Precision and flow rate of electromagnetic flow meter

Precision and flow rate of electromagnetic flow meter

1. Accuracy level and function

The performance of general-purpose electromagnetic flowmeters on the market is quite different, some have high precision and many functions, and some have low precision and simple function. The basic error of the instrument with high accuracy is (±0.5% ~ ±1%) R, and the instrument with low accuracy is (±1.5% ~ ±2.5%) FS, and the price difference between the two is 1 to 2 times.

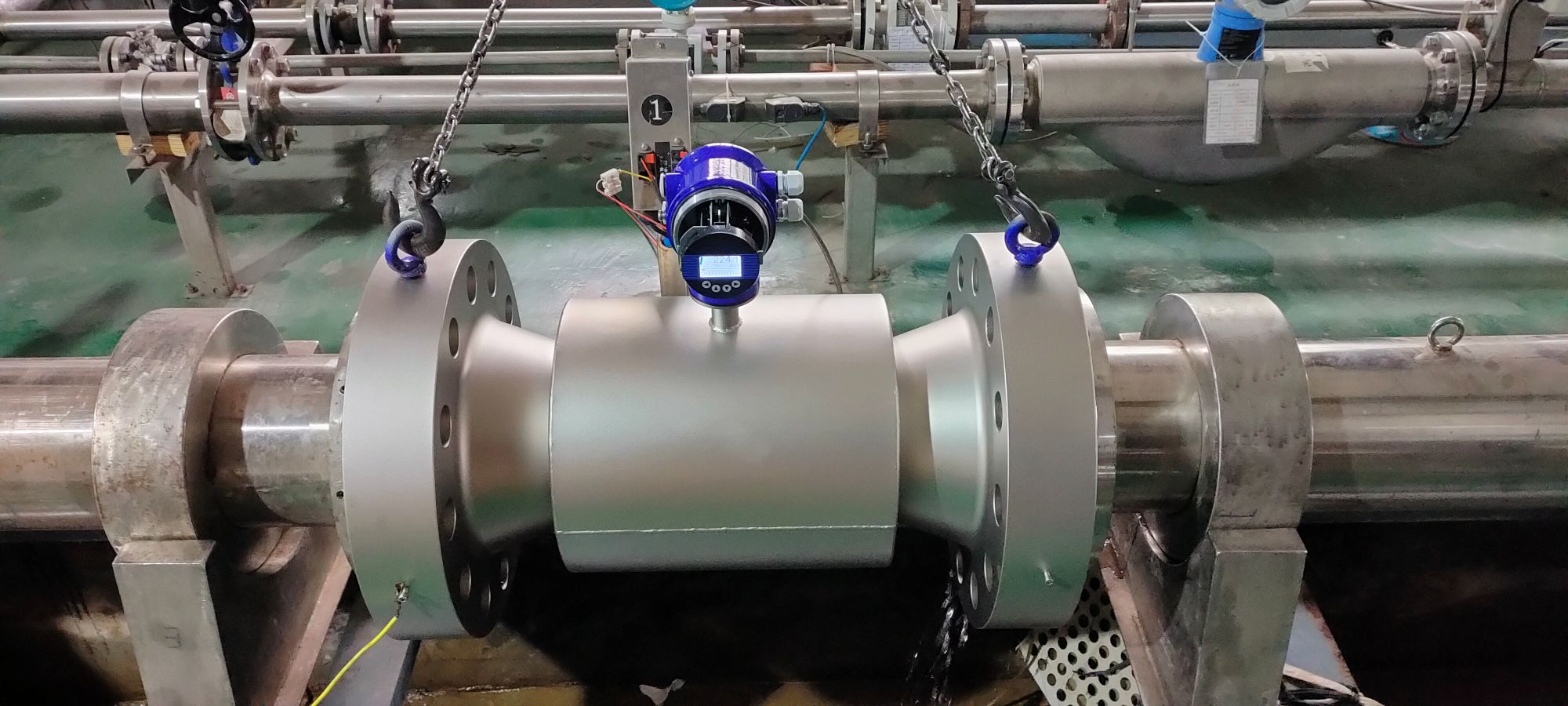

Some models claim to have higher accuracy, the basic error is only (±0.2% ~ ±0.3%) R, but there are strict installation requirements and reference conditions, such as the ambient temperature of 20 ~ 22℃, The length of the front and back straight pipe section is required to be greater than 10D, and 3D (usually 5D,2D) even proposes that the flow sensor should be integrated with the front and back straight pipe for real flow calibration on the flow standard device to reduce the impact of poor clamping. Therefore, when comparing a variety of models, do not simply look at high indicators, but read the manufacturer’s samples or instructions in detail for comprehensive analysis.

The function of the electromagnetic flowmeter on the market is also very different, simple is just to measure one-way flow, only the output analog signal to drive the post-meter; The multifunctional instrument has bidirectional flow measurement, range switching, upper and lower limit flow alarm, air pipe and power cut alarm, small signal cutting, flow display and total calculation, automatic check and fault self-diagnosis, communication with the host computer and motion configuration. The serial digital communication function of some models of meters can choose a variety of communication interfaces and special chip (ASIC) to connect to HART protocol system, PROFTBUS, Modbus, CONFIG, FF fieldbus, etc.

2. Flow rate, full degree flow, range and caliber

The selected gauge diameter is not necessarily the same as the pipe diameter and should depend on the flow rate. Process industry transport water and other liquids with different viscosity, the pipeline flow rate is generally the economic flow rate of 1.5 ~ 3m/s. Electromagnetic flowmeters are used in such pipelines, and the sensor diameter is the same as the pipe diameter.

EMF full flow rate when the liquid flow rate can be selected in the range of 1 ~ 10m/s, the range is relatively wide. The upper flow rate is in principle unlimited, however it is generally recommended not to exceed 5m/s, unless the lining material can withstand flow erosion, practical applications rarely exceed 7m/s, and more rarely exceed 10m/s. The flow rate limit of full degree flow is generally 1m/s, and some models of meters are 0.5m/s. In some new construction projects with low flow at the initial stage of operation or in the pipe system with low flow rate, from the perspective of measurement accuracy, the instrument diameter should be changed to less than the pipe diameter and connected with reducing pipe.

For fluids with easy adhesion, deposition, scaling and other substances, the flow rate should be not less than 2m/s, and should be increased to 3 ~ 4m/s or more to play a role in self-cleaning and preventing adhesion deposition. For abrasive fluids such as pulp, the usual flow rate should be lower than 2 ~ 3m/s to reduce the wear of the lining and electrode. In the measurement of low conductivity liquid close to the threshold, as far as possible to select a low flow rate (less than 0.5 ~ 1m/s), flow noise will increase due to the increase of flow rate, resulting in output shaking phenomenon.

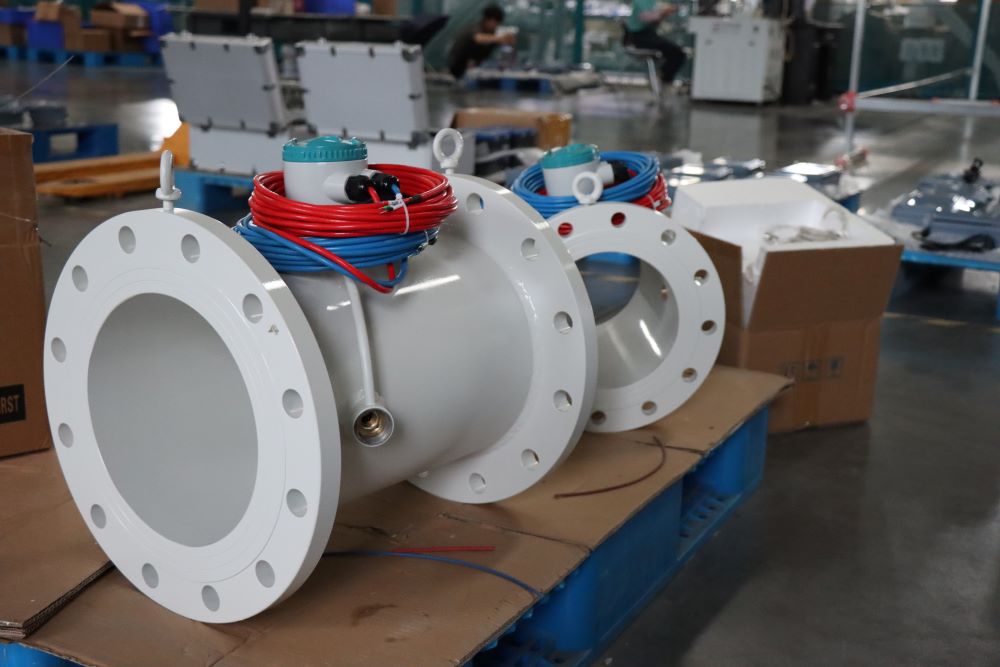

The range of the electromagnetic flowmeter is relatively large, usually not less than 20, and the instrument with the automatic range switching function can exceed 50 to 100. The caliber of styling products that can be provided in China ranges from 10mm to 3000mm, and the actual application is still mostly small and medium-sized caliber, but compared with most other principle flow meters (such as positive displacement, turbine, vortex or Coriolis mass, etc.), large caliber meters occupy a larger proportion.

-.jpg)