Precession vortex flowmeter common faults

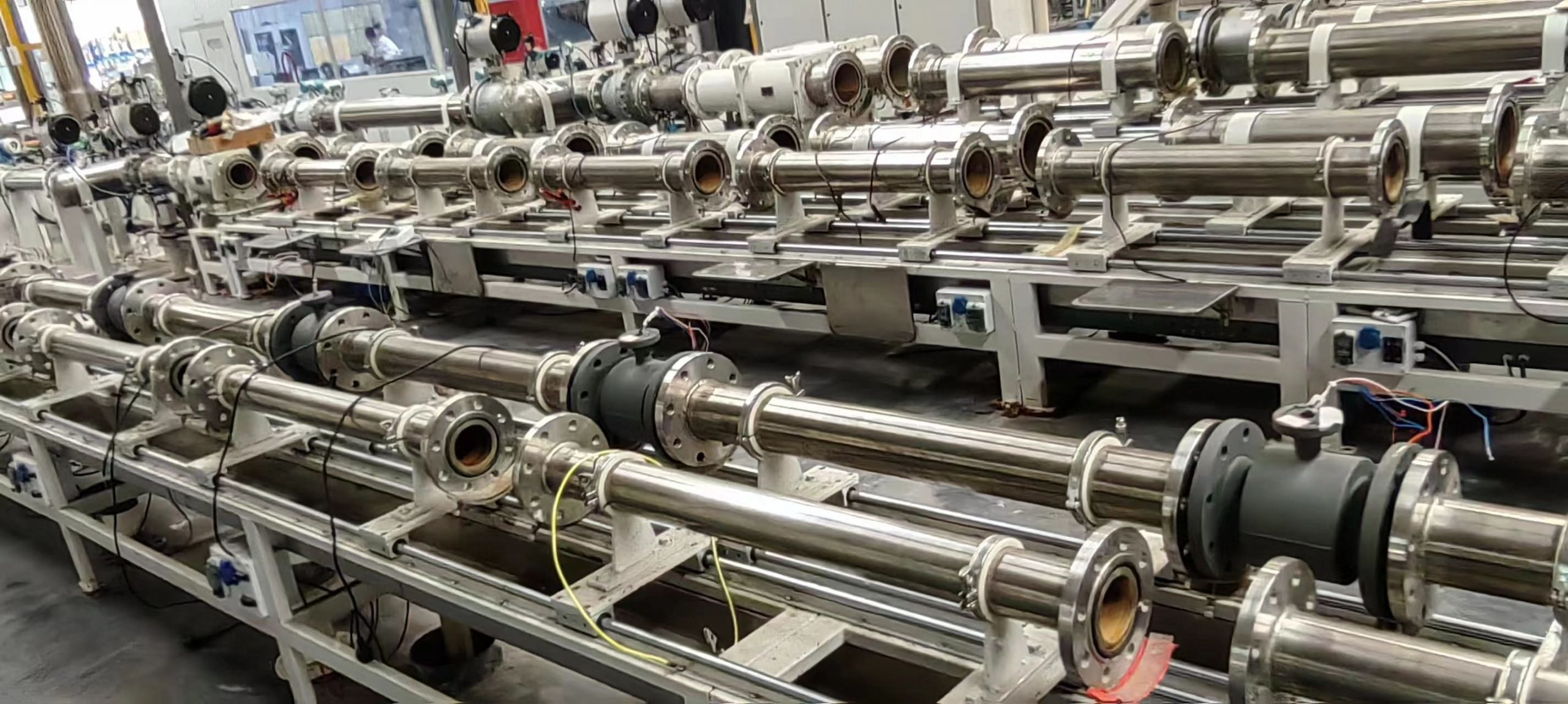

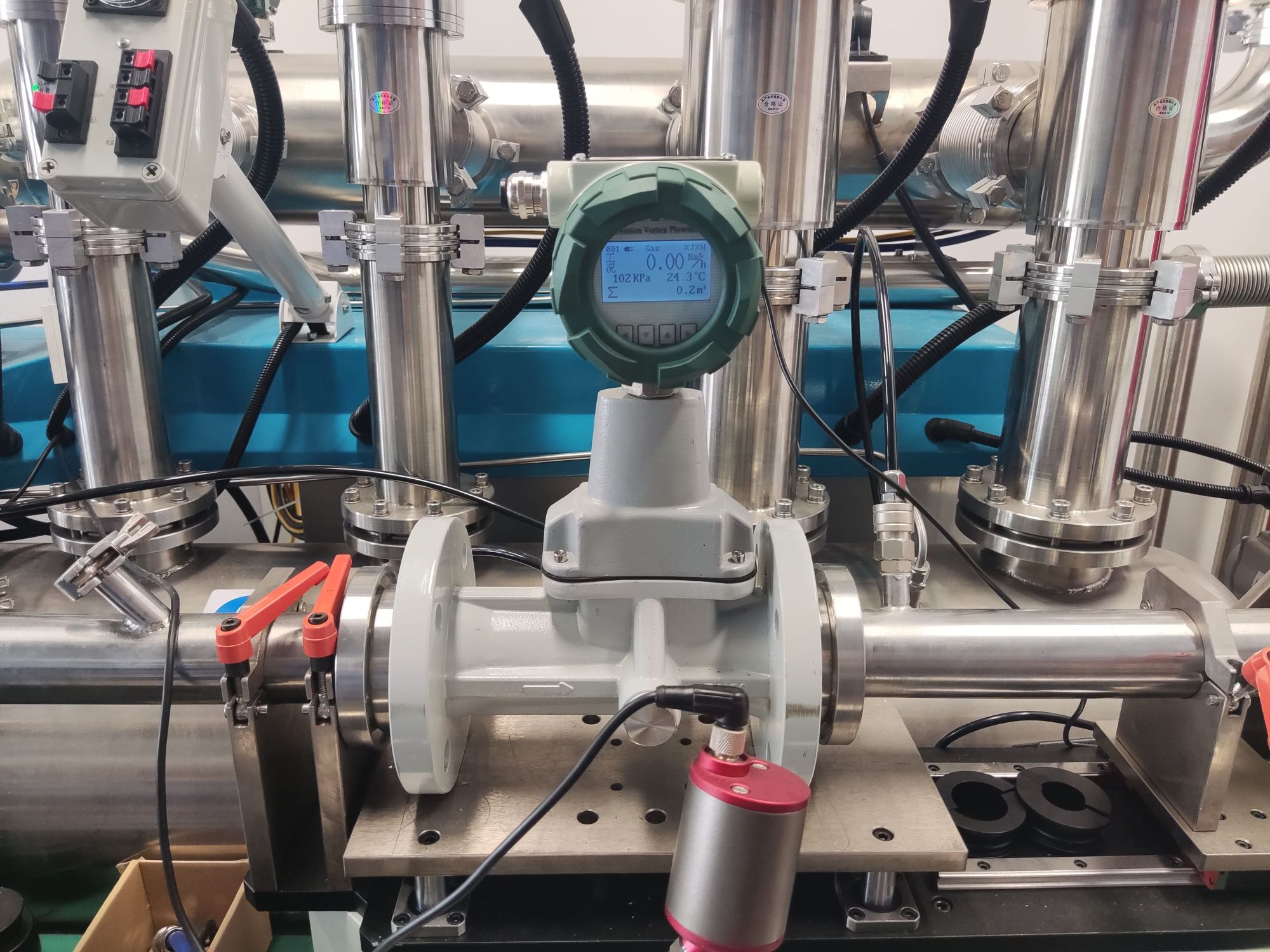

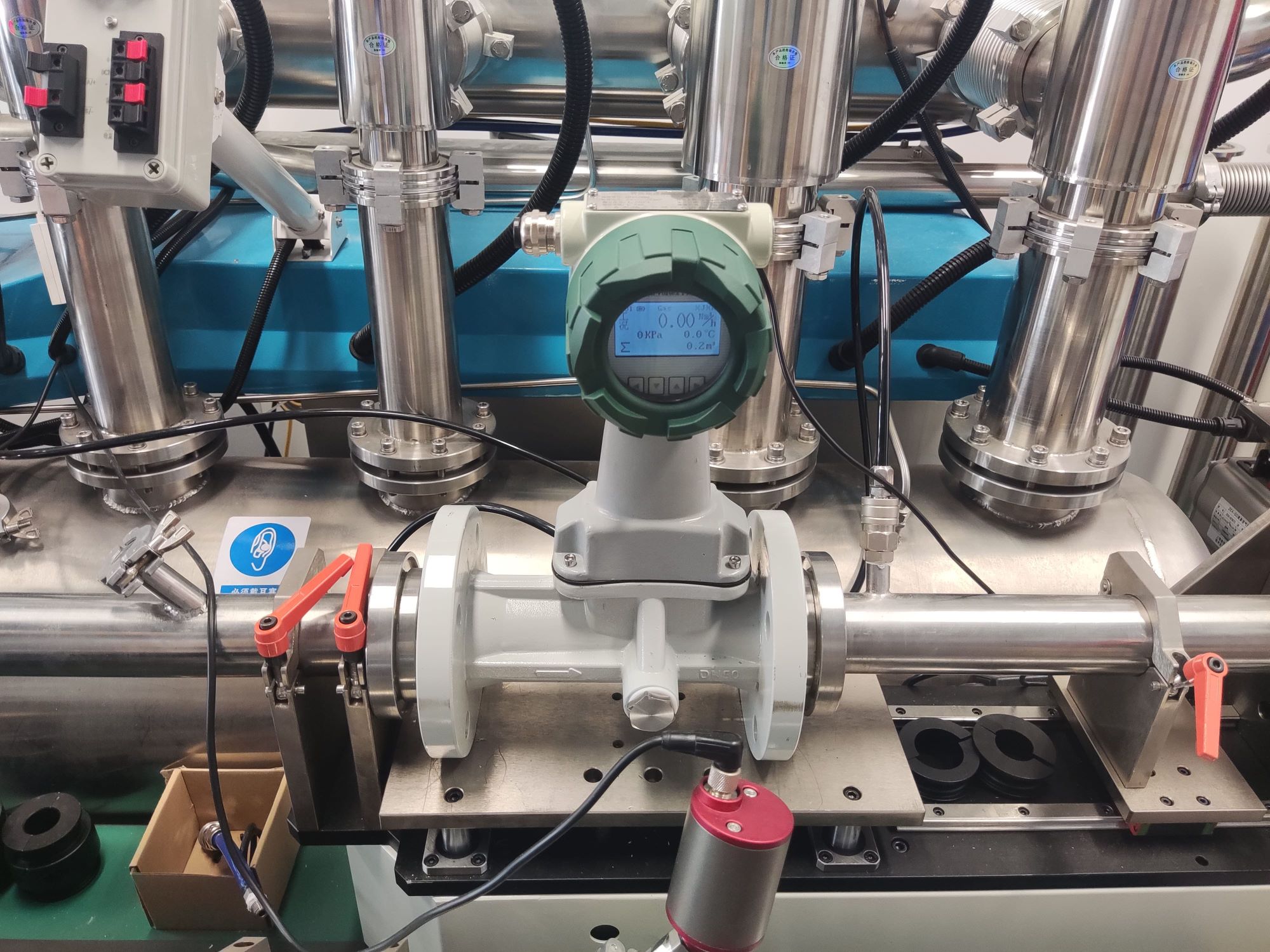

The precession vortex flowmeter is a kind of velocity flow meter, which can be used for the flow measurement of oil, steam, natural gas and other media, and realize the online automatic compensation of dynamic parameters such as pressure, temperature and compression coefficient, which can not only display various parameters on the spot, but also can transmit various signals far out.

It is widely used in various gas metering and flow control of petroleum, chemical, metallurgical, pharmaceutical and urban gas transmission and distribution networks. In the oil field, it is mainly used in the measurement of associated gas in oil Wells, inlet gas in combined stations, and external gas transmission.

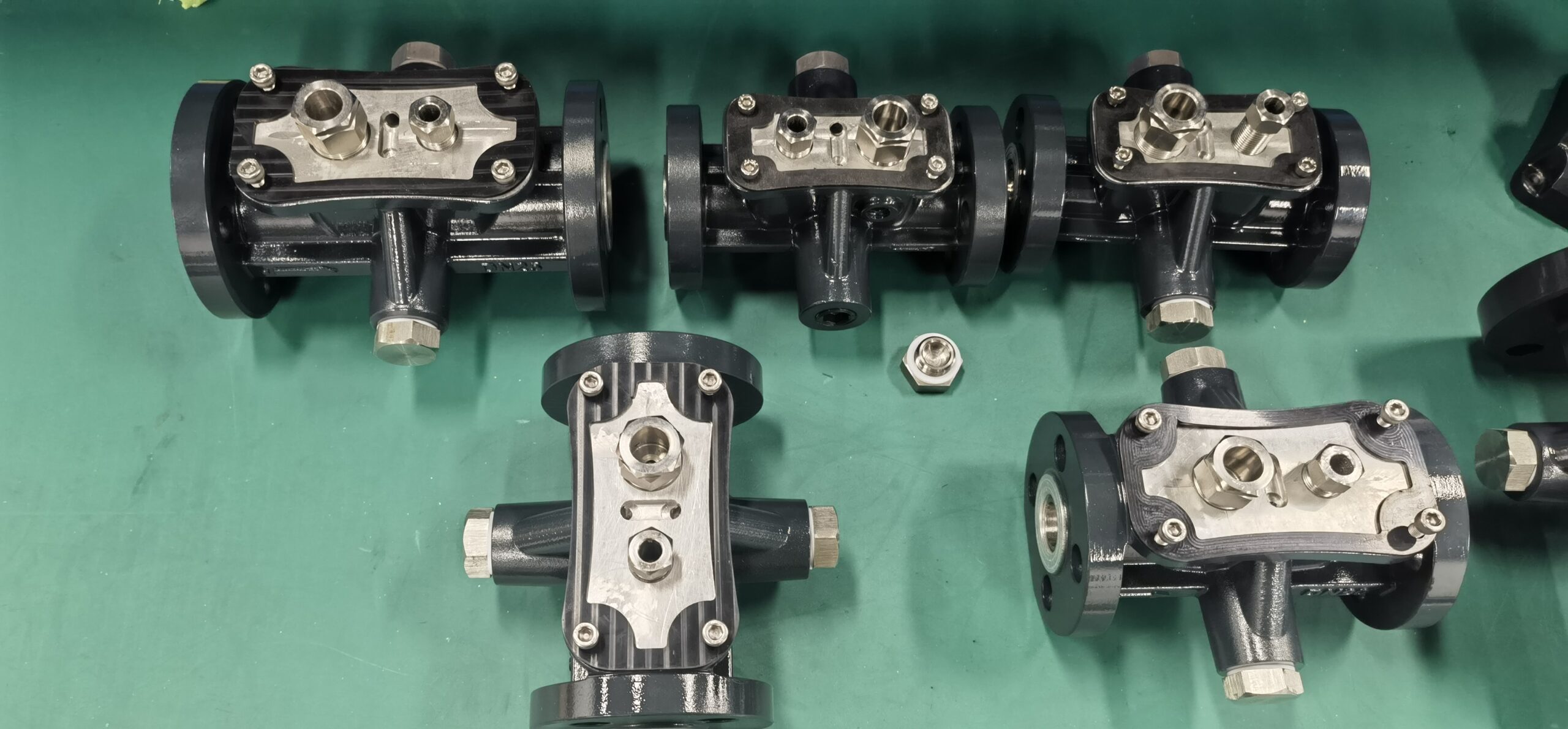

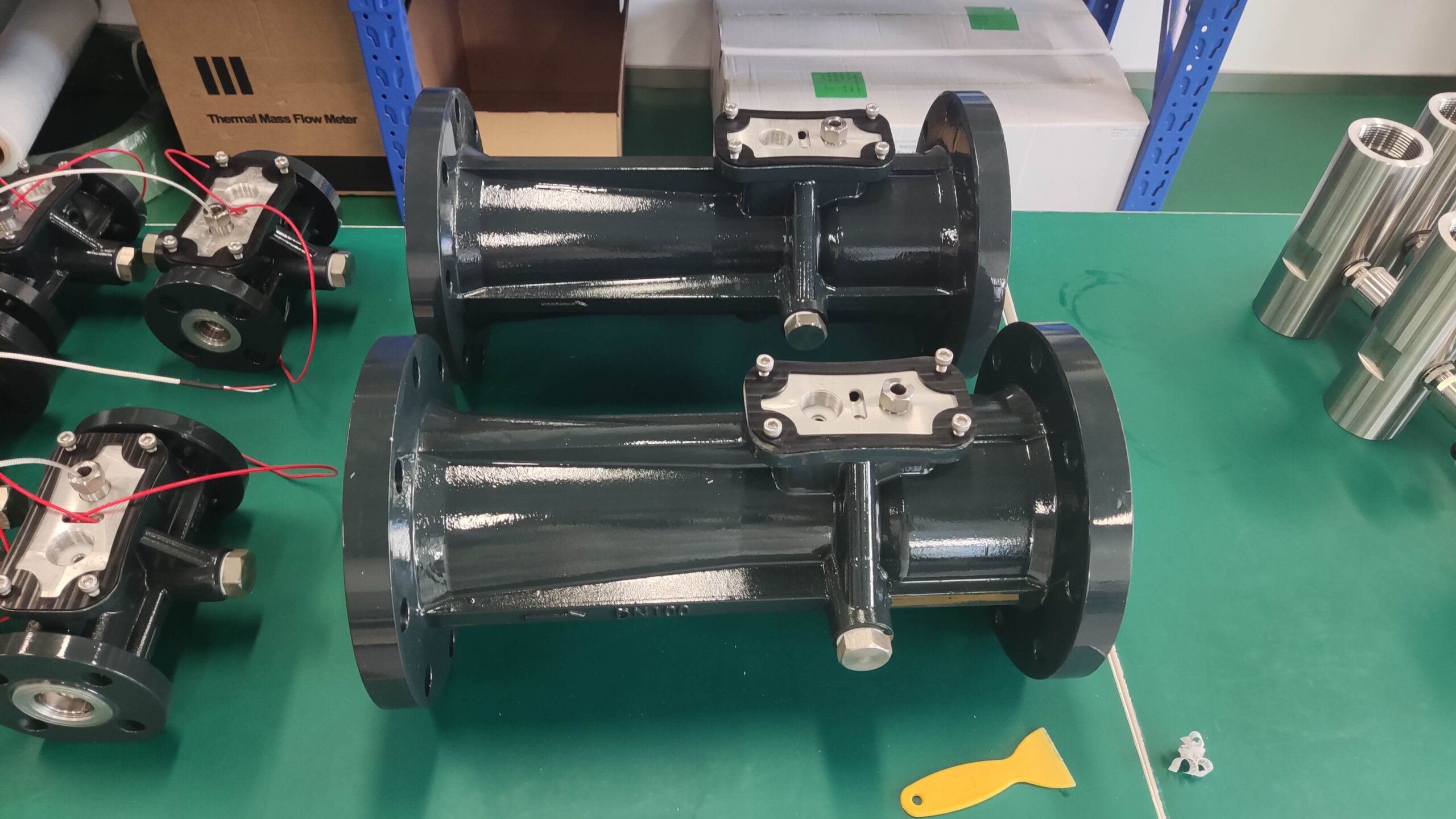

1, the precession vortex flowmeter installation does not meet the requirements

The precession vortex flowmeter is a fluid oscillation instrument, which has high requirements on the site. However, when the instrument is installed on the site, the distance between the front and back pipe segments is relatively close, and the center line of the shell and the center line of the pipe are different, such as the elbow and the diameter reduction, which will cause measurement errors of the instrument.

2, the gas flow is not stable

The gas volume changes with time, belonging to pulsating fluid. The random pulsating pressure will have a random impact on the vortex-generating body, which will affect the measurement accuracy.

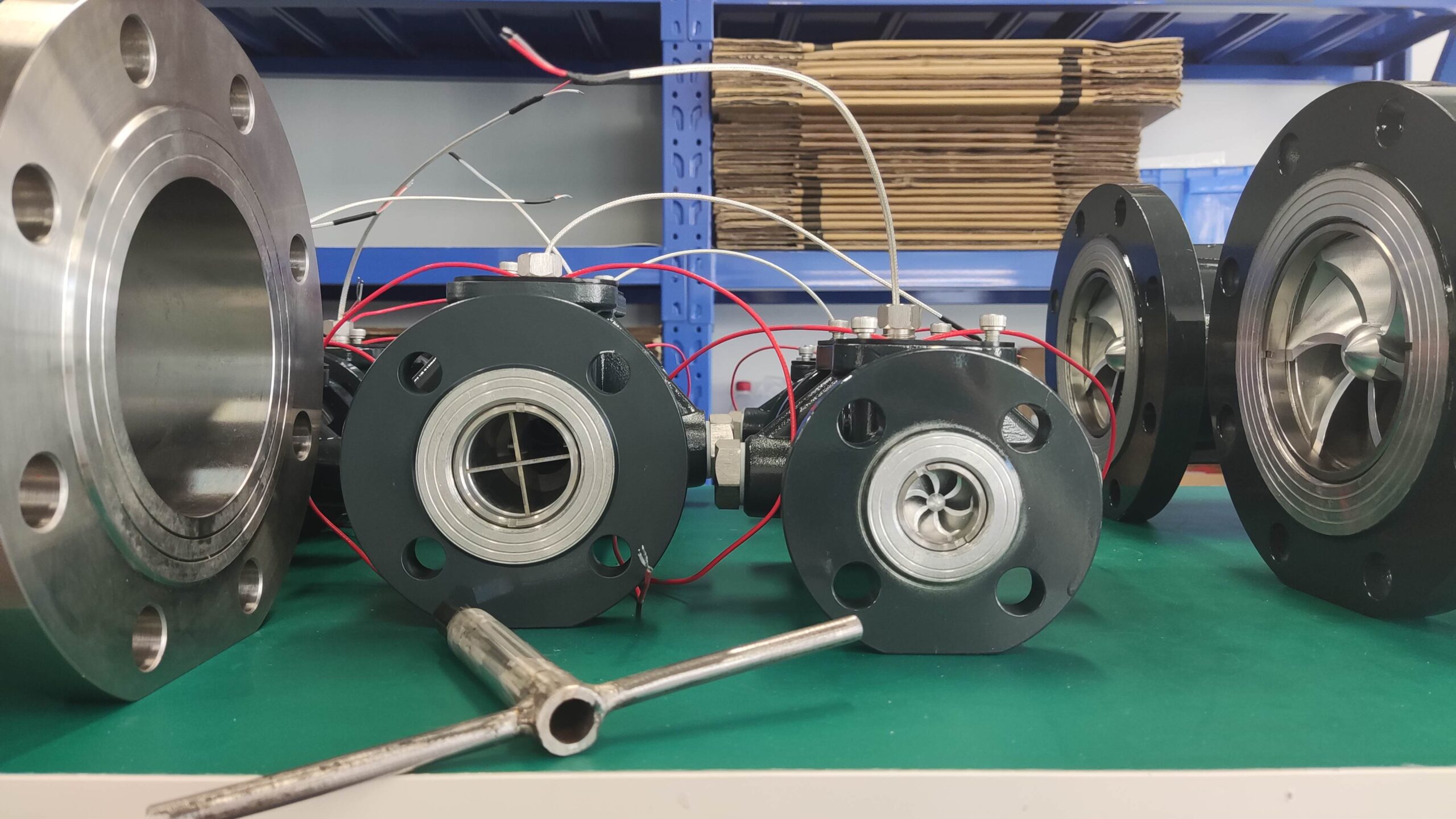

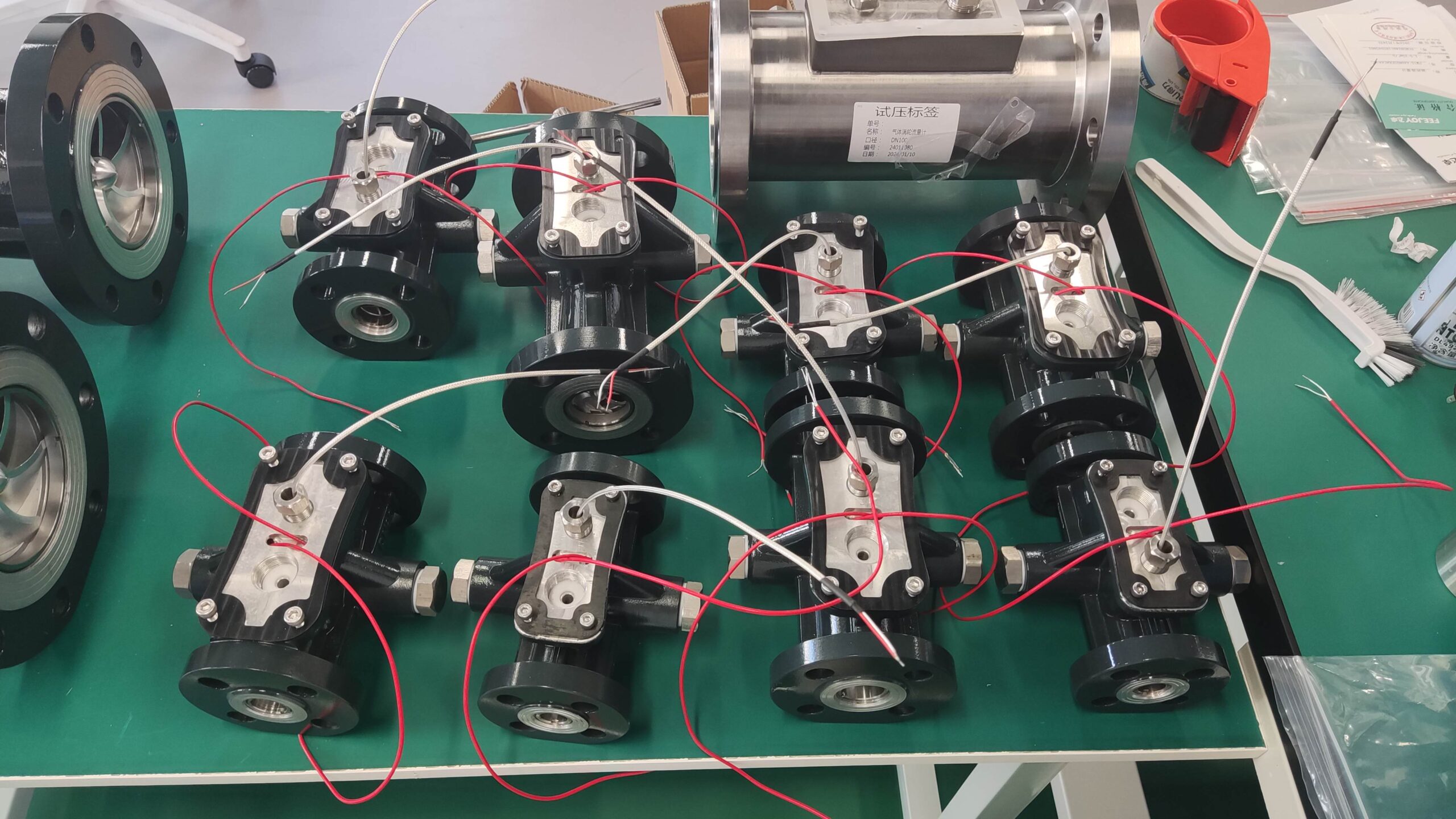

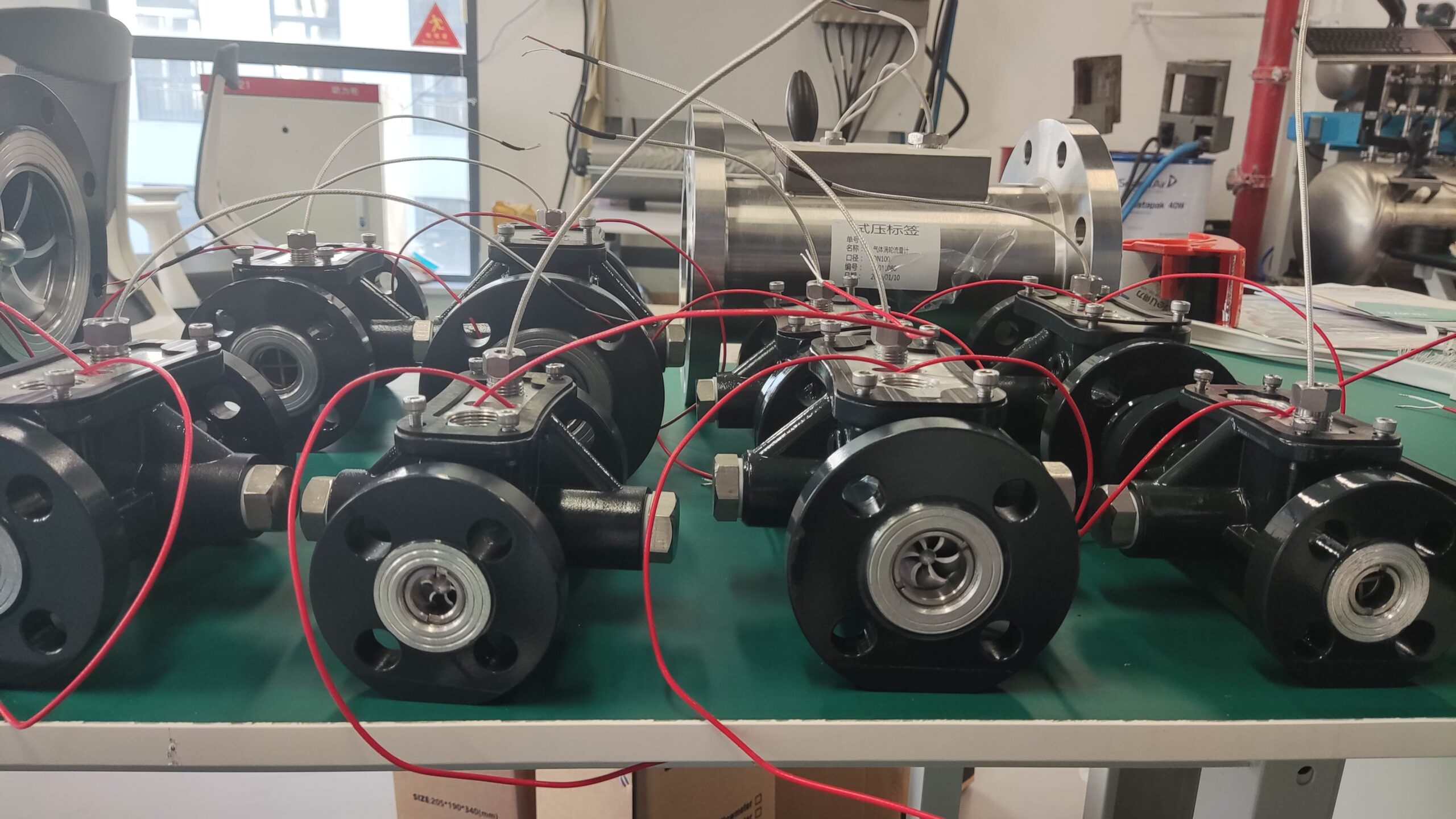

3, the precession vortex flowmeter is a fluid oscillation instrument, in the pipeline vibration, the piezoelectric sensor can detect the change caused by the oscillation, so there will be signal output;

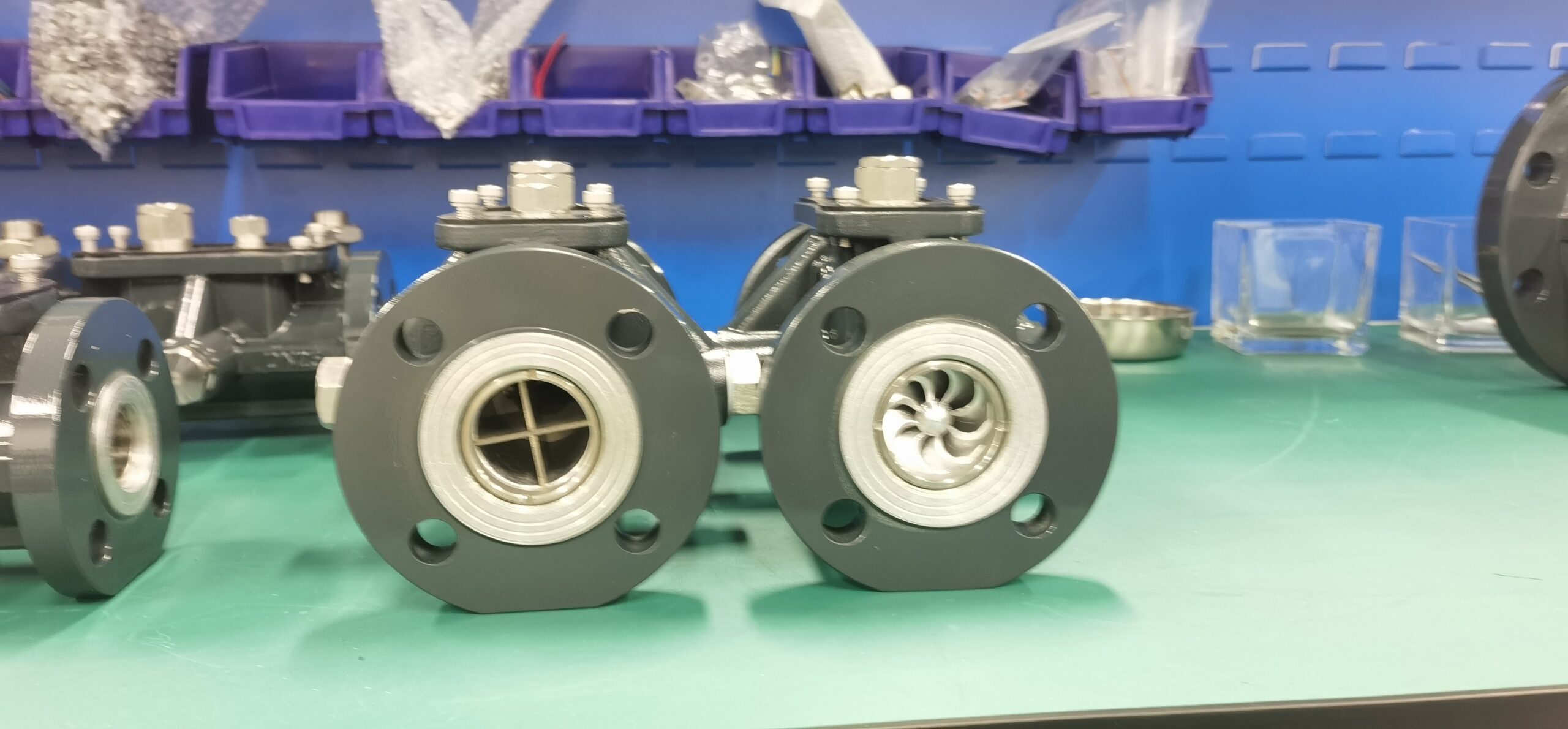

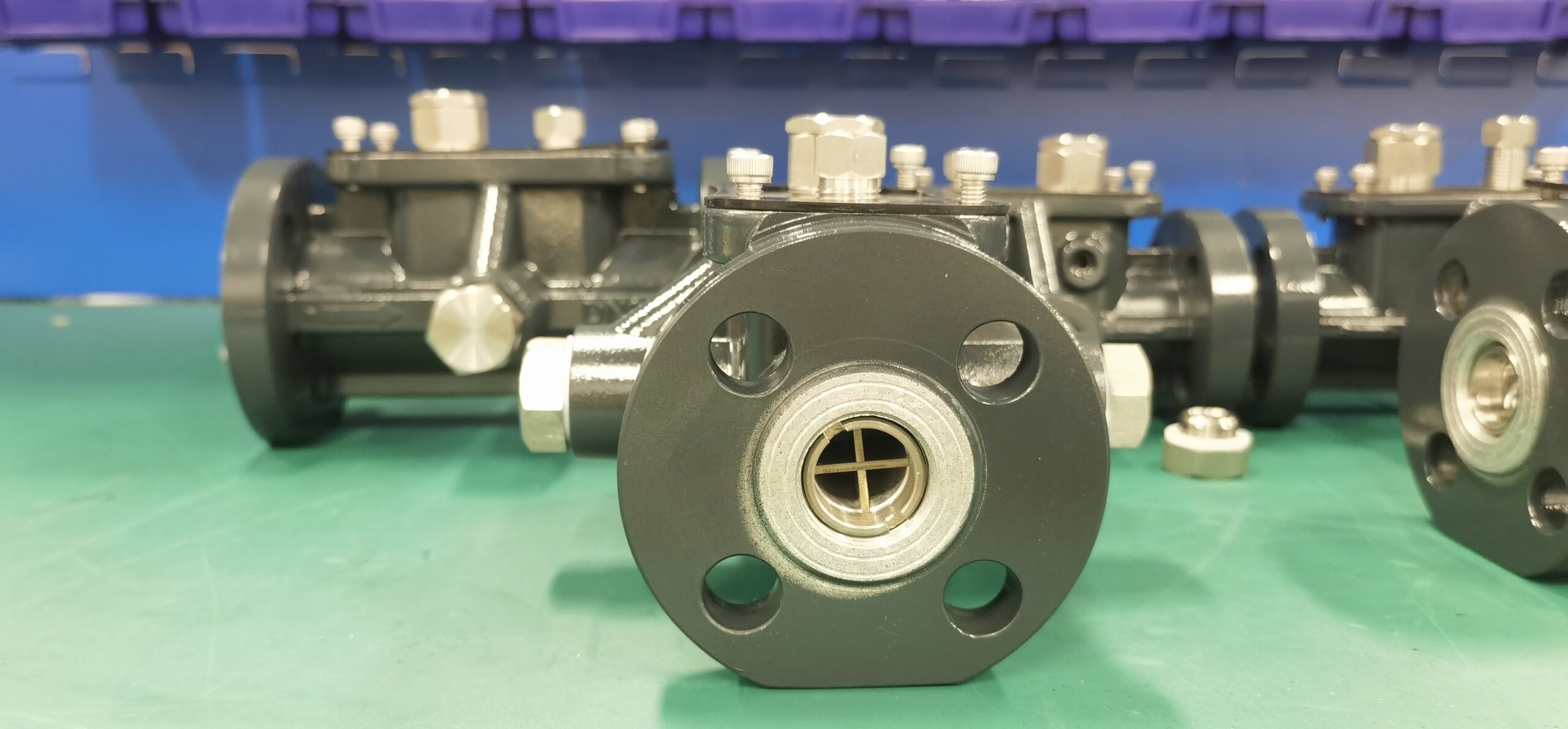

4, the vortex flow meter requires the medium to be clean, because the natural gas contains a large number of saturated water vapor, water condensation when the temperature is reduced, the metering separator often has the phenomenon of gas running oil, resulting in liquid accumulation in the pipeline, a single well associated gas separation is not clean or contains impurities such as dirty oil and sand, sand wear vortex body and dirty oil and other impurities stuck on the surface of the vortex body make the instrument measurement error.