Notes and requirements for thermal gas mass flow meter options

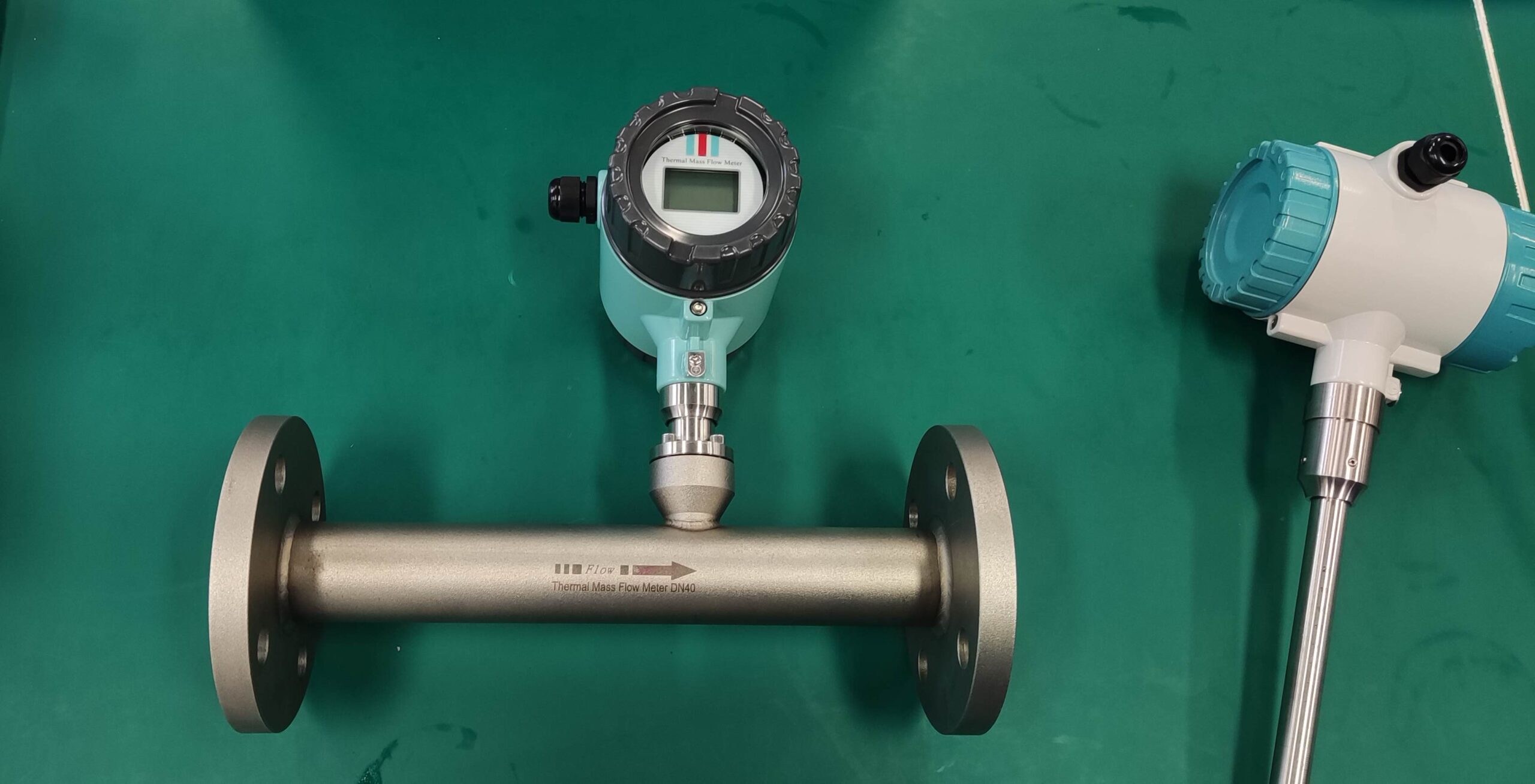

Thermal gas mass flow meter is used to measure and control the gas mass flow meter, different from other gas flow meters, do not need to carry out pressure and temperature correction, directly measure the gas mass flow.

1. Application field:

a. Semiconductor manufacturing industry;

b. Analytical instruments and equipment industry;

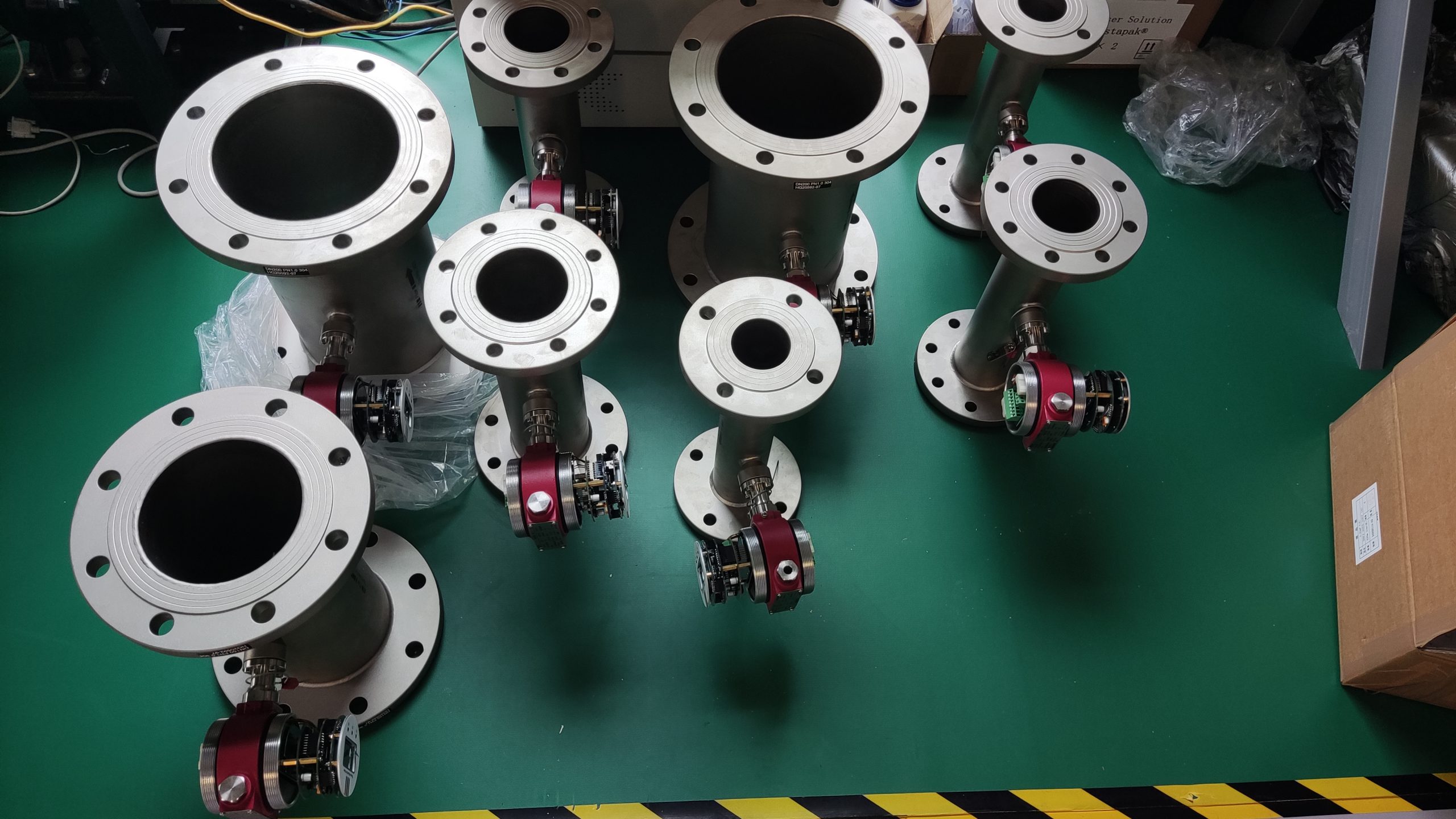

c. Various forms of vacuum coating equipment;

d. Environmental testing and analysis equipment;

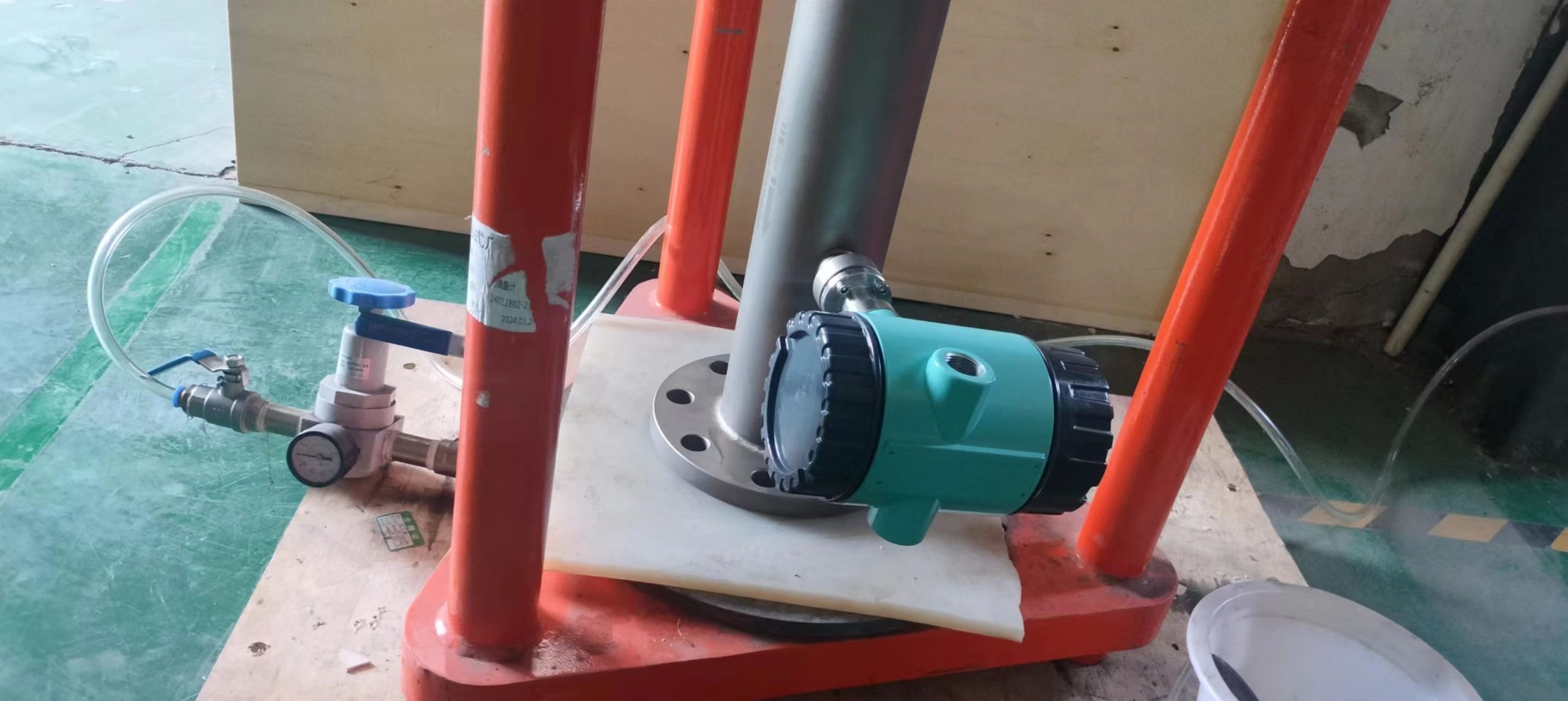

e. Chemical, petrochemical, food, metallurgy, optical fiber smelting and other industries;

f. Special material surface treatment device and combustion;

g. Mixed gas distribution system and leak detection system, etc.

2. When selecting a hot gas mass flowmeter, you need to pay attention to several aspects:

a. Passing medium. Thermal gas flowmeters are suitable for a variety of gases, including special gases and corrosive gases. Take corrosive gases as an example: When the corrosive gas passes through the flow meter, if the flow meter has not been specially treated, it will cause the failure of the sealing element and other aspects because of the characteristics of the corrosive gas, which affects the normal use of the flow meter, so the media with relevant characteristics need to pay special attention to the information such as sealing materials, such as all-metal seals, ammonia resistant rubber and other sealing materials. In addition, flammable gases such as hydrogen and methane need to pay attention to the explosion point problem caused by too high gas concentration.

b. Range range (or flow range). When selecting the flow meter, we must first determine the range of the required flow meter. Take the products of HORIBAMETRON as an example: the company’s products are calibrated with nitrogen (N2), such as conversion when using other gases, and the conversion coefficient between nitrogen and the gas is used to determine the calibrated flow rate when using non-nitrogen media.

c. Pressure range. The pressure range of the HORIBAMETRON flowmeter is 3MPa, and the pressure difference range is (0.05-0.3) MPa. Within 3MPa can be directly installed and used without any compensation; It should be noted that some industries need to work under high pressure, and it is necessary to determine whether the pressure range is satisfied.

d. Interface path. When selecting the interface, it is necessary to choose according to the pipeline condition, for now, it is mainly with 3mm ~ 10mm, 1/4 “Swagelok(or VCR), and the hose connector is mainly with 4mm ~ 10mm.

e. Supply voltage and control. For the HORIBAMETRON flowmeter, the supply voltage is ±15V and 24V. The control interface is available in 9-pin and 15-pin, and also in 9-hole and 15-hole.

f. Communication protocol. Compared with the digital flowmeter, many times it will involve the communication protocol problem, with MODBUS, Profibus, DeviceNet as the standard, pay attention to the protocol type when choosing. Note (Some industries can meet the requirements when selecting flow timing analog control).

g. For other related questions, please consult the relevant technical personnel of the manufacturer in detail.