Technical requirements and precautions for measuring natural gas with precession vortex flow meter

Technical requirements and precautions for measuring natural gas with precession vortex flow meter

1. The requirements of the precession vortex flowmeter for the measured air flow conditions

a. The measured gas should be a single-phase, continuous round pipe flow through the pipeline.

b. Before the gas flows through the flowmeter, its flow rate must be parallel to the pipe axis, and there must be no vortex flow.

c. The airflow should be subsonic, non-pulsating, and its flow rate changes slowly over time.

2. Installation requirements for the precession vortex flowmeter

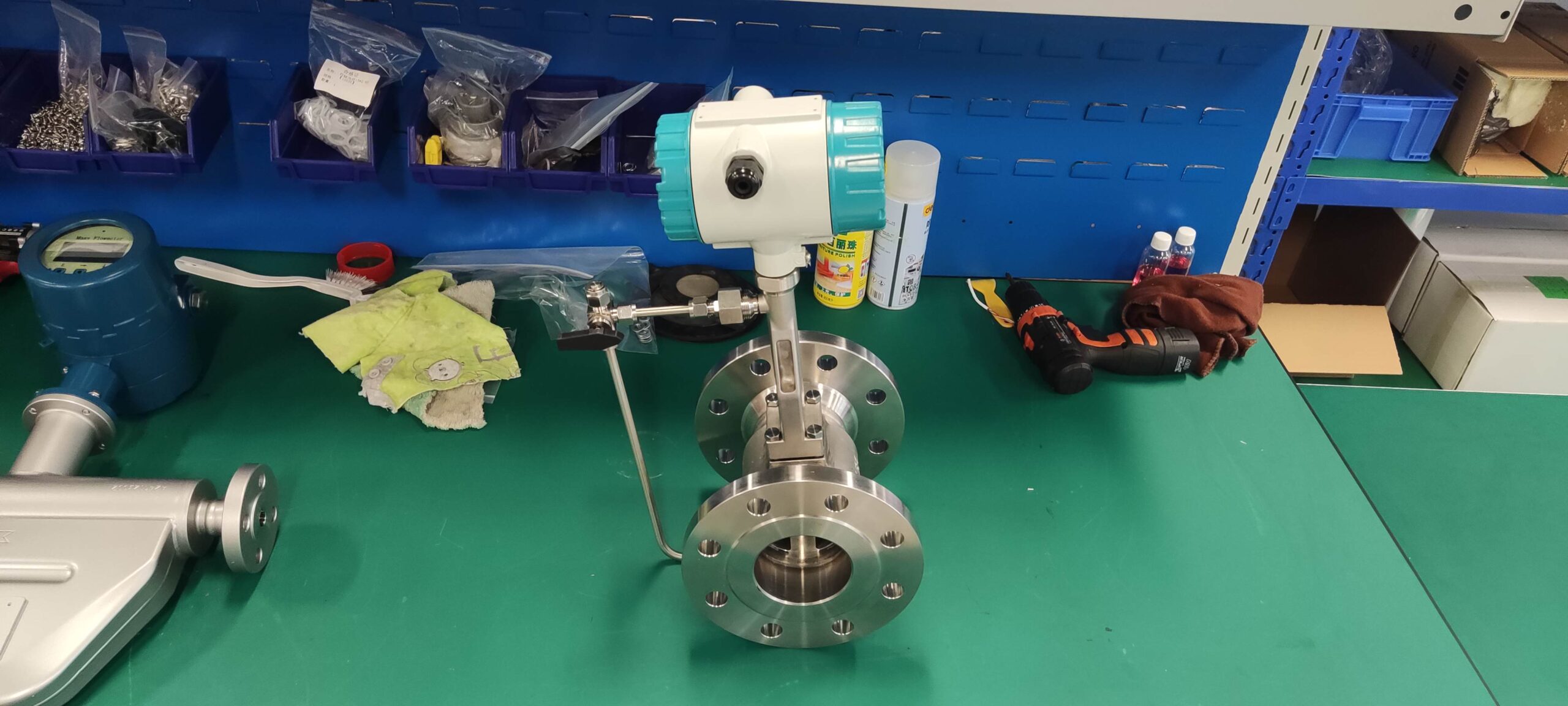

Precession vortex flowmeter does not have too many special requirements for process installation and use environment, but any kind of flow measuring instrument has such a common, That is, as far as possible to avoid vibration and high temperature environment with the flow state interference elements (such as compressors, separators, pressure regulator, small head and manifold, elbow, etc.), keep the instrument front and rear straight pipe wall smooth and straight, to ensure that the measured medium is clean single-phase fluid.

3. Matters that should be noted in the installation and use of the precession vortex flowmeter

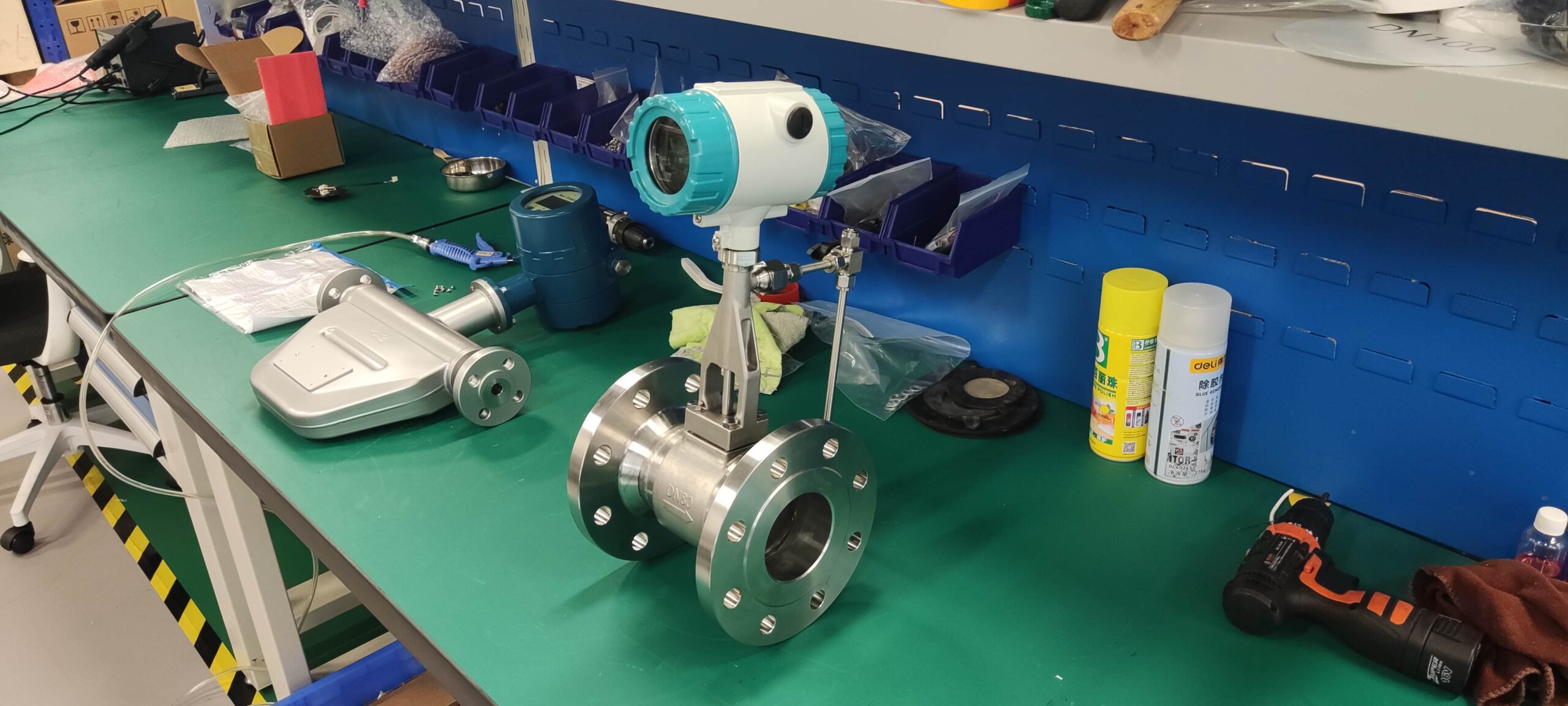

Precession vortex flowmeter without mechanical moving parts, small size, corrosion resistance, stable performance; It can directly display the working pressure, temperature, flow rate and gas volume under standard state of the medium; With the advantages of wide measuring range and small measuring error, it has been widely used in production measurement of oil and gas Wells and sales measurement of natural gas. In the field application for many years, we believe that the flow meter is more suitable for relatively clean dry gas measurement, and gradually become a metering instrument for small and medium-sized gas measurement.

To ensure accurate metering and reduce metering errors of the precession vortex flowmeter, please note:

a. Reasonable selection does not make the actual smaller flow QVmin lower than the lower limit of the flow range of the selected runoff meter.

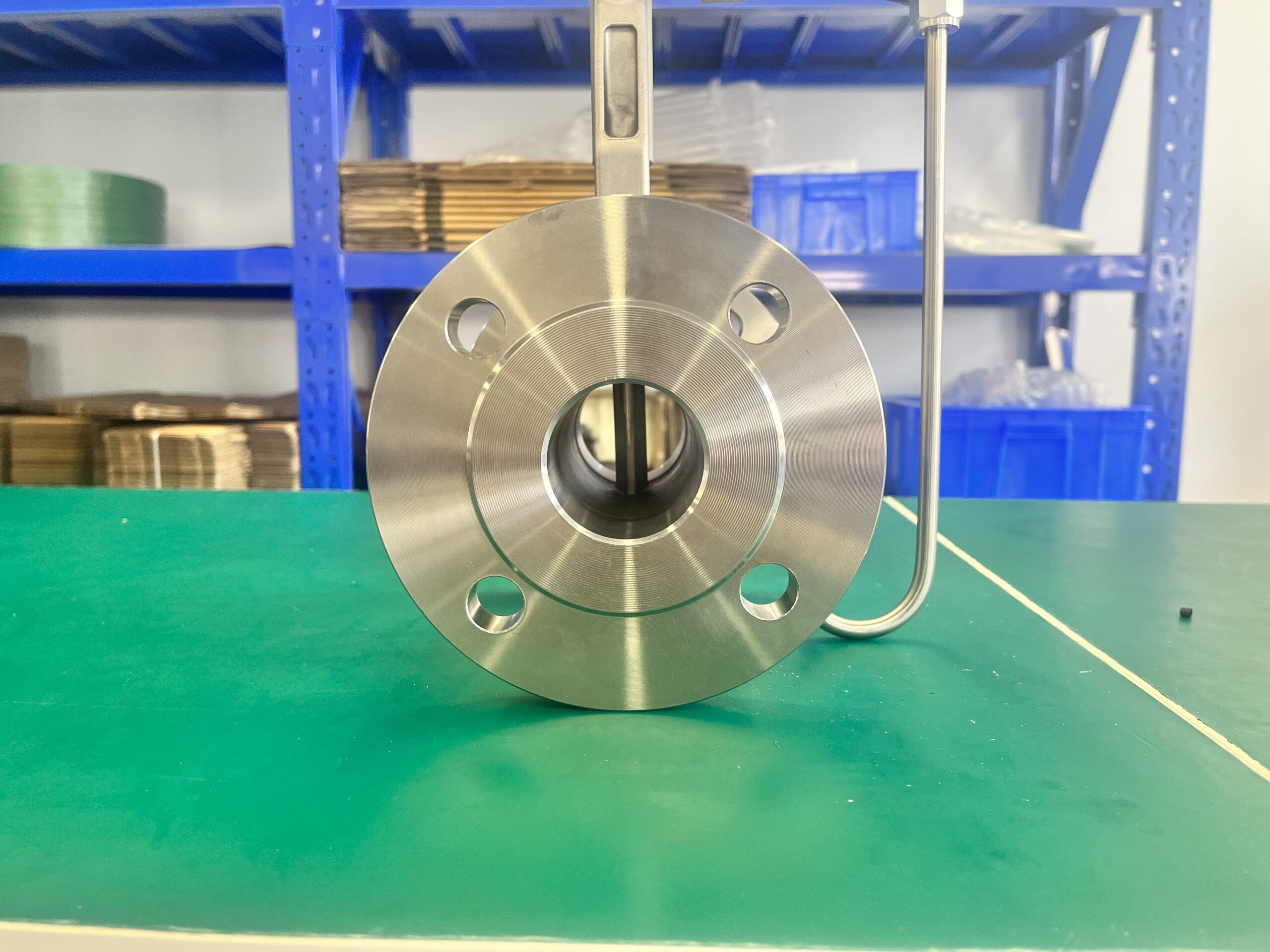

b. Install a metering straight pipe section of at least 10D length upstream of the correct flow meter. The inner wall of the straight pipe section should be smooth, and there should be no steps, and the weld of the connecting flange should be smoothed, and the flange gasket should not burst into the pipeline. The installation direction of the flowmeter can not be reversed. The test proves that all unreasonable installation will lead to low metering value of the flowmeter.

c. Stay away from the shock source, or install support piers on the flow meter and downstream to avoid the effect of pipeline vibration. Avoid the interference of strong magnetic field on the flowmeter chip.

d. The temperament is relatively clean, especially can not appear liquid gas two-phase flow; When the temperament is dirty, the flowmeter should be cleaned immediately.

e. Reduce the impact of air pulsation by installing a buffer tank in front of the flow meter, or extending the length of the metering straight pipe section upstream of the flow meter.

f. Timely metrological verification of the precession vortex flowmeter to ensure accurate and reliable value.