Precautions for installation and commissioning of thermal gas mass flowmeter in the early stage

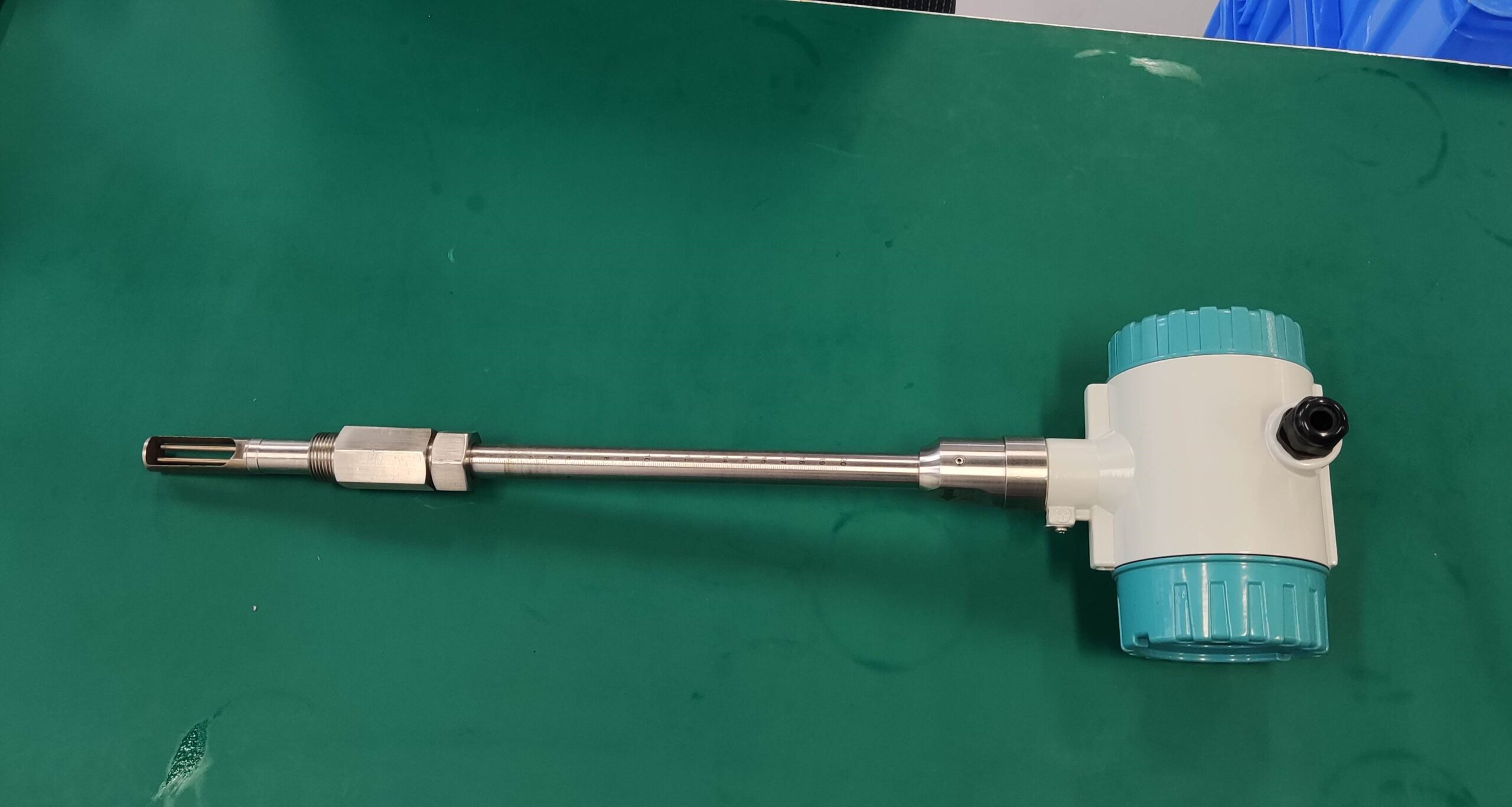

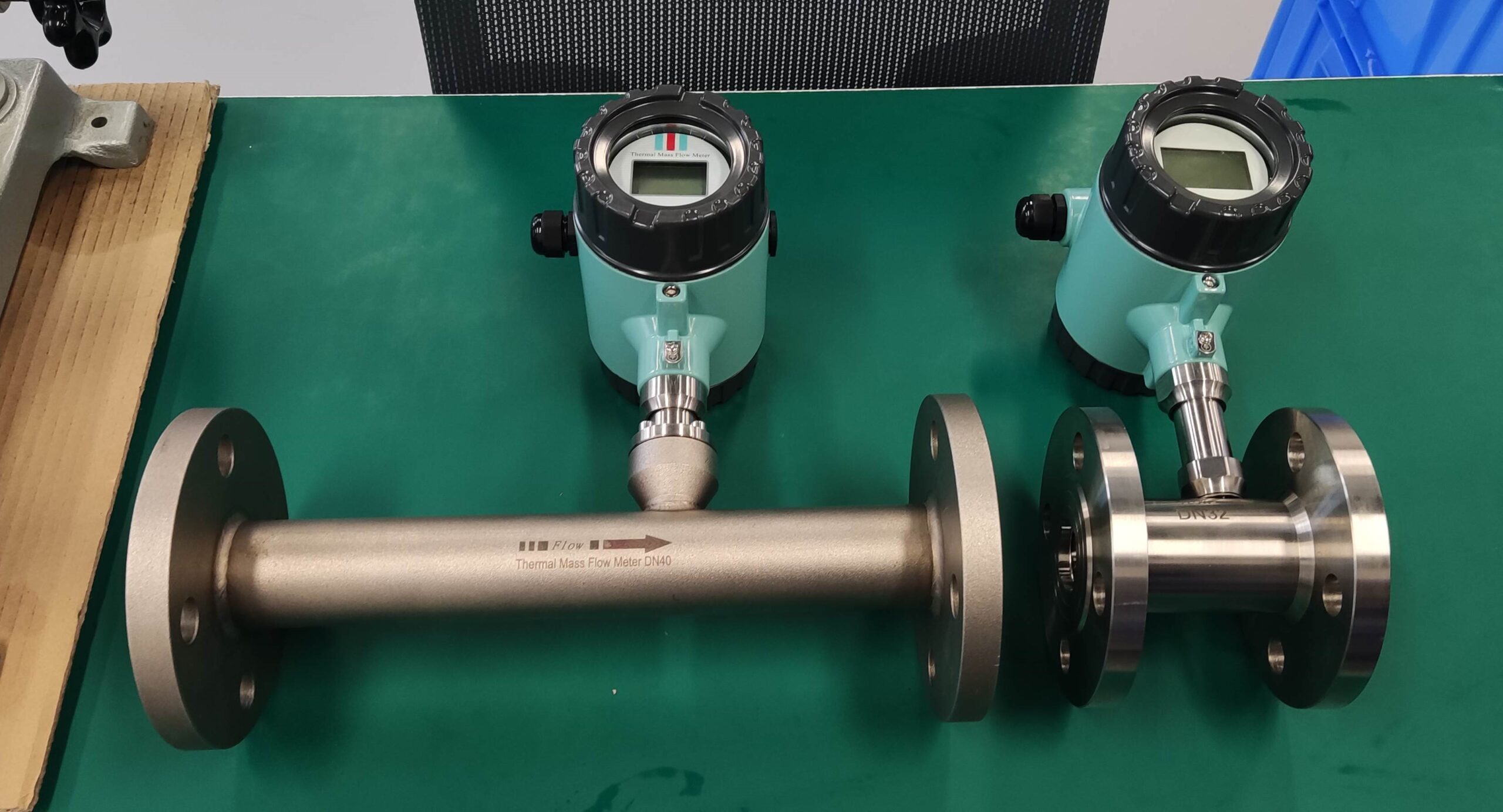

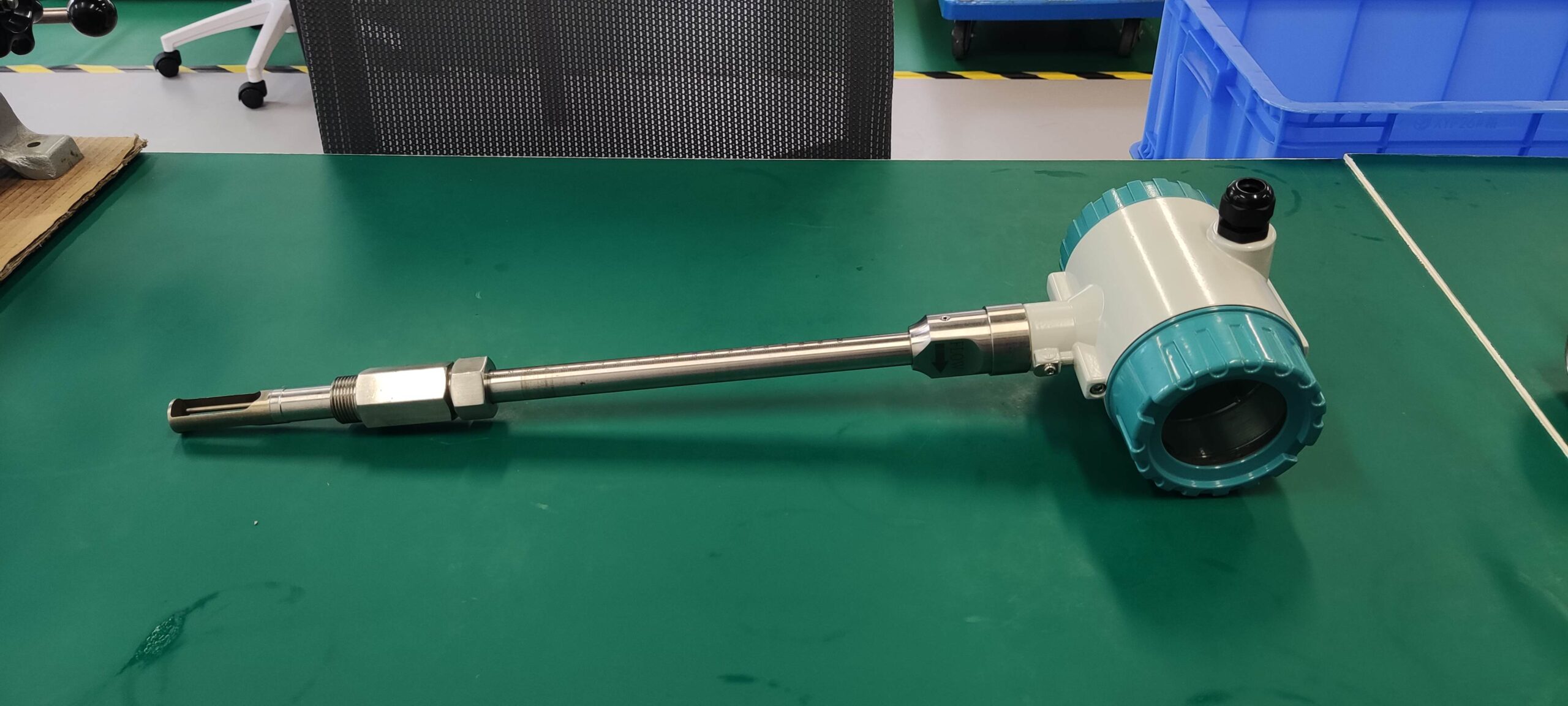

The thermal gas mass flowmeter is an instrument for measuring fluid flow by using the principle of heat conduction. The instrument uses constant temperature difference method to accurately measure the gas mass flow.

The thermal gas mass flowmeter has the advantages of small size, high digitization, easy installation, wide range ratio and accurate measurement. Suitable for all kinds of single or mixed gas flow measurement. No matter how good the flowmeter is, if the early installation is not in place, it is difficult to ensure the normal operation of the later period. Today we mainly talk about the installation and commissioning of thermal gas mass flowmeters.

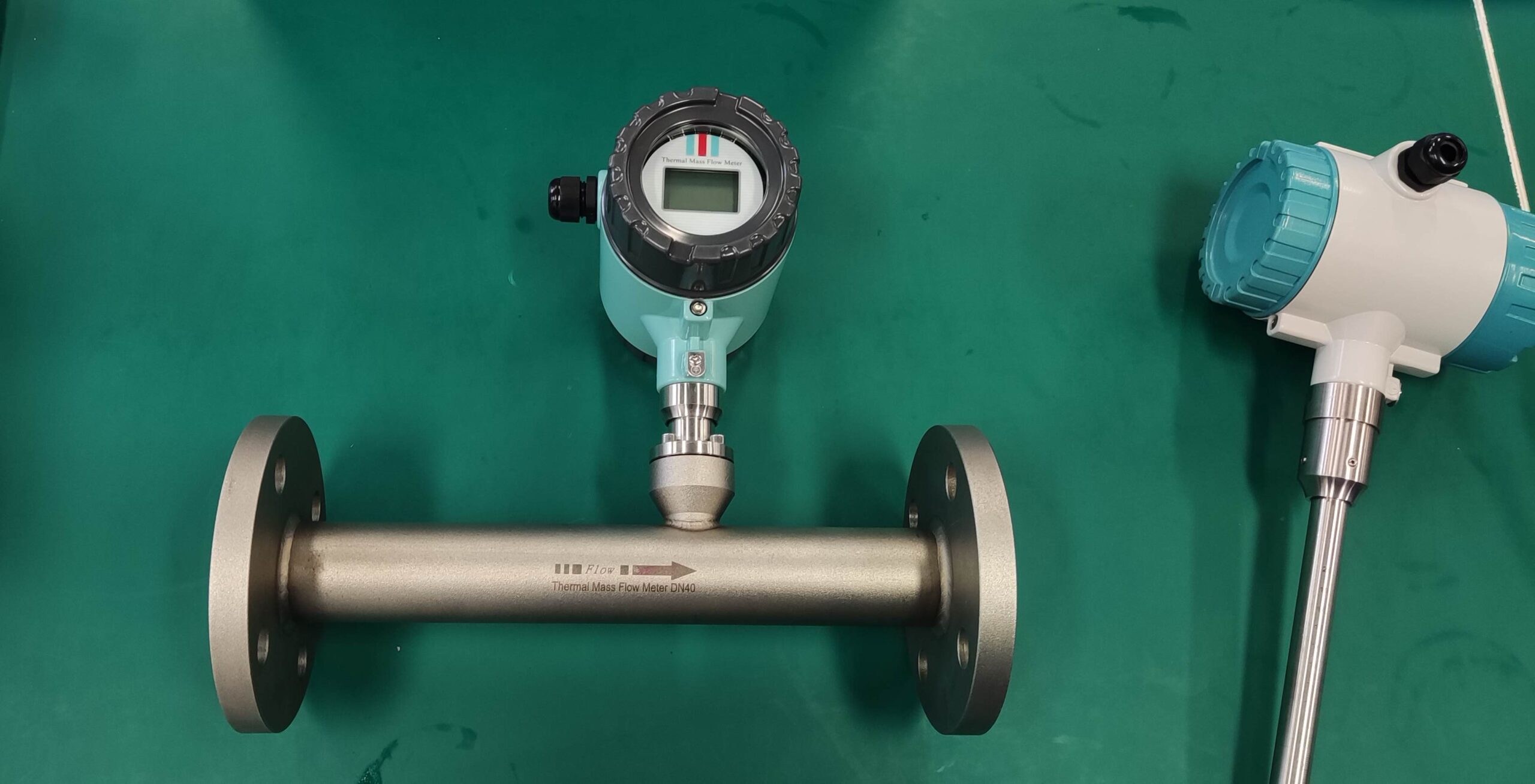

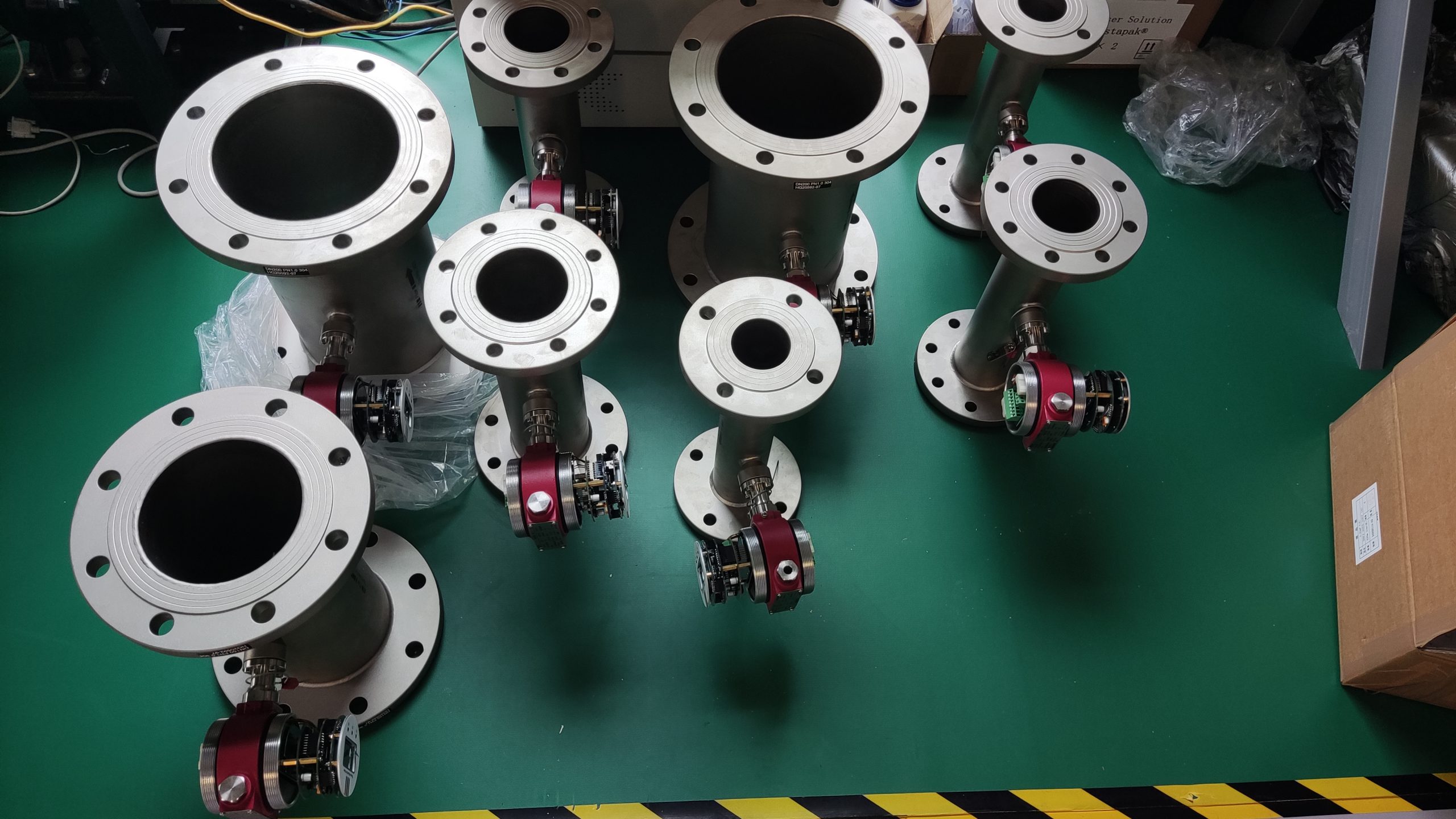

1, straight pipe section requirements

During installation, the upstream straight pipe section of the flowmeter is required to be greater than 20D, and the downstream straight pipe section is 10D.

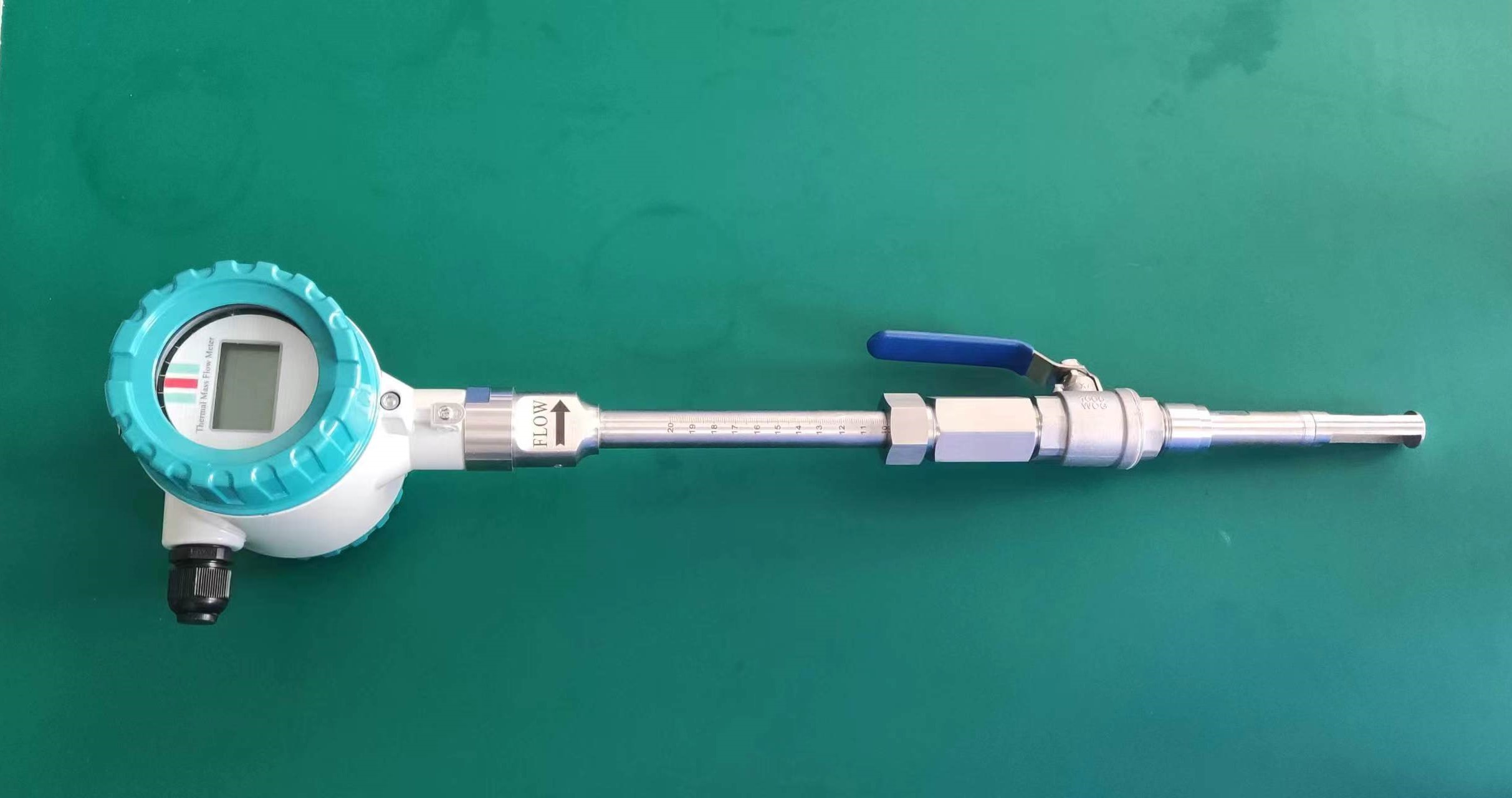

2. Confirm the direction of flow

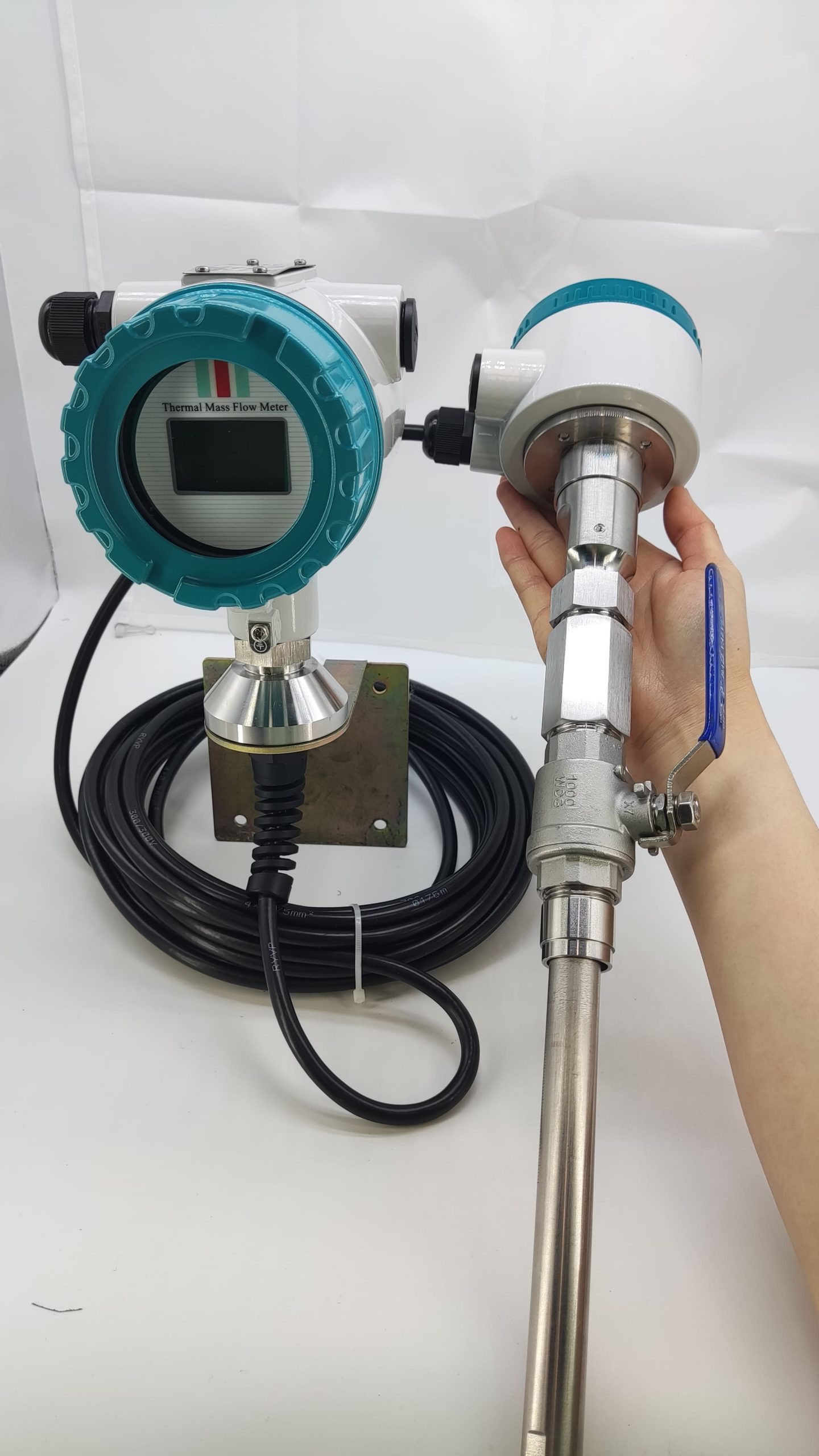

There is a small plane at the end of the flow element near the package, and there is an arrow indicating the flow direction of the fluid on this small plane. When installing, it should be noted that the small plane marked with the flow direction of the flow direction of the process medium is parallel to the direction of the flow direction of the flow direction of the flow direction of the process medium.

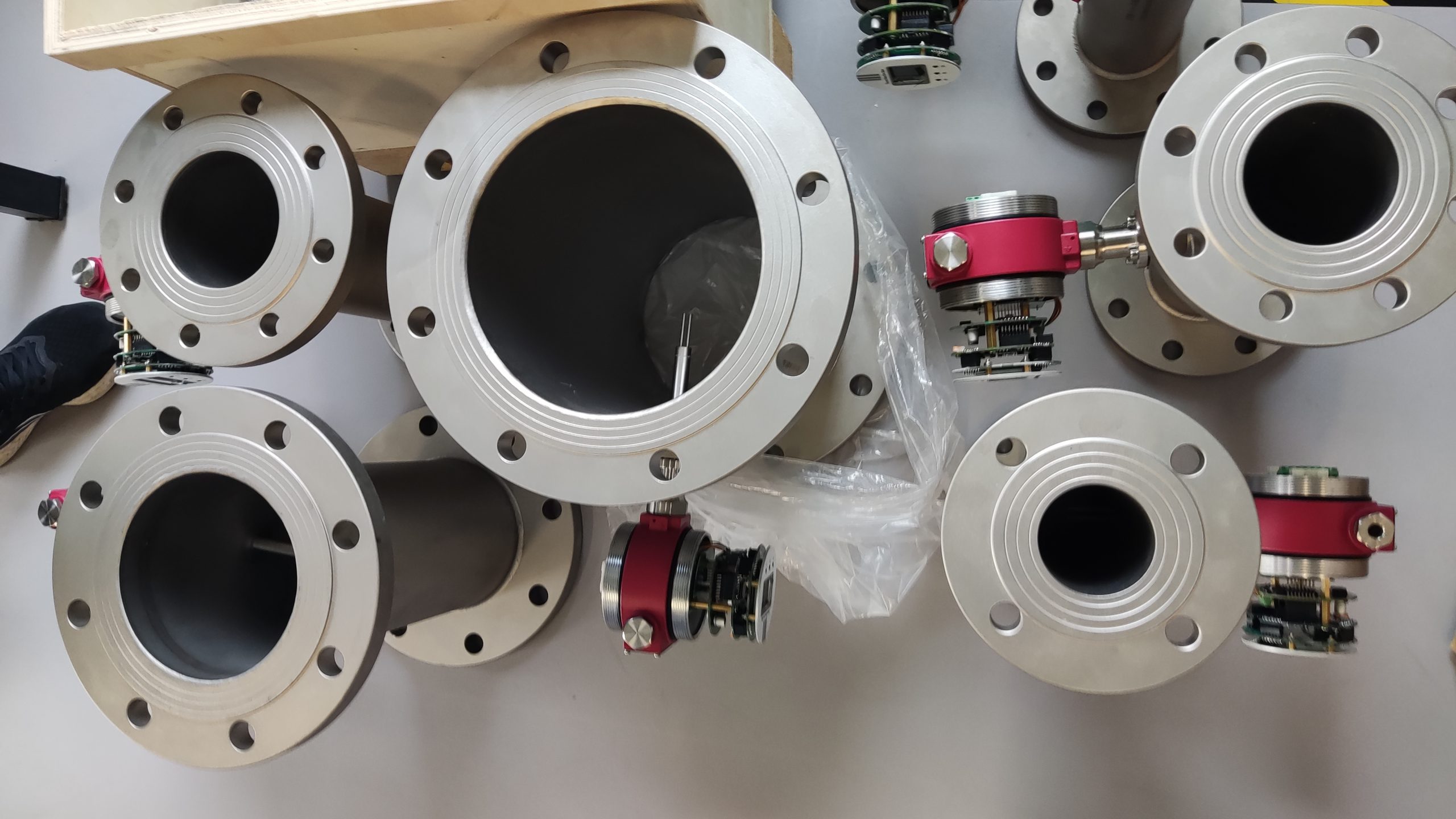

3. Confirm that the series number of the flow element and the electronic circuit part is consistent

The flow element and the electronic part are matched, if the series number does not match, it will lead to no reading, and special attention should be paid to the initial installation.

4. Avoid installing the sensor on the vibrating pipeline.

5, flowmeter output data and DCS operation station display data measurement unit to be unified.

6, flowmeter output data calibration and DCS control system to accept data calibration to be consistent.