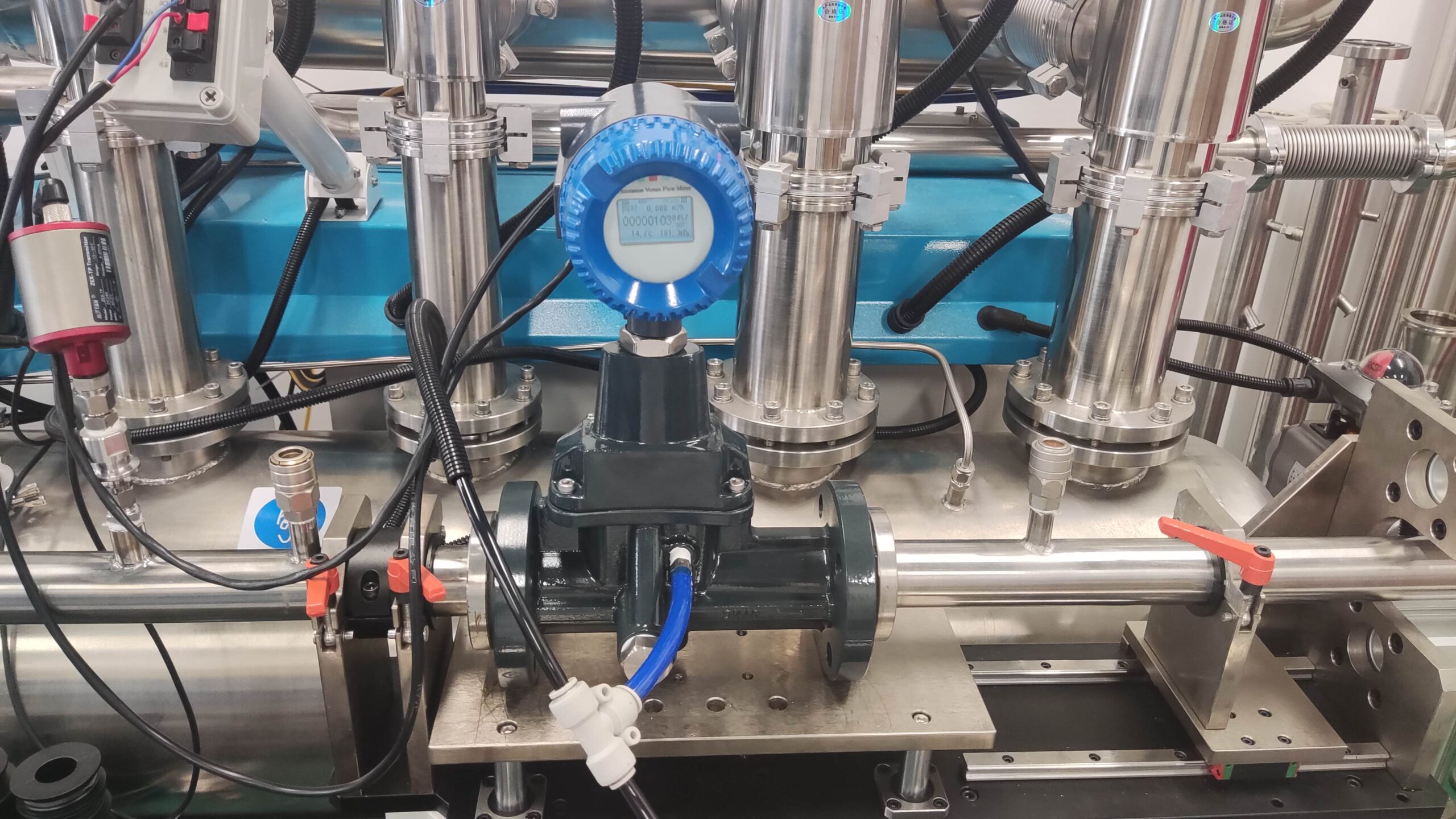

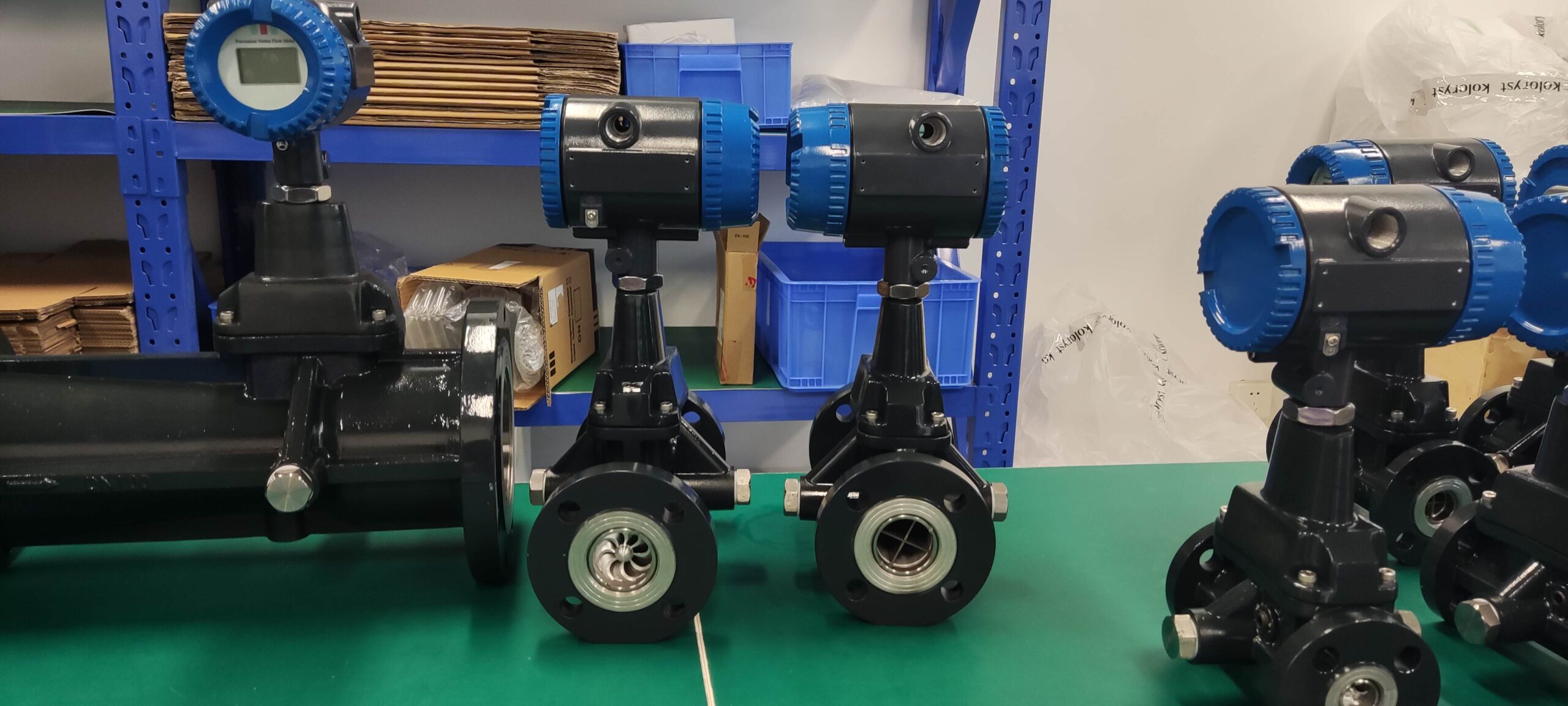

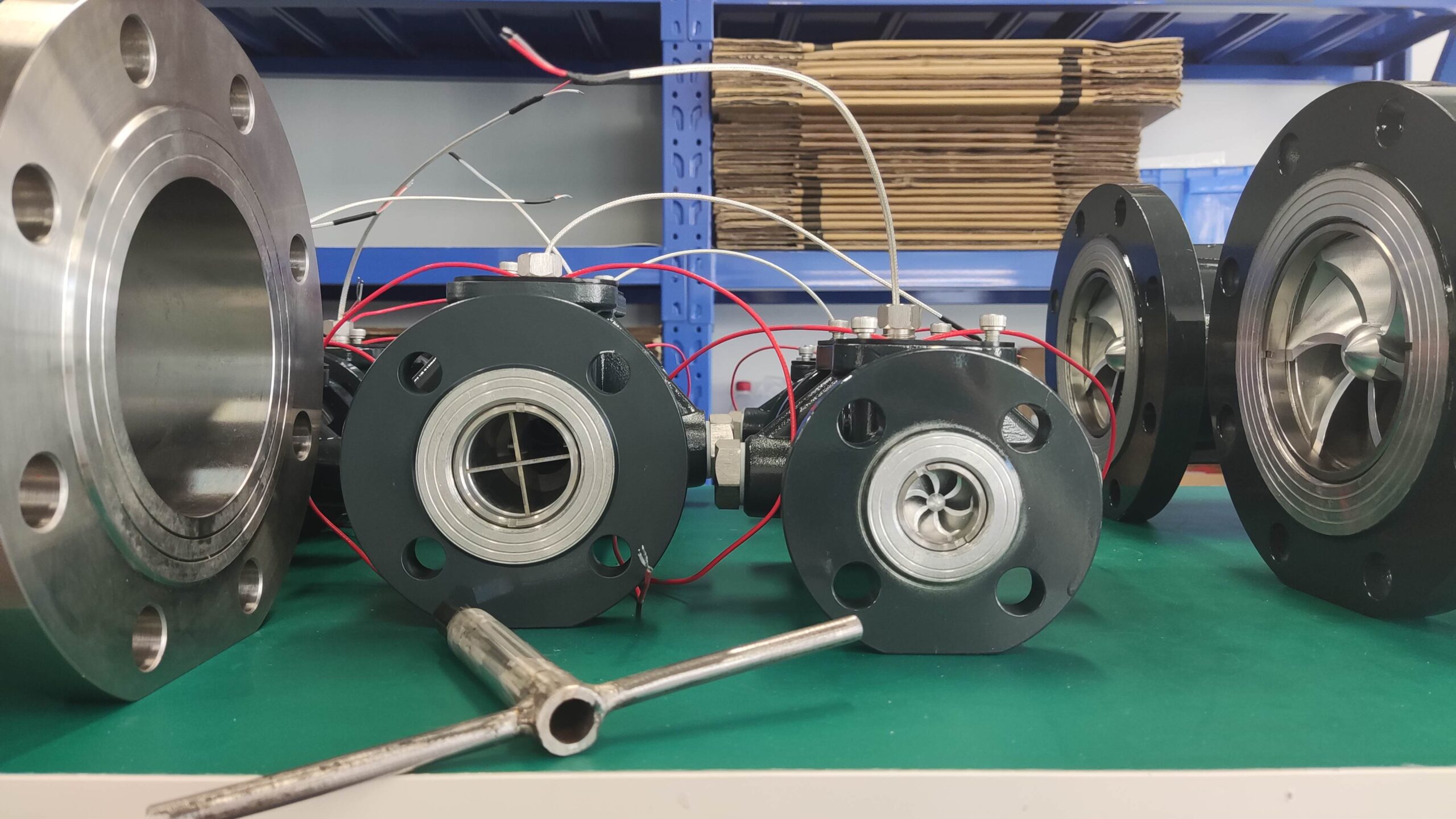

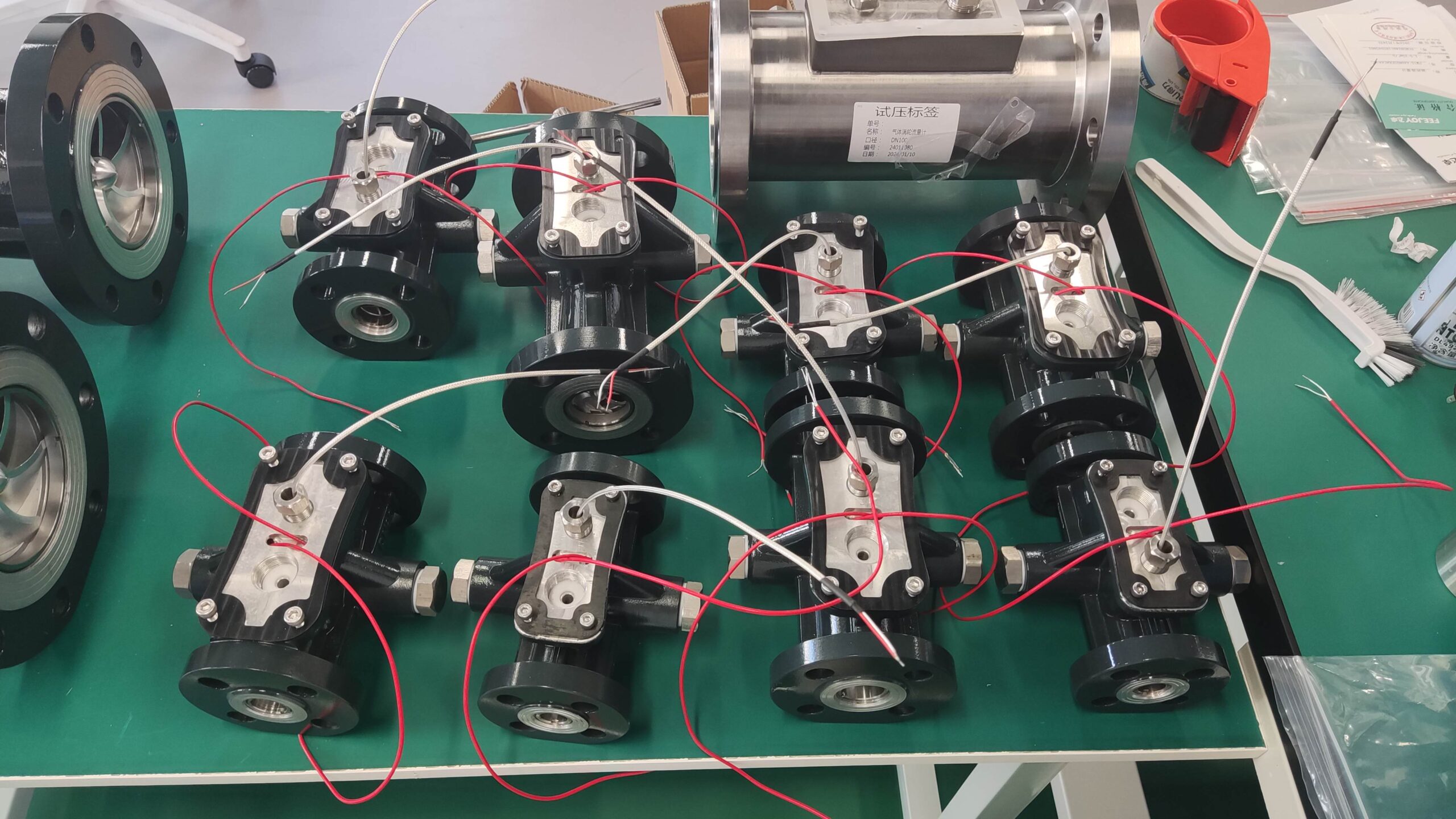

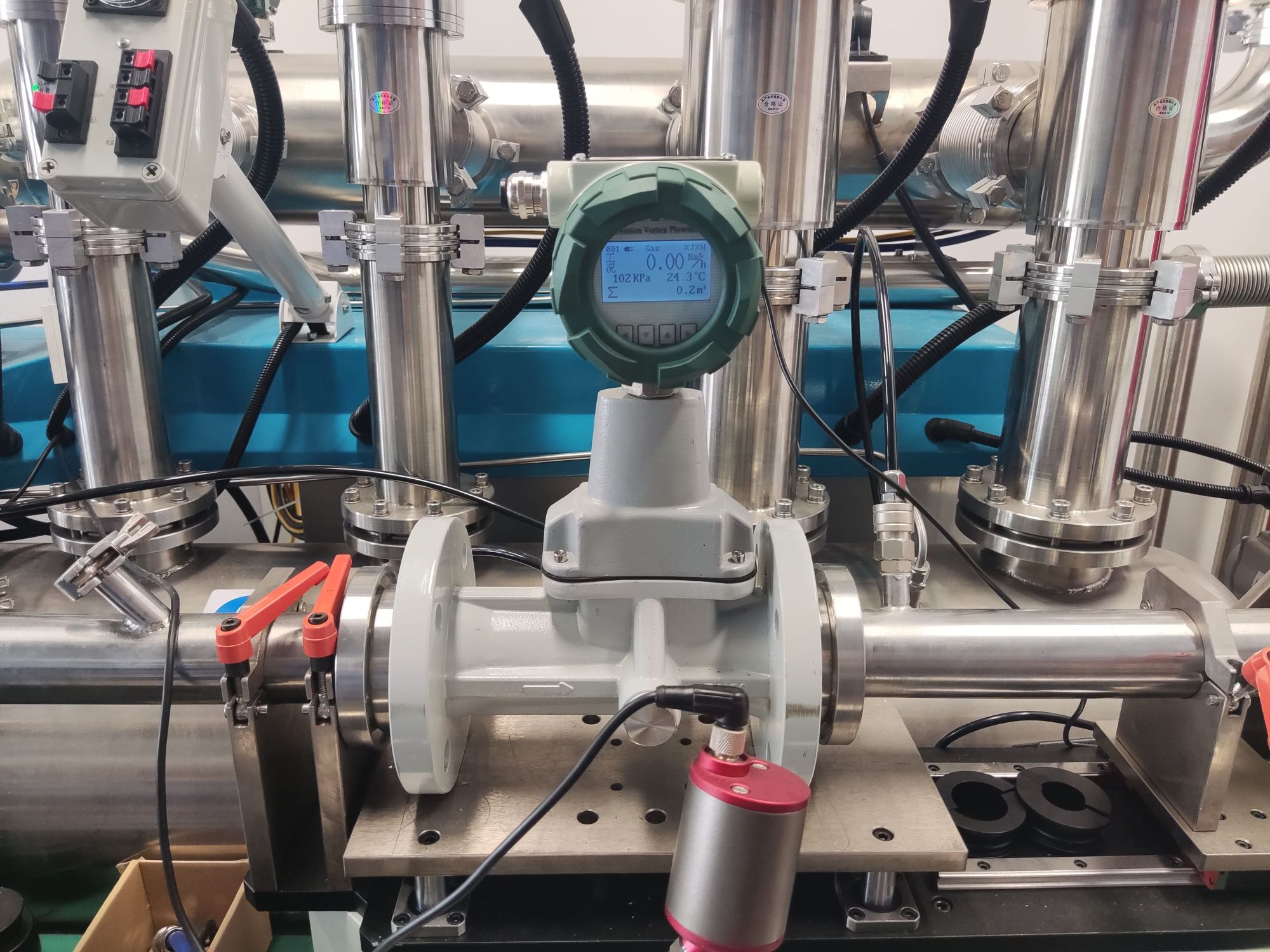

Low Price Vortex Precession Flowmeter Swirl Vortex Precession Flow Meter for Oxygen

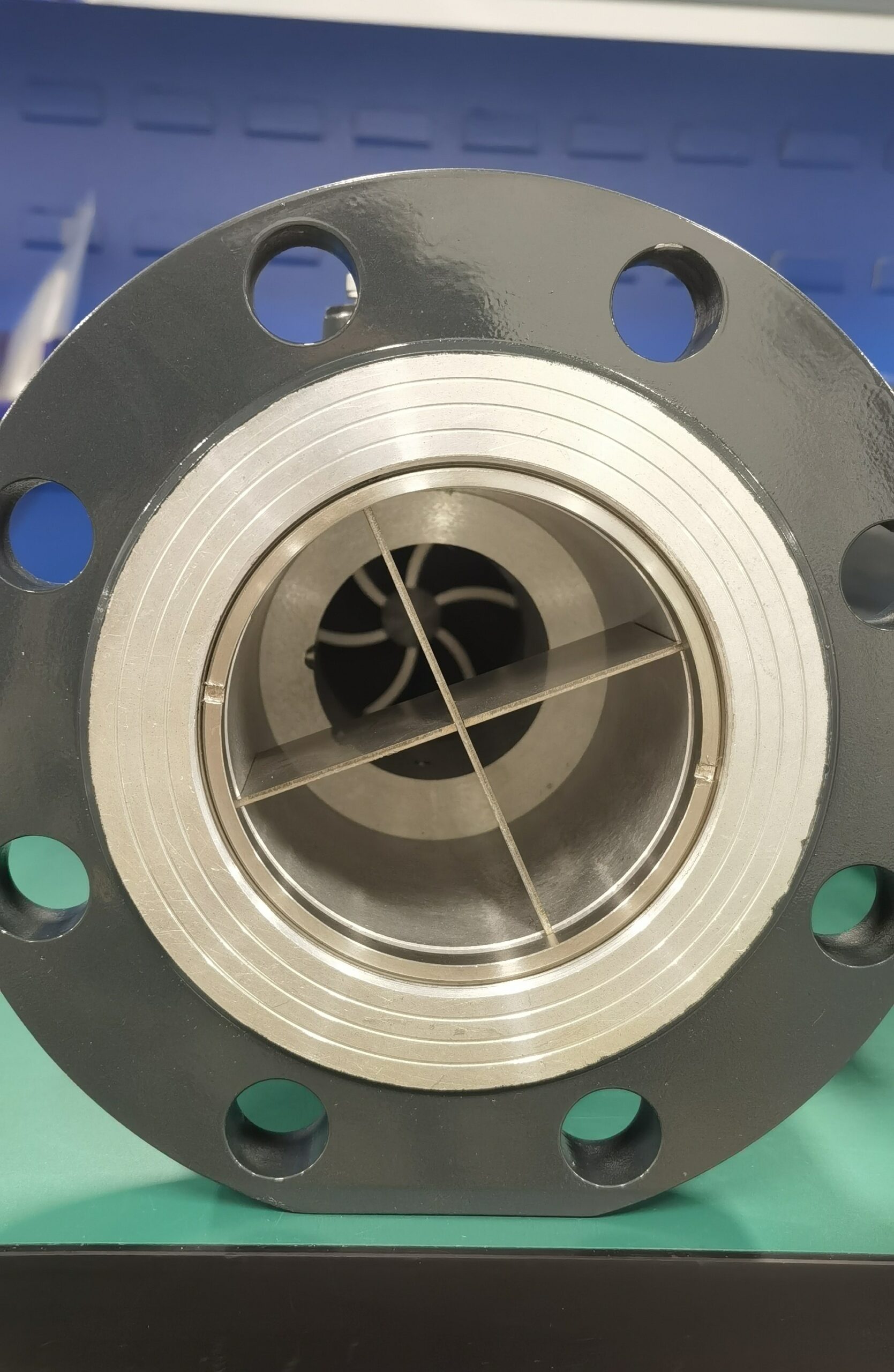

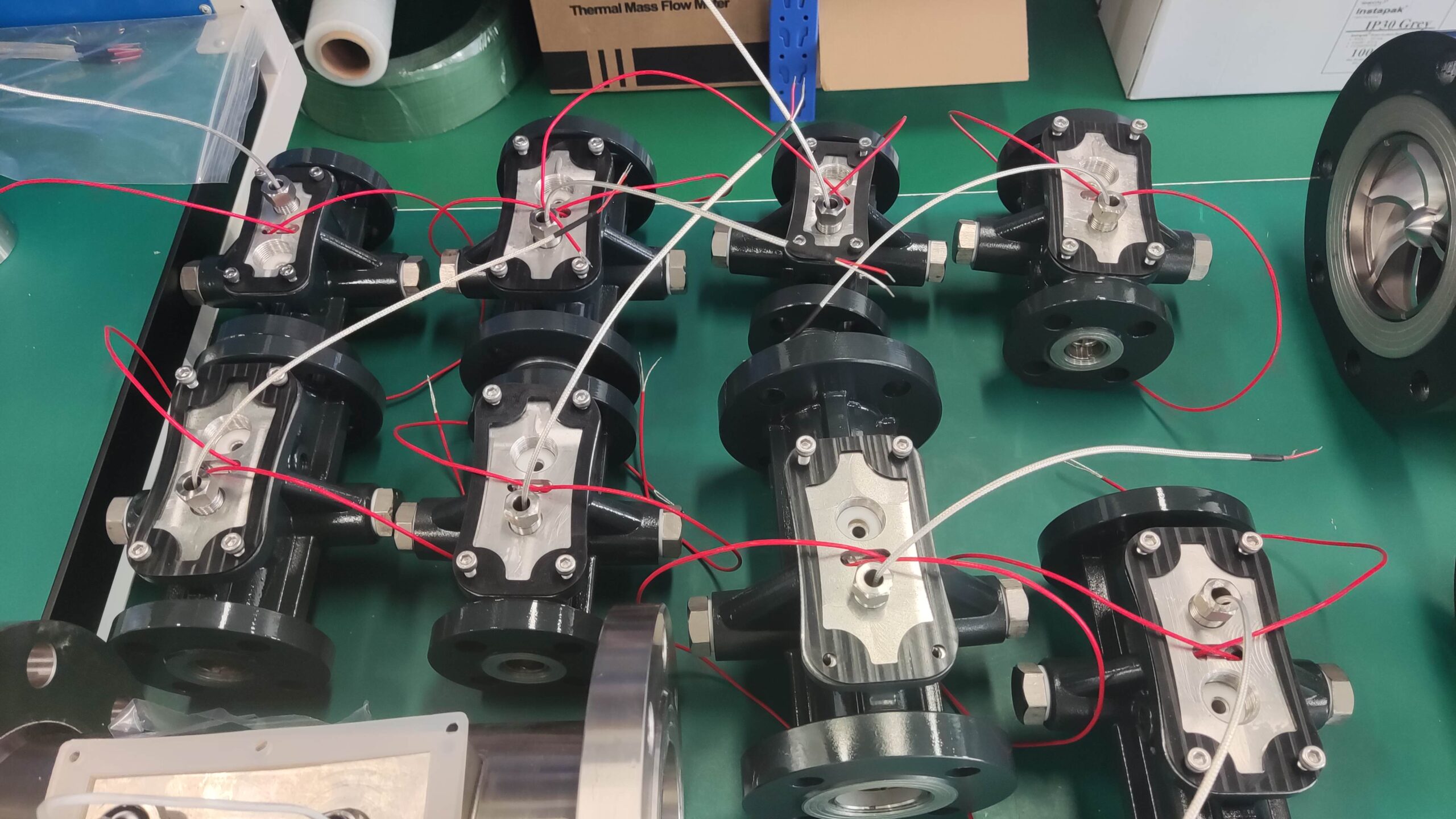

Nominal diameter: DN15-DN200mm

Accuracy: 1.0/1.5

Body material: Aluminum alloy, 304 stainless steel

Applicable media: Compressed air, oxygen, nitrogen, carbon dioxide, natural gas, argon, liquefied gas, etc., corrosion, moisture can not be measured, such as chlorine, hydrogen, steam, ammonia.

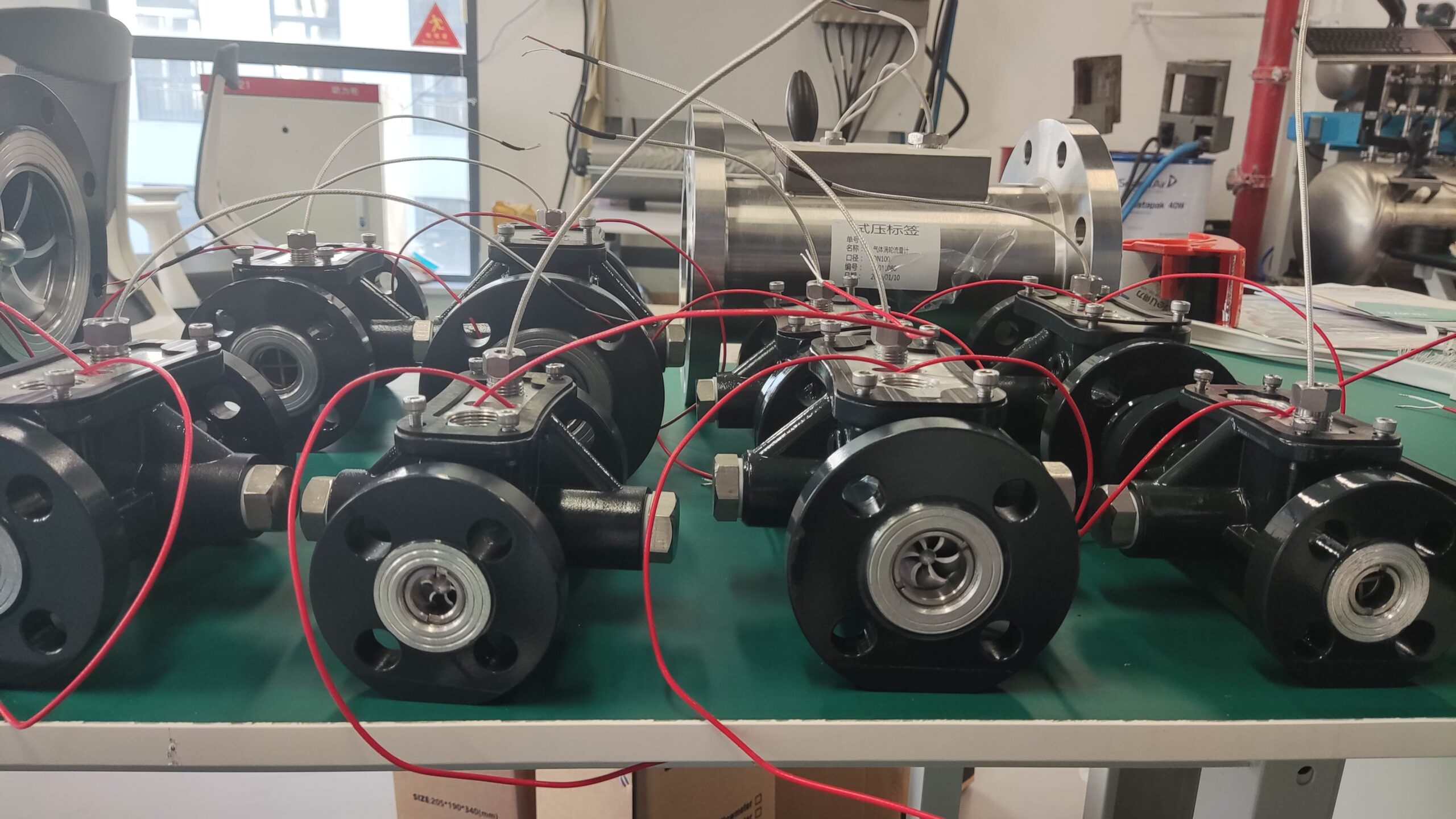

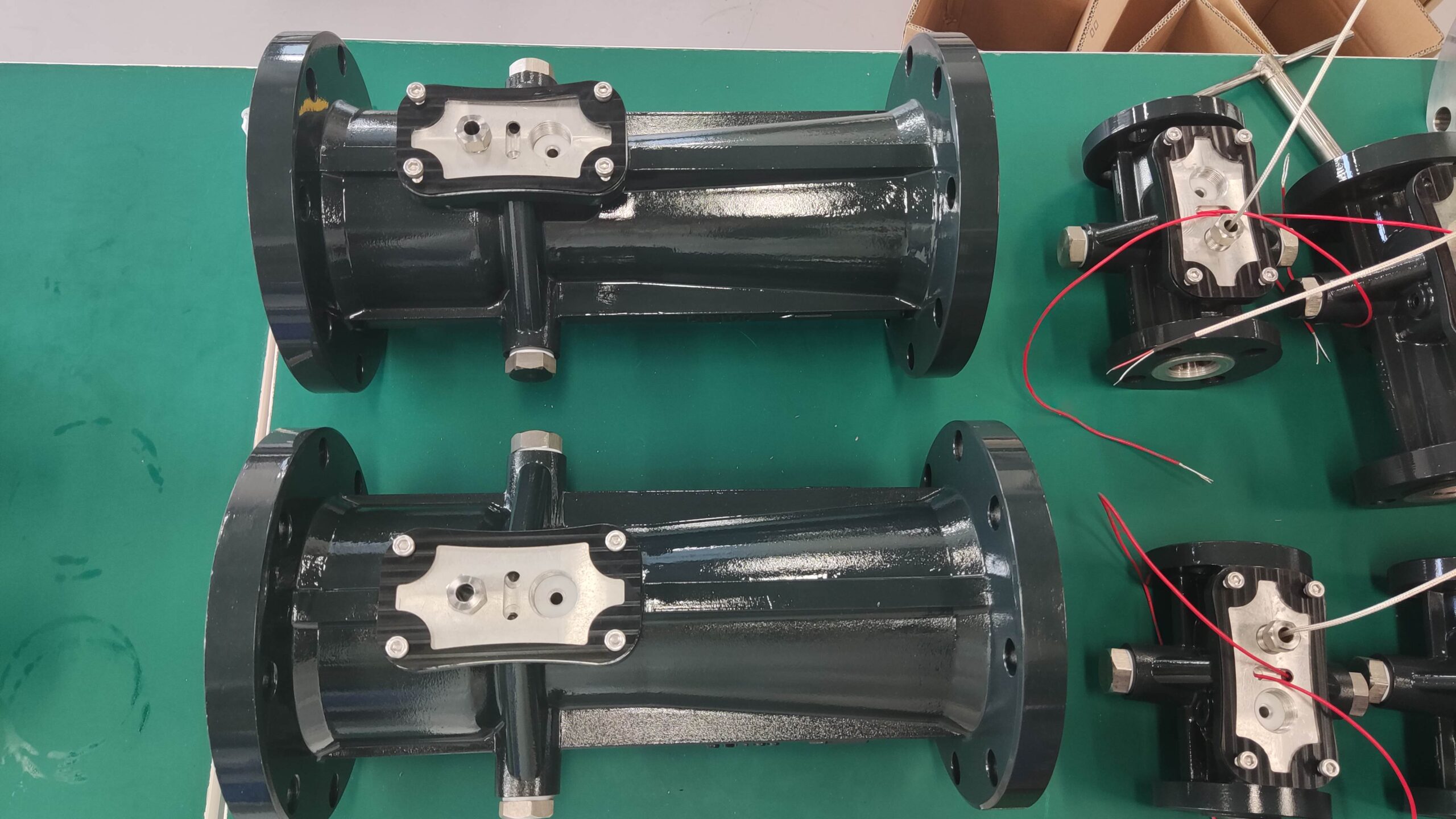

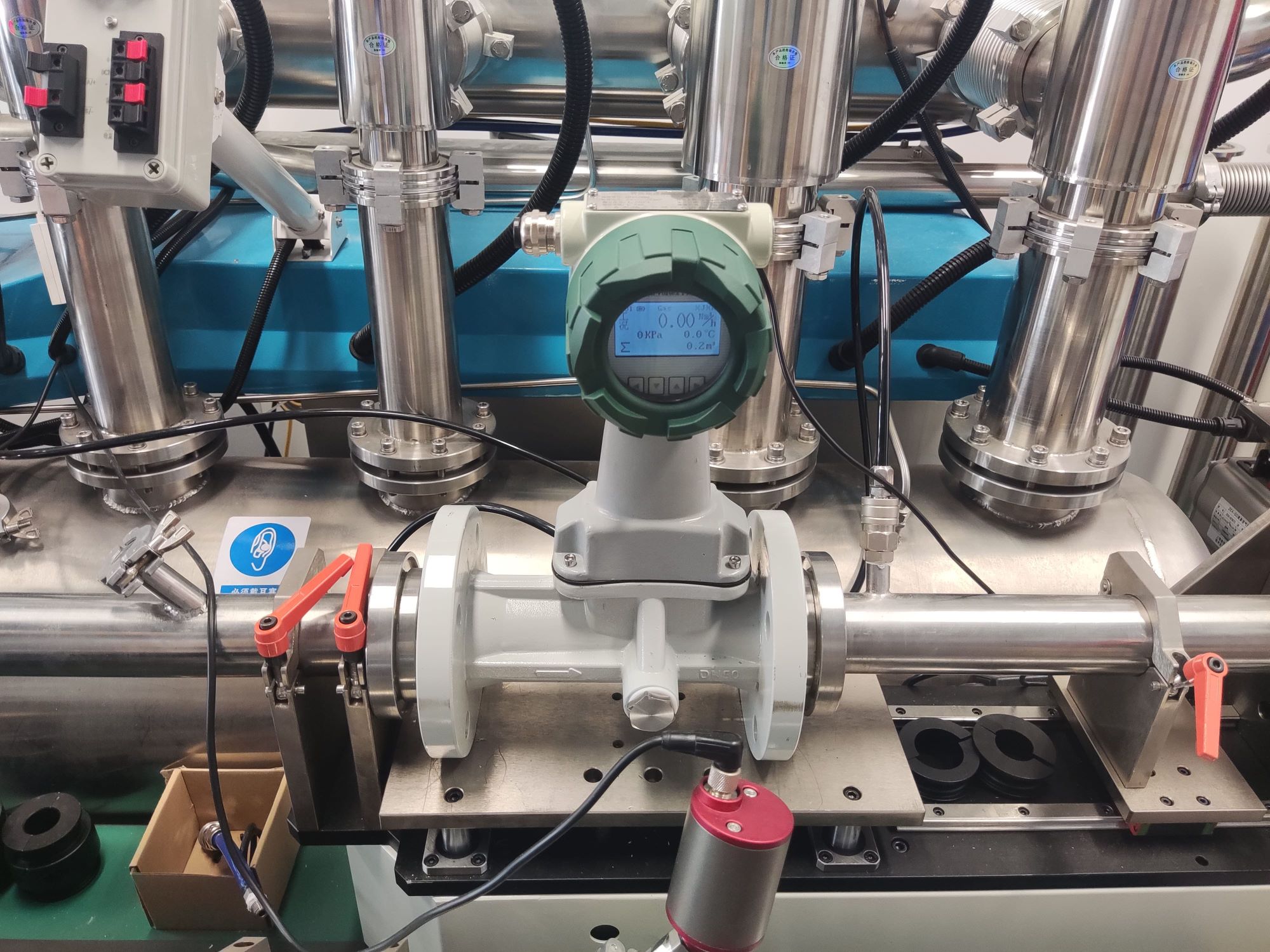

Installation

1.When the flow meter is installed, it is strictly prohibited to weld directly at the inlet and outlet flanges to avoid burning the internal parts of the flow meter.

2.The newly installed or repaired pipeline must be cleaned, and the flow meter can be installed after removing the debris in the pipeline.

3.The flowmeter should be installed in a place that is easy to maintain, free from strong electromagnetic field interference, strong mechanical vibration and thermal radiation.

4.Flowmeters should not be used in the case of frequent flow interruption and strong pulsating flow or pressure pulsation.

5.When the flowmeter is installed outdoors, the upper part should be covered to prevent rain immersion and sun exposure from affecting the service life of the flowmeter.

6.The flow meter can be installed at any Angle, and the flow direction of the fluid should be consistent with the flow direction marked on the flow meter.

7.In pipeline construction, it should be considered to install expansion pipes or bellows to avoid serious stretching or breaking of the flow meter.

8.The flow meter should be installed coaxial with the pipe and prevent the seal and butter from entering the pipe cavity.

9.When the external power supply is used, the flow meter must be reliably grounded, and the ground wire must not be shared with the strong current system. When the pipeline is installed or repaired, the ground wire of the welding system must not be bonded with the flow meter.

10.In order not to affect the normal transmission of fluid and facilitate maintenance, bypass pipelines are required to be installed, and straight pipe sections ≥3DN in front and ≥1DN in back are guaranteed.