Measurement principle and application of thermal gas mass flow meter

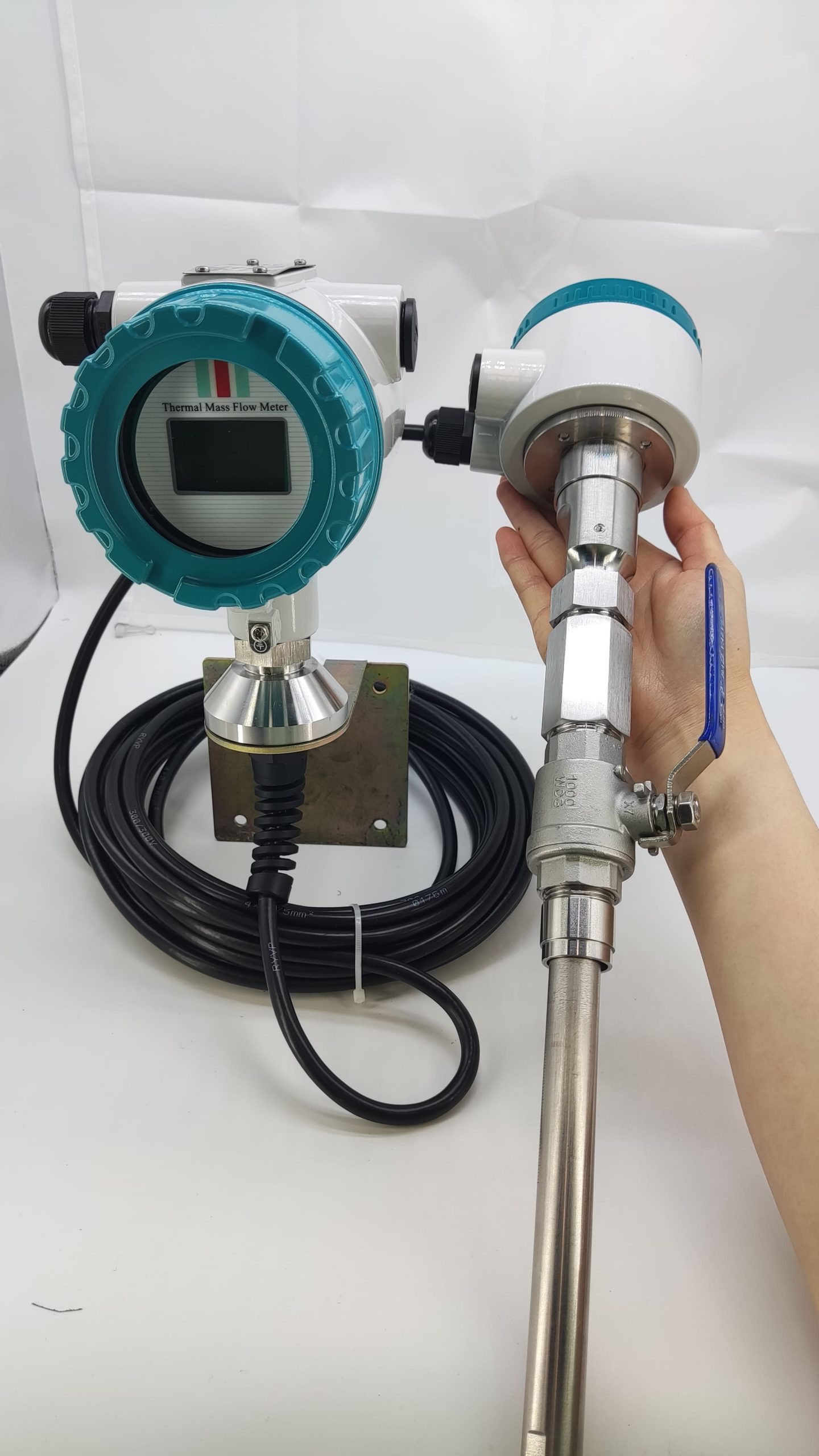

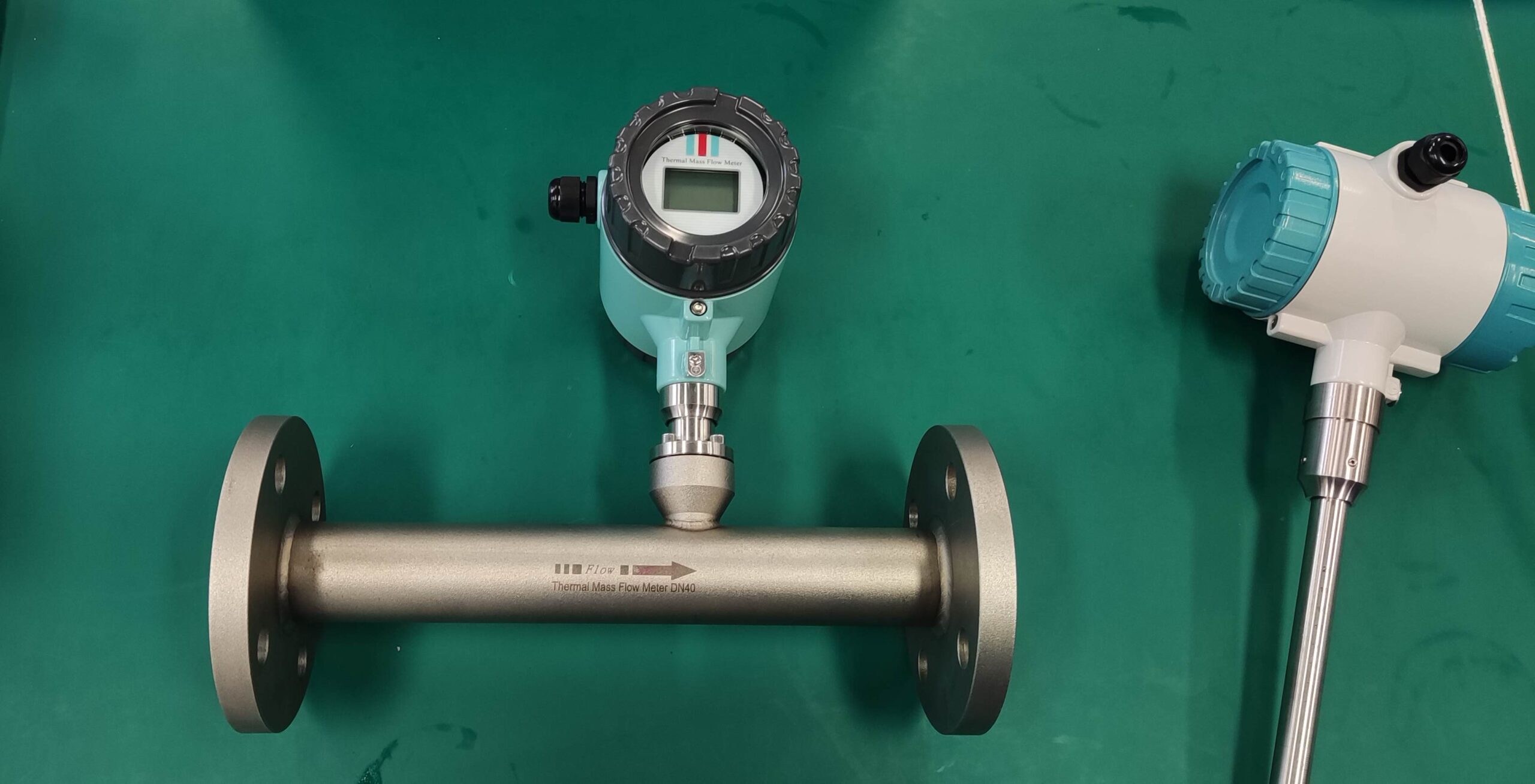

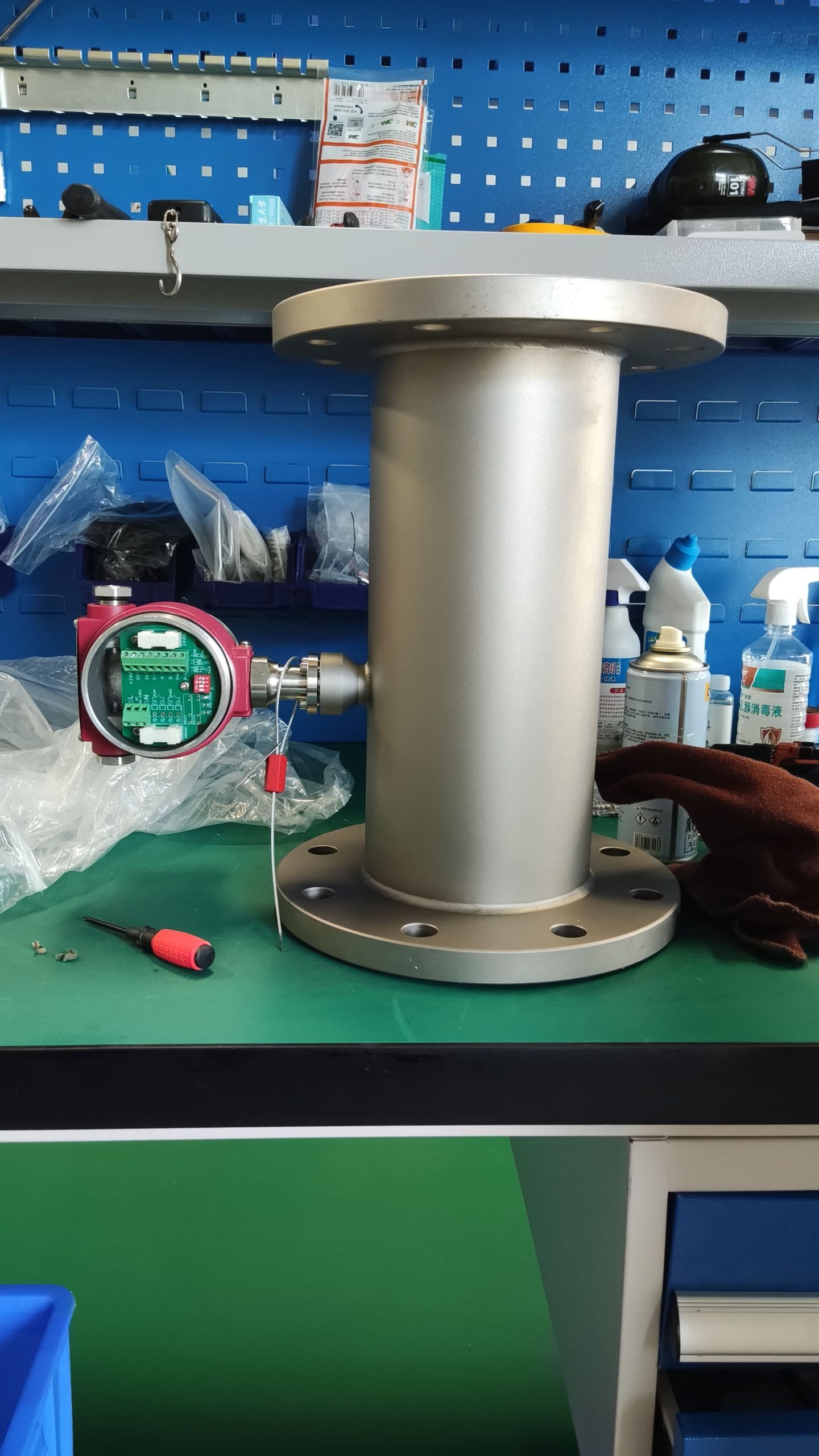

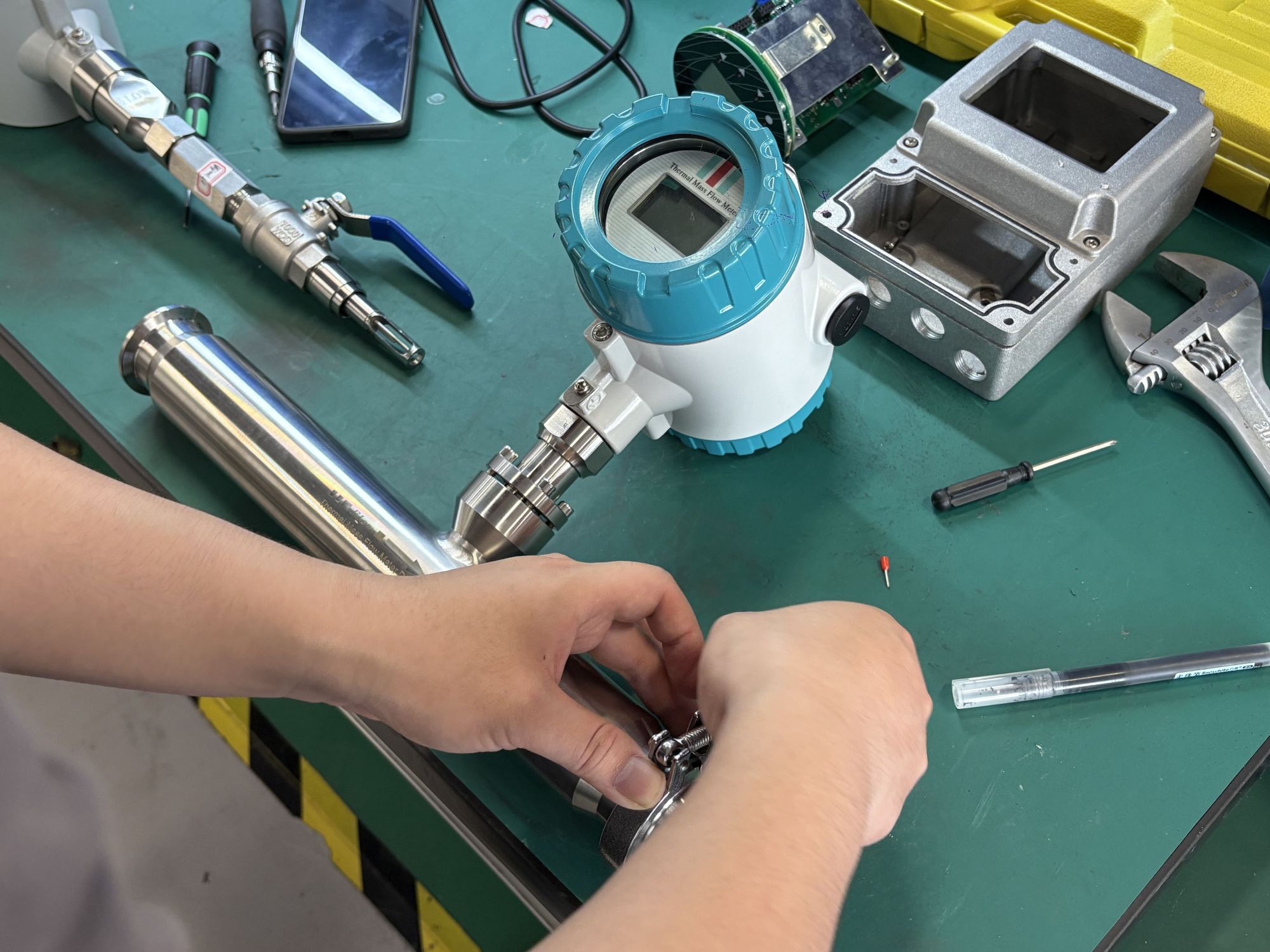

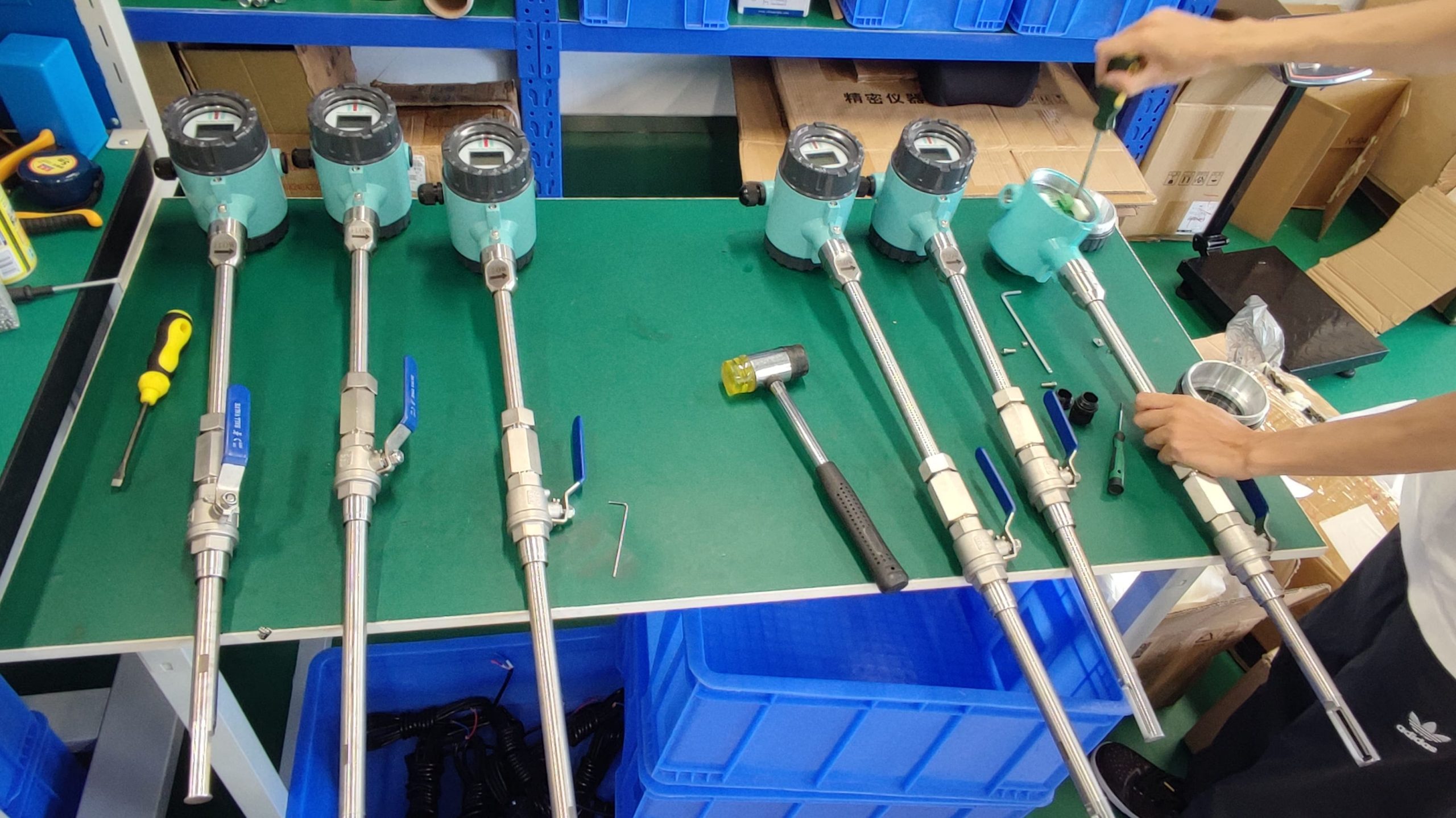

The thermal gas mass flowmeter is an instrument for measuring fluid flow by using the principle of heat conduction. The instrument uses constant temperature difference method to accurately measure the gas mass flow. The thermal gas mass flowmeter has the advantages of small size, high digitization, easy installation and accurate measurement.

1. Public works

Electricity, gas, water treatment of monitoring pipeline gas; Universal system; Methane; Gas; Natural gas; Liquefied gas; Boiler preheating air;

2, oil and gas industry energy exchange;

Filling gas recovery; Gas metering; Gas quality analysis; Leakage gas test; Natural gas measurement; Monitoring of flare gas;

3. Gas measurement in the gas distribution process of fuel systems in the power industry;

Measurement of various gases in boilers and auxiliary systems; Gas measurement in gas furnace; Hydrogen measurement; Measurement of primary air and secondary air of blast furnace in power plant;

4, chemical industry flue gas cycle monitoring;

Gas flow measurement in sampling system; Gas flow measurement of induced draft fan; Ammonia measurement in fertilizer plant; Battery factory various gas flow measurement;

5, metallurgy industry steel plant gas measurement;

Measurement of blast furnace gas in ironworks; Measurement of coke oven gas in coke plant; Measurement and control of heating furnace gas (blast furnace gas, coking gas, natural gas, etc.) in rolling mill; Control of hydrogen, oxygen, nitrogen and other gases in heat treatment quenching furnaces;

6. Measurement of gas in wastewater treatment system of pulp and paper industry;

Flue flow monitoring; Boiler recovery of secondary/tertiary air; Boiler gas and air supply measurement;

7. The addition of fresh air in the processing operation of food and pharmaceutical industry;

Co2 treatment in breweries; Flow of hot air in the bottle sterilizer; Gas flow measurement in the process of thermal oxidation; Ventilation system; Boiler intake, exhaust gas, process control;

8. Gas measurement in the process of environmentally friendly biogas utilization;

Chlorine gas measurement during chlorine gas treatment; Gas measurement in aeration tank during sewage treatment; SO2 and NOX emission are monitored in flue gas;

9, other industries factory compressed air measurement;

Pulverized coal combustion process powder/gas ratio control fuel; Cement industry vertical mill discharge hot gas flow control.

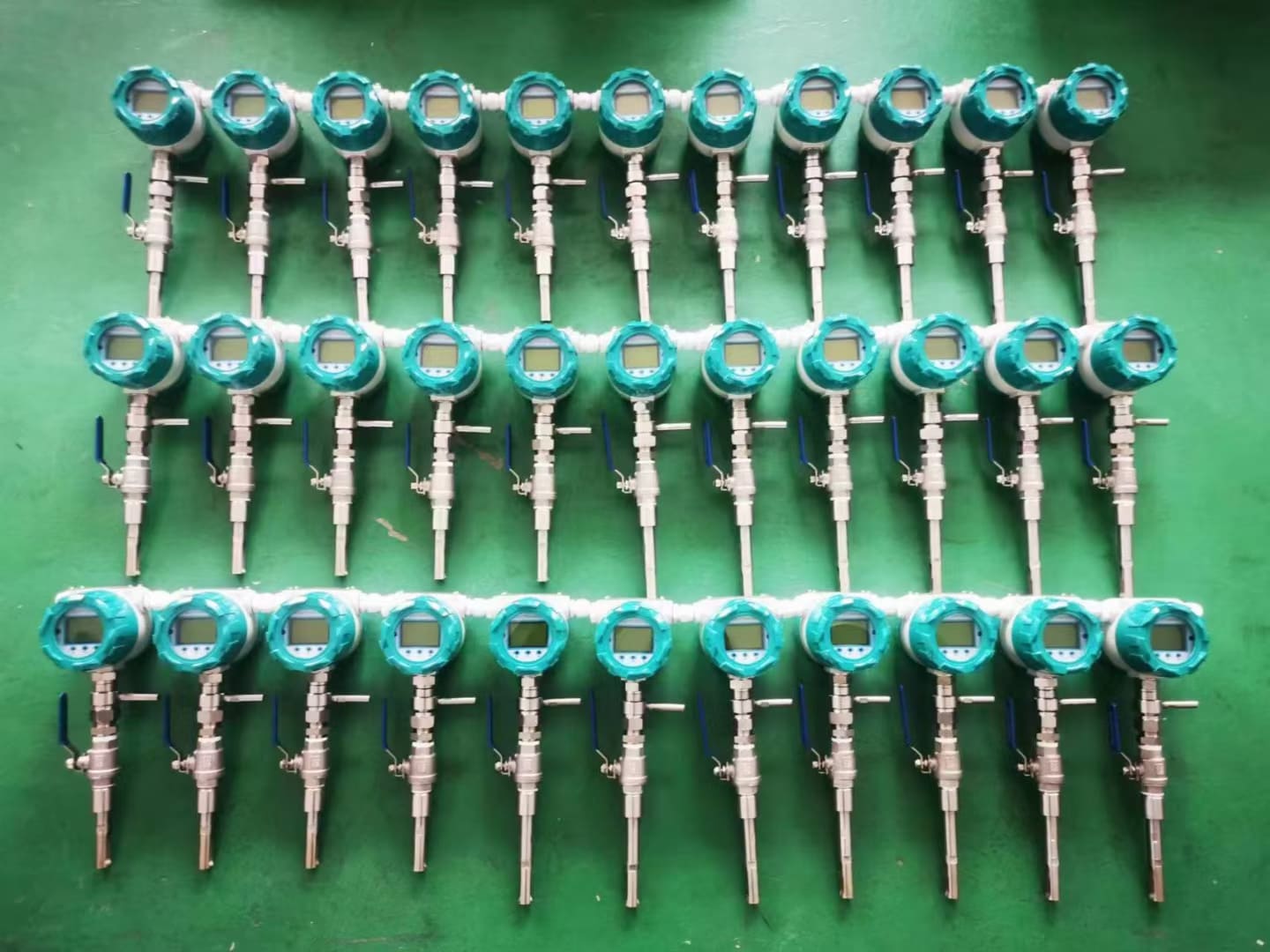

Thermal gas mass flowmeter is not only widely used, the measurement range is also wide, the range ratio can reach 1:100, Aister instrument has many years of production experience, equipped with gas verification device, Venturi sonic nozzle verification device real flow calibration, to ensure product accuracy.