The difference between ultrasonic level meter and radar level meter

The transmission of sound waves requires a medium, so they cannot travel in a vacuum. Therefore, the limitations of ultrasonic level meter in practical application are still very large, and there are many shortcomings compared with radar level meter.

1. Ultrasonic level meter has a temperature limit, the general temperature at the probe can not exceed 80 degrees, and the sonic speed is greatly affected by temperature.

2. Ultrasonic level meter is greatly affected by pressure, generally within 0.3MPa, because the sound wave depends on vibration to emit, and the sound components will be affected when the pressure is too large.

3. When the fog or dust in the measuring environment is very large, it will not be a good measurement.

All of these limit the application of ultrasonic level gauges. In contrast, radar is electromagnetic wave, not affected by vacuum degree, the medium temperature and pressure of the application range is very wide, with the emergence of high-frequency radar, its application range is more extensive, so in the level measurement, radar is a very good choice.

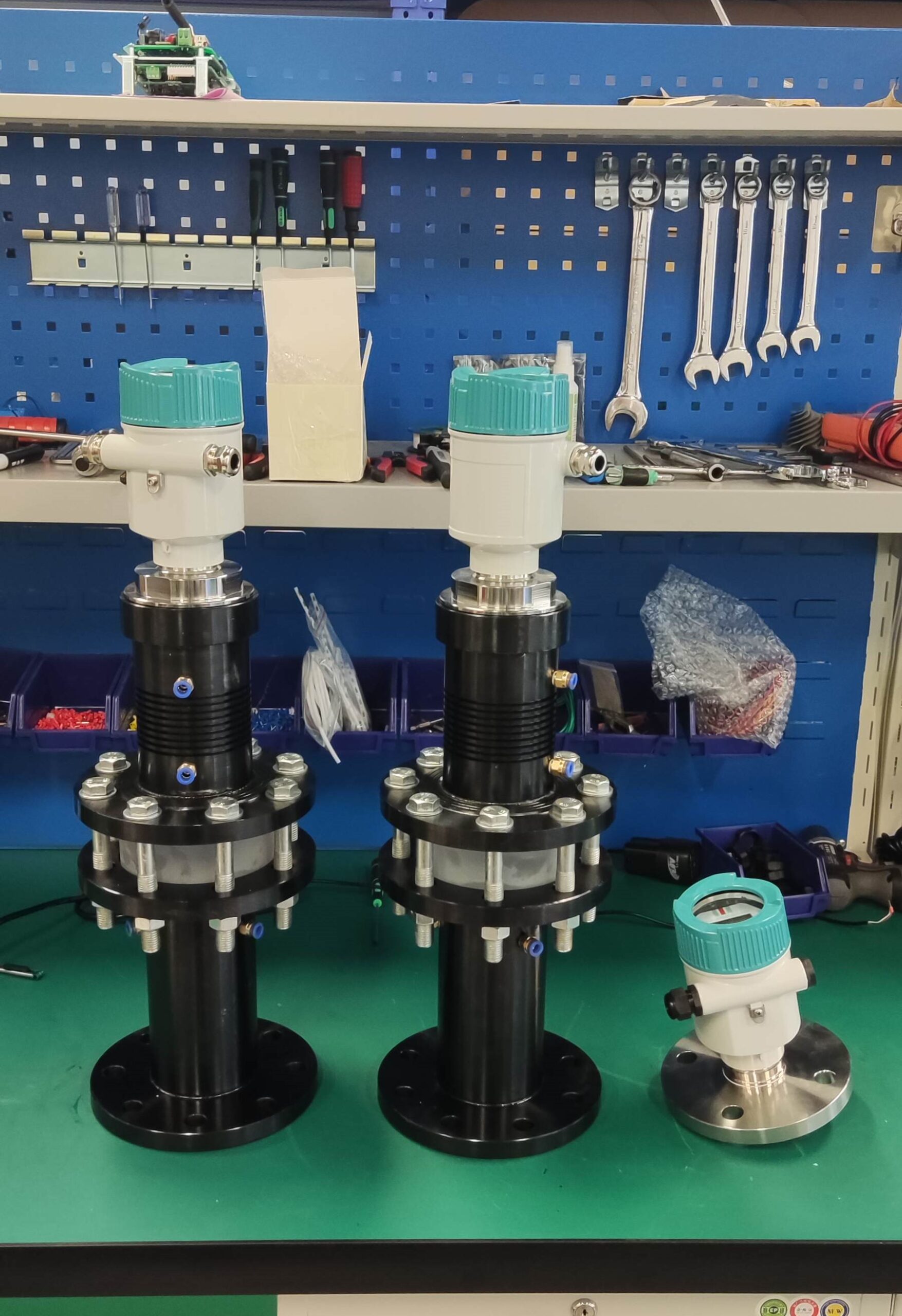

However, whether it is radar or ultrasonic level meter, it is necessary to pay attention to the installation position and pay attention to the blind area during the installation process. For example, when installed on the tank, do not install it in the feed port, do not install it near the ladder, and have a distance of 300 to 500mm from the tank wall to prevent echo interference. When there is stirring and the liquid level fluctuates greatly, it is also necessary to choose the appropriate installation method.

a. Radar measurement range is much larger than ultrasonic.

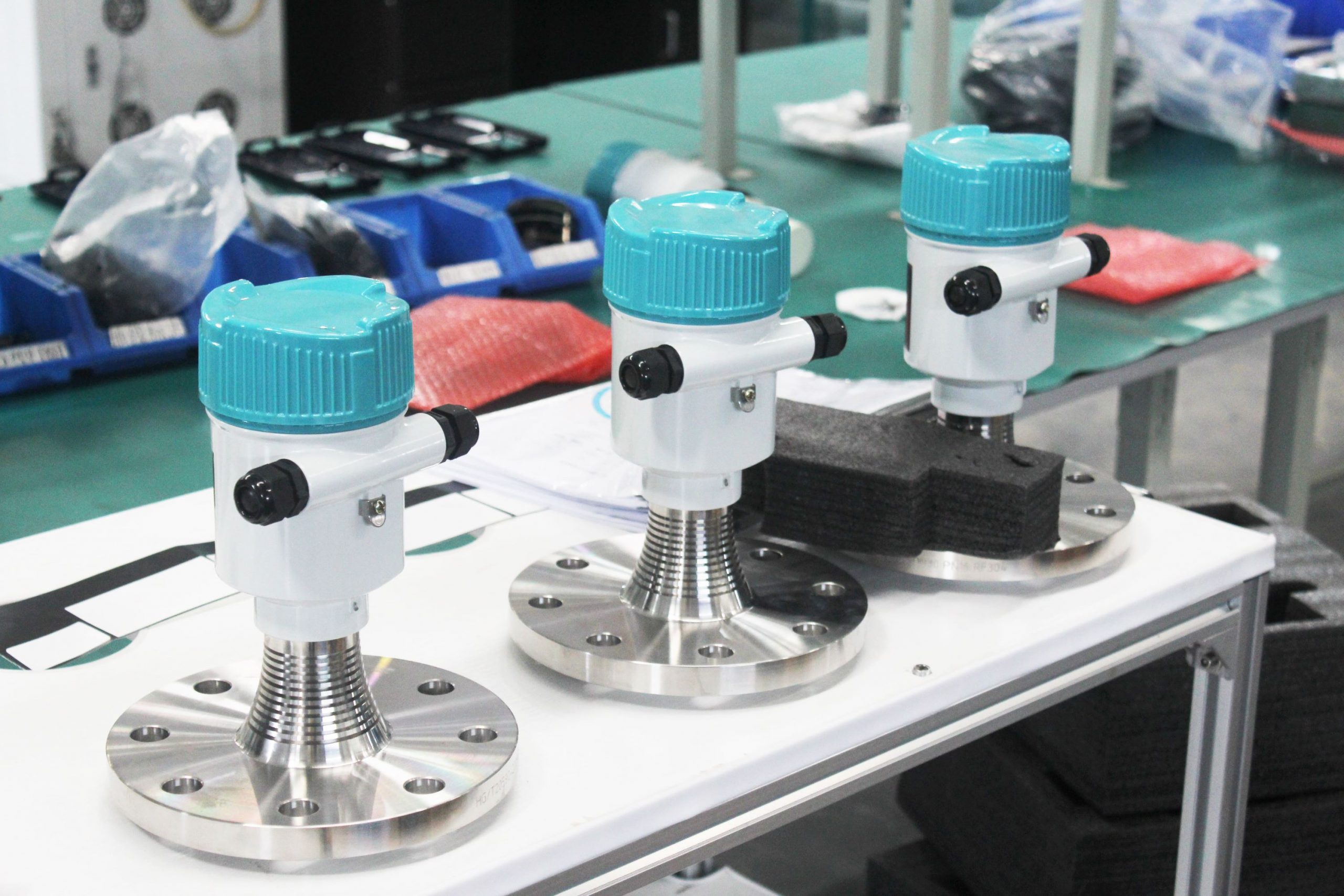

b. Radar has horn type, rod type, cable type, compared with ultrasonic can be applied to more complex conditions.

c. Ultrasonic accuracy is not as good as radar.

d. Radar is relatively expensive.

e. Consider the dielectric constant of the medium when using radar.

f ultrasonic can not be applied to vacuum, high steam content or liquid surface foam conditions.