The importance of electromagnetic flow meter grounding and how to choose grounding

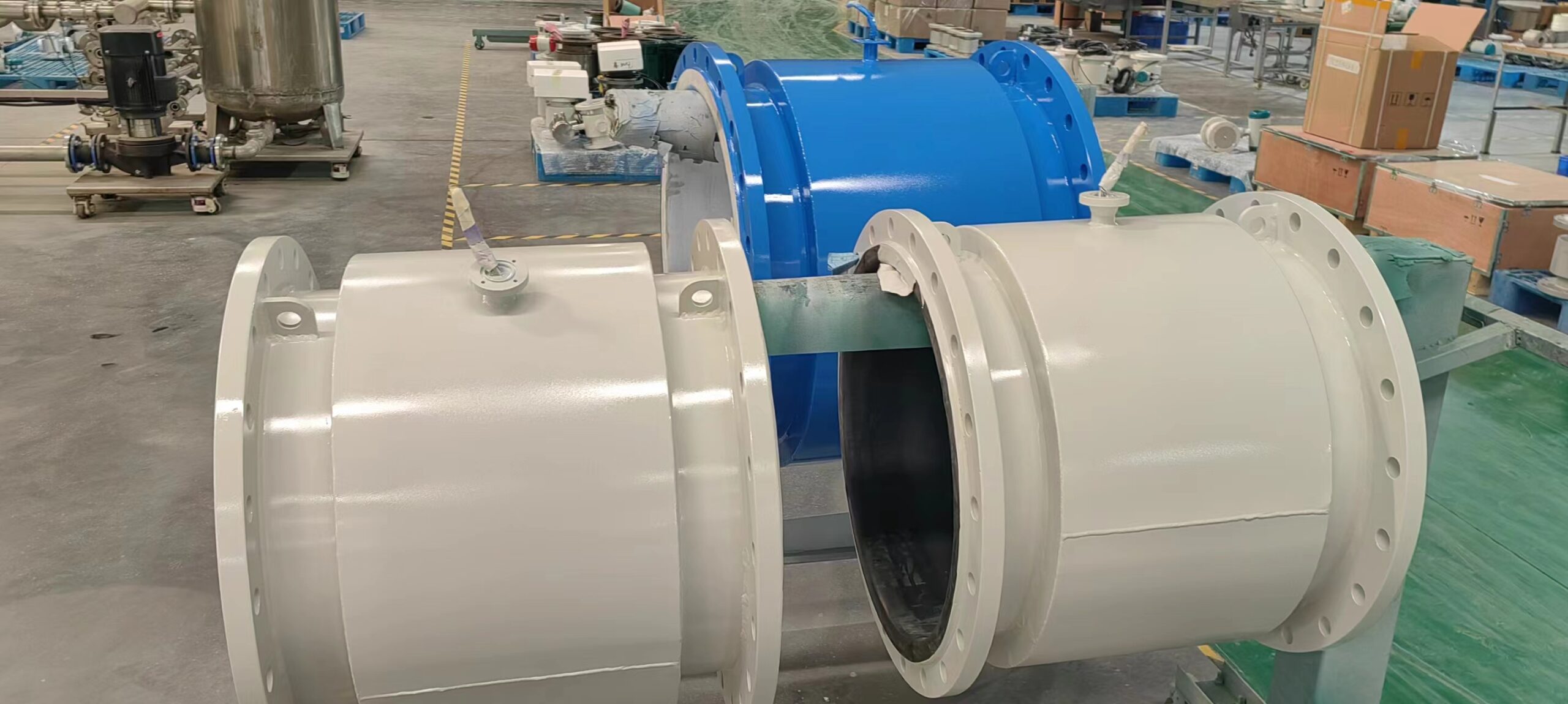

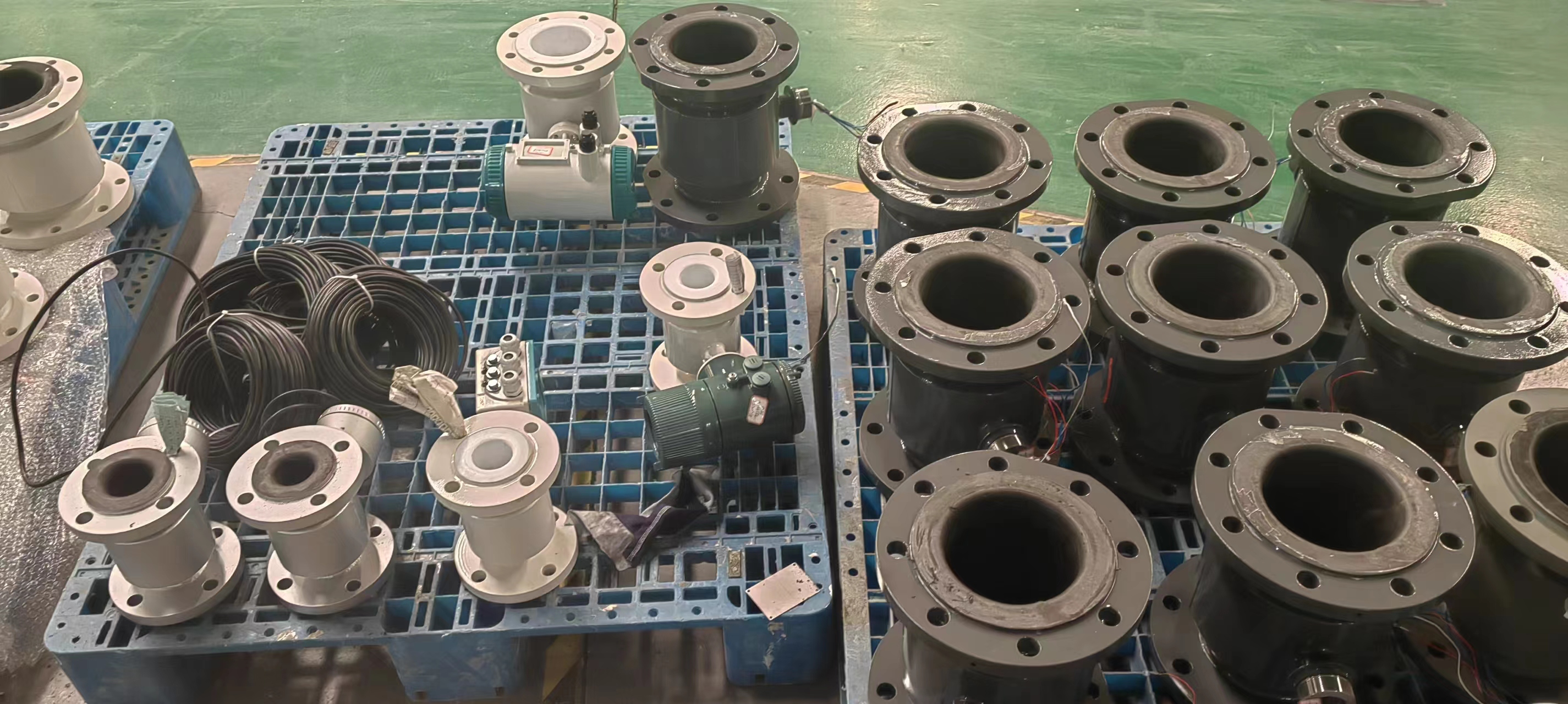

The grounding of the electromagnetic flowmeter is equipped with a grounding ring, and then the grounding ring is connected to the pipeline. If it’s lined, you need a third electrode to ground it.

How to choose the ground ring of electromagnetic flowmeter

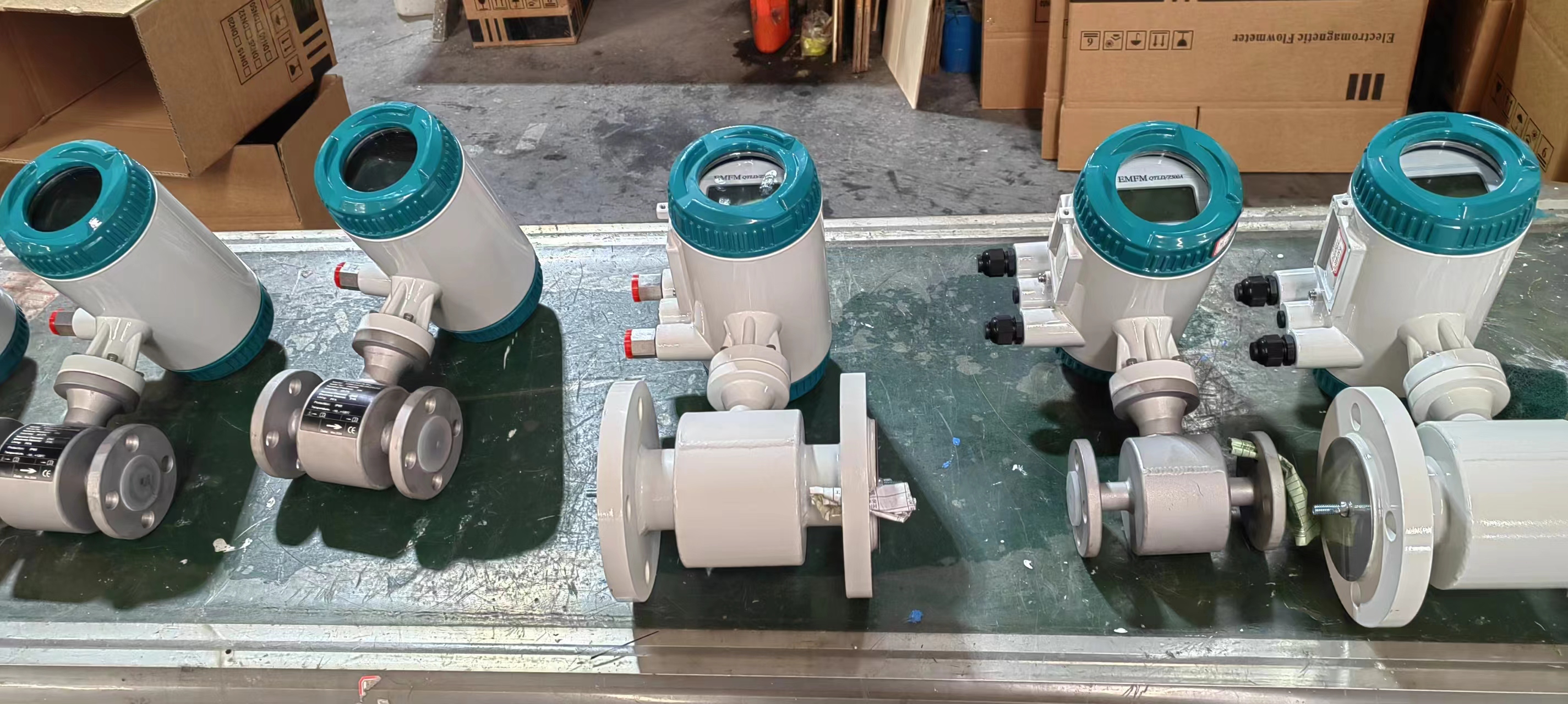

At present, electromagnetic flowmeters are mainly used in water supply industry, sewage treatment, farmland irrigation, food industry, paper and other light industries. Electromagnetic flowmeter with waterproof, anti-corrosion, anti-interference, anti-lightning ability.

There are no moving parts in the pipeline of the electromagnetic flowmeter, and there is almost no additional pressure loss in the measurement. About the choice of grounding ring:

1. Protection ring: The F46 lining sensor should use a protection grounding ring, which is fixed on the flange through screws to protect the flanging of the lining from damage.

2. The ground ring is made of stainless steel. If the owner has special requirements, it can be explained separately.

3. Standard ground rings: On plastic and cathodic protection pipes with insulated inner and outer walls to protect against electrolytic corrosion, ground rings must be installed on both sides of the sensor.

-.jpg)

-.jpg)

-.jpg)