The advantages of electromagnetic flow meter used in sewage metering

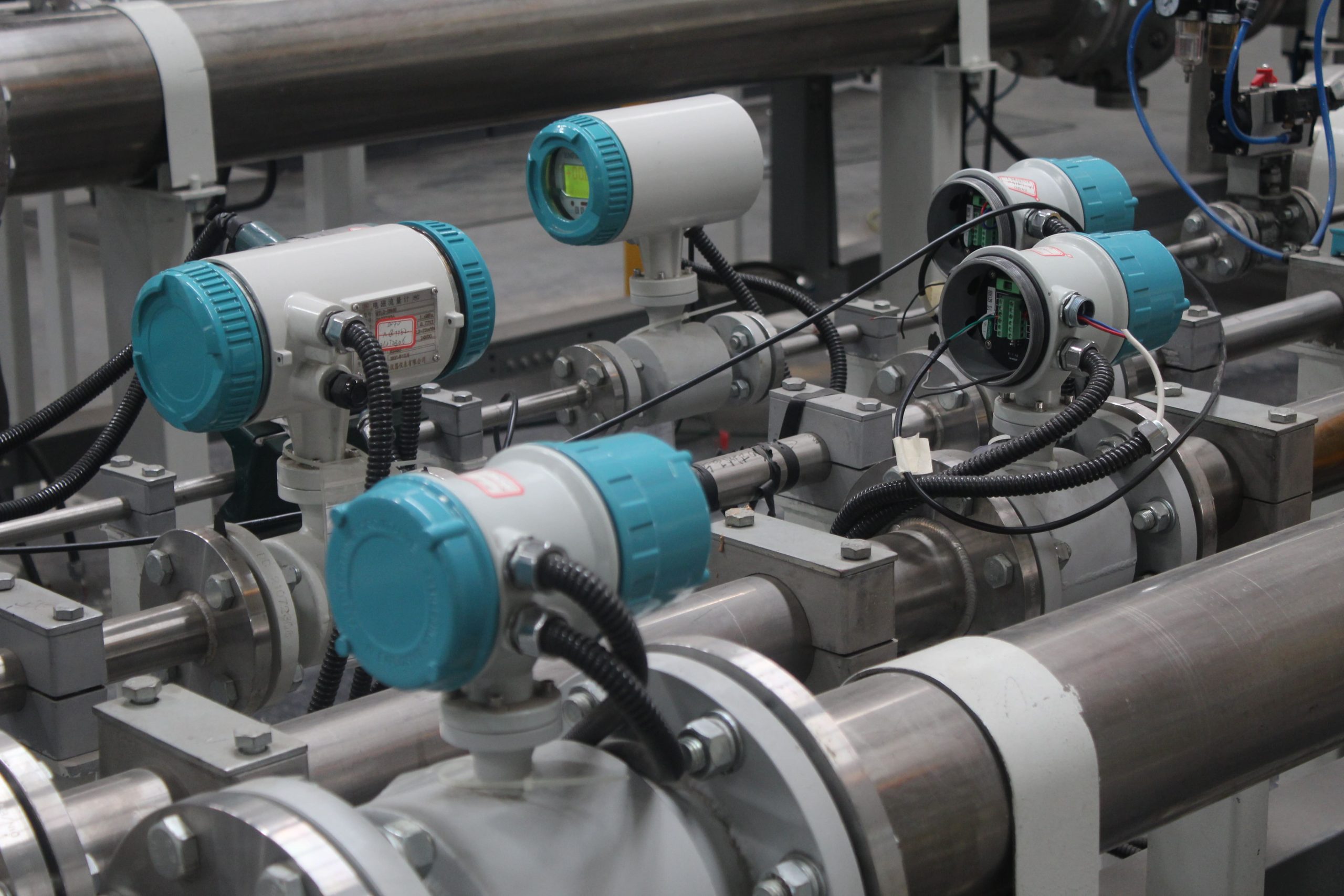

Sewage flowmeter can be widely used in municipal water supply, steel, petroleum, chemical, electric power, industry, water conservancy, water resources and other departments of liquid volume flow measurement, especially suitable for channels, small river flow measurement and environmental protection disposal of sewage measurement.

Electromagnetic flowmeter suggests that sewage flowmeters mainly have the following six advantages:

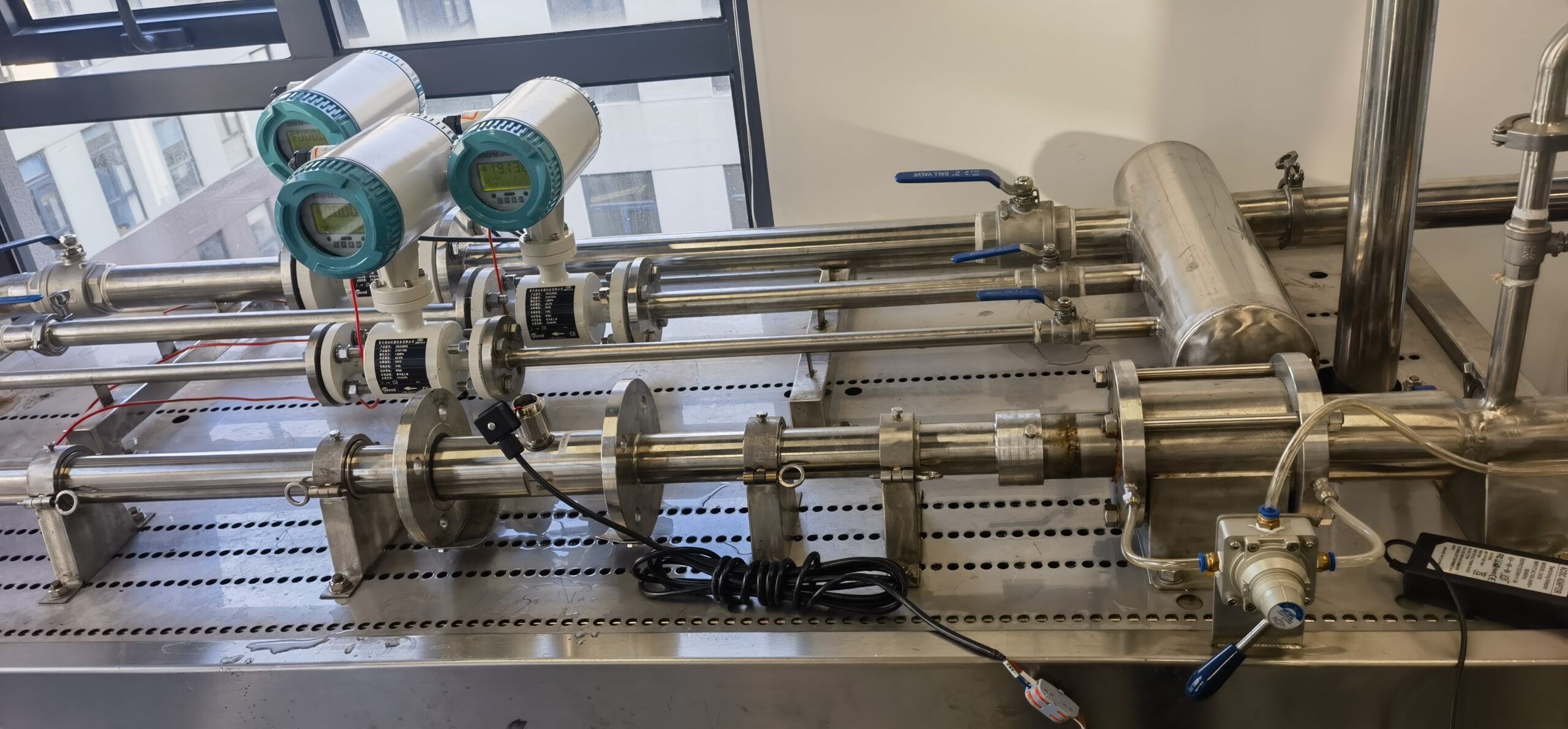

1. Convenient installation and maintenance

2. The sewage flowmeter has no mechanical inertia, flexible response, can measure the instantaneous pulsating flow rate, and can also measure the flow in both positive and negative directions.

3. The flow rate of dirty media, corrosive media and suspended liquid-solid two-phase flow can be measured. This is due to the barrier-free moving parts inside the measuring tube, and the measured body is only in contact with the measuring tube lining and electrodes, and the data can be selected according to the nature of the measured body. For example, with polytrifluoroethylene or polytetrafluoroethylene as the lining, can measure a variety of acid, alkali, salt and other corrosive media; The use of wear-resistant rubber as the lining is particularly suitable for measuring the liquid-solid two-phase flow such as slurry and cement slurry with solid particles and large wear, as well as a variety of suspensions such as fiber liquids and paper pulp.

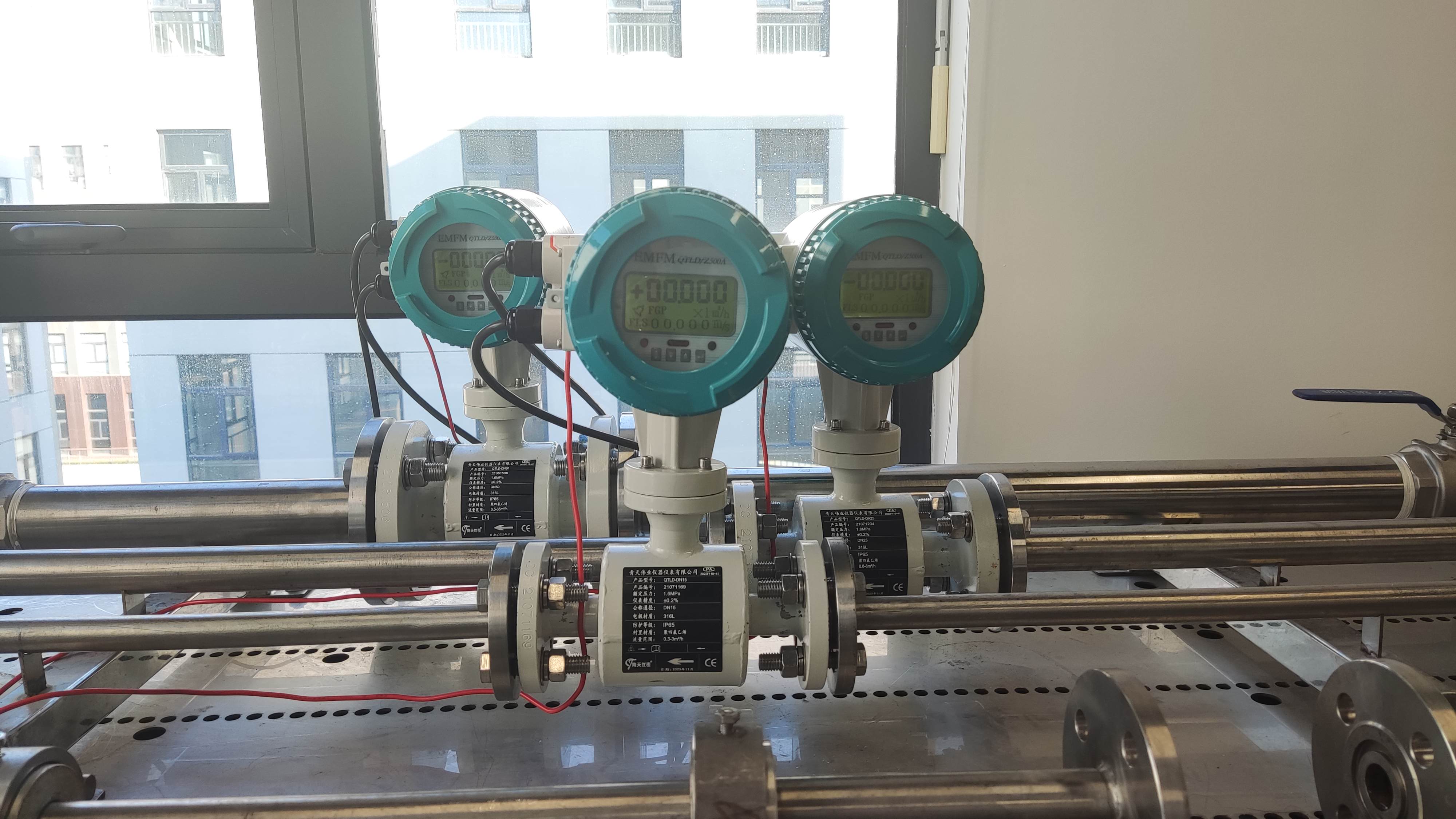

4. Sewage flowmeter, tap water flowmeter, is a volume flow measurement instrument, in the measurement process, it is not affected by the temperature of the measured medium, viscosity, density and conductivity (in a certain range). Therefore, the electromagnetic flowmeter can be used to measure the flow of other conductive liquids only after water calibration.

5. The output of the sewage flowmeter is only proportional to the uniform flow rate of the measured medium, and has nothing to do with the activity state (laminar flow or turbulence) under symmetrical dispersion. Therefore, the measuring range of the electromagnetic flowmeter is extremely wide, and its measuring range can reach 100:1, and some can reach 1000:1.

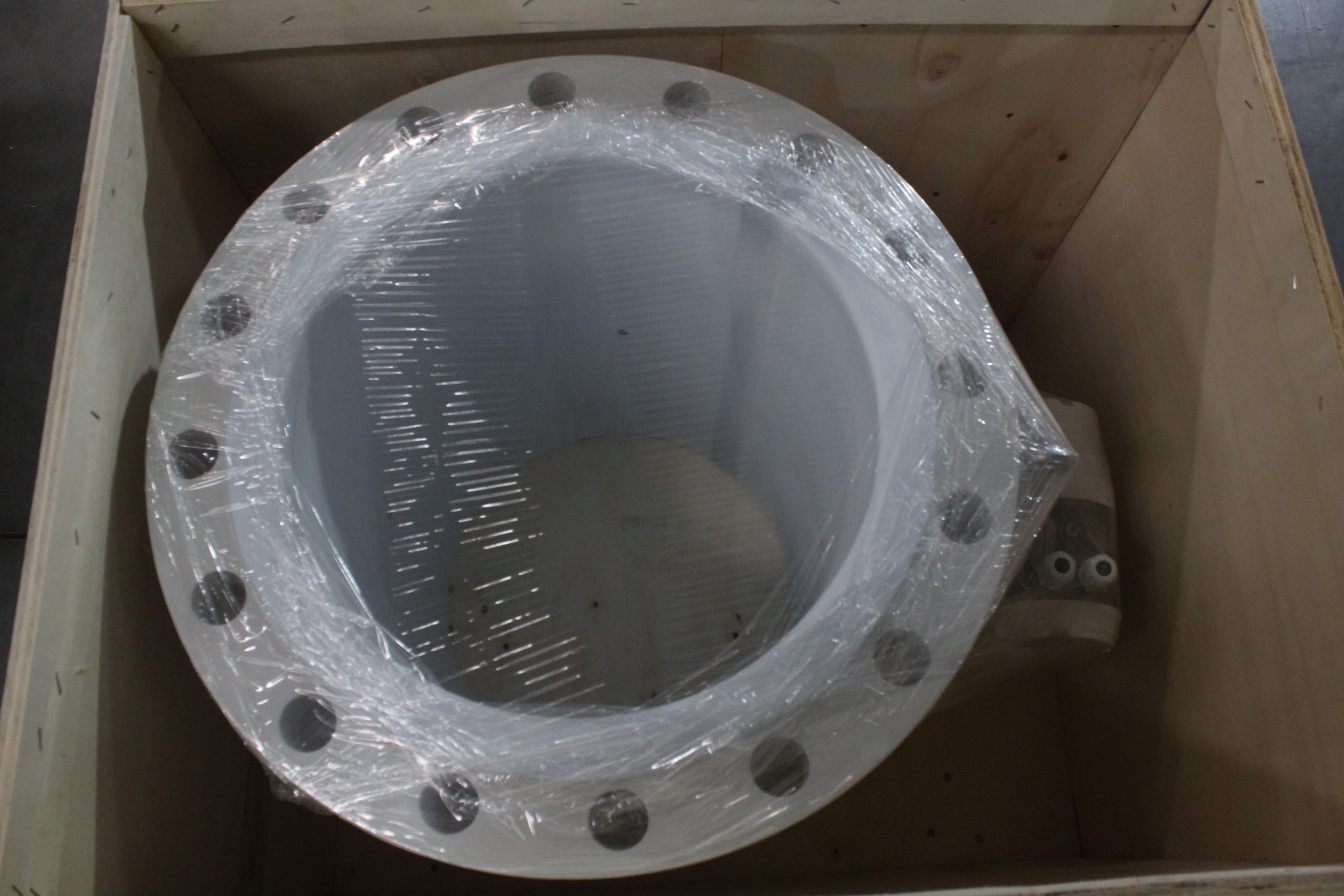

6. The diameter range of industrial sewage flowmeters is extremely wide, from a few millimeters to a few meters, and the actual flow calibration equipment with a caliber of 3m in China has laid the foundation for the application and development of electromagnetic flowmeters.

-.jpg)