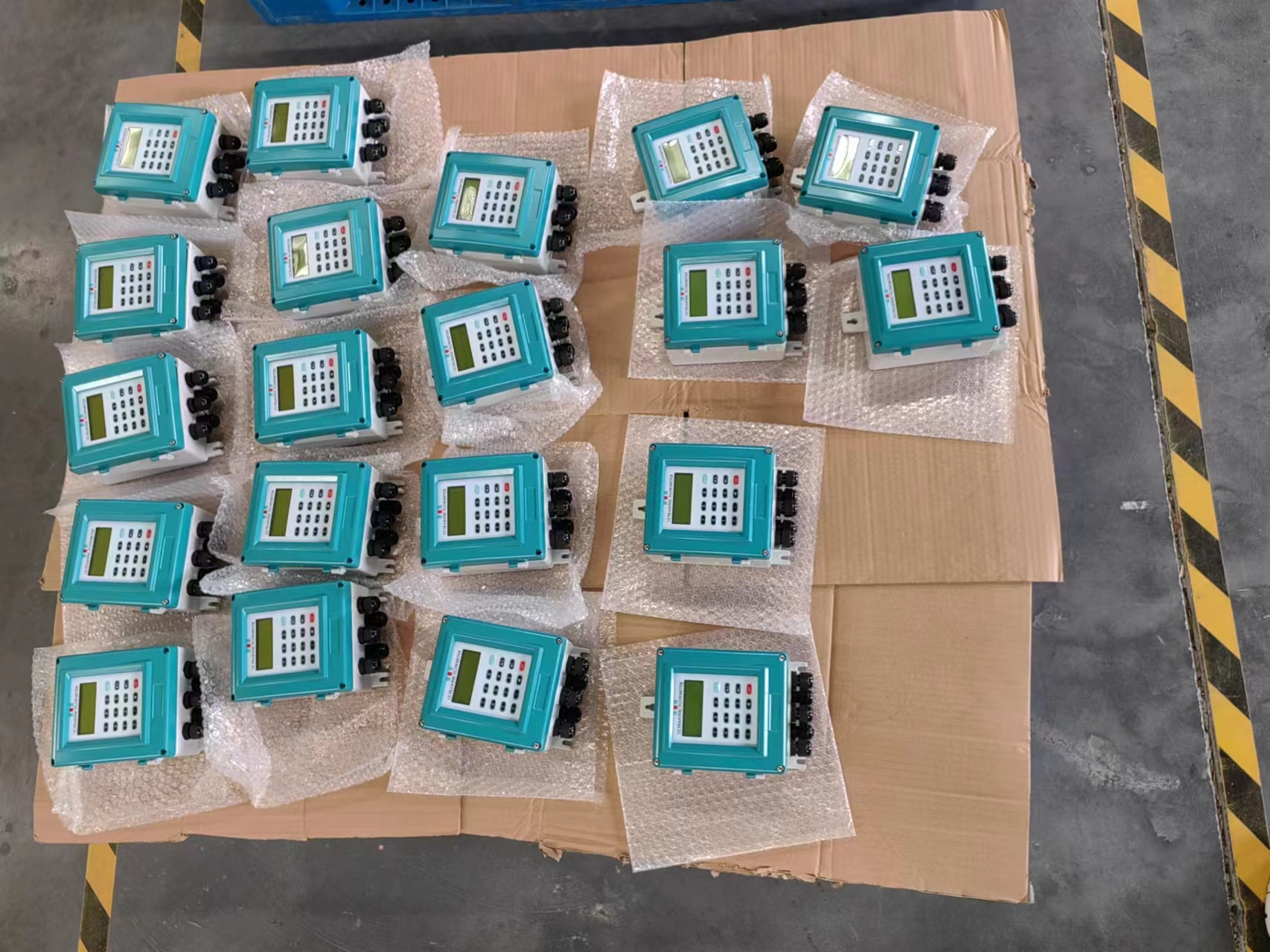

on Sale OEM Service Ultrasonic Water Flow Meter Price Ultrasonic Flowmeter

Correction methods for ultrasonic flowmeters are essential to ensure accurate and reliable measurements. Here are some specific correction methods commonly used in practice:

Temperature and Pressure Compensation:

Method: Ultrasonic flowmeters often provide compensation algorithms for changes in temperature and pressure. These corrections adjust the speed of sound in the fluid, accounting for variations.

Implementation: Ensure that the flowmeter is configured with the correct fluid properties and use built-in compensation features.

Transducer Alignment and Installation:

Method: Proper alignment and installation of transducers are crucial for accurate measurements. Misalignment can introduce errors in the time-of-flight calculations.

Implementation: Follow manufacturer guidelines for installation, including correct transducer alignment and coupling. Regularly inspect and adjust if necessary.

Signal Quality Improvement:

Method: Enhancing the quality of the ultrasonic signal helps mitigate signal loss or weak signal issues.

Implementation: Clean transducer surfaces regularly to remove deposits, air bubbles, or impurities. Ensure there are no obstacles in the fluid path and use signal filtering techniques to minimize interference.

Flow Profile Correction:

Method: Ultrasonic flowmeters assume a certain flow profile for accurate measurements. Corrections may be applied if the actual flow profile deviates from the assumed profile.

Implementation: Use flow conditioners or straight pipe runs upstream and downstream of the flowmeter to achieve a more uniform flow profile.

Zero Offset Correction:

Method: Calibration may introduce zero offset errors. This correction compensates for any deviation from the true zero flow condition.

Implementation: Periodically check and adjust the zero offset according to the manufacturer’s recommendations.

Density Compensation:

Method: In some applications, variations in fluid density can affect measurement accuracy. Density compensation corrects for changes in fluid density.

Implementation: Configure the flowmeter with the correct fluid density properties, and use compensation algorithms if provided.

Velocity Profile Correction:

Method: Correcting for variations in the velocity profile across the pipe diameter improves accuracy.

Implementation: Some flowmeters allow for the input of velocity profile information. Use this feature if available or install flow conditioners to achieve a more uniform profile.

Pipe Wall Thickness Correction:

Method: Correct for variations in pipe wall thickness, which can affect the propagation of ultrasonic signals.

Implementation: Input the correct pipe wall thickness into the flowmeter’s configuration. Some flowmeters may automatically compensate for this parameter.

Periodic Calibration:

Method: Regular calibration ensures ongoing accuracy by accounting for any drift or changes in the flowmeter’s performance.

Implementation: Follow the manufacturer’s recommended calibration schedule and procedures. Periodically validate the flowmeter against a reference standard.