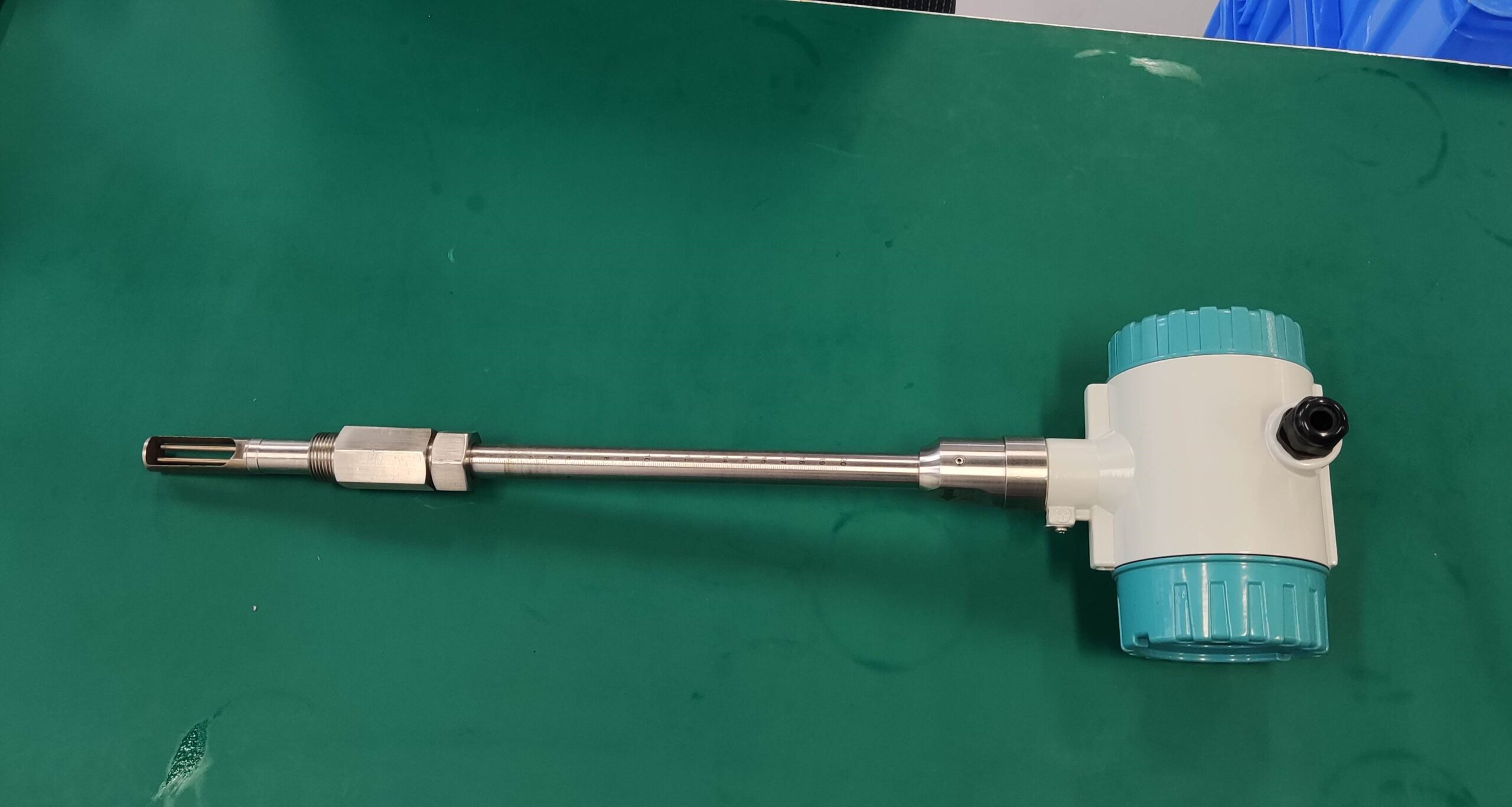

SS316 Sensor Gas Flow Meter Gas Industry Instrument Thermal Mass Gas Flow Meter

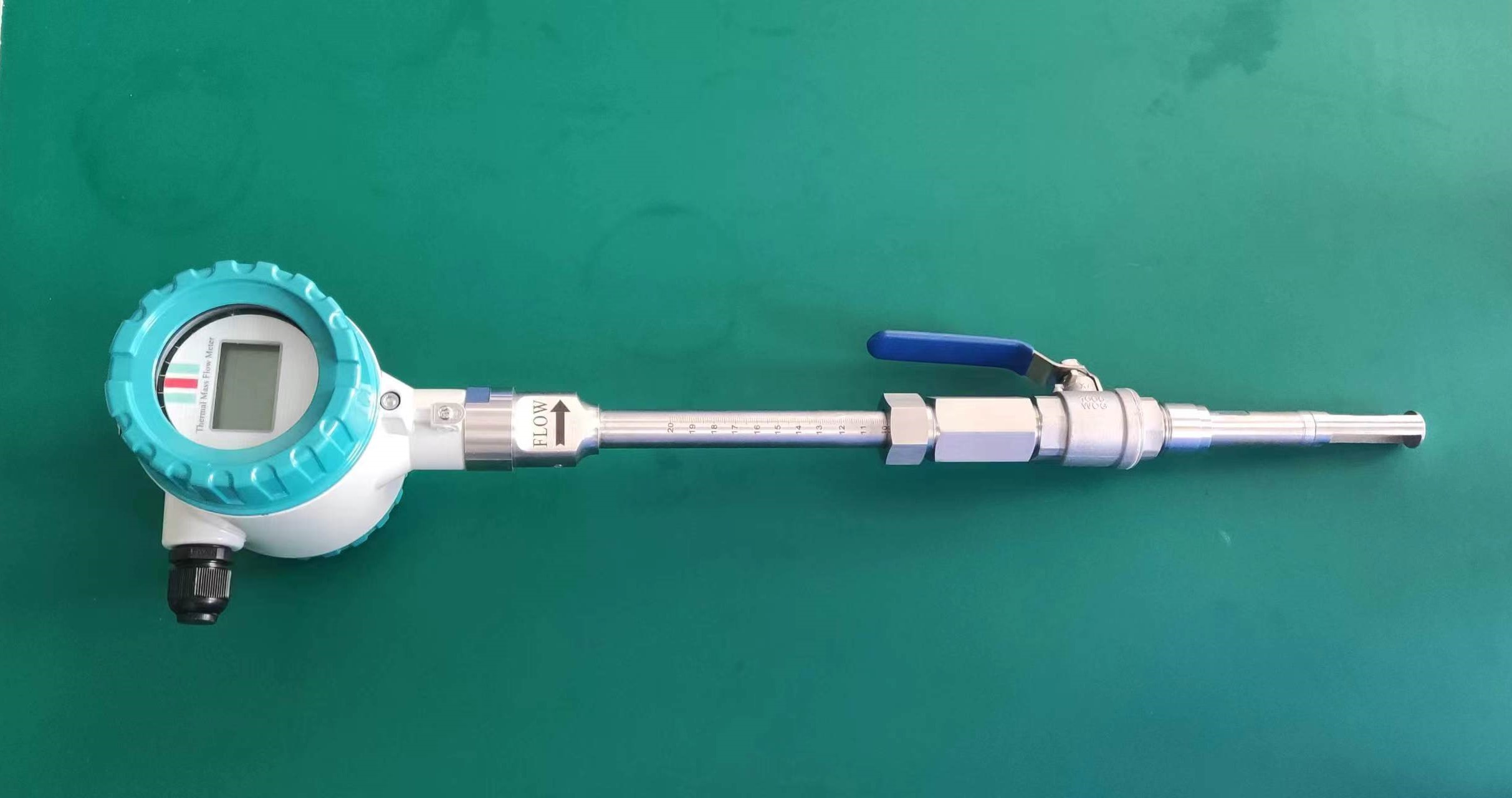

Choosing the correct installation direction for a thermal gas mass flowmeter is essential for optimal performance and accurate measurement. The installation direction should be determined based on factors such as the flow profile, flow conditions, and manufacturer recommendations. Here are some guidelines to help you choose the appropriate installation direction for a thermal gas mass flowmeter:

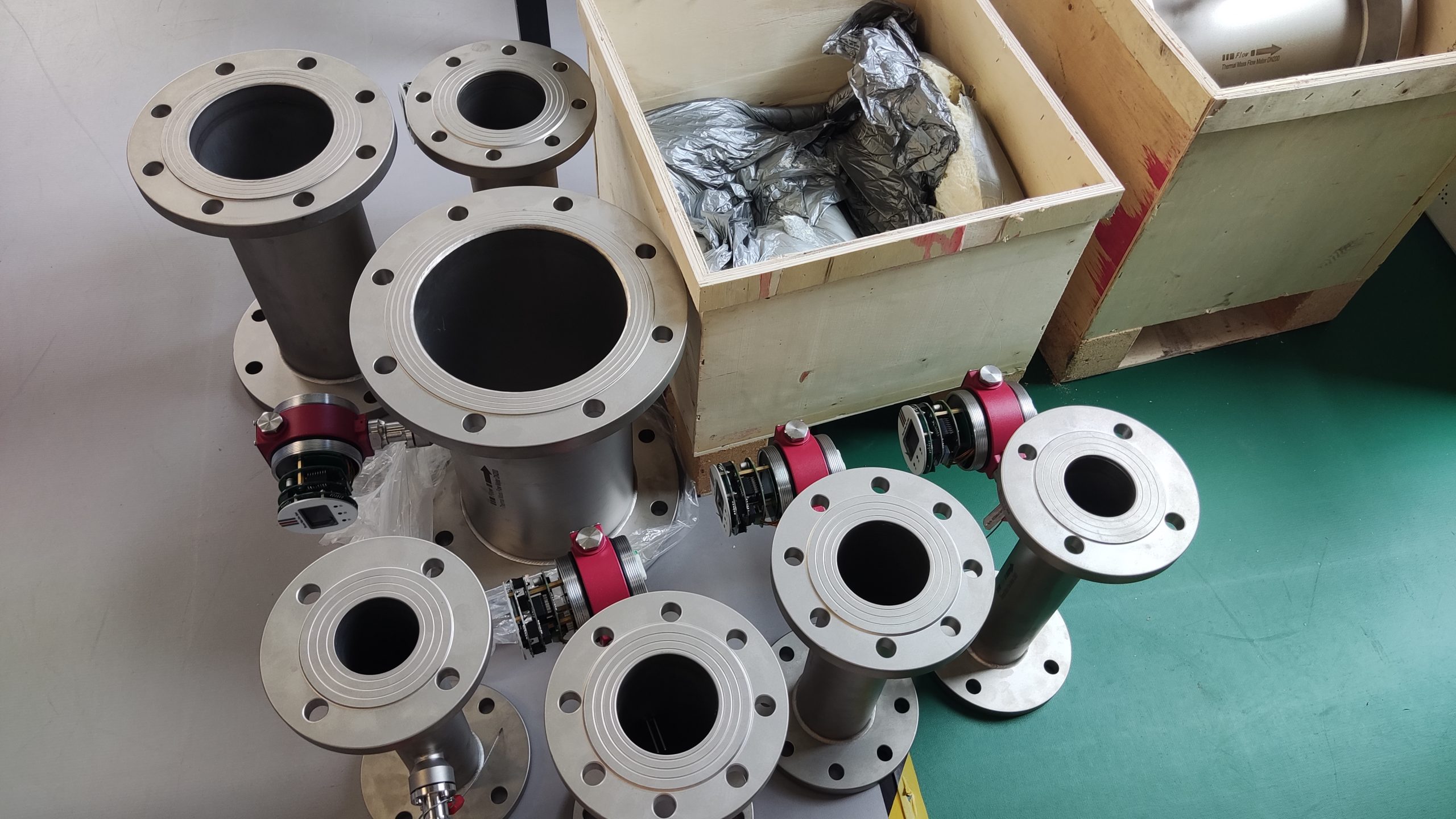

Flow Profile: Consider the flow profile within the pipe where the flowmeter will be installed. Ideally, the flow profile should be fully developed, meaning the velocity distribution across the pipe’s cross-section is uniform. In cases where the flow profile is not fully developed, such as near bends or elbows, it’s advisable to install the flowmeter downstream of these disturbances to ensure accurate measurement.

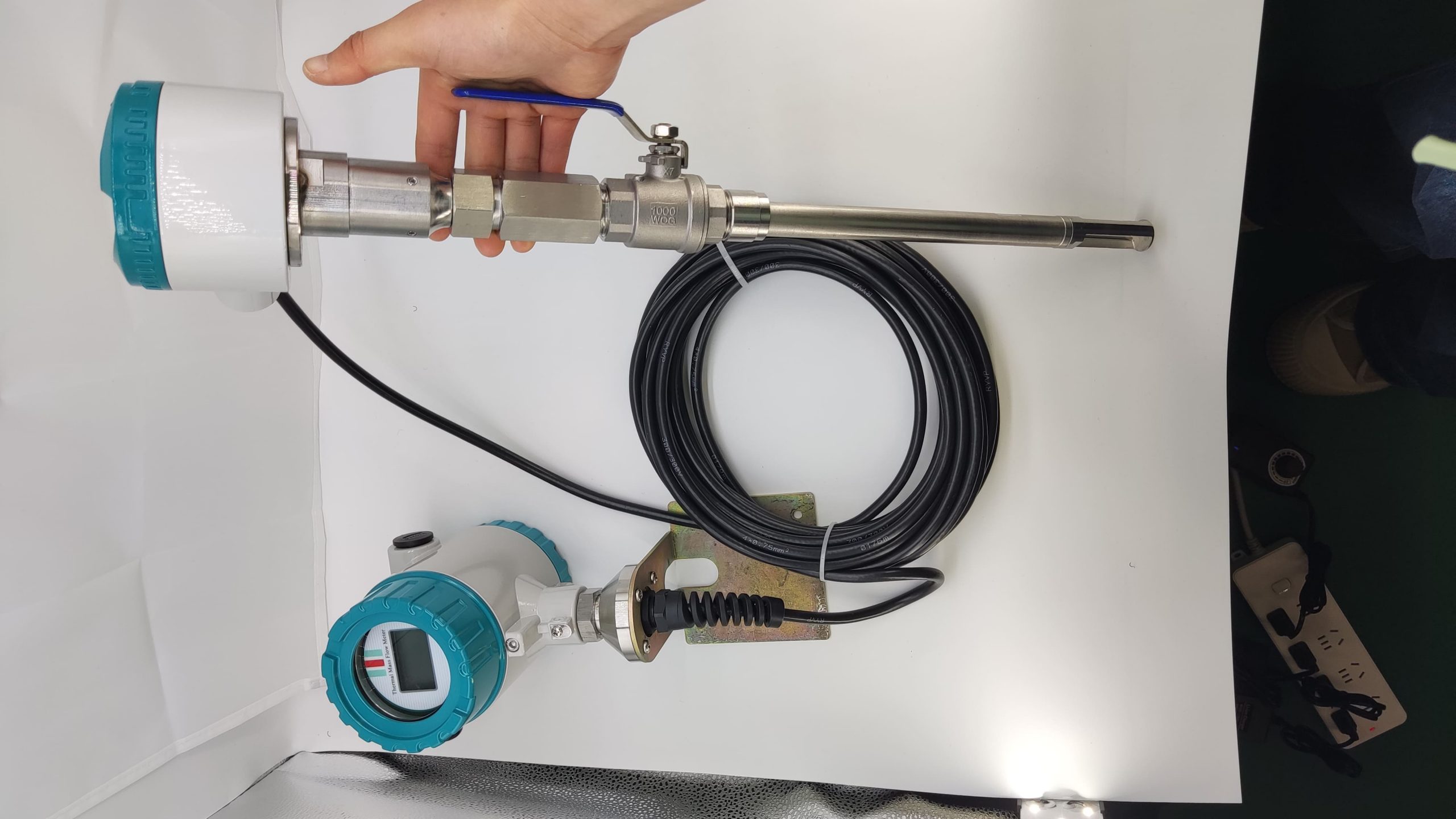

Straight Run Requirements: Ensure that there are sufficient straight pipe lengths both upstream and downstream of the flowmeter as per the manufacturer’s recommendations. Straight pipe sections help to establish a stable and uniform flow profile, minimizing flow disturbances that could affect the flowmeter’s accuracy. The length of straight pipe required may vary depending on factors such as pipe diameter, flow rate, and flow conditions.

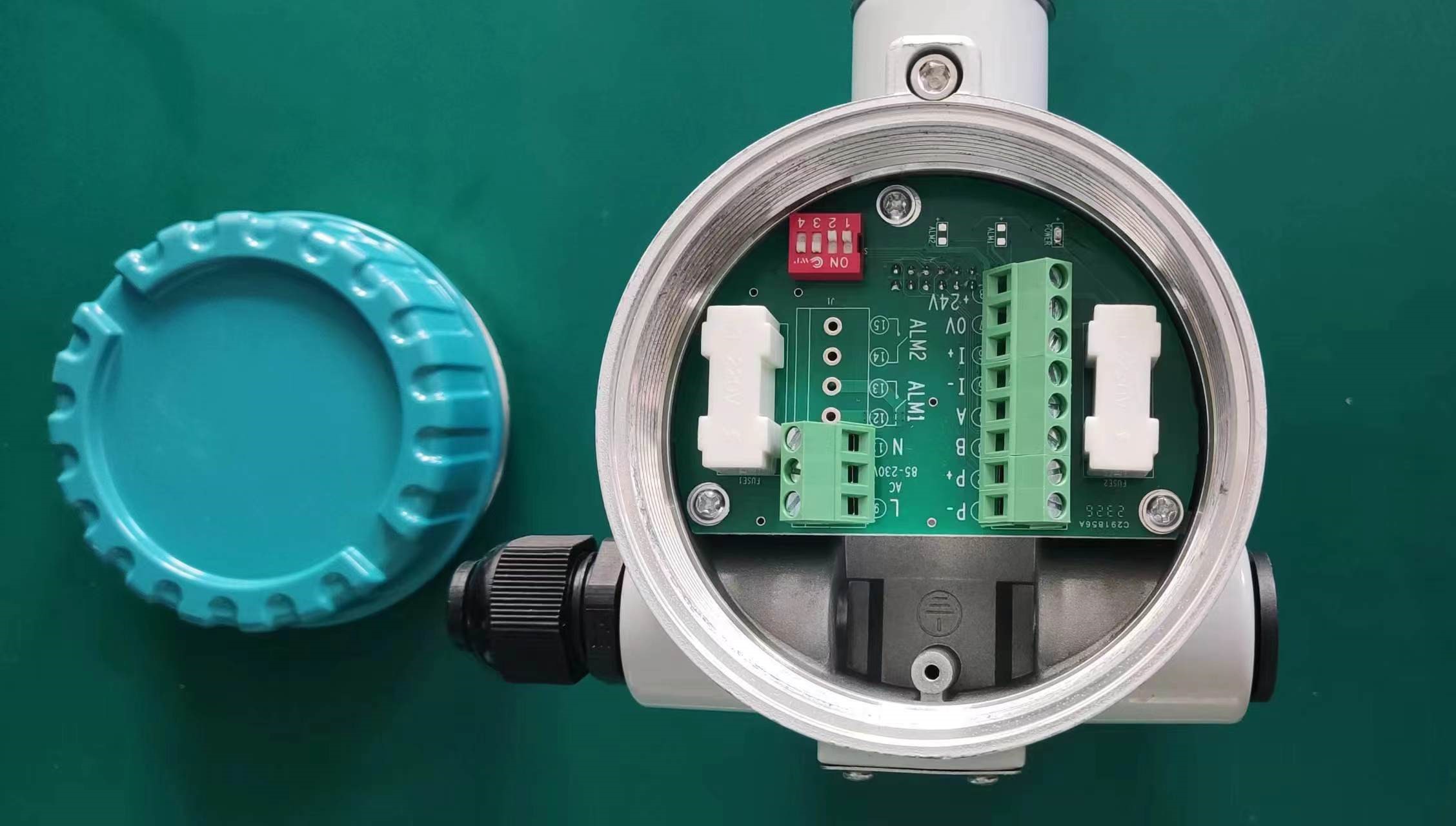

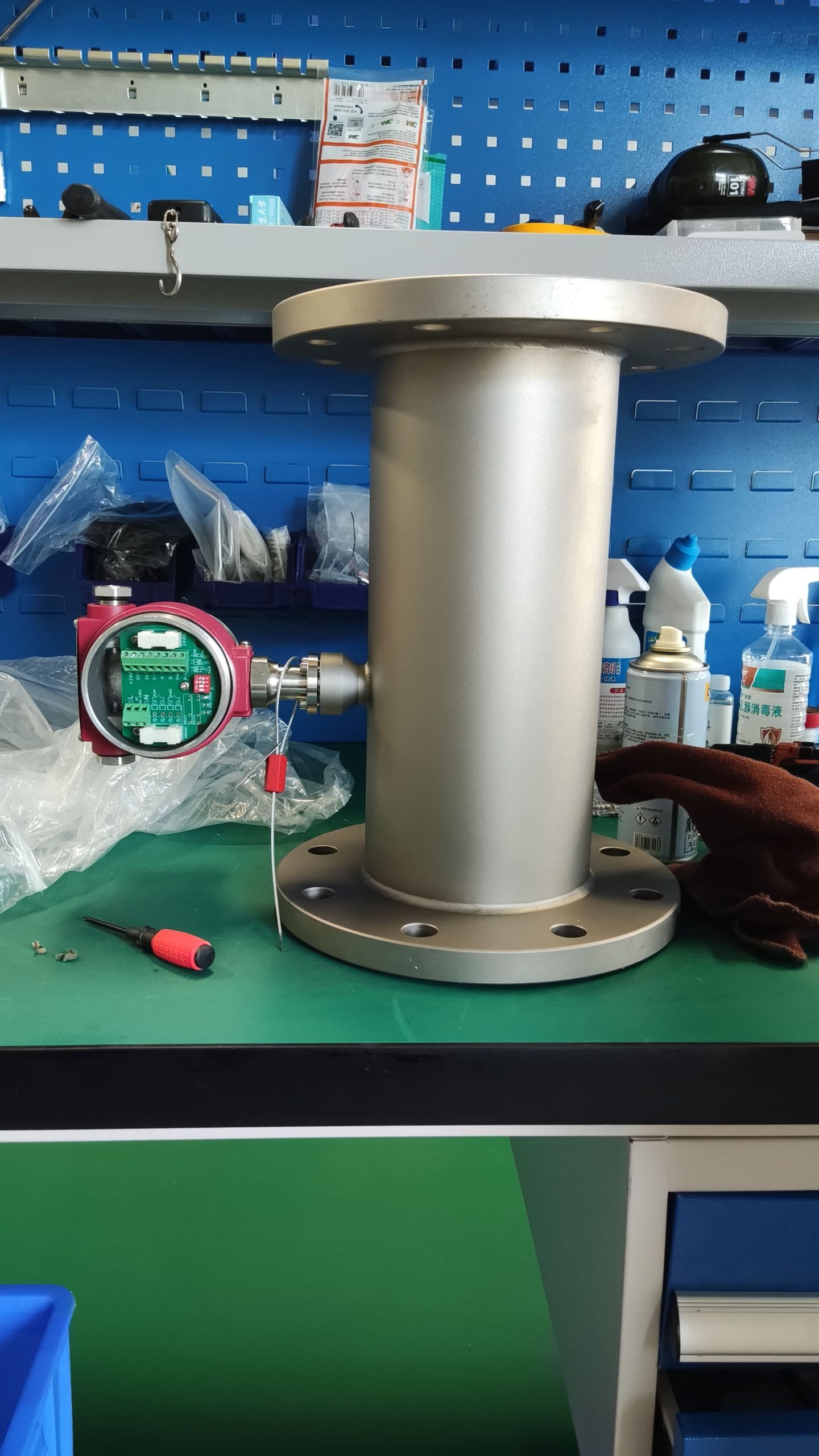

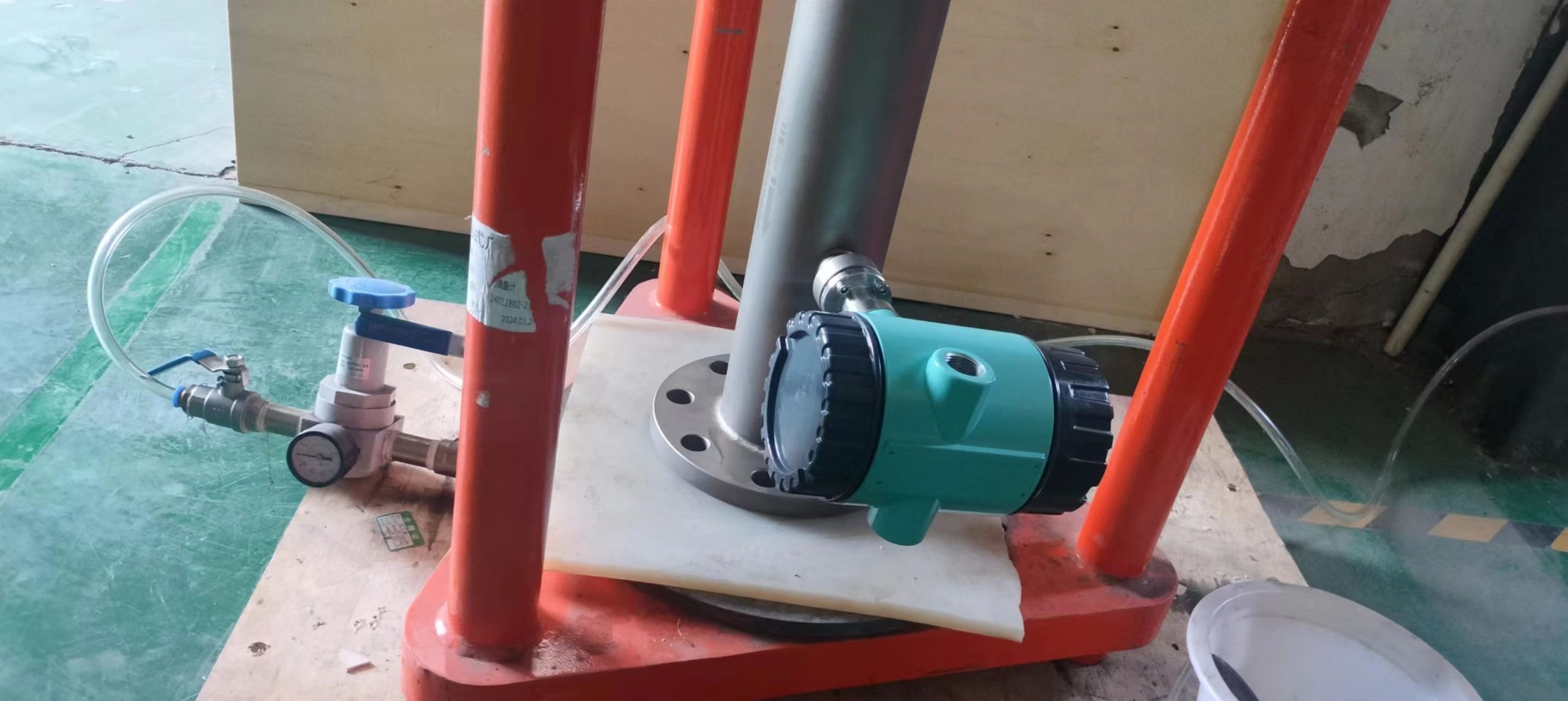

Orientation Guidelines: Follow the manufacturer’s guidelines and recommendations regarding the installation orientation of the flowmeter. Thermal gas mass flowmeters may have specific orientation requirements based on the design and configuration of the sensor elements. For example, some flowmeters may be designed for vertical installation, while others may be suitable for horizontal installation. Installing the flowmeter in the correct orientation ensures proper alignment of the sensor elements with the direction of flow.

Avoid Flow Disturbances: Install the flowmeter in a location where flow disturbances, such as turbulence, eddies, or swirl, are minimized. Avoid placing the flowmeter near obstructions, valves, elbows, or other flow disturbances that could disrupt the flow profile and affect measurement accuracy. Positioning the flowmeter away from disturbances helps to maintain a stable and uniform flow environment for accurate measurement.

Consider Accessibility and Maintenance: Choose an installation location that provides easy access for maintenance and inspection of the flowmeter. Ensure that there is sufficient space around the flowmeter for servicing and calibration activities. Accessibility is important for routine maintenance tasks such as sensor cleaning, calibration, and troubleshooting.

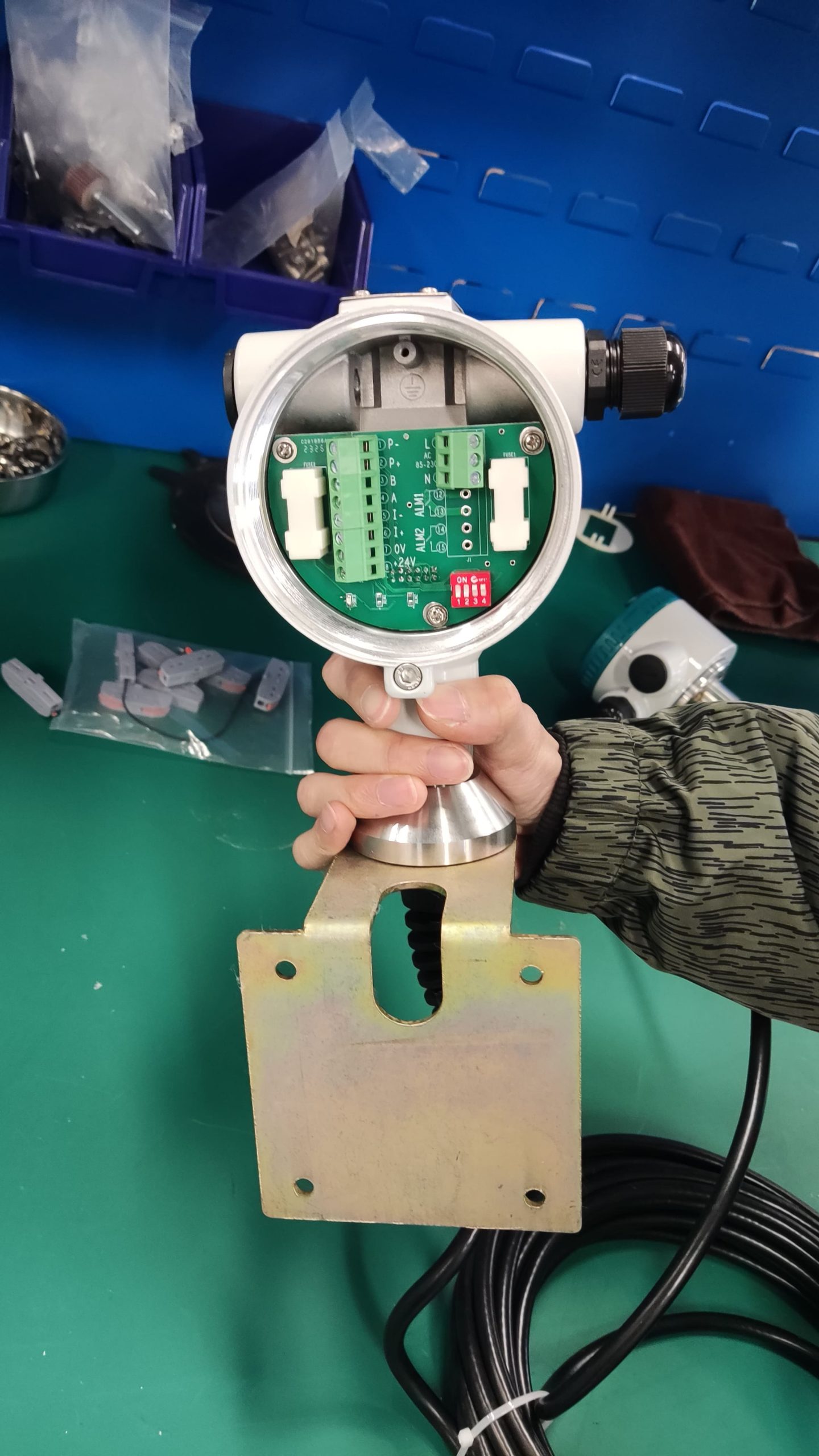

Consult Manufacturer Documentation: Refer to the flowmeter’s installation manual or technical documentation for specific guidance on installation direction and best practices. The manufacturer may provide detailed instructions and recommendations tailored to your flowmeter model and application requirements.

By considering these factors and following manufacturer recommendations, you can choose the appropriate installation direction for a thermal gas mass flowmeter to ensure accurate and reliable measurement of gas flow rates in your application.