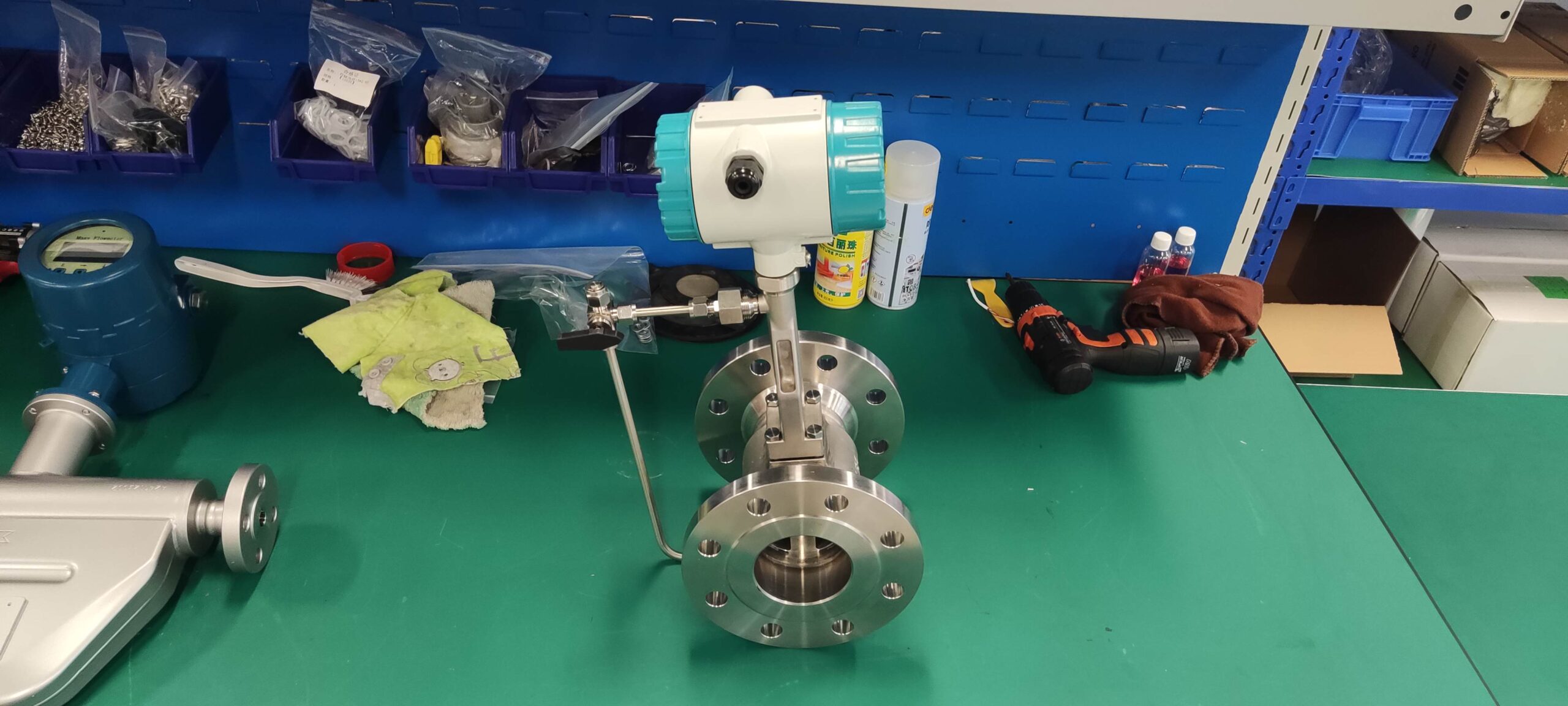

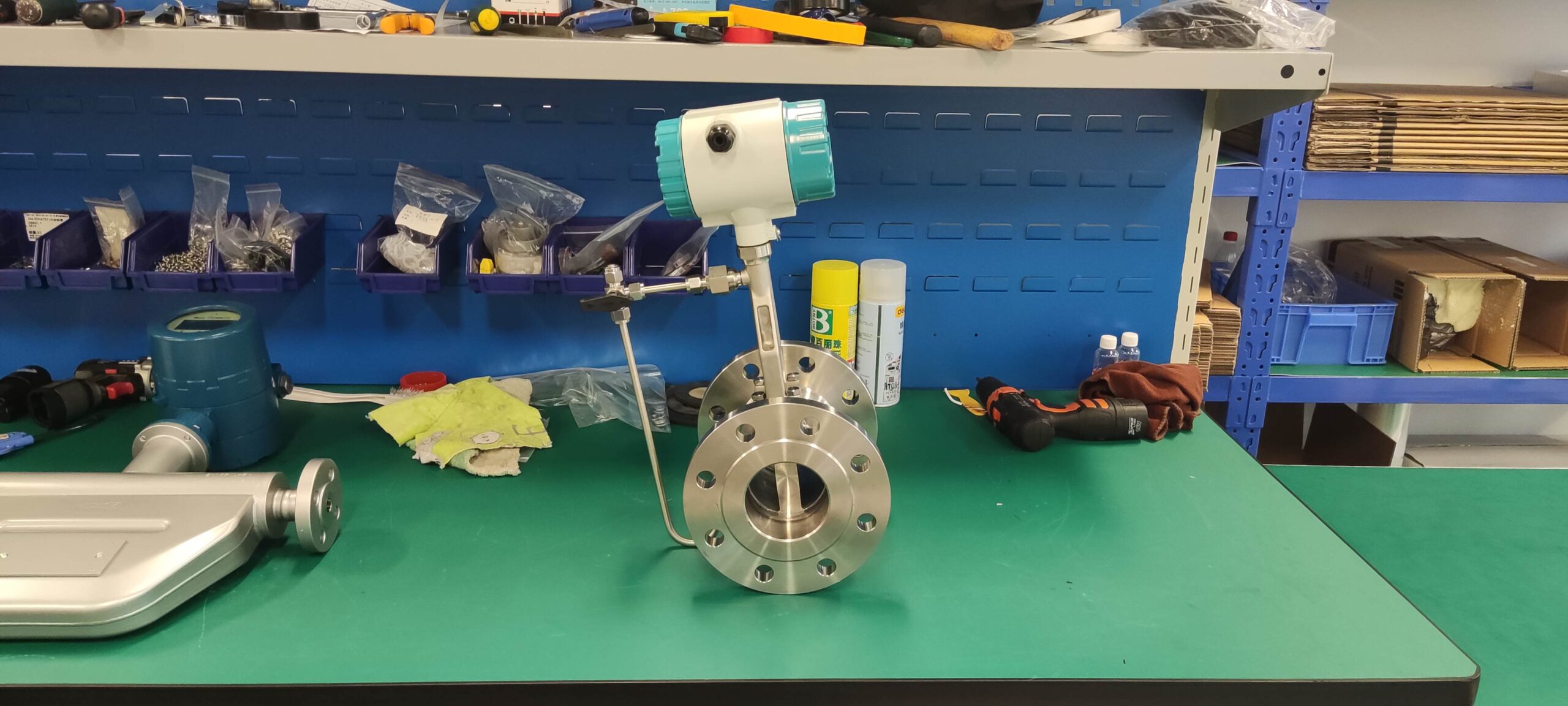

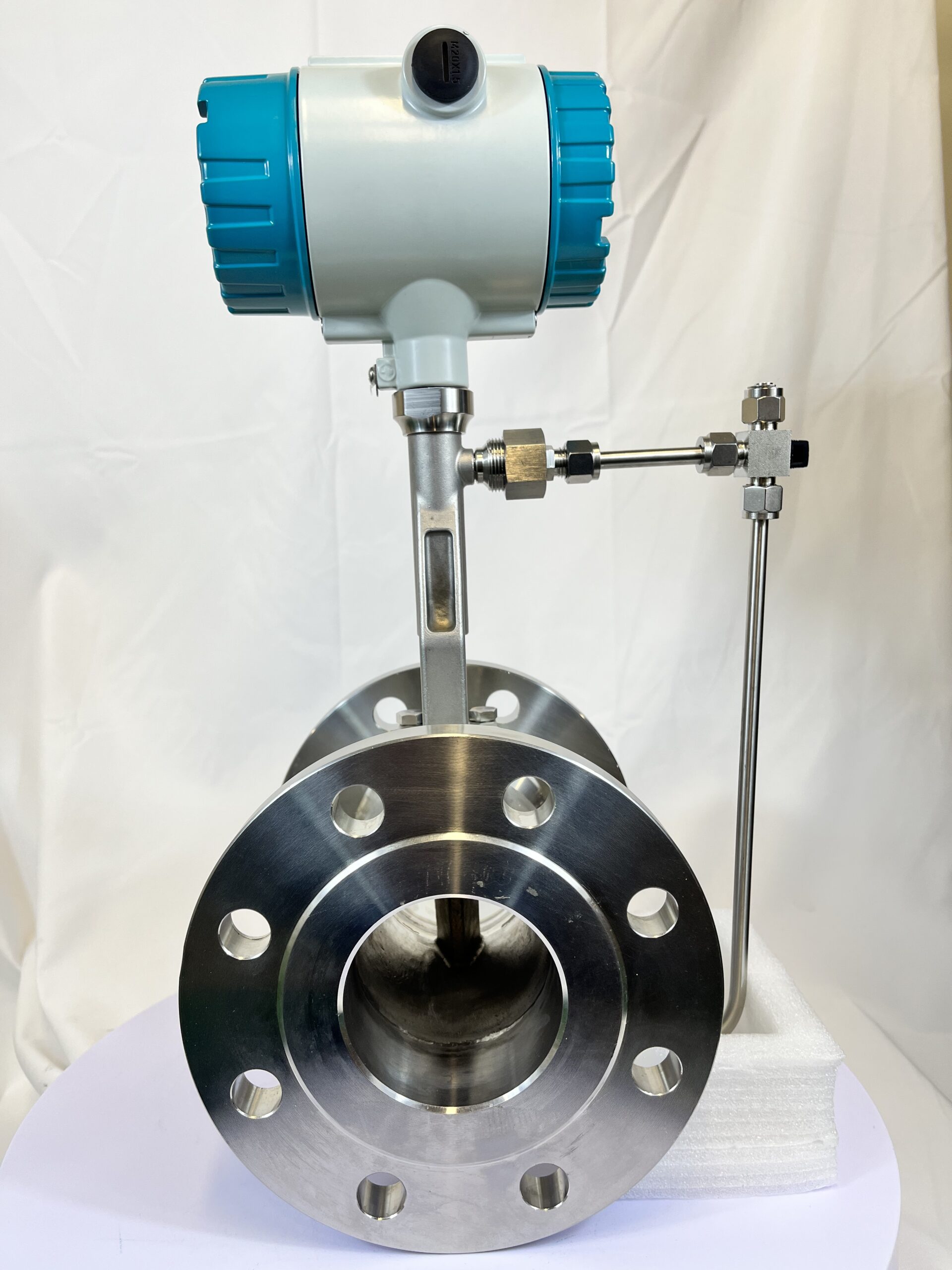

The advantages and technical indicators of integrated vortex flow meter

Temperature and pressure compensation integrated vortex flowmeter performance advantages:

1. The advantage is that the vibration resistance is particularly good, no zero drift, high reliability.

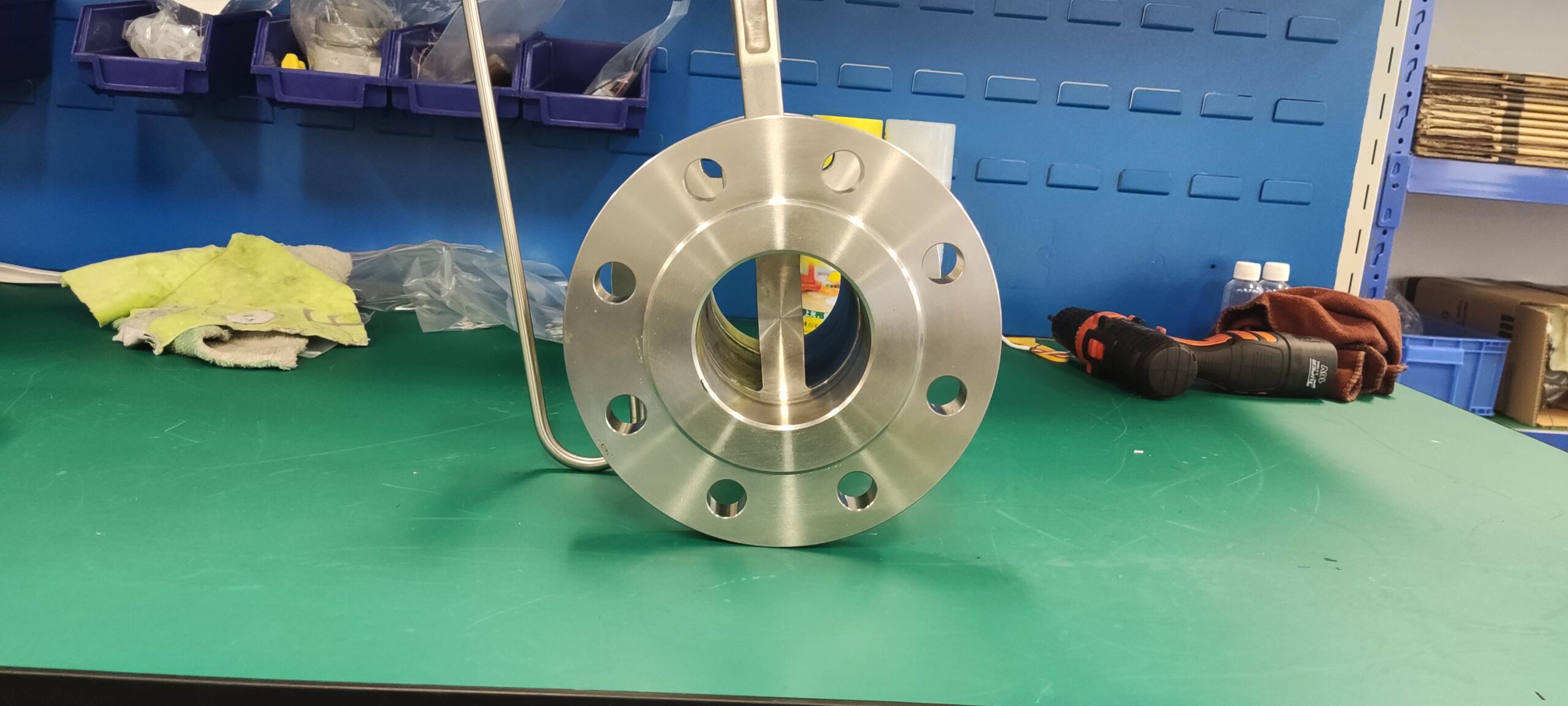

2. The universality of the temperature and pressure compensation integrated vortex flowmeter sensor is very strong, so that the sensor has good interchangeability. Advanced CNC equipment is used to process the surface body and vortex generator of the sensor, etc., to ensure the processing accuracy, so that the universality of the parts (especially the vortex generator) is strong, so that the repeatability and accuracy of the sensor will not be affected by the replacement of the parts; It can produce a strong and stable vortex signal.

3. Within a certain range of Reynolds number, the flow characteristics are not affected by fluid pressure, temperature, viscosity, density, and composition, but are only related to the shape and size of the vortex-generating body.

4. Output pulse signal or analog signal proportional to the flow, no zero drift, high precision, convenient and computer networking.

5. Simple and firm structure, no moving parts, high reliability, easy to use and maintain.

6. The detection element is not in contact with the medium, stable performance, long service life, the sensor uses the detection probe and the vortex generator body installed separately, and the high-temperature piezoelectric crystal is sealed in the detection probe, not in contact with the measured medium, so the vortex flowmeter has the characteristics of simple structure, good versatility and high stability.

7. Wide measuring range, range ratio up to 1:10.

8. There is no need to compensate when measuring the volume flow, and the output signal of the vortex is actually linear with the flow rate, that is, proportional to the volume flow. The purpose of pressure and temperature compensation is to obtain the density of the fluid, multiplied by the volume flow rate to obtain the mass flow rate, if the volume flow of the gas is measured, there is no need to compensate.

Temperature and pressure compensation integrated vortex flowmeter technical indicators:

1. Measuring medium: liquid, gas, steam;

2. Measuring range: 8-10000m3/h;

3. Nominal diameter: DN15-DN300mm non-standard products can be customized according to user requirements;

4. Temperature range: piezoelectric -40℃ ~ 350℃ capacitive -60℃ ~ 450℃;

5. Pressure specification: PN1.6Mpa; PN2.5 Mpa; PN4.0Mpa, higher pressure specifications can be specially customized;

6. Range: normal range 1:10 after the extension range 1:15;

7. System measurement accuracy: ±1% of liquid and gas indication value;

±1.5% of steam indication value;

±2.5% of the plug-in indication value;

8. Supply voltage: sensor +12VDC, +24VDC (optional) transmitter +24VDC;

Field display meter comes with 3.6V lithium battery;

9. Output signal: sensor pulse frequency signal 0.1 ~ 3000Hz low level ≤1V high level ≥6V;

Transmitter two-wire system 4 ~ 20mA.DC current signal;

10. Vibration acceleration: piezoelectric type ≤0.2g capacitive type ≤1.0g;

11. Ambient temperature: Sensor: -30℃ ~ 65℃ transmitter, field display: -10℃ ~ 50℃;

12. Ambient humidity: relative humidity 5 ~ 85%;

13. Atmospheric pressure: 86 ~ 106Kpa;

14. Signal transmission distance: ≤500m;

15. Signal line interface: internal thread M20×1.5;

16. Explosion-proof rating: (ia)Ⅱ CT2-T5;

17. Protection level: ordinary IP65 submersible IP68;

18. Instrument material: The instrument shell is made of aluminum alloy, the body part is made of 304 stainless steel, and special materials can also be used according to user requirements.