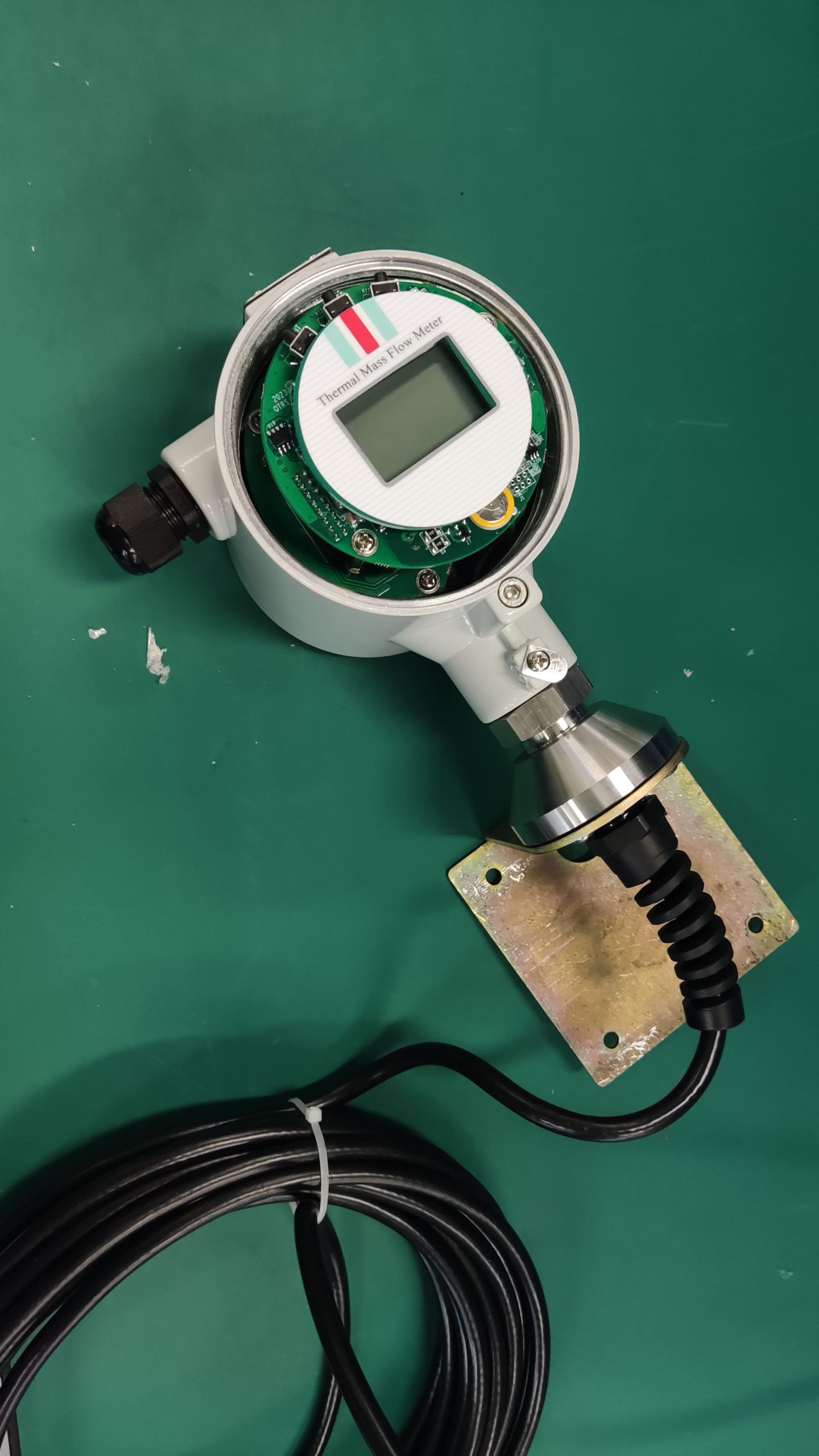

Precautions for using thermal gas mass flow meter

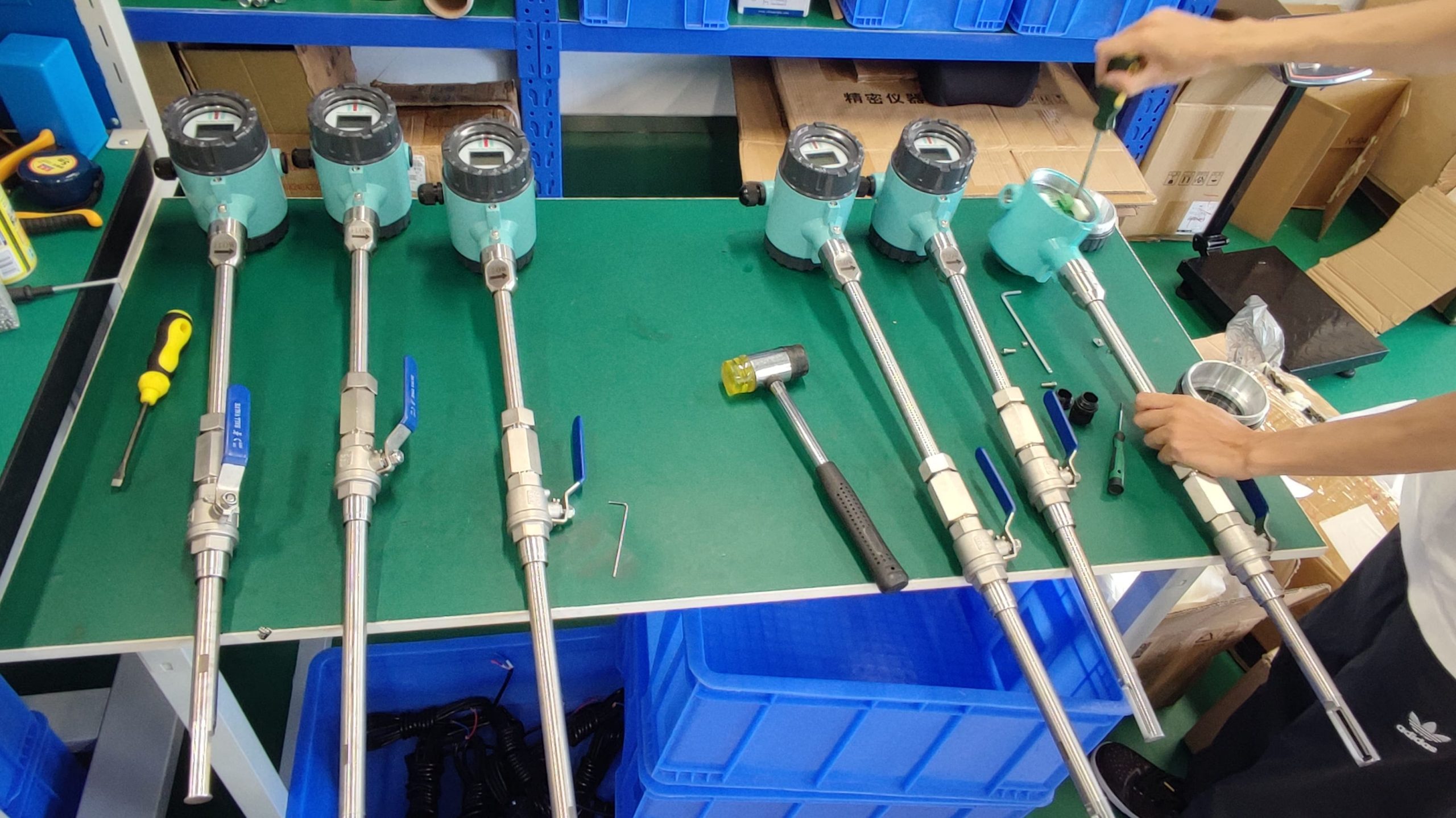

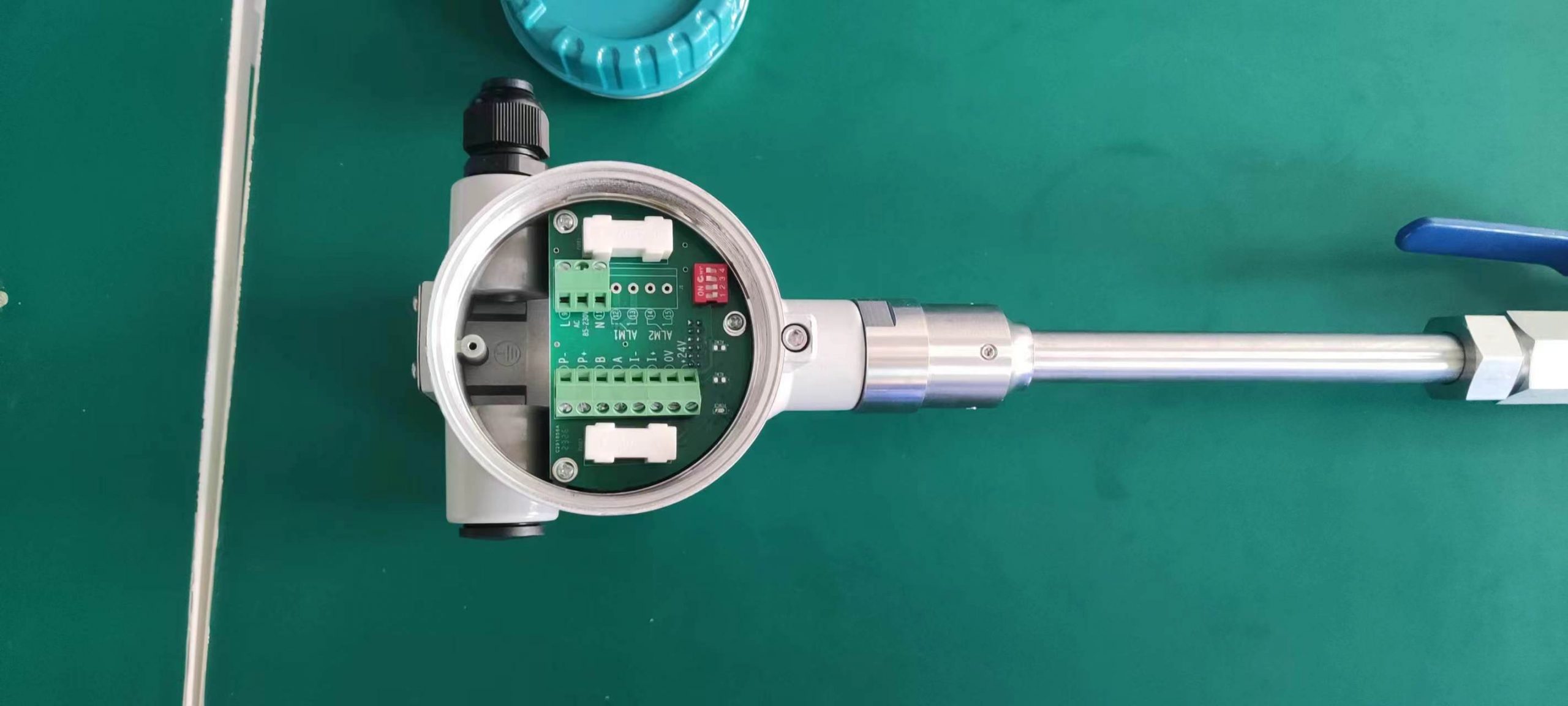

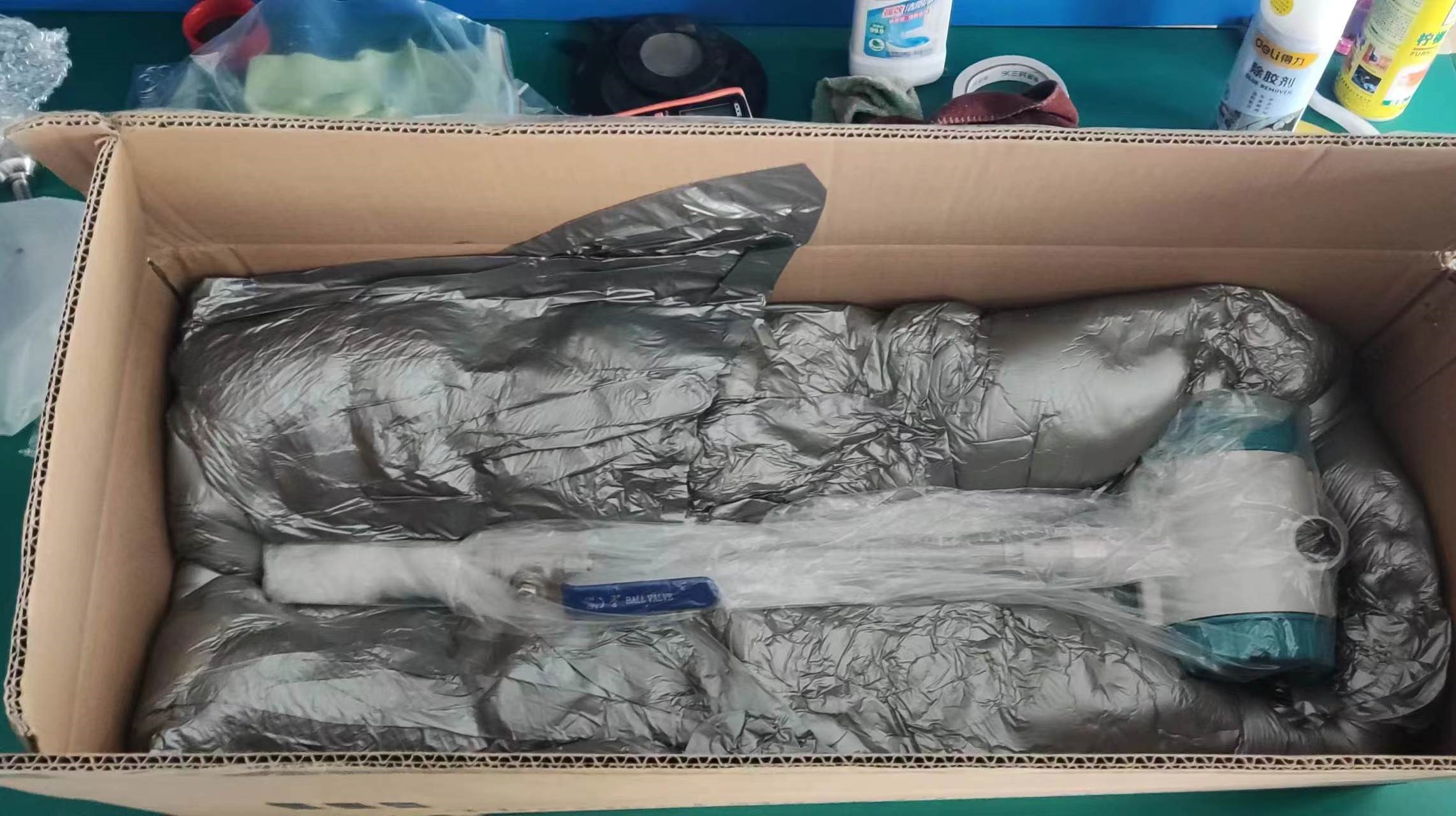

Thermal gas mass flowmeter has certain operating procedures and precautions in use, and must pay attention to these points when in use:

1. Disable the flow medium, the use of gas must be purified, avoid dust, liquid and oil. If necessary, install a filter dryer in the gas path. If the instrument outlet is connected to the liquid original bottle, a check valve should be installed at the flow outlet to prevent the liquid backflow from damaging the instrument.

2. Use corrosive gases, instrument channel material is 0Cr17Ni14Mo2(equivalent to 316L stainless steel), fluorine rubber, etc. Under the conditions of no water vapor, low leakage, frequent cleaning and proper use of the user system, general corrosive gases can be measured. When used in ammonia, organic solvent vapor or other highly corrosive gases, it should be specially indicated when ordering, so as to replace the sealing material.

3. the valve should pay attention to seal, the instrument’s solenoid valve is a regulating valve, not a stop valve, can not be used as a stop valve, the user should be equipped with another stop valve. Especially when using corrosive gases, a stop valve should usually be added at the entrance and exit of the instrument to ensure safety. After long-term work, if the leakage rate of the instrument valve is within 2%FS, it is normal. If the leak is greater than 2% of full scale, it should be repaired.

4. Pay attention to the valve control operation, after the operation of the valve for cleaning, you can not directly turn to the “valve control” position, you must first put the valve in the “off” position, and then turn to the “valve control” position.

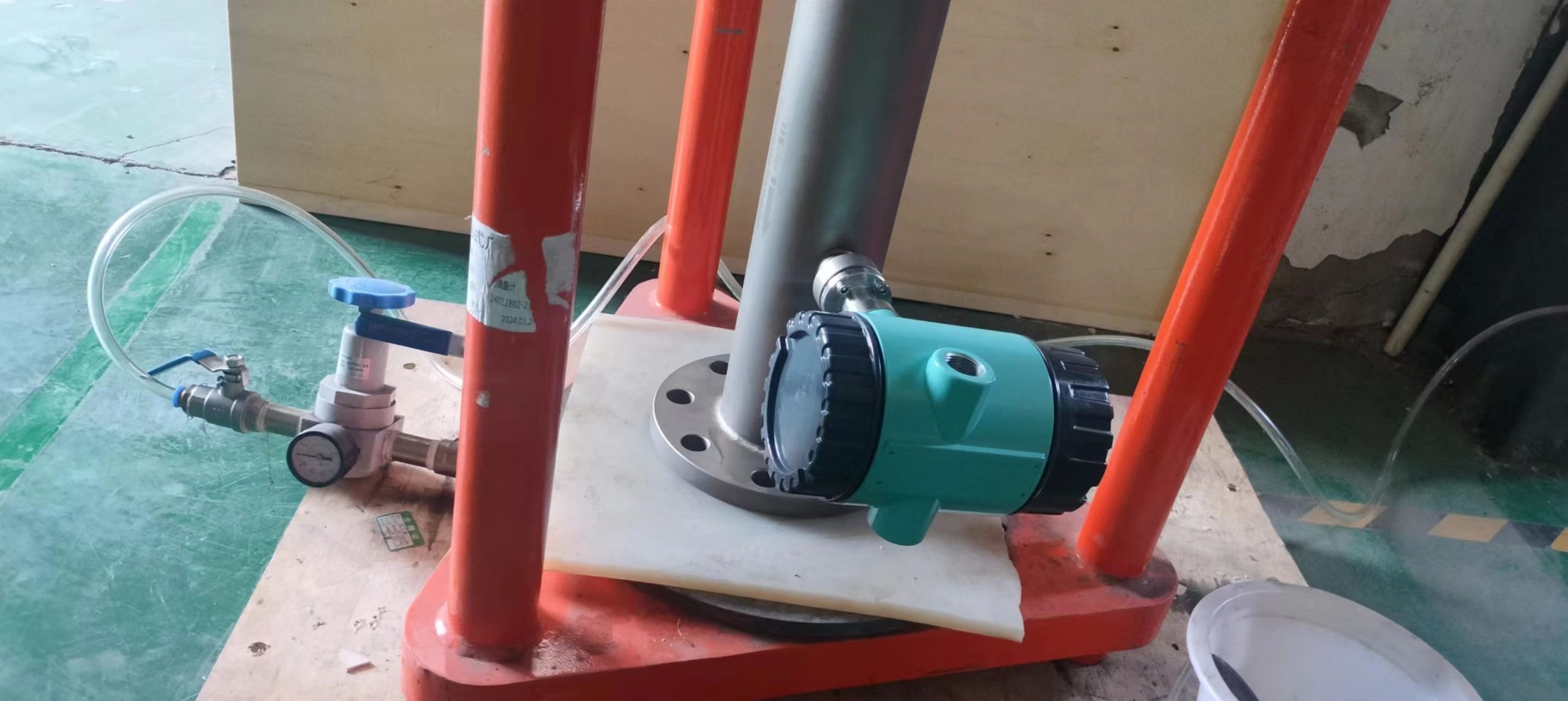

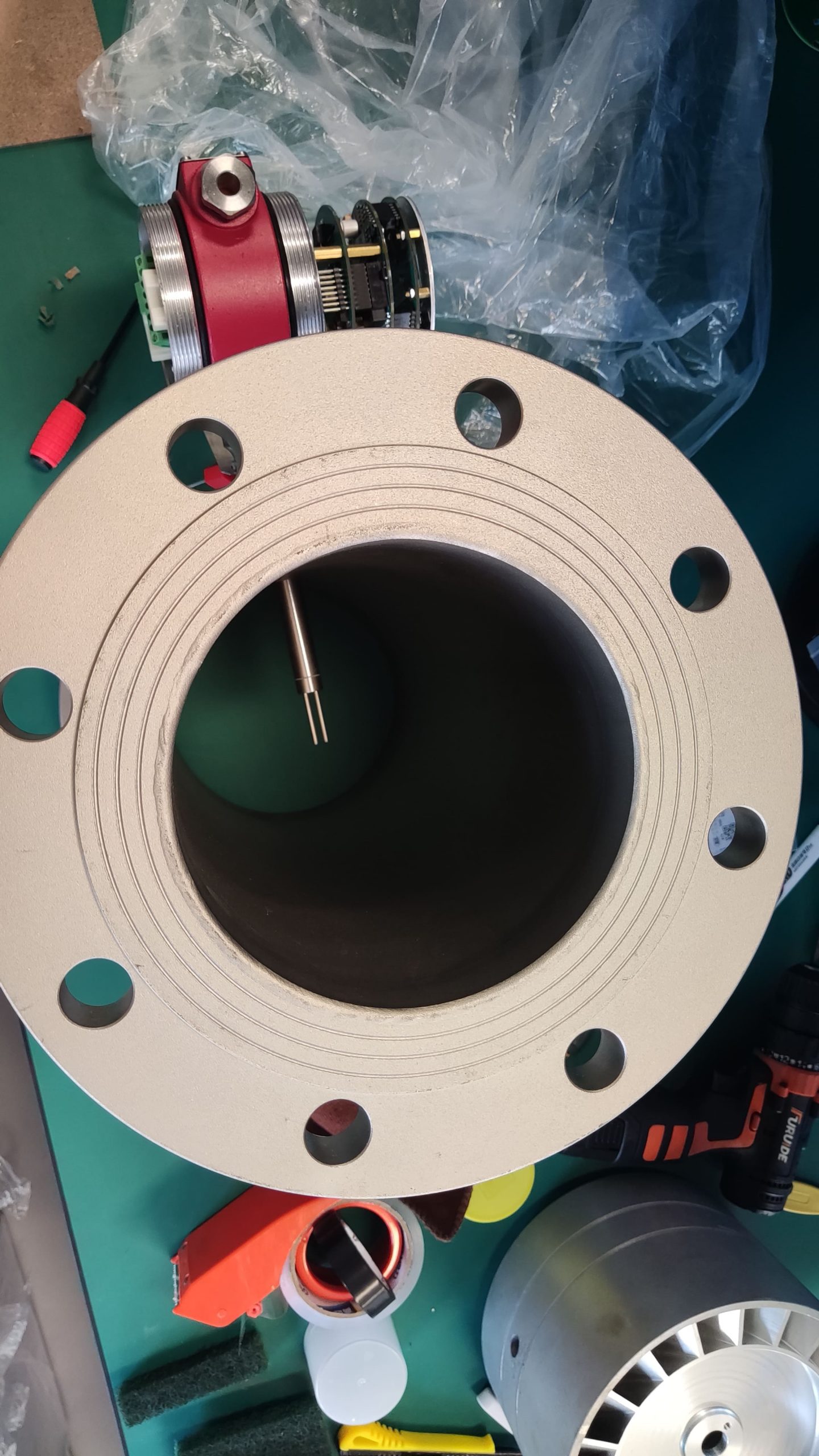

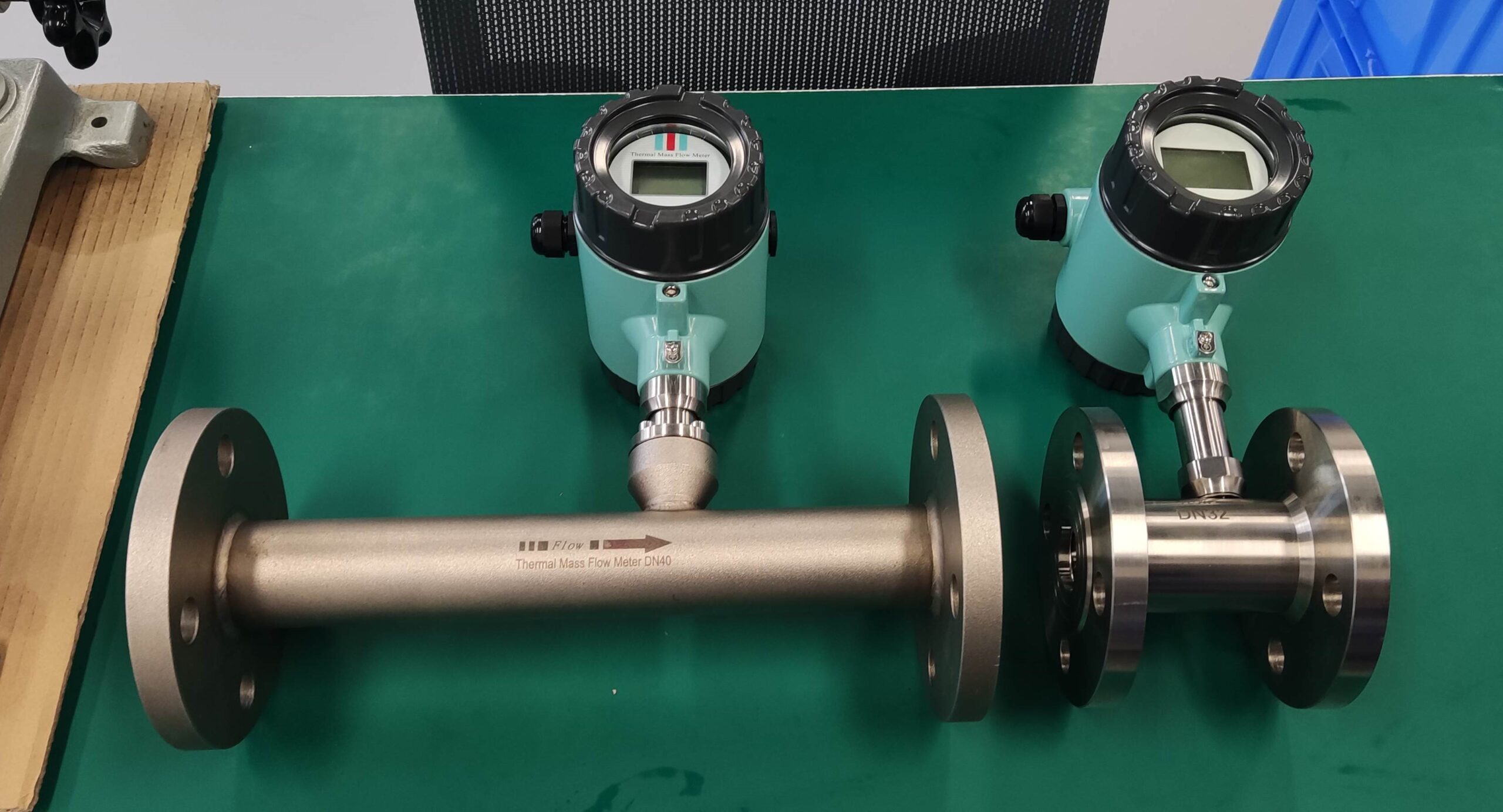

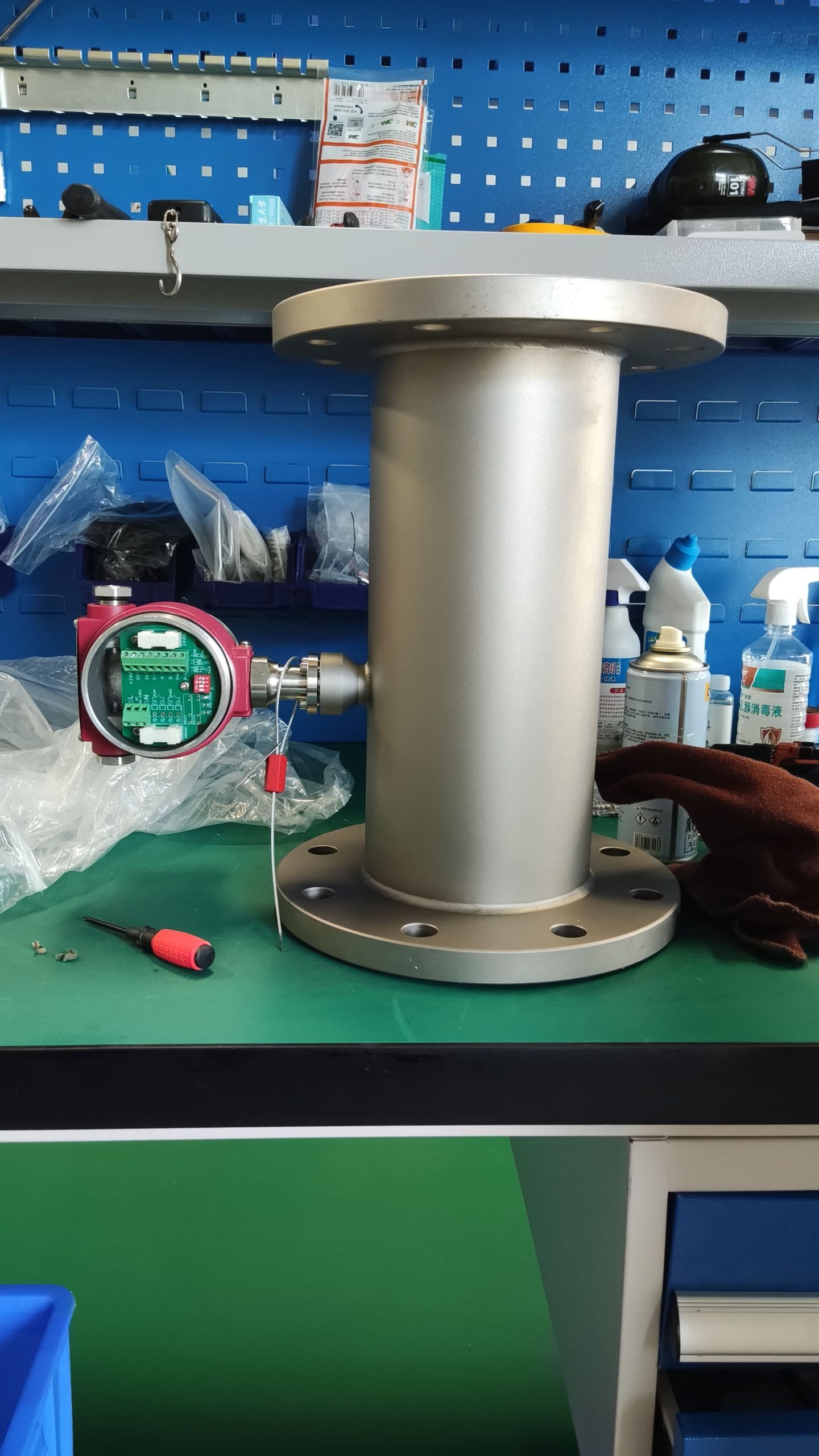

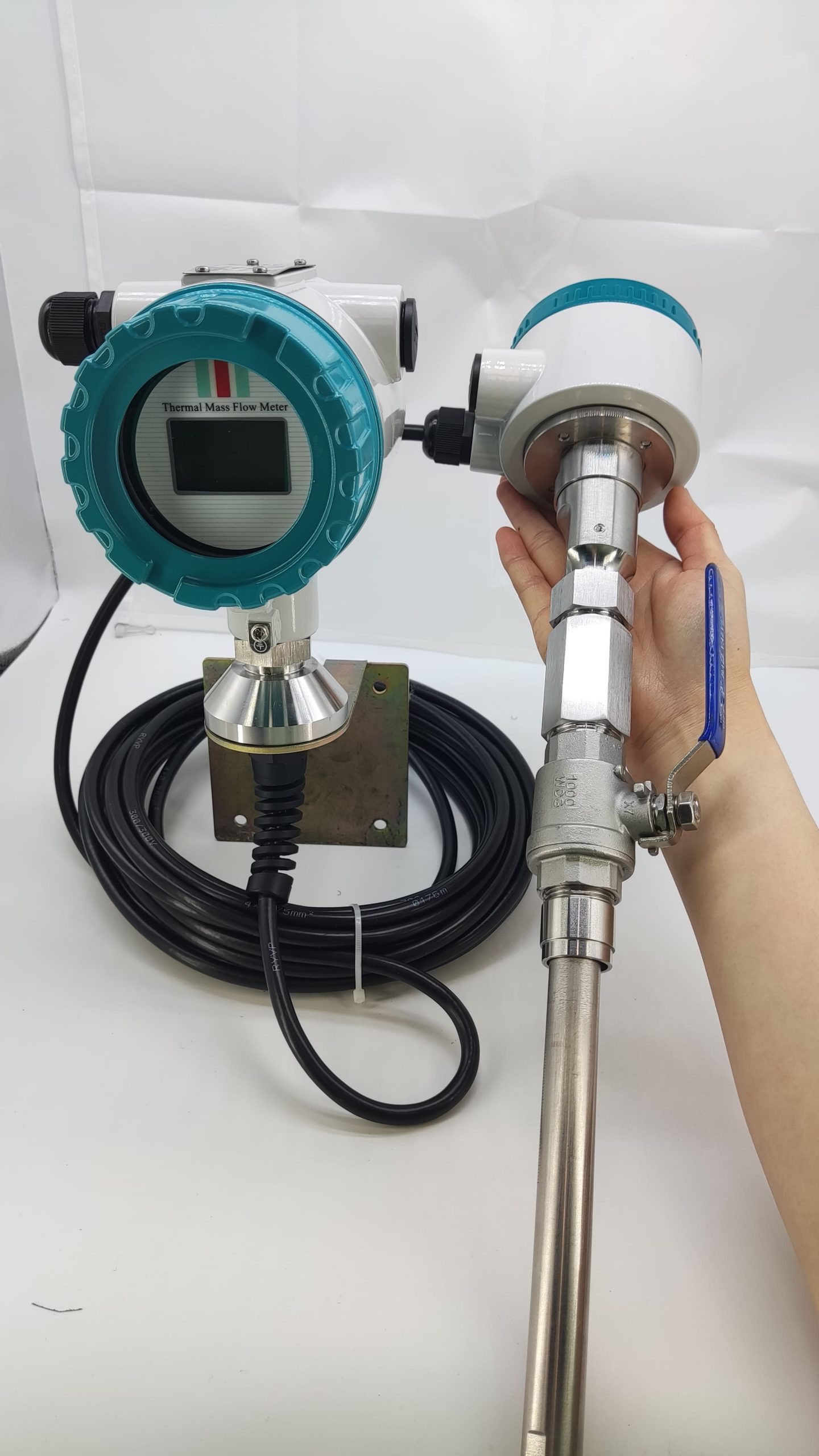

5. pay attention to the installation, the gas mass flow meter/controller installation to keep the installation surface level, but not particularly sensitive to the position, can be installed at any position, non-horizontal installation such as zero offset, can be adjusted after zero work. If the user indicates the installation position when ordering, our company can be calibrated according to this after the factory.

6. Pay attention to the working pressure difference, pay special attention to the pressure of the working medium for the instrument, and pay attention to keeping the working pressure difference at both ends of the instrument in and out of the gas within the palliative range. Especially when working under high pressure, the pressure difference is too large, and the flow rate will not be able to be closed or reduced. When using a large flow meter, it is necessary to pay attention to properly thicken the pipeline and reduce the internal resistance of the air source. If the working pressure difference is less than the required value, the flow may not reach the full scale value.