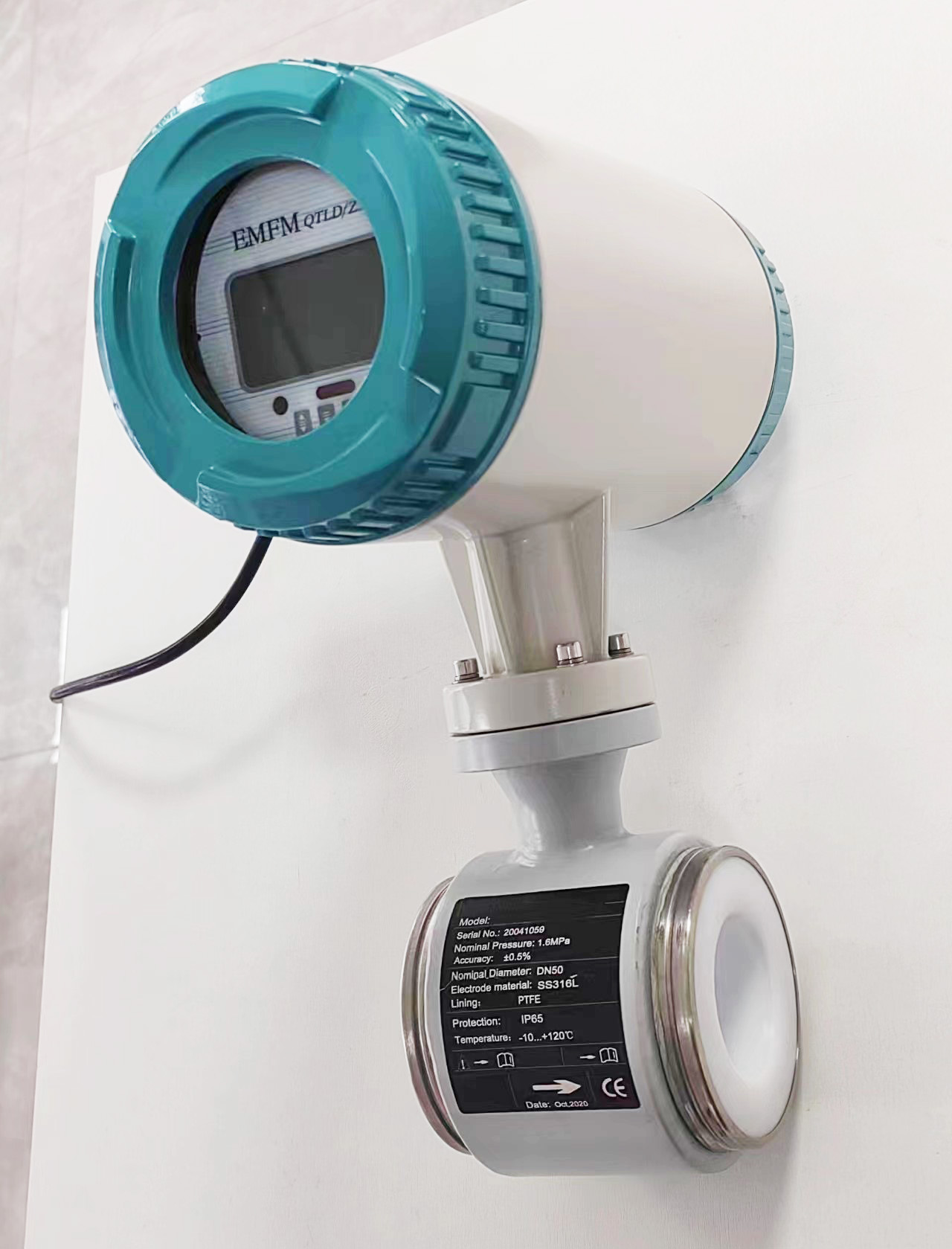

IP68 Water-Proof 4-20mA Pulse Alarm Output Digital Water Electromagnetic Flowmeter

What are the problems encountered when electromagnetic flowmeters are used in paper mills

When the electromagnetic flowmeter is in use, it can be used in the paper industry, which can provide a lot of technical support for this industry. However, we will also encounter some problems when using, which is introduced by Xiaobian below. Recently, there has been an increase in the application of electrodeless electromagnetic flowmeters as a measure to improve the leakage of liquid in the electrode site. The PFA lining flowmeter is increased in the pipeline with calcium scale layer by mirror finishing.

Electromagnetic flowmeters can be applied in the paper industry, and some problems will exist in use:

(1) Because of the different varieties of paper, liquid REDOX potential changes and can not meet the measurement accuracy of many conditions, I hope there are improved ways in the future.

(2) The measuring green liquid, black liquid and other decatizing liquid will form a scale layer on the ceramic lining in a short period of time.

(3) Measuring the liquid containing clay, starch, etc., the meter measurement value is less than the actual value.

(4) The pulp bleaching process on the PFA lining is considered to be an oil-based substance and adheres to a defoamer, and covers the electrode and cannot be measured. Can be washed with gasoline can continue to use.

The above introduces some problems that we will encounter when the electromagnetic flowmeter is used in the paper mill. I hope that in the later development, we can improve and solve these problems.

-.jpg)

-.jpg)

-.jpg)