Tap water flow meter selection guide: Choose the most suitable solution for you

The choice of water flow meter is a comprehensive consideration process, involving many aspects of factors. Here is a guide to tap water flow meter selection to help you choose the most suitable solution:

1. Understand flowmeter types

There are many kinds of water flowmeters, common electromagnetic flowmeters, turbine flowmeters, vortex flowmeters, ultrasonic flowmeters and so on. Each flowmeter has its own unique characteristics and application scenarios.

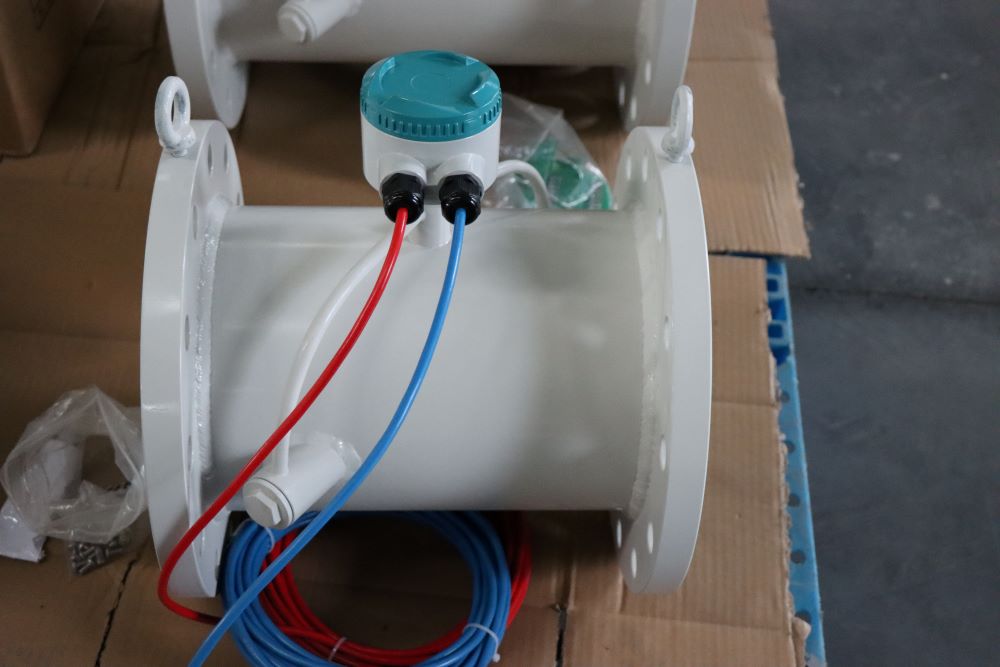

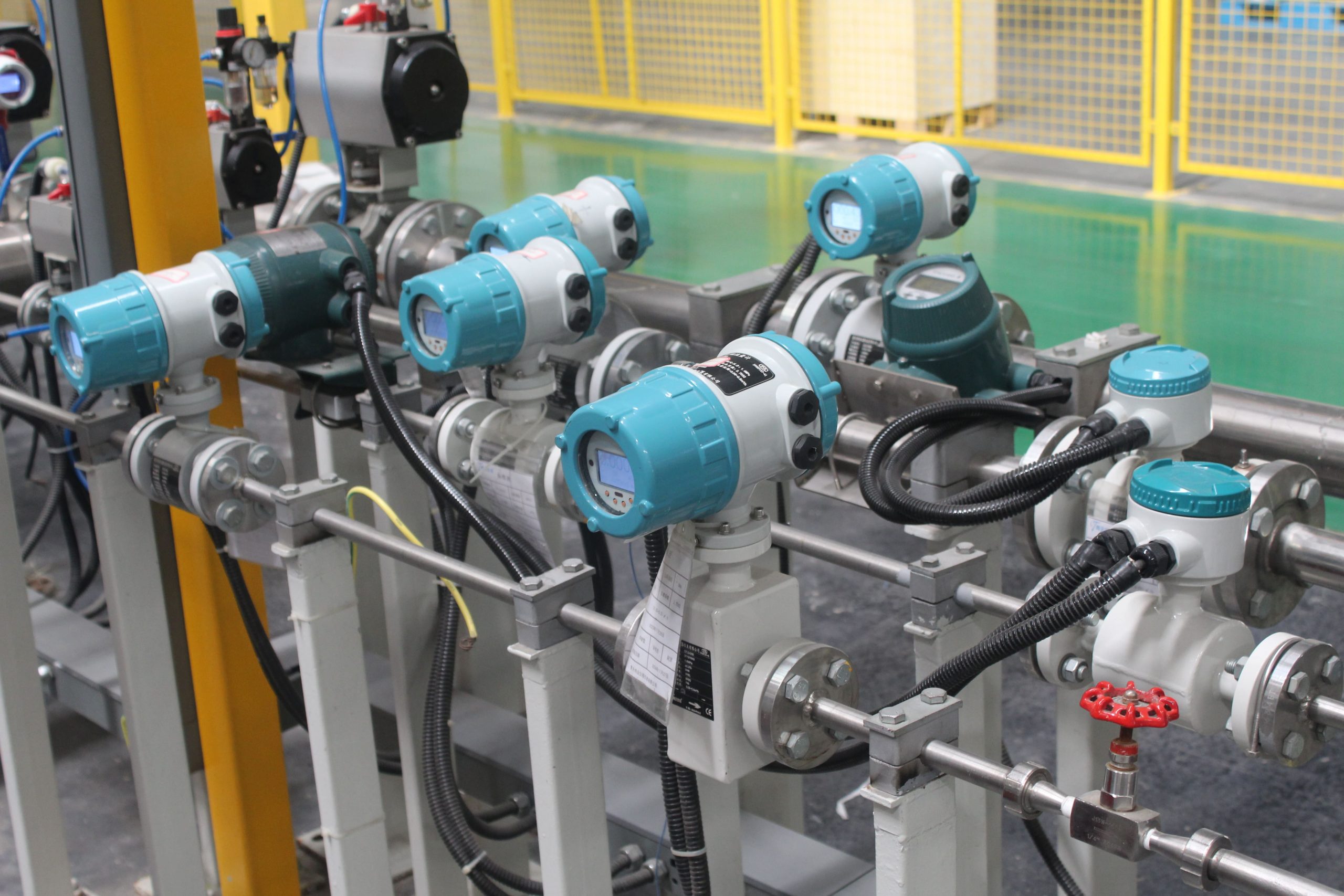

Electromagnetic flowmeter: suitable for measuring conductive liquid, such as tap water, with high precision, strong anti-interference ability, wide measuring range and other advantages.

Turbine flowmeter: Suitable for applications requiring high precision measurement, compact and lightweight, but weak against impurities and bubbles in the fluid.

Vortex flowmeter: large range, advanced circuit, small resistance loss, suitable for a variety of industrial pipeline fluid measurement medium.

Ultrasonic flowmeter: non-contact measurement, easy to install, suitable for not easy to break pipe or pipe material is not suitable for welding flange occasions.

2. Consider your actual needs

Measurement accuracy: Select the appropriate accuracy level according to the measurement requirements. Generally speaking, the higher the measurement accuracy, the higher the price of the flowmeter.

Stability: Tap water may contain impurities and bubbles, so the flow meter needs to have good anti-interference ability and stability to ensure accurate measurement.

Response time: The shorter the response time, the more timely the flow meter can reflect the flow fluctuations, which is particularly important for situations requiring rapid response.

Maintenance convenience: Considering the ease of installation, maintenance and replacement of the flow meter, choose a model that is easy to operate and maintain.

3. Analyze site conditions

Pipe material and connection method: Different flow meters have different requirements for pipe material and connection method. For example, electromagnetic flowmeters require pipes that can be welded with flanges, while plastic or cement pipes are not suitable.

Field power supply: Select the right flowmeter according to the field power supply. External clamped ultrasonic flowmeter can use AC220V or battery power supply, suitable for field measurement.

Installation environment: Select a dry and ventilated installation site that avoids interference from ferromagnetic objects and strong electromagnetic fields.

4. Comprehensive comparison and selection

Technical parameters: Compare the technical parameters of different models of flowmeters, such as measuring range, accuracy level, working pressure, medium temperature, etc., to ensure that the actual needs are met.

Cost-effectiveness: Considering the price, performance and service life of the flow meter, choose cost-effective products.

Brand and after-sales: Choose well-known brands and reliable after-sales service to ensure product quality and follow-up technical support.

5. Case analysis

Taking a water plant as an example, if it is necessary to measure the flow of a large diameter water pipeline and the measurement accuracy is high, electromagnetic flowmeters can be selected. If the pipe material is not suitable for welding flanges, and you want easy installation, you can consider the external clamp ultrasonic flowmeter. The specific selection also needs to be considered according to the site conditions and actual needs.

-.jpg)