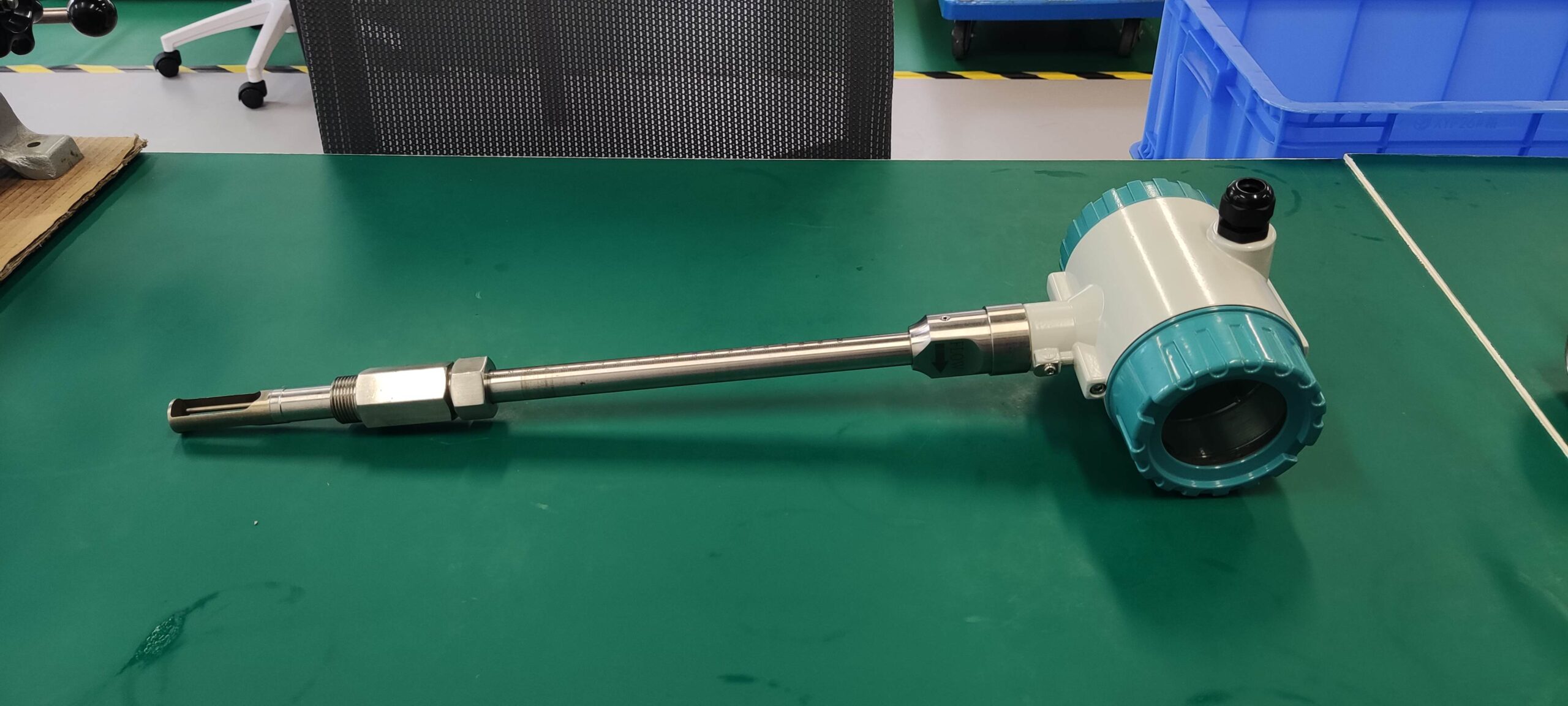

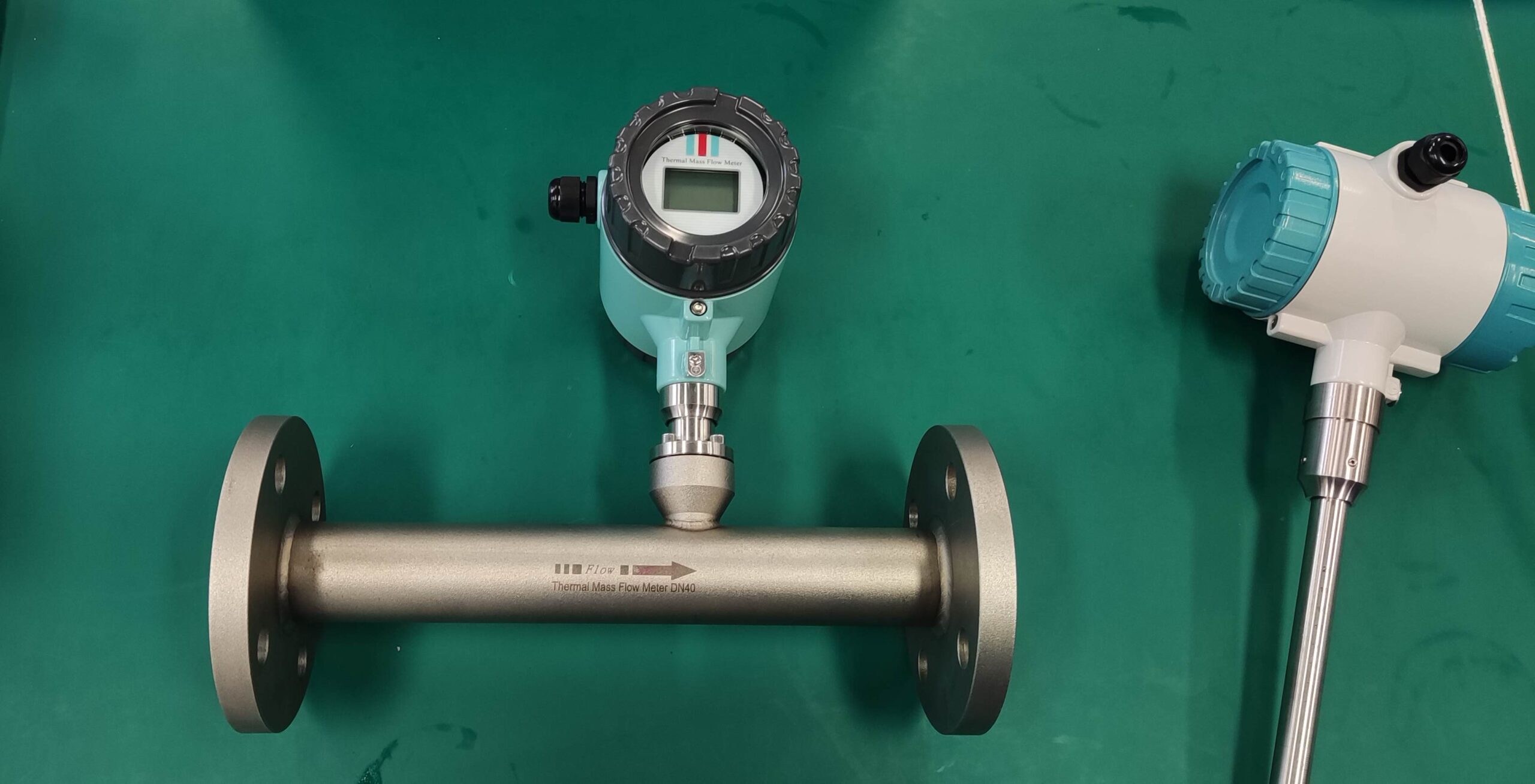

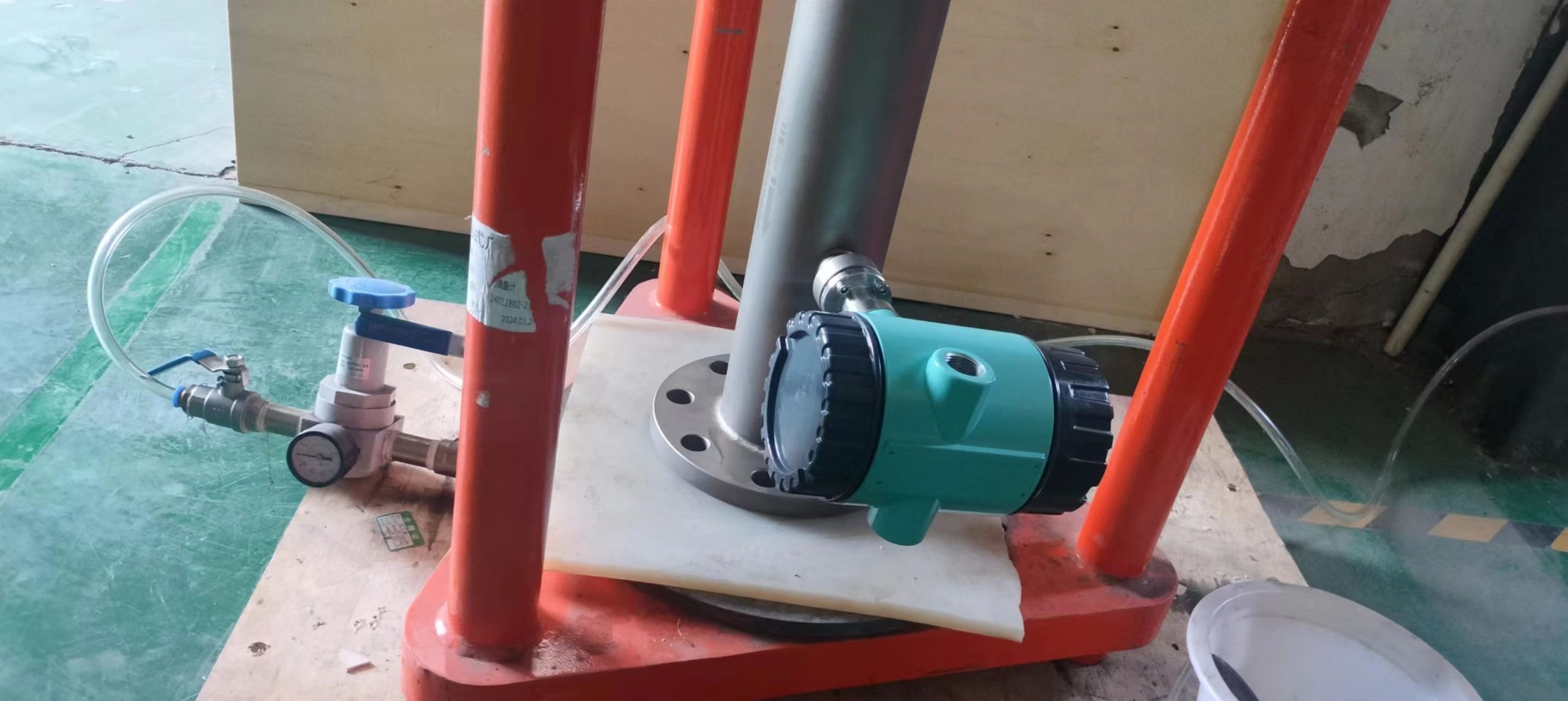

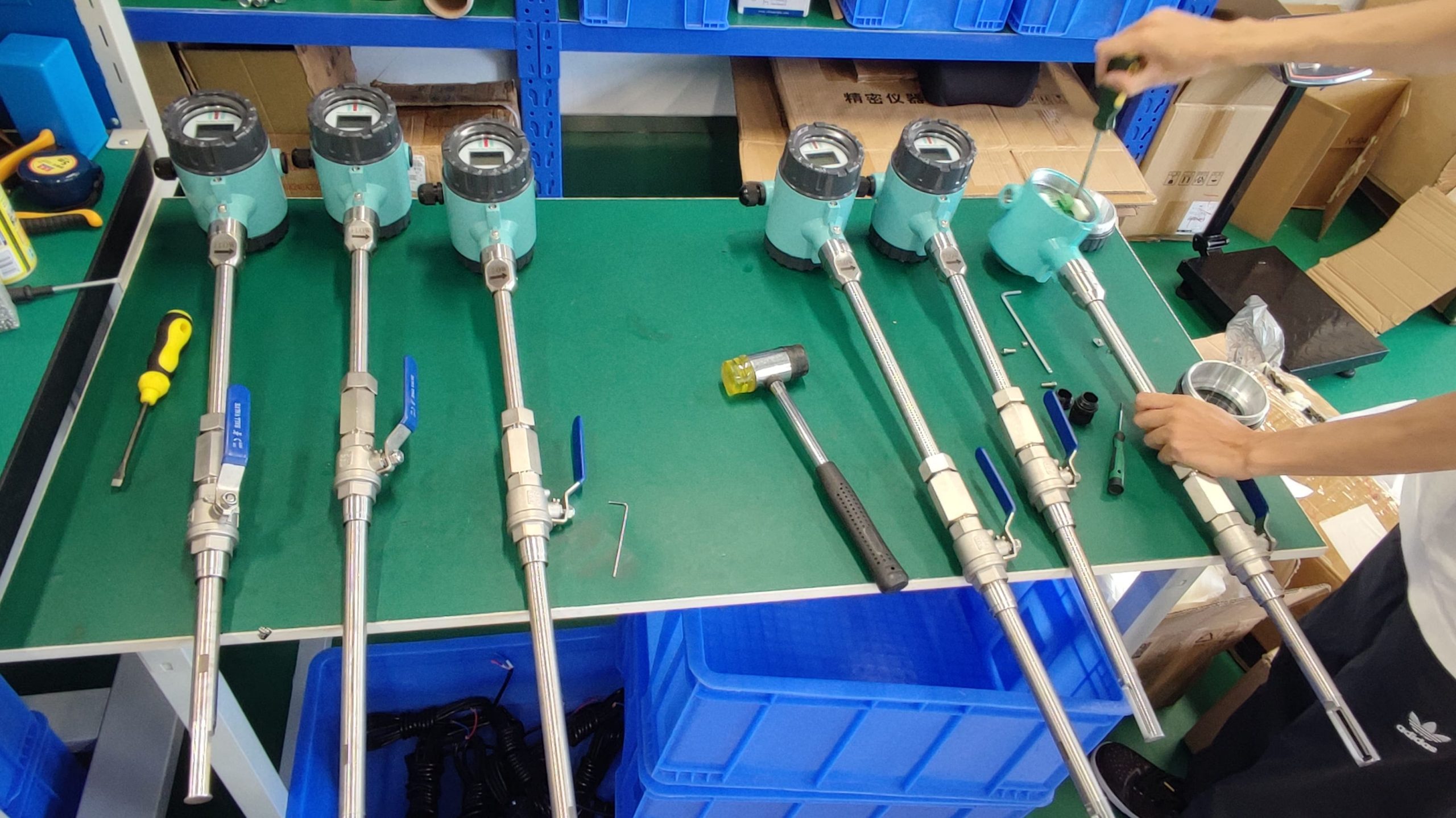

Low Price Compress Air Thermal Mass Gas Flow Meter Hydrogen Oxygen Measure Gas Flowmeter China Manufacturer

Common faults encountered with thermal mass flowmeters can disrupt their accurate measurement capabilities. Here are some typical issues along with potential solutions:

1. Sensor Contamination:

Symptoms: Reduced accuracy, erratic readings, or complete failure to measure flow.

Cause: Dust, particulates, or condensates accumulating on the sensor elements.

Solution: Regular cleaning and maintenance of the sensor elements using appropriate methods and cleaning solutions. Implementing filtration systems upstream can also prevent contamination.

2. Sensor Drift:

Symptoms: Gradual deviation from calibrated values, leading to inaccurate measurements over time.

Cause: Changes in sensor characteristics due to environmental factors, aging, or electronic issues.

Solution: Periodic calibration and verification of the flowmeter’s performance. Replacement of aging components if necessary. Utilizing advanced diagnostics features if available to detect and compensate for drift.

3. Temperature and Pressure Fluctuations:

Symptoms: Inaccurate readings during variations in process temperature and pressure.

Cause: Thermal mass flowmeters are sensitive to changes in temperature and pressure, which can affect their accuracy.

Solution: Employing temperature and pressure compensation techniques. Using sensors and algorithms to adjust flow measurements based on real-time temperature and pressure conditions. Ensuring proper insulation and environmental control in the installation area.

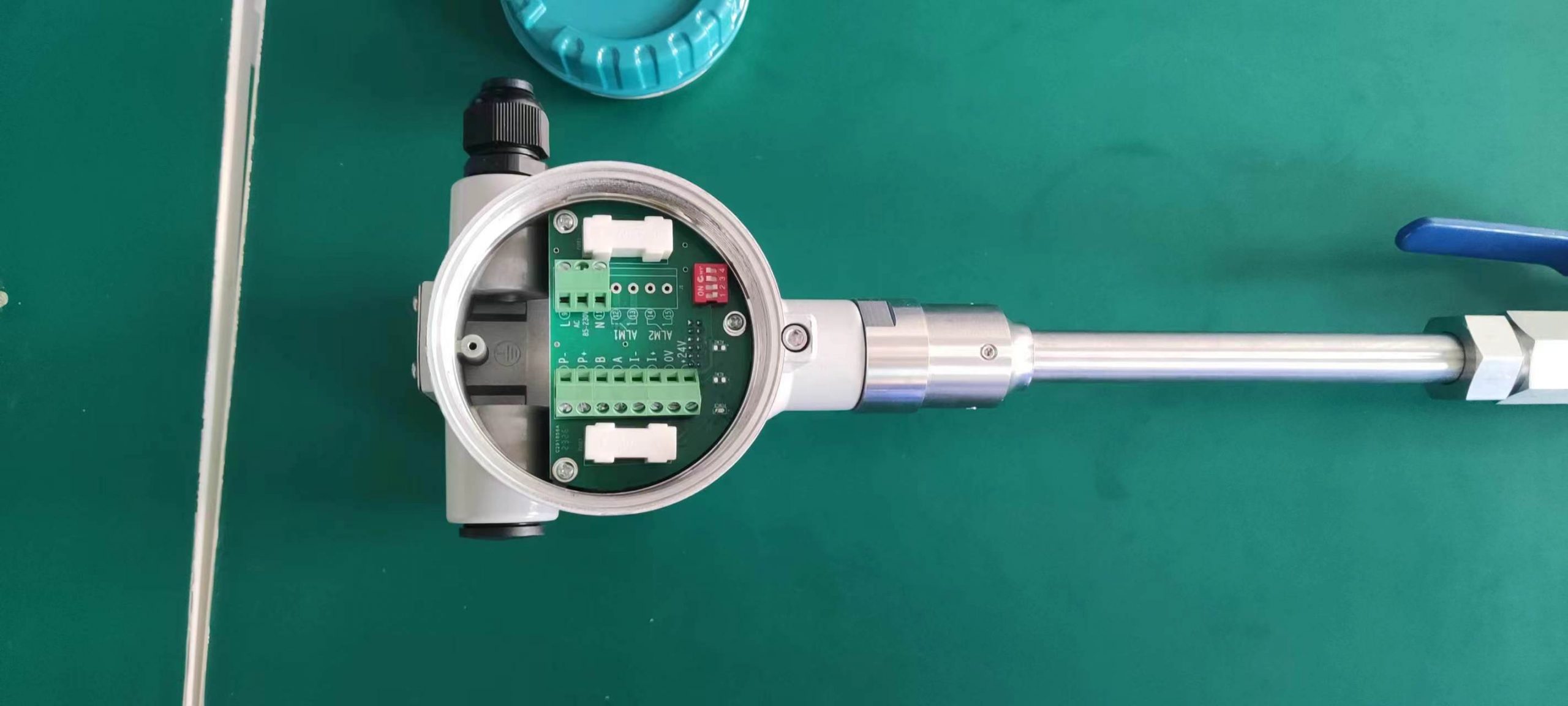

4. Electrical or Electronics Issues:

Symptoms: Power supply failures, signal loss, or erratic behavior of the flowmeter.

Cause: Wiring faults, electronic component failure, or power supply issues.

Solution: Conducting regular inspections of electrical connections and wiring. Performing diagnostic tests to identify faulty components. Ensuring proper grounding and electrical protection measures. Contacting the manufacturer’s technical support for troubleshooting and repairs.

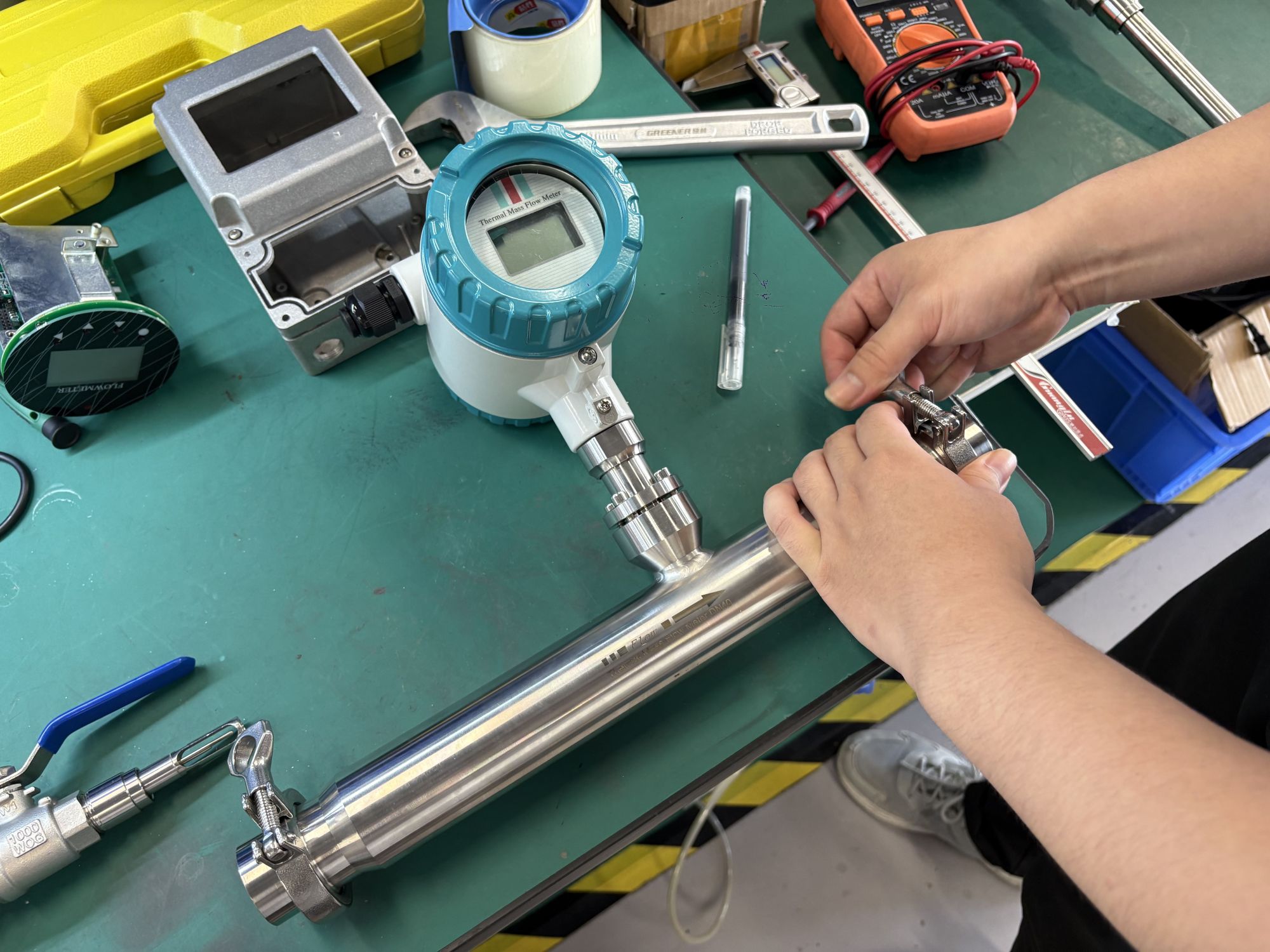

5. Flow Profile Distortion:

Symptoms: Non-uniform flow patterns leading to inaccurate measurements.

Cause: Irregularities in piping, flow disturbances, or obstructions upstream or downstream of the flowmeter.

Solution: Properly sizing and installing straight pipe runs upstream and downstream of the flowmeter to ensure a uniform flow profile. Installing flow conditioning devices if necessary. Conducting hydraulic analysis to identify and rectify flow disturbances.

6. Calibration Drift:

Symptoms: Gradual deviation from calibrated values over time.

Cause: Changes in sensor characteristics or calibration constants due to environmental factors or component aging.

Solution: Regular calibration checks and adjustments as per the manufacturer’s recommendations. Utilizing calibration services provided by accredited laboratories or the flowmeter manufacturer.

Regular preventive maintenance, calibration, and troubleshooting practices are essential for maintaining the performance and reliability of thermal mass flowmeters. Additionally, following manufacturer guidelines for installation, operation, and maintenance can help mitigate potential faults and ensure accurate flow measurement.