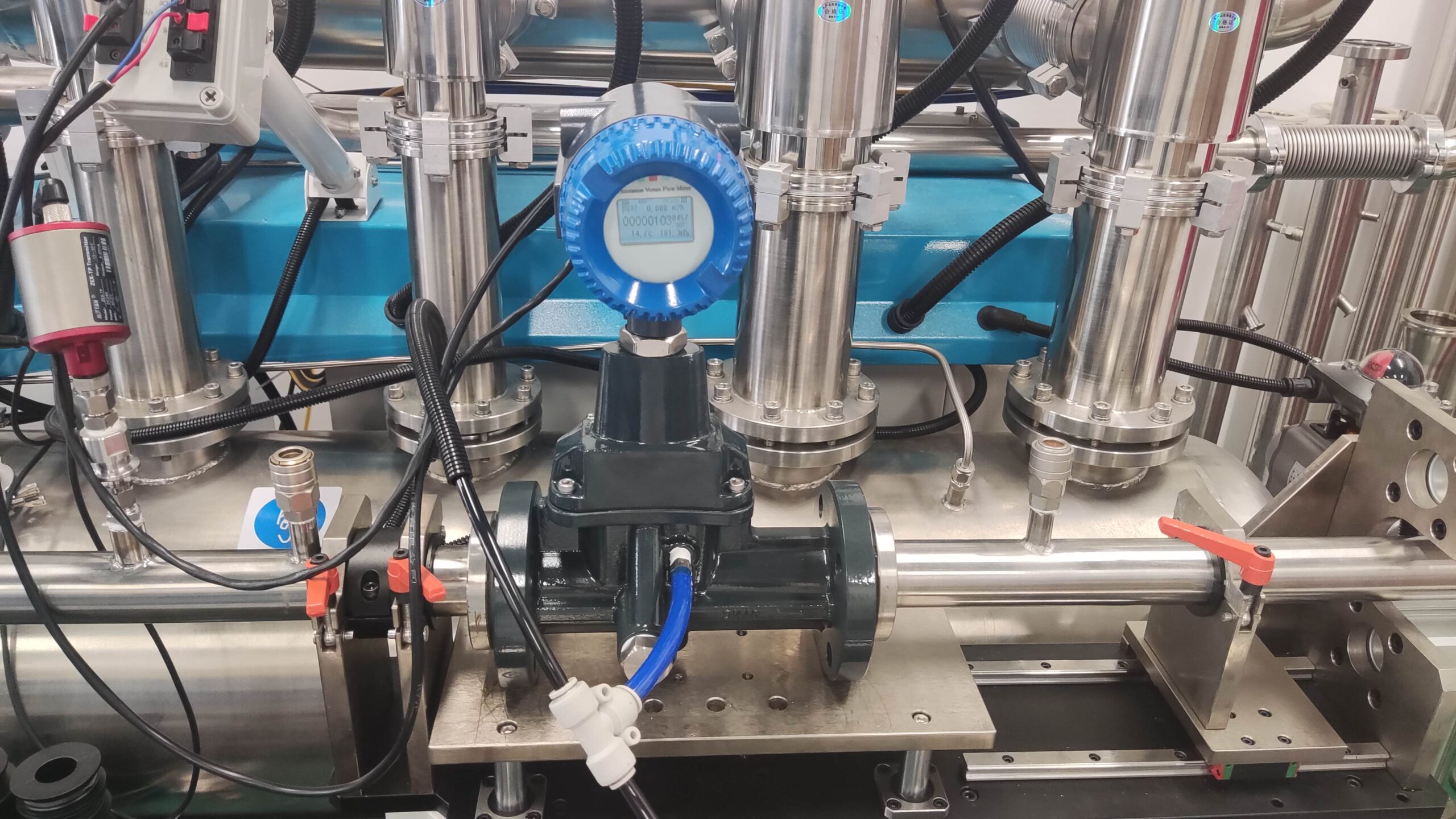

1, the sensor can be installed in vertical, horizontal or arbitrary tilt position according to the flow direction;

2, when the pipeline is long or close to the vibration source, support should be installed on the upper and lower reaches of the flow meter to eliminate the impact of pipeline vibration;

3, the installation site of the sensor should have enough space to facilitate the inspection and maintenance of the flow meter, and should meet the environmental requirements of the flow meter; The interference of external strong magnetic field should be avoided;

4, in the outdoor installation and use, there should be a cover to avoid sun exposure and rain erosion, affecting the service life of the precession vortex flowmeter;

5, should pay attention to the impact of installation stress, installation flowmeter upstream and downstream pipelines should be coaxial, otherwise it will produce shear stress;

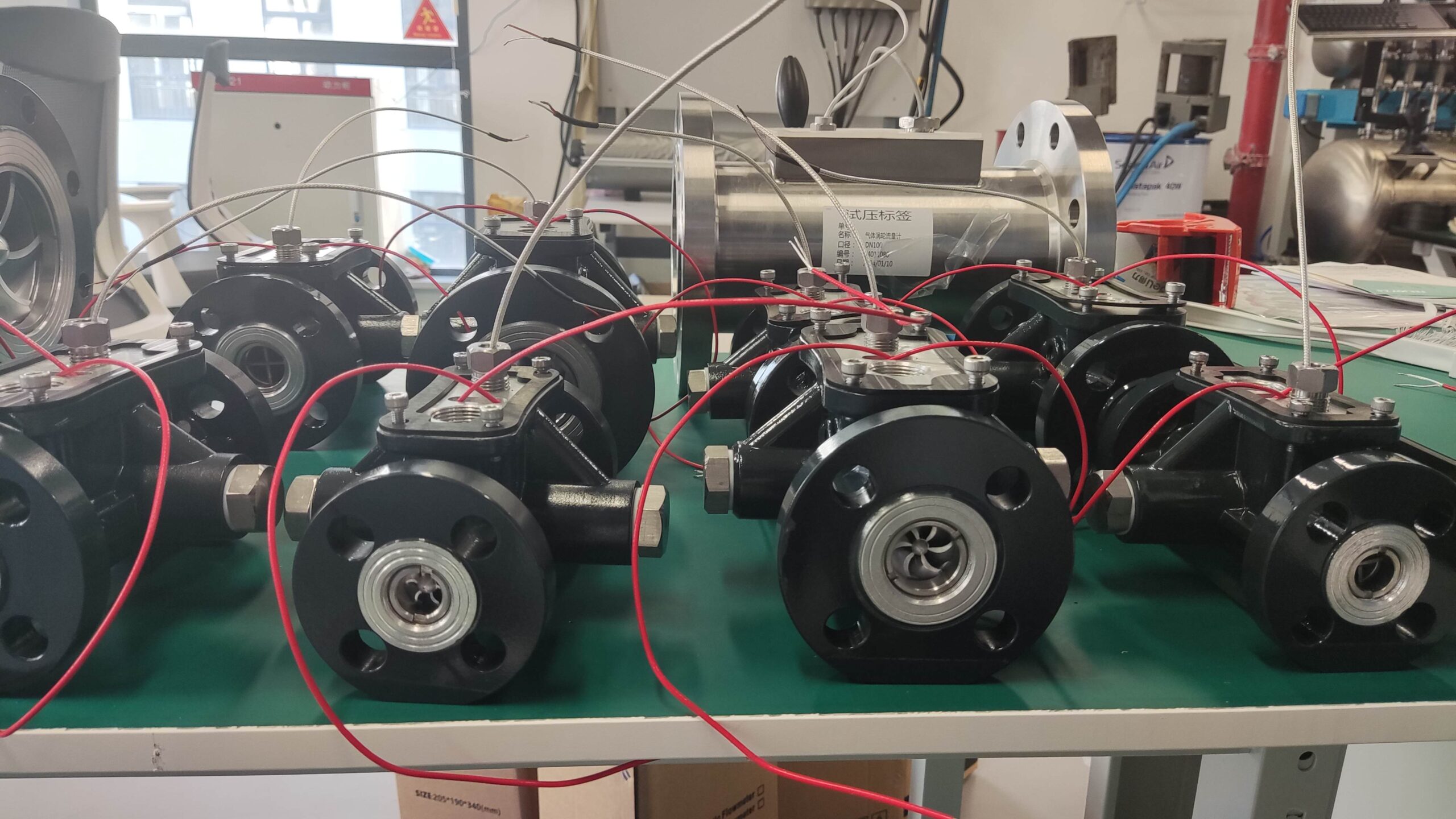

6, pipeline pressure test, should pay attention to the pressure measurement range of the pressure sensor configured by the intelligent flowmeter, so as to avoid overpressure damage to the pressure sensor;

7, the location of the installation of the flow meter should consider the thickness of the sealing gasket, or install an elastic expansion joint on the downstream side;

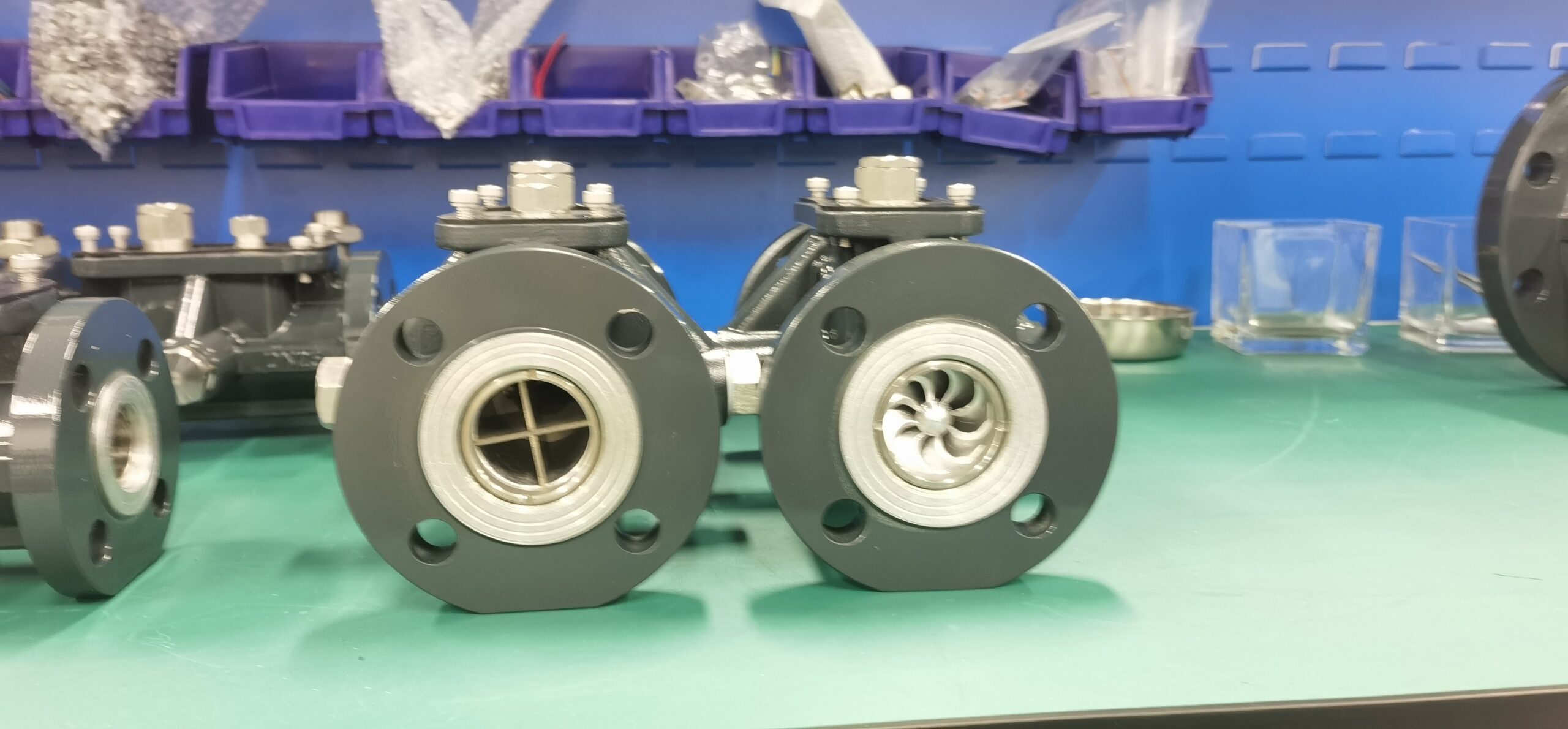

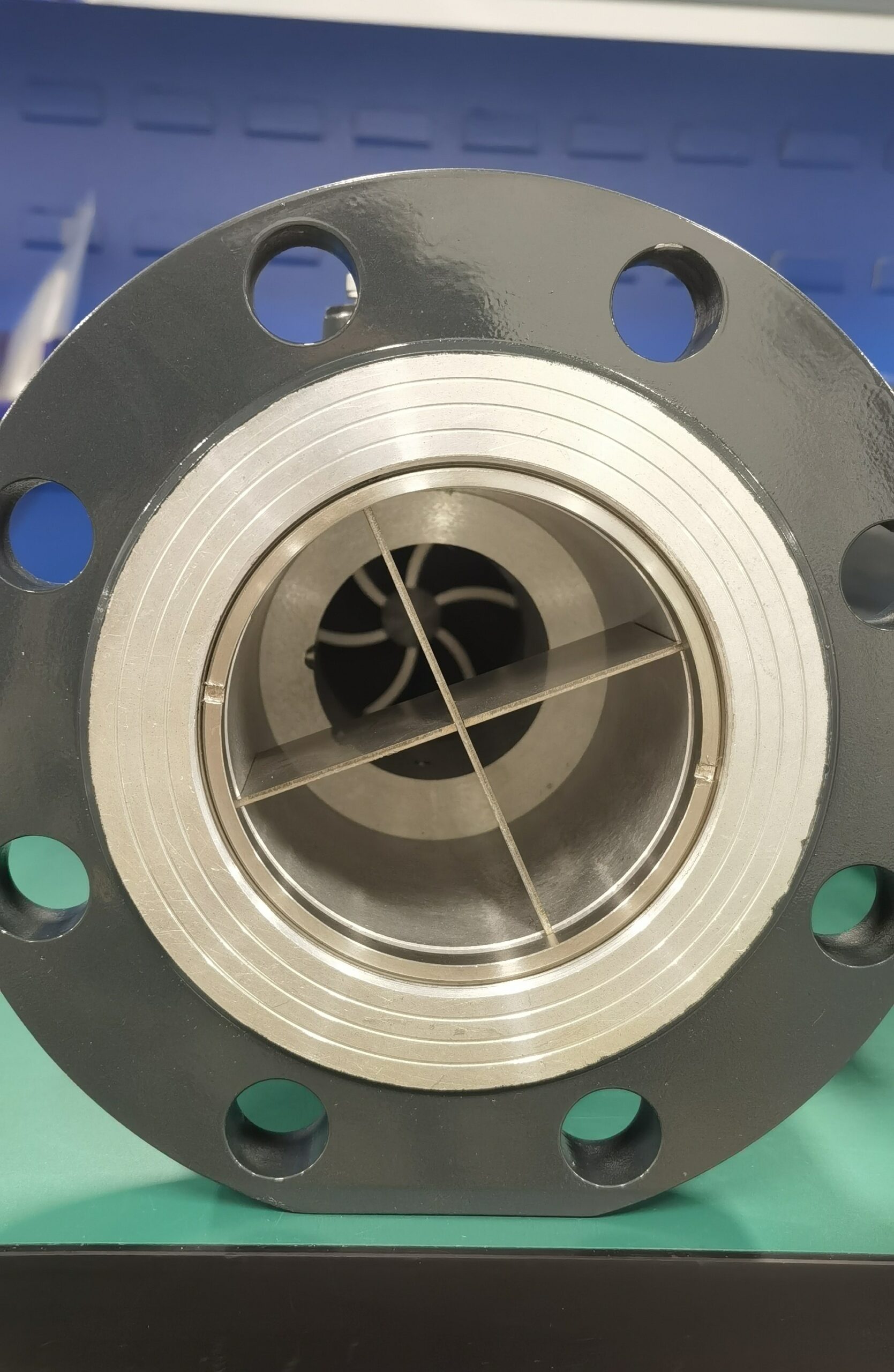

8, before installing the flow meter should first remove the welding slag and other debris in the pipeline. When it is put into operation, the upper and downstream valves of the flowmeter should be slowly opened to avoid the instantaneous airflow being too rapid and damaging the rotor.