Some suggestions for the installation of steam flow meter

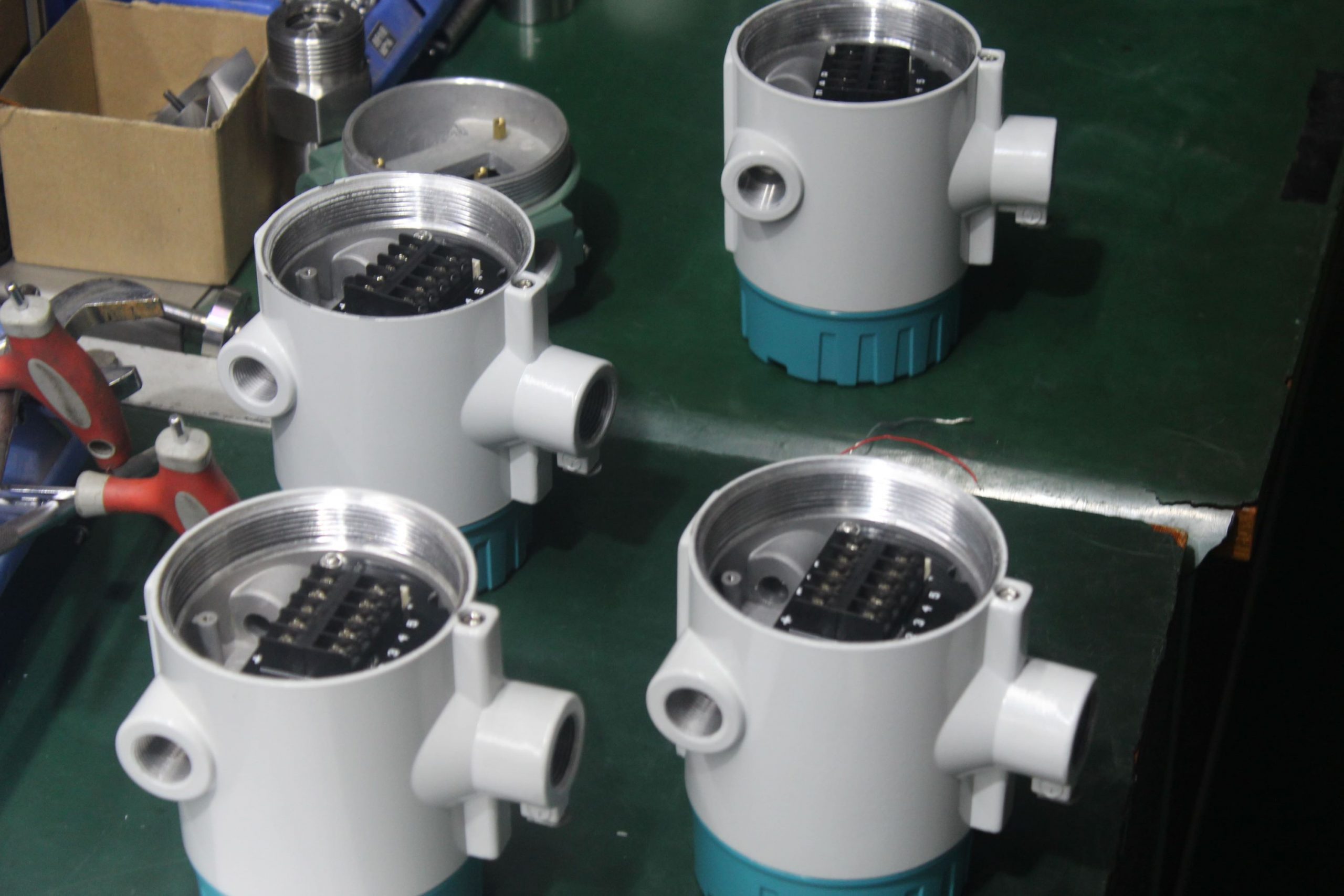

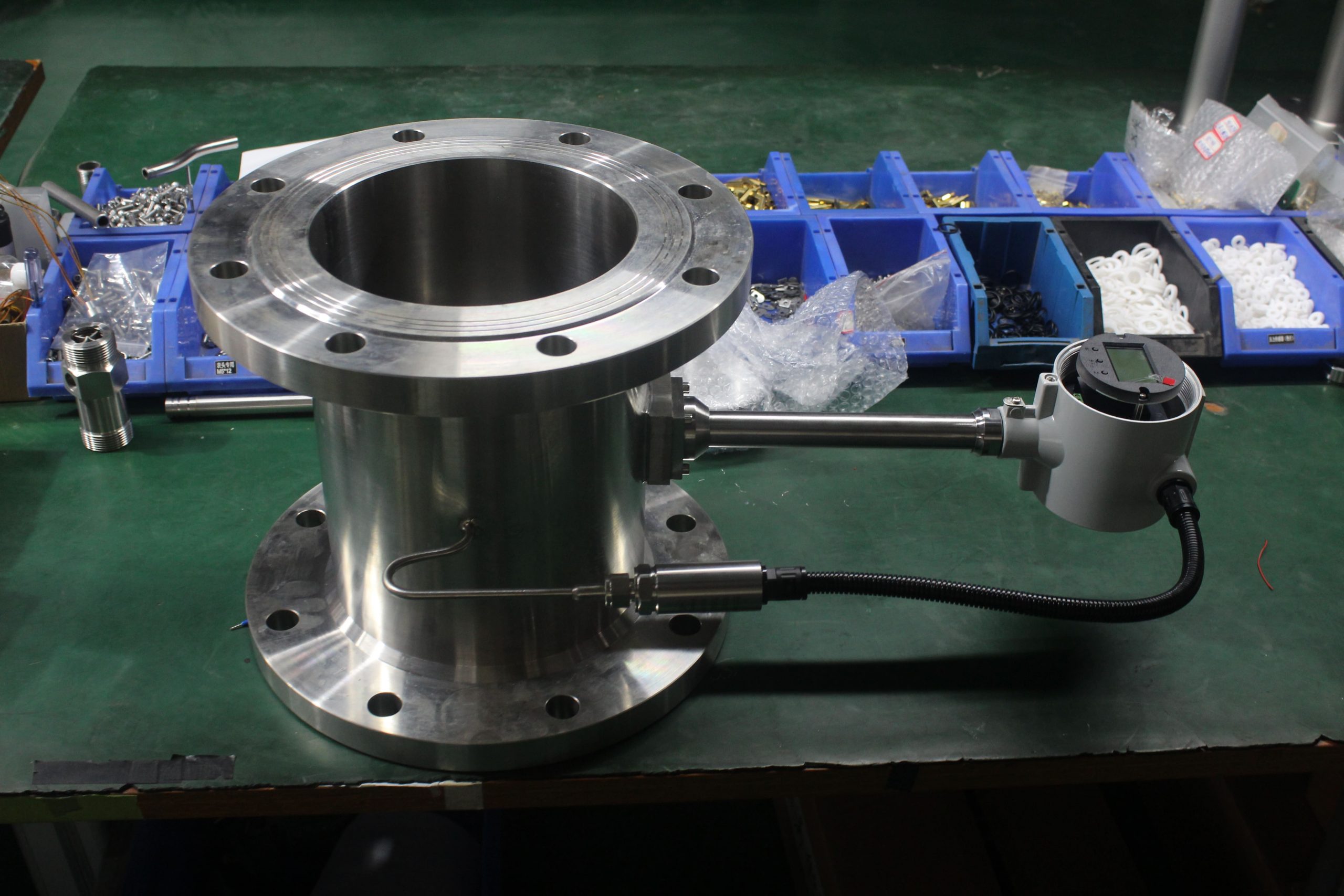

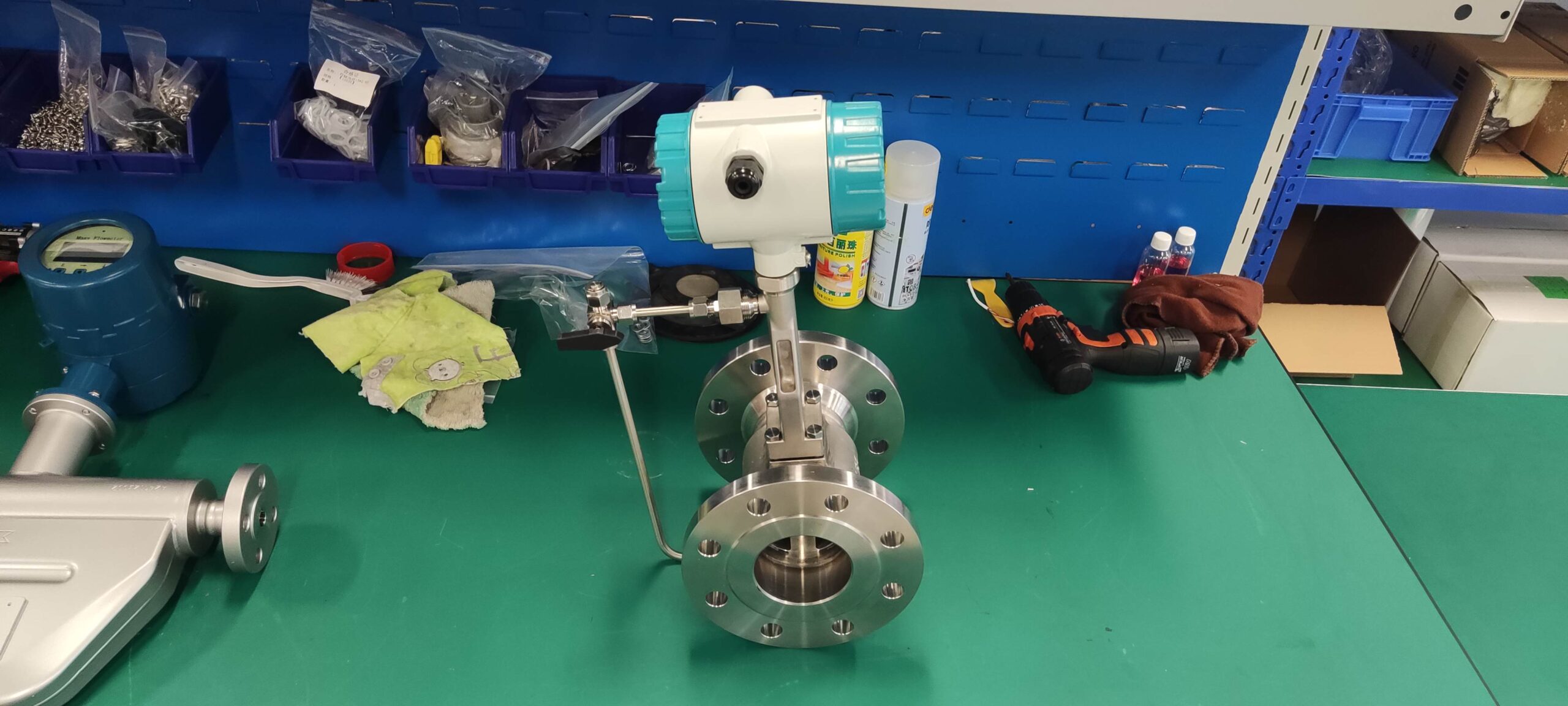

Vortex flowmeter is used to generate stable vortices when the fluid flows through the obstruction, and the flow measurement is achieved by measuring the frequency of the vortices. Vortex flowmeter is composed of vortex flow sensor and flow display instrument. The display instrument is a general flow display instrument. The following introduces the installation points of steam flowmeter.

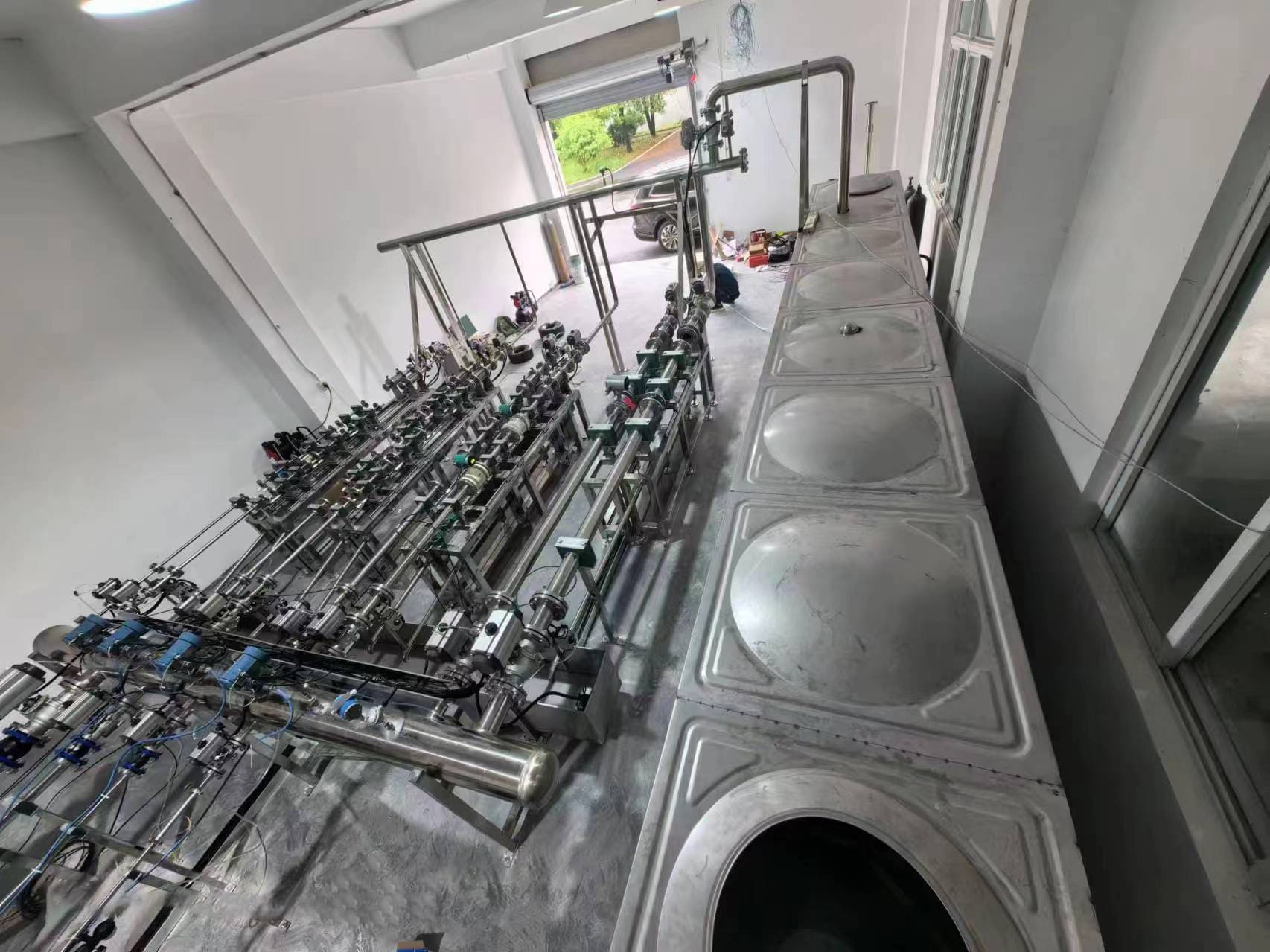

1, the steam flowmeter must be installed in the horizontal steam pipe, if the steam pipe is a vertical pipe, it should be set up a horizontal bypass pipe. The inlet side of the flow meter should have a straight pipe section of 10~15D (D is the inner diameter of the pipeline), and the outlet side should have a straight pipe section of 5 ~10D, and the inner diameter of the pipeline must be the same as the nominal diameter of the flow meter.

2. When the actual steam pipe diameter is inconsistent with the nominal diameter of the steam flowmeter, in addition to ensuring the length of the straight pipe section before and after the flowmeter, the horn tube should be installed at the connection of the size pipe.

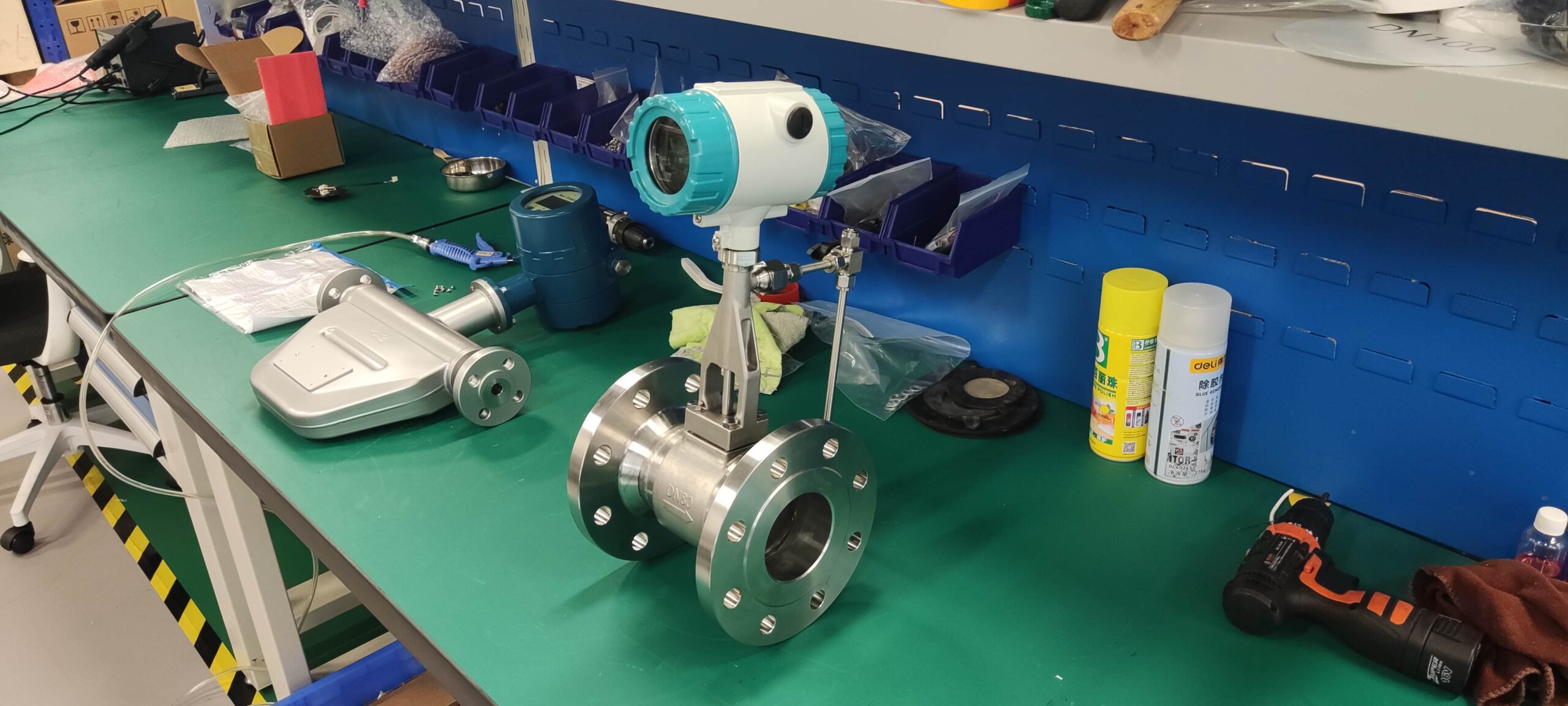

3. The flow direction of the steam flow meter must be consistent with the direction of the arrow on the flow meter body, and the indicator must be under the pipeline when installed, and the dial plane of the indicator is perpendicular to the ground.

4, for wet saturated steam with higher moisture content, the flow meter should be installed in the downstream of the trap in order to discharge the liquid phase fluid.

5, on the meter pressure gauge interface or the straight pipe section of the flowmeter inlet side, a pressure gauge should be installed in order to adjust the pressure compensation device of the flowmeter according to the pressure value.

6, adjust the pressure compensation device of the steam flowmeter, so that the actual steam working pressure is consistent with the calibration pressure of the flowmeter. When adjusting, open the back cover of the indicator, loosen the nut, turn the ruler tube, so that the pressure indicator index line of the dial is aligned with the corresponding pressure indicator index line of the ruler, and then tighten the nut, and then close the back cover.

7. Before the steam flowmeter works, the water injection box must be filled with damping liquid. You can unscrew the four bolts at the water injection port and the drain port on the water injection tank, fill the water injection port, and tighten the drain bolt when the liquid from the drain port is confirmed to be free of yellow rust and dirt. Tighten the bolt of the water injection port when the water injection port overflows and no gas exists in the water injection tank. The damping liquid in the water injection box must be filled, otherwise the measurement accuracy will be affected and the internal parts of the flowmeter will be damaged. Damping liquid is generally used with tap water, when the ambient temperature around the flow meter is lower than zero or intermittent use, the limiting liquid should be antifreeze treatment, antifreeze damping liquid using 5% ethylene glycol aqueous solution, should be released when stopping use.

The measuring accuracy of vortex flowmeter reaches 1.0 level, which is used to measure low temperature media such as liquid, gas, steam and various corrosive media. It is widely used and has broad development prospects.