Measurement advantages of split electromagnetic flow meter

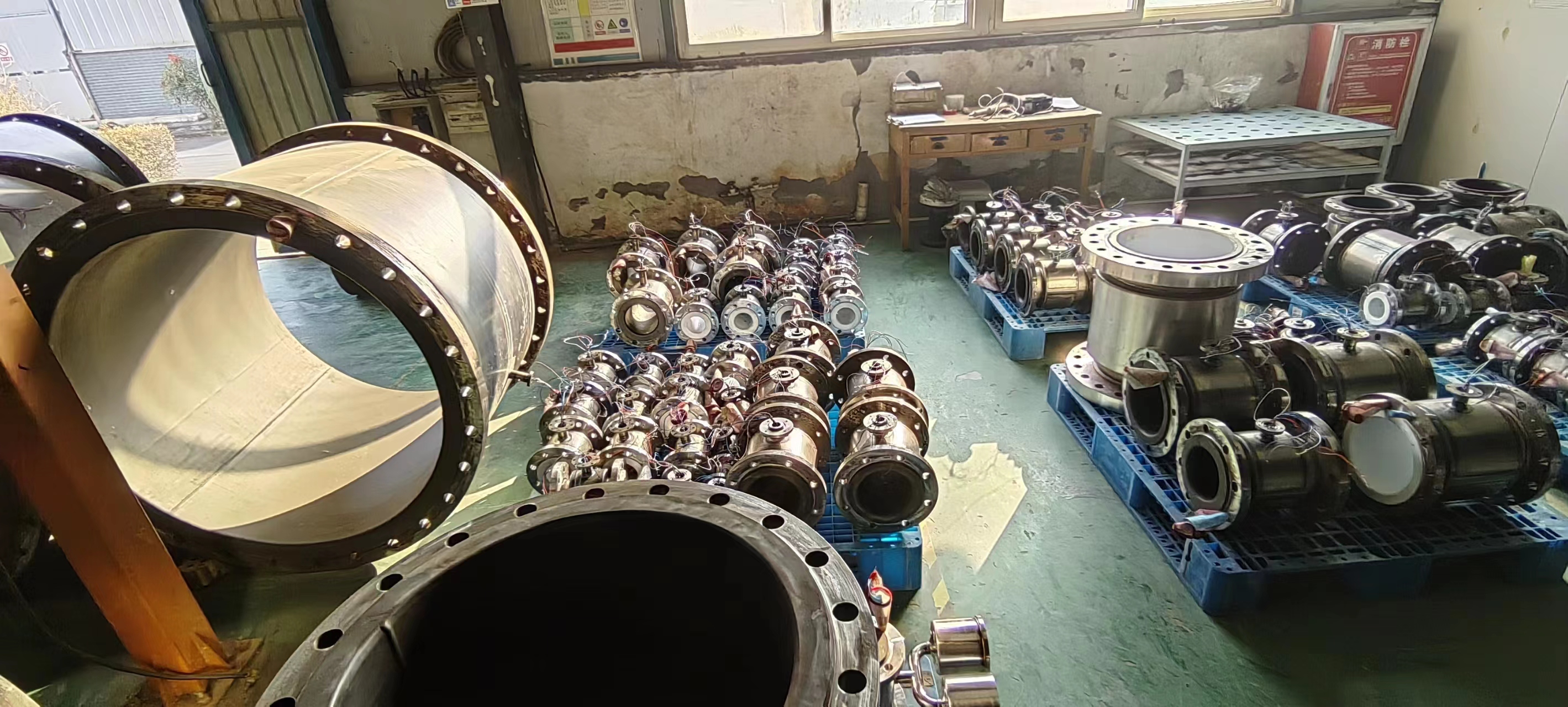

Electromagnetic flowmeters are classified according to the assembly method of converters and sensors, with split type and one type. Split type electromagnetic flowmeter is relative to the integrated, its components are: measuring tube, electrode, excitation coil, iron core and yoke housing. Used to measure the volume flow of conductive liquid and slurry in closed pipes.

Analysis of the advantages of split electromagnetic flowmeter measurement:

1. The sensor structure of the electromagnetic flowmeter is simple, and there are no moving parts in the measurement tube, nor any throttling parts that prevent fluid activity. Therefore, when the fluid passes the flow meter, it will not cause any additional pressure loss, and it is one of the flow surfaces with lower energy consumption in the flow meter.

2. It can measure the flow rate of dirty media, corrosive media and suspended liquid-solid two-phase flow. This is because there are no blocking moving parts inside the external measuring tube, and only the measuring tube lining and electrode are touched by the measured body, and the data can be selected according to the nature of the measured body. For example, with polytrifluoroethylene or polytetrafluoroethylene as the lining, can measure a variety of acid, alkali, salt and other corrosive media; The selection of wear-resistant rubber as the lining is particularly suitable for measuring the liquid-solid two-phase flow such as slurry and cement slurry with solid particles and wear larger, as well as a variety of suspensions such as fiber liquid and paper pulp.

3. Electromagnetic flowmeter is a volume flow measurement surface, in the measurement process, it is not affected by the temperature of the measured medium, viscosity, density and conductivity (in a certain scale). Therefore, the electromagnetic flowmeter can be used to measure the flow of other conductive liquids only after water calibration.

4. The output of the electromagnetic flowmeter is only proportional to the uniform flow rate of the measured medium, and has nothing to do with the activity condition (laminar flow or turbulence) under symmetrical distribution. Therefore, the range of the electromagnetic flowmeter is extremely wide, and its measurement scale can reach 100:1, and some can even reach 1000:1.

5. The electromagnetic flowmeter has no mechanical inertia, the reaction is active, and can measure the instantaneous pulsating flow rate, and can also measure the flow in both positive and negative directions.

6. Industrial electromagnetic flowmeters have a very wide diameter scale, from a few millimeters to a few meters, and have realized a real flow calibration equipment with a caliber of 3m, laying the foundation for the application and development of electromagnetic flowmeters.

-.jpg)

-.jpg)