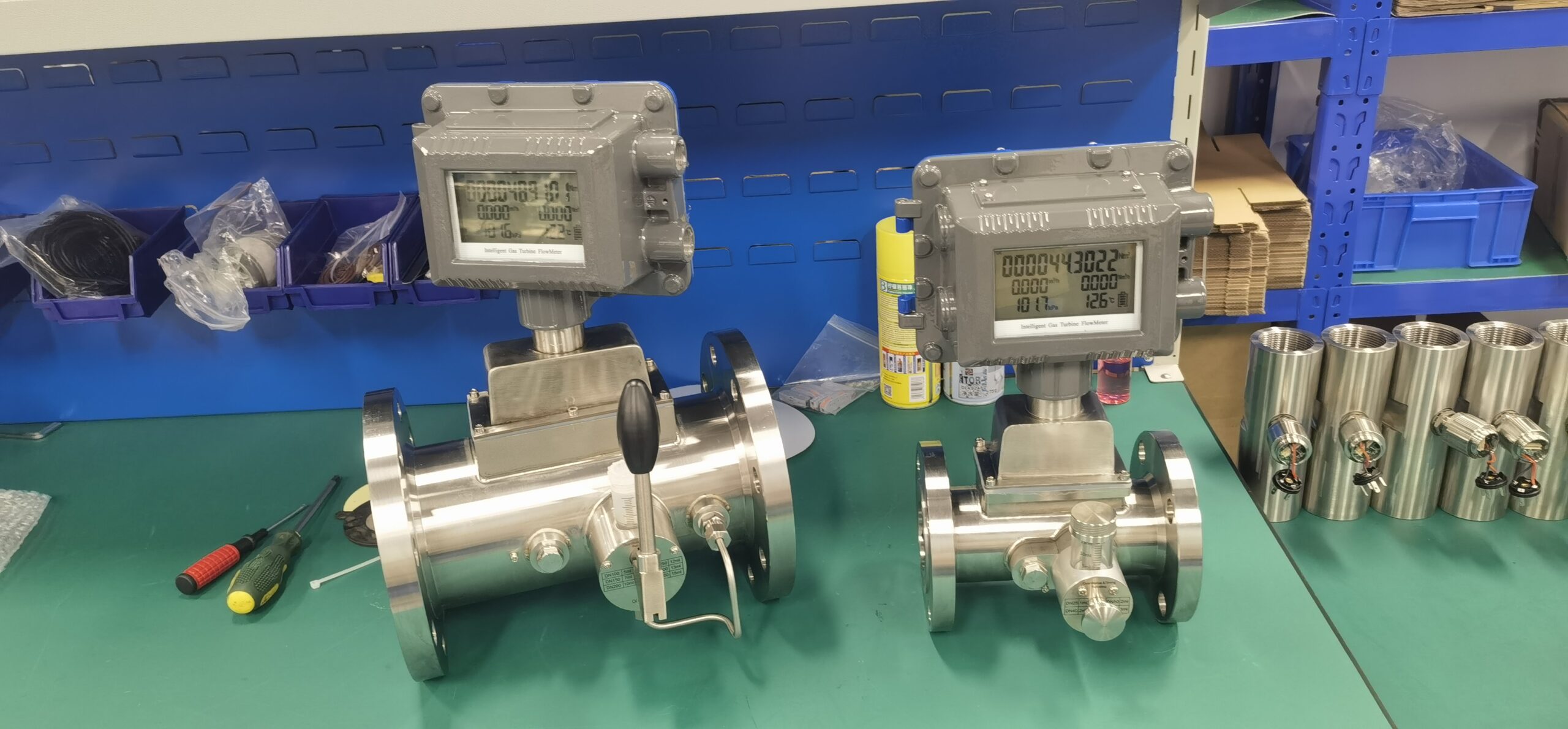

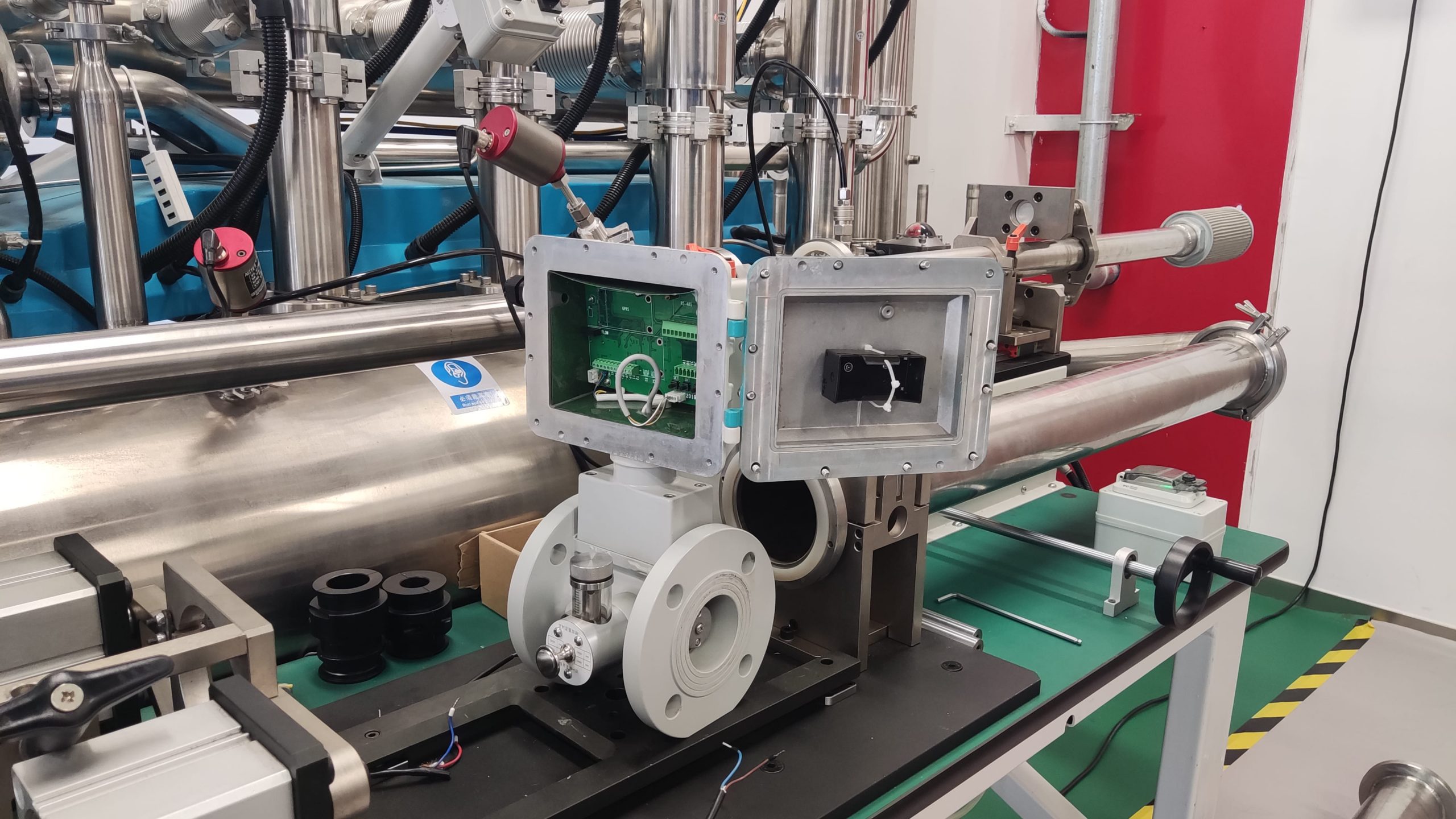

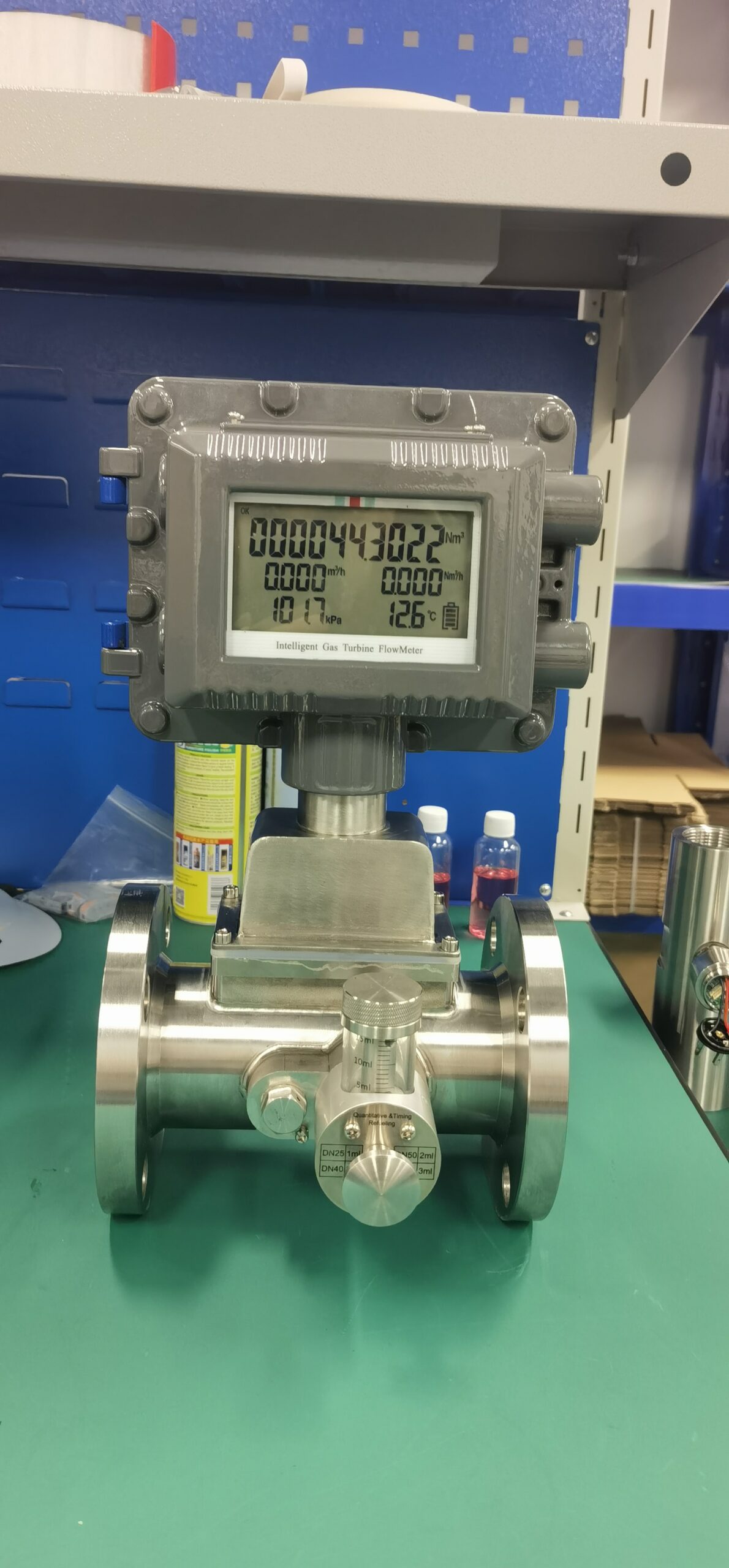

Overall installation requirements for temperature and pressure compensated gas turbine flow meters

There are many things to pay attention to in the installation of the temperature and pressure compensation gas turbine flowmeter, such as: the need for good grounding, the need to install filters during installation and the requirements of the installation environment, etc., only we really understand its installation precautions, can effectively ensure the measurement accuracy and service life of the gas turbine flowmeter.

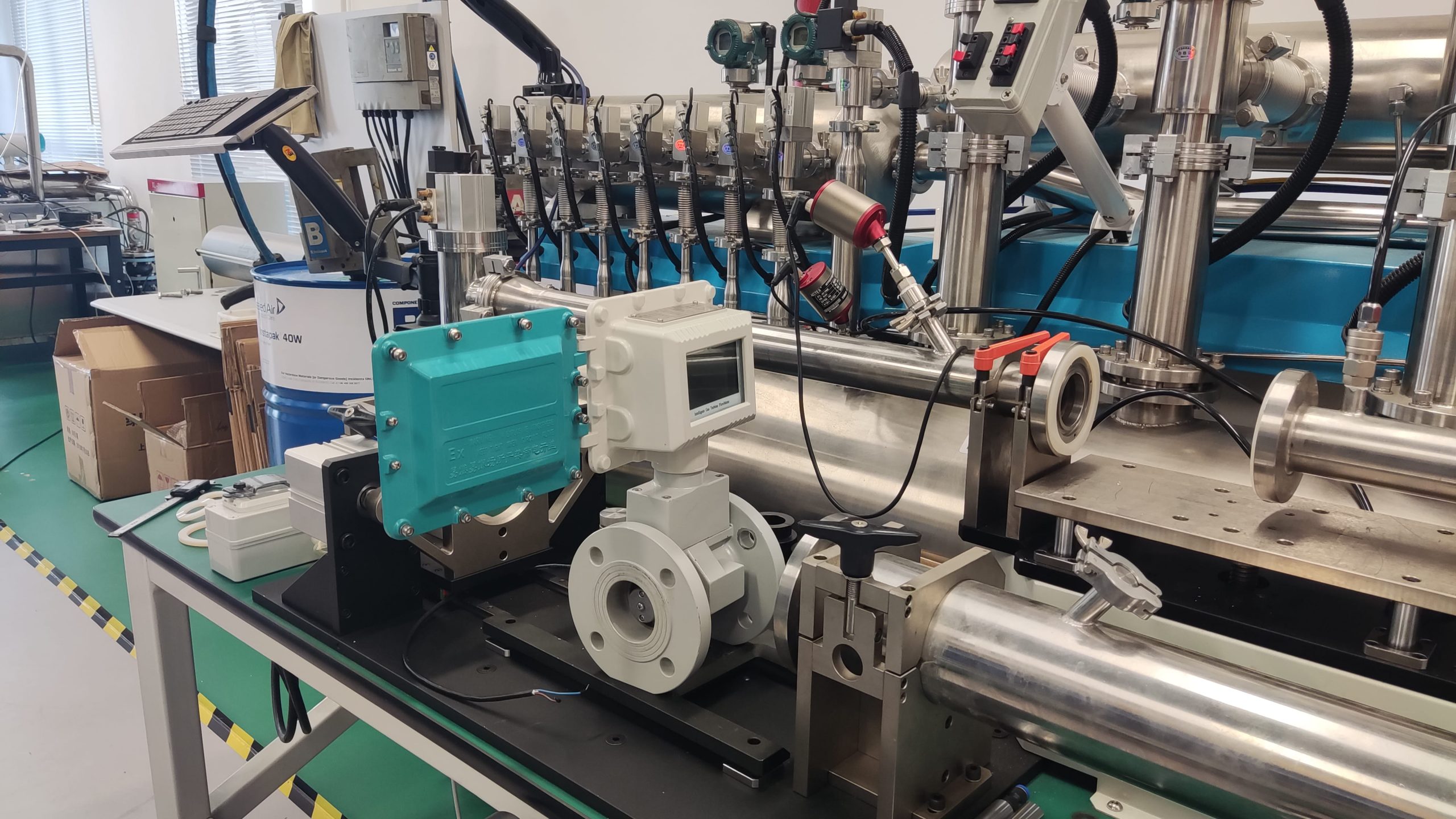

The overall installation requirements of the temperature and pressure compensation gas turbine flowmeter, the requirements for the external environment: installed indoors, it must be required to take sunscreen and rainproof measures when installed outdoors, so as not to affect the service life.

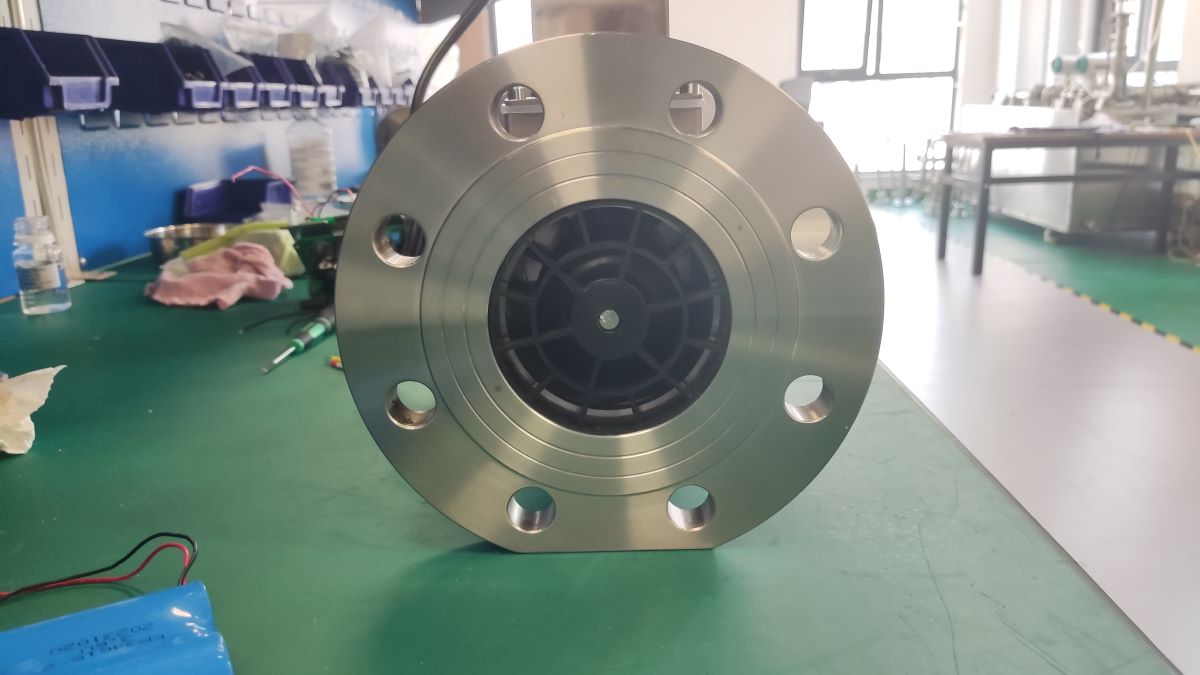

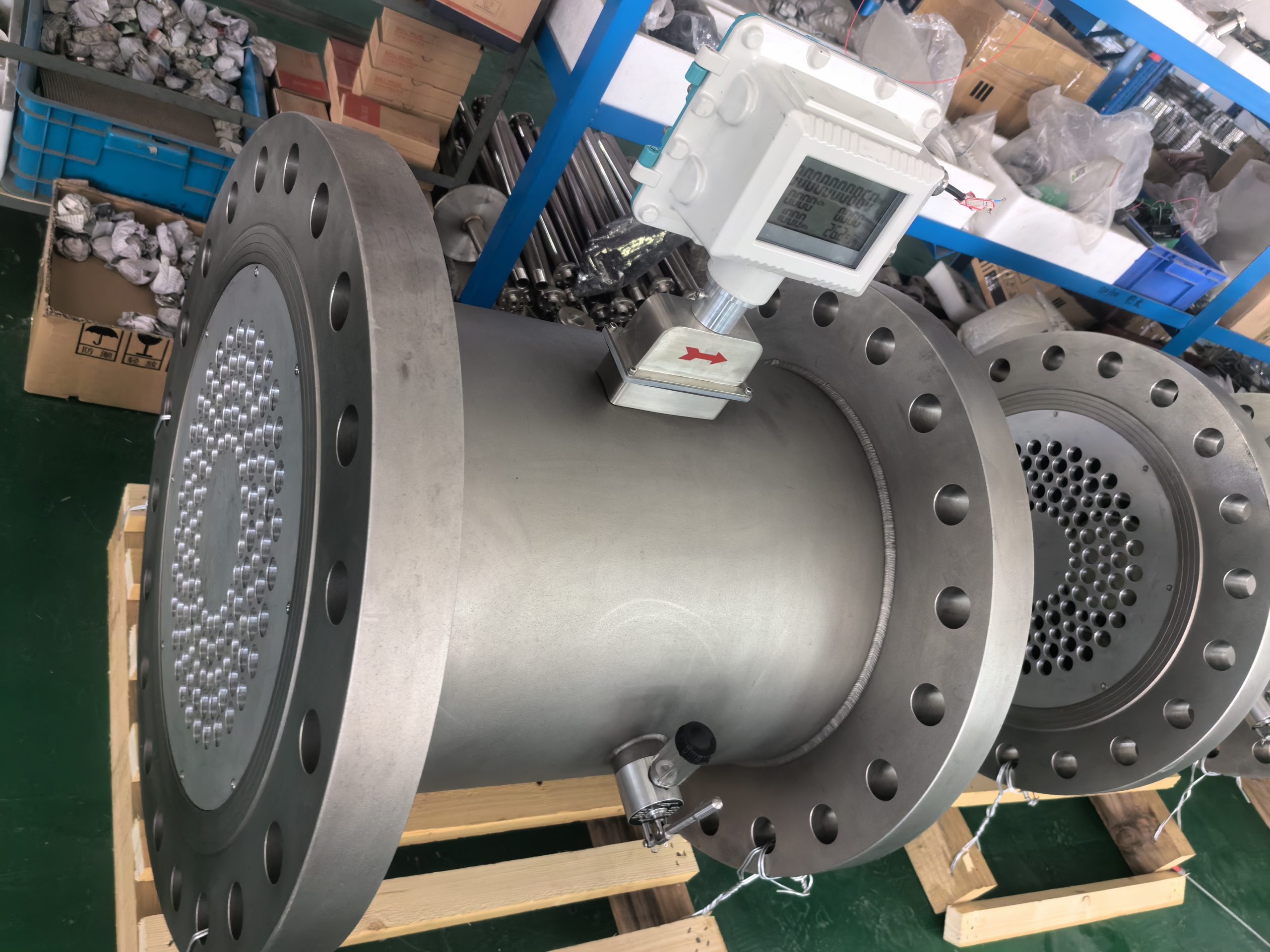

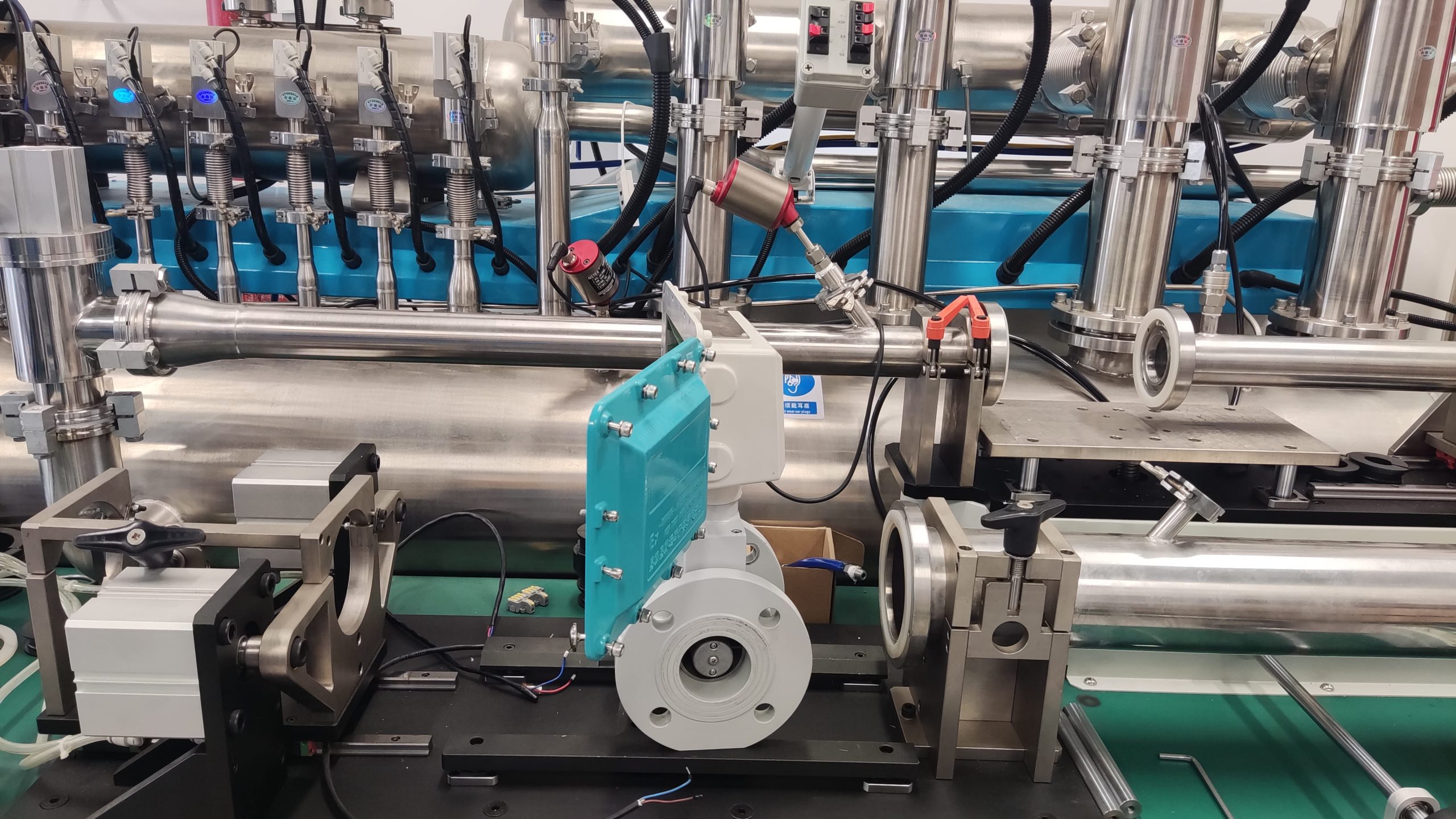

The overall installation requirements of the temperature and pressure compensation gas turbine flowmeter, the requirements for the external environment: installed indoors, it must be required to take sunscreen and rainproof measures when installed outdoors, so as not to affect the service life. Requirements for impurities in the medium: In order to ensure the service life of the temperature and pressure compensated gas turbine flowmeter, a filter should be installed in front of its straight pipe section.

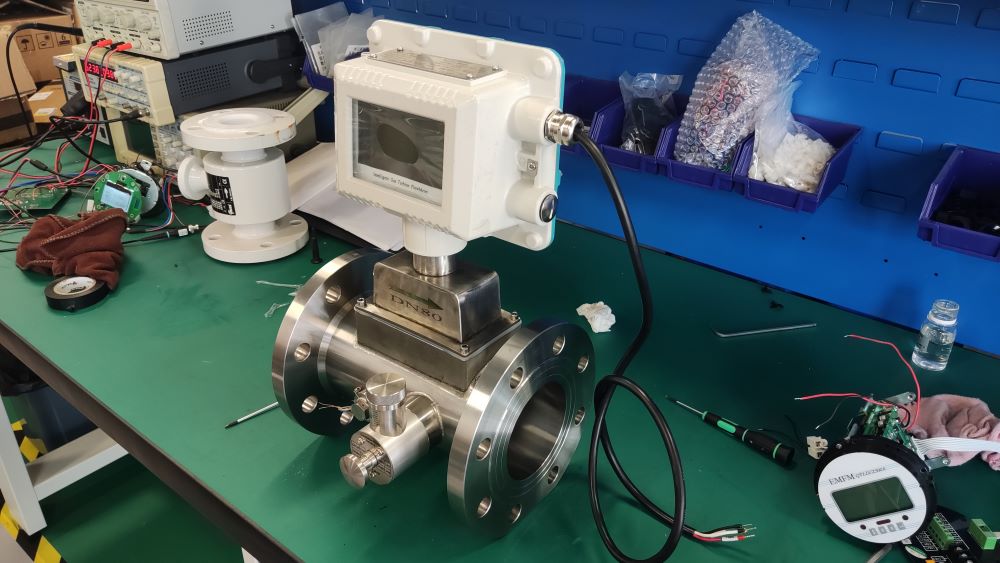

Installation location: It should be installed in a place that is easy to maintain and free from strong electromagnetic interference and thermal radiation.

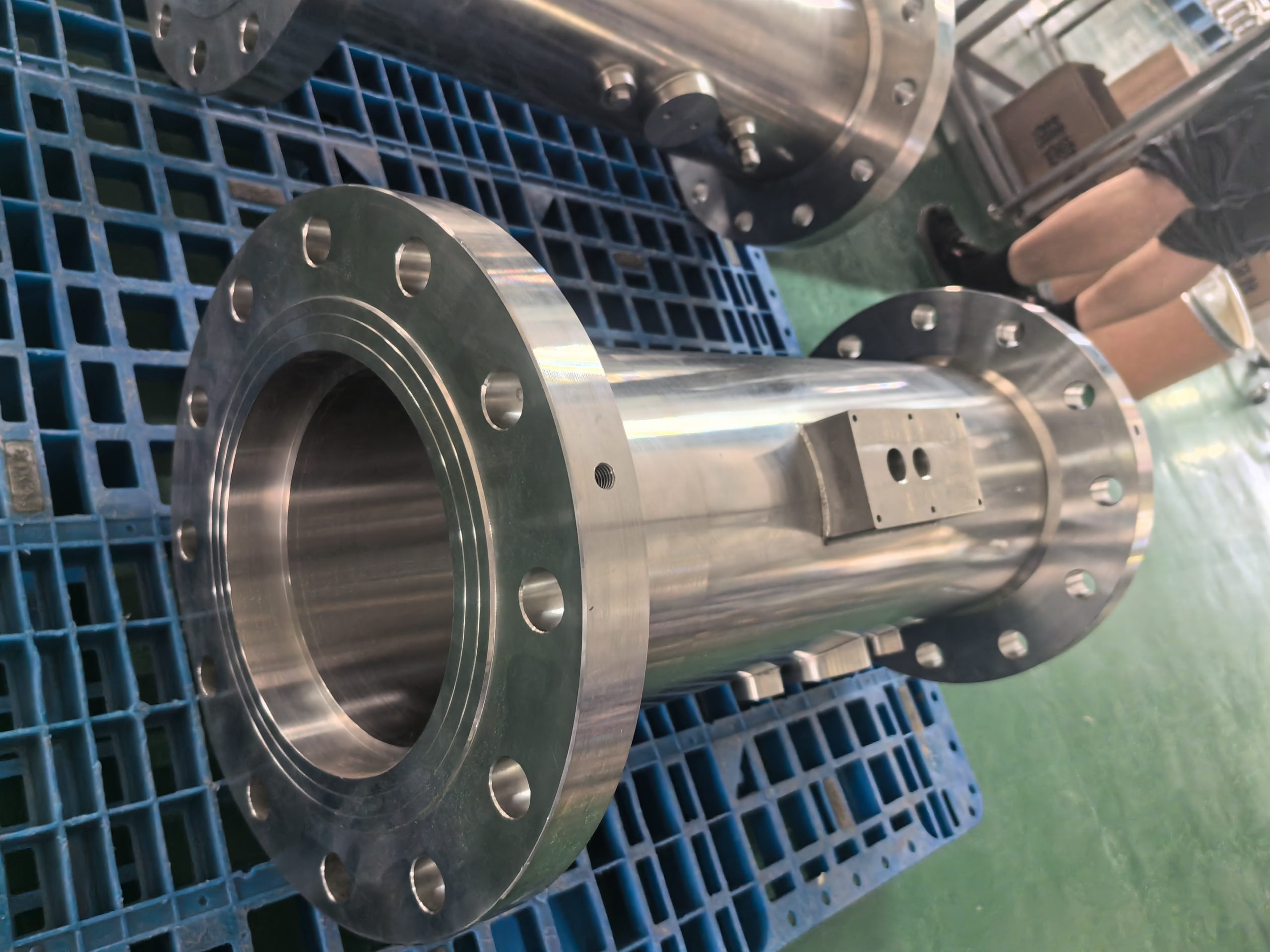

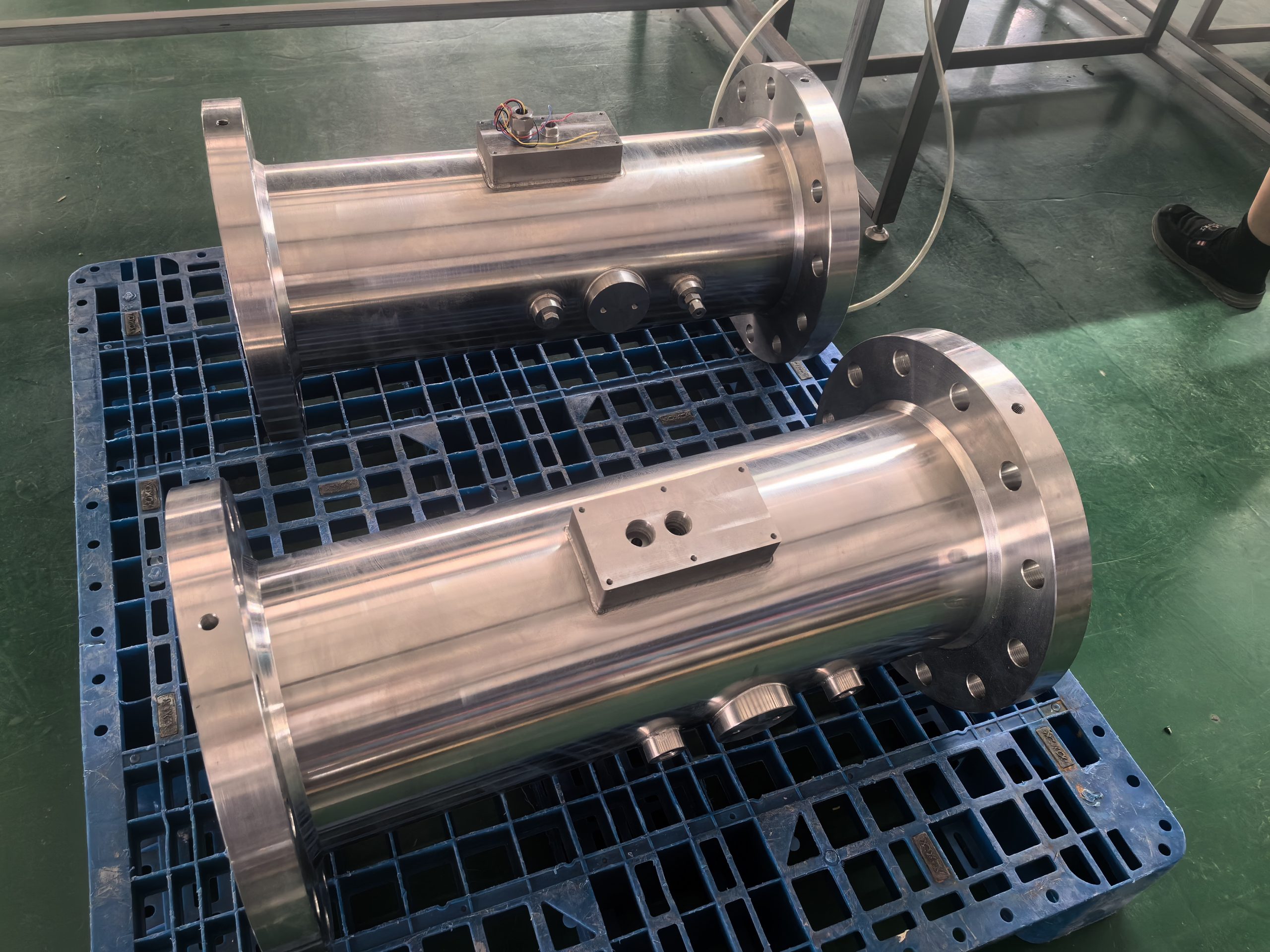

Installation welding requirements:

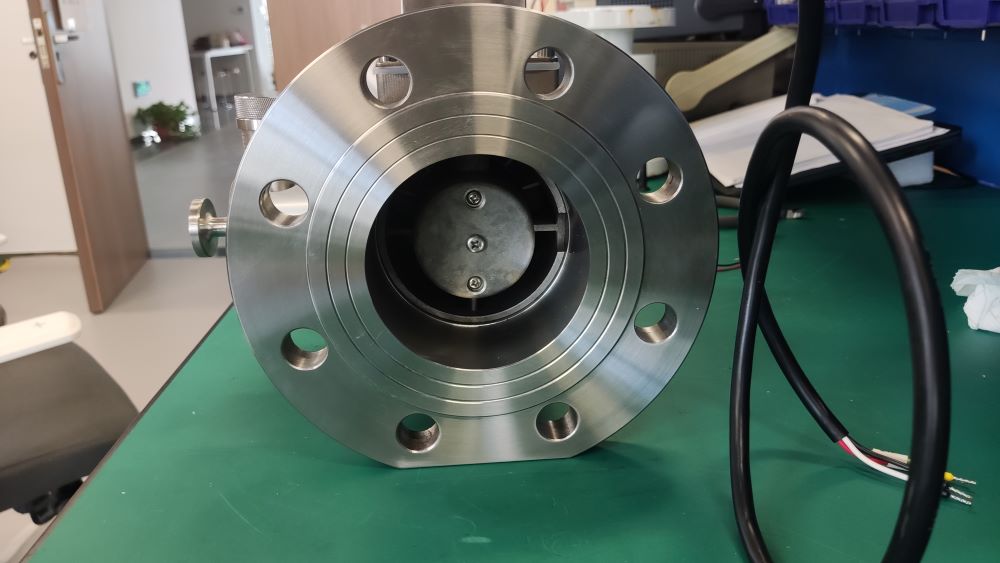

a. The user configures another pair of standard flanges to be welded on the front and rear pipes. Welding of gas turbine flowmeters with temperature and pressure compensation is never allowed.

b. Before installing the temperature and pressure compensated gas turbine flowmeter, the welding slag and other dirt in the pipeline should be strictly removed, and the pipe with equal diameter (or side channel) should be replaced by the temperature and pressure compensated gas turbine flowmeter to purge the pipeline. To ensure that the temperature and pressure compensation gas turbine flowmeter is not damaged during use. When installing temperature and pressure compensated gas turbine flow timing, the gasket between flanges should not be concave into the pipeline.

Grounding requirements: The flowmeter should be reliably grounded and cannot share the installation requirements of the explosion-proof temperature and pressure compensation gas turbine flowmeter with the ground wire of the strong electric system. For safe and normal use, it is necessary to review whether the use environment of the explosion-proof temperature and pressure compensation gas turbine flowmeter is consistent with the user’s explosion-proof requirements, and the installation and use process should strictly comply with the national explosion-proof product requirements. The user shall not change the connection mode of the explosion-proof system by himself, and shall not open the front and back cover and pressure inlet of the temperature and pressure compensation gas turbine flowmeter at will.