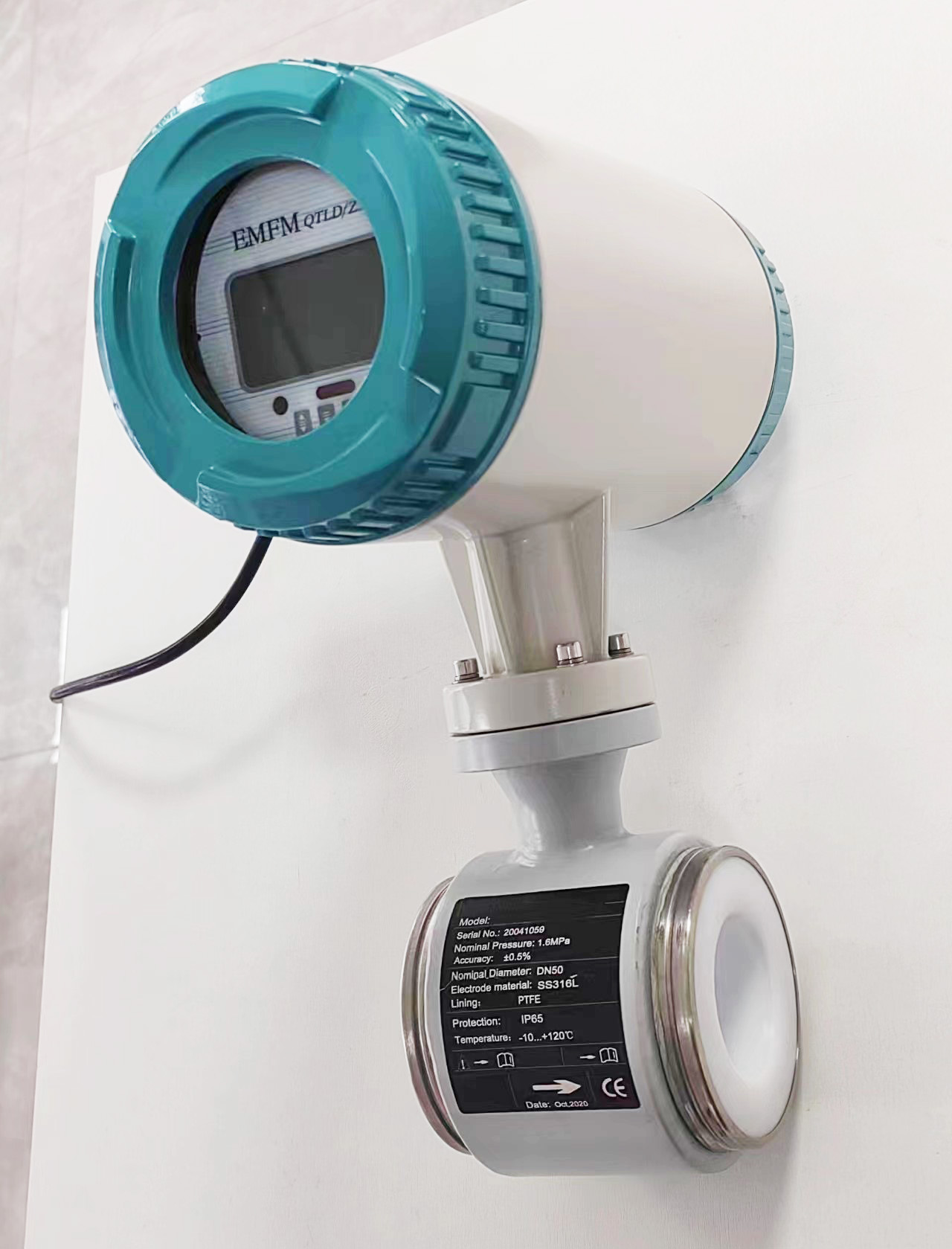

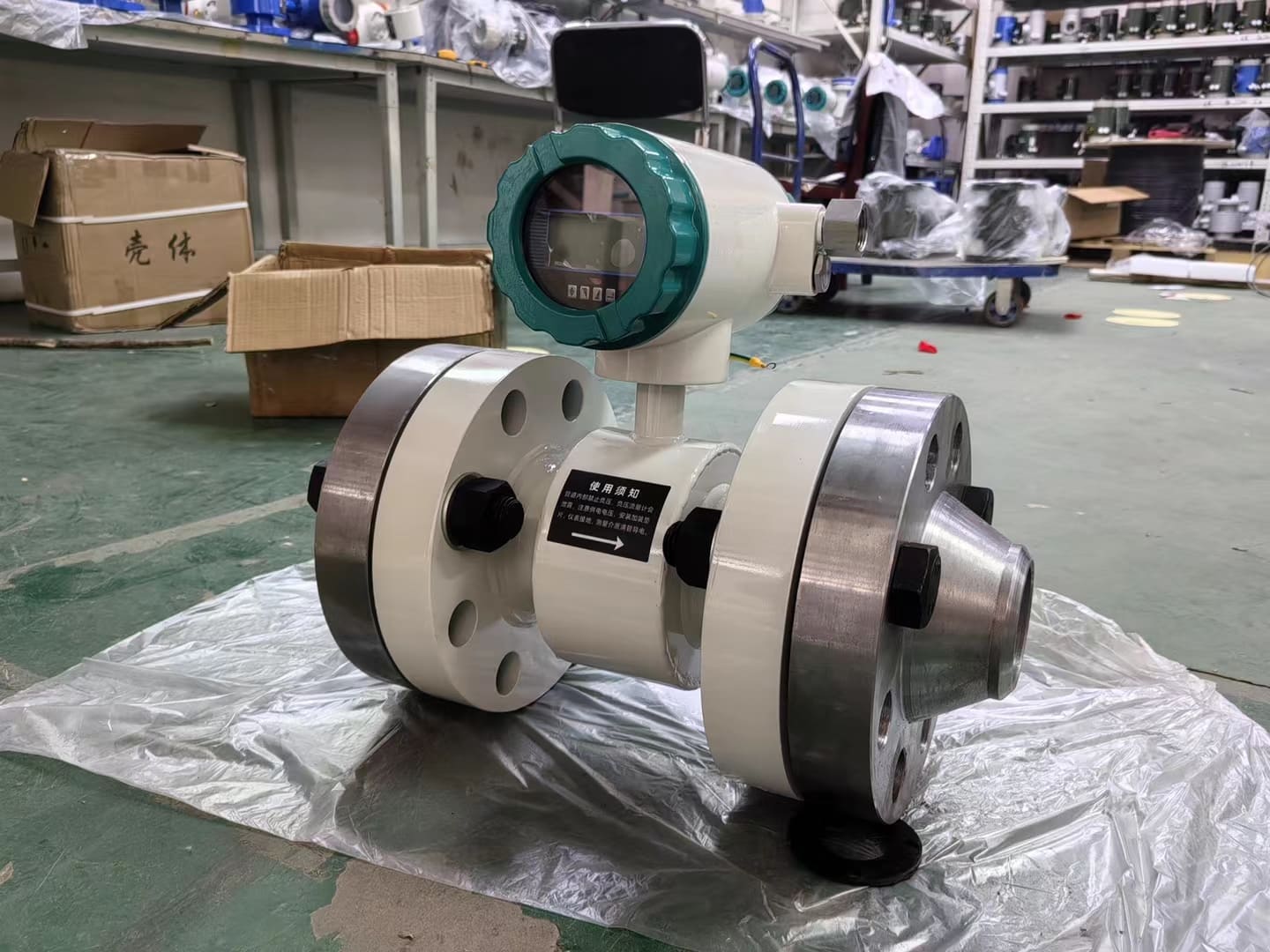

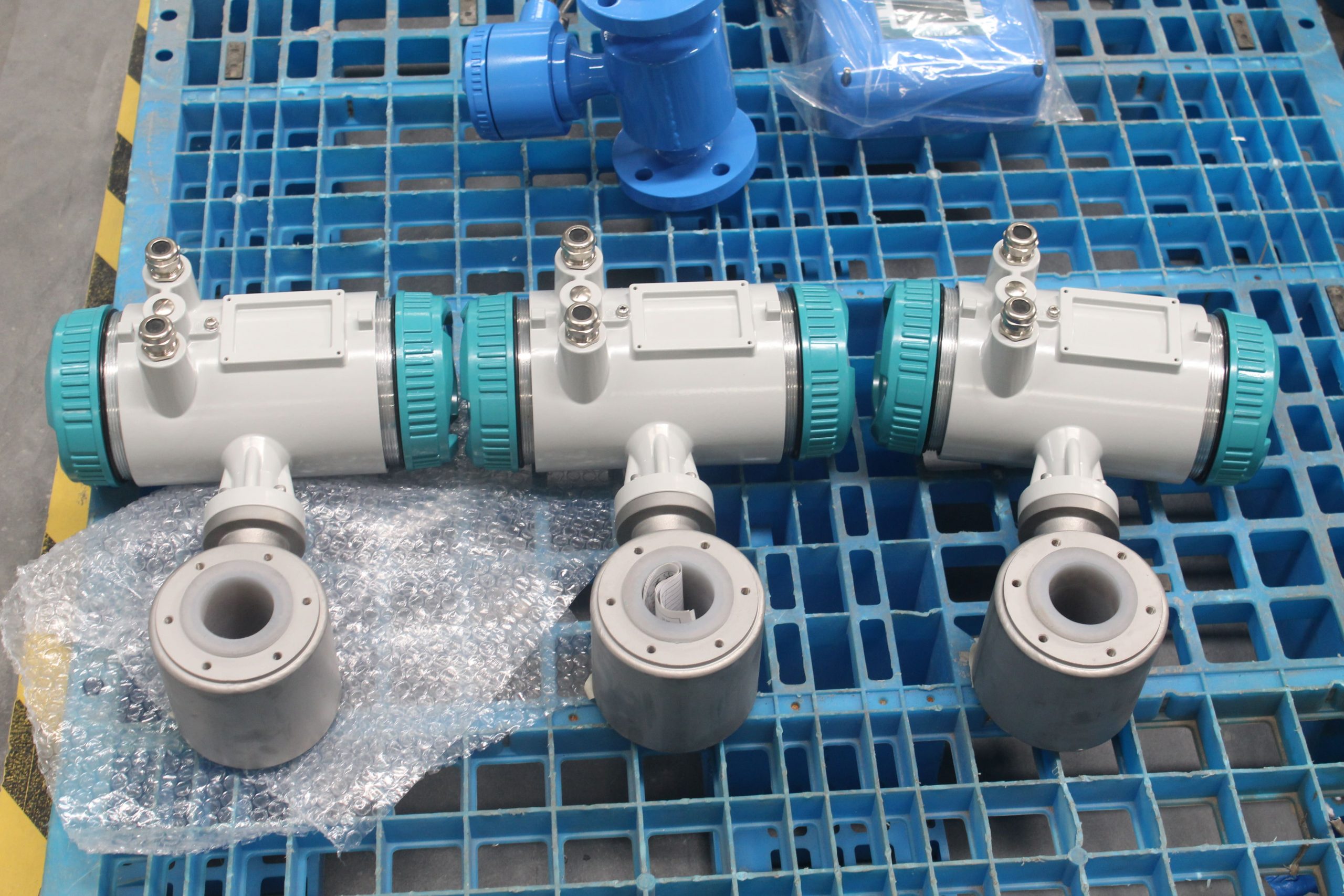

Low Cost Industrial Waste Water Electromagnetic Flowmeter Electro Magnetic Flow Meter

Impurities in the medium flowing through electromagnetic flowmeters can have several effects on their performance and accuracy. While electromagnetic flowmeters are known for their versatility and ability to handle a variety of fluids, the presence of certain impurities may impact their operation. Here are some potential effects:

Conductivity Changes: Electromagnetic flowmeters rely on the conductivity of the fluid to generate accurate measurements. Impurities that significantly alter the conductivity of the medium may affect the meter’s ability to produce reliable readings. It is crucial to ensure that the fluid maintains a minimum level of conductivity for the electromagnetic flowmeter to function effectively.

Electrode Coating and Fouling: Impurities in the fluid, such as sediments or particles, can lead to the coating or fouling of the electrodes inside the flowmeter. This can insulate the electrodes, reducing their effectiveness in generating the electromagnetic field necessary for flow measurement. Regular maintenance and cleaning may be required to prevent the buildup of impurities and maintain the meter’s accuracy.

Corrosion: Depending on the nature of the impurities, corrosion of the materials inside the flowmeter may occur. Corrosion can affect the longevity and structural integrity of the device, potentially leading to malfunctions. Selecting materials resistant to corrosion and ensuring compatibility with the fluid is essential in preventing this issue.

Signal Disturbance: Particles or impurities in the fluid can interfere with the electromagnetic signals generated by the flowmeter. This interference may result in signal noise or distortions, impacting the accuracy of the flow measurements. Adequate filtration and proper fluid conditioning may be necessary to minimize the effects of impurities on the electromagnetic flowmeter signals.

Maintenance Requirements: The presence of impurities may increase the frequency of maintenance required for the electromagnetic flowmeter. Regular inspections and cleaning procedures may be necessary to ensure optimal performance and prevent long-term damage.

It’s important to note that the specific effects of impurities can vary depending on the type and concentration of impurities, as well as the design and materials of the electromagnetic flowmeter. Proper selection, installation, and maintenance practices are crucial to mitigating the potential impacts of impurities on the performance of electromagnetic flowmeters.

-.jpg)