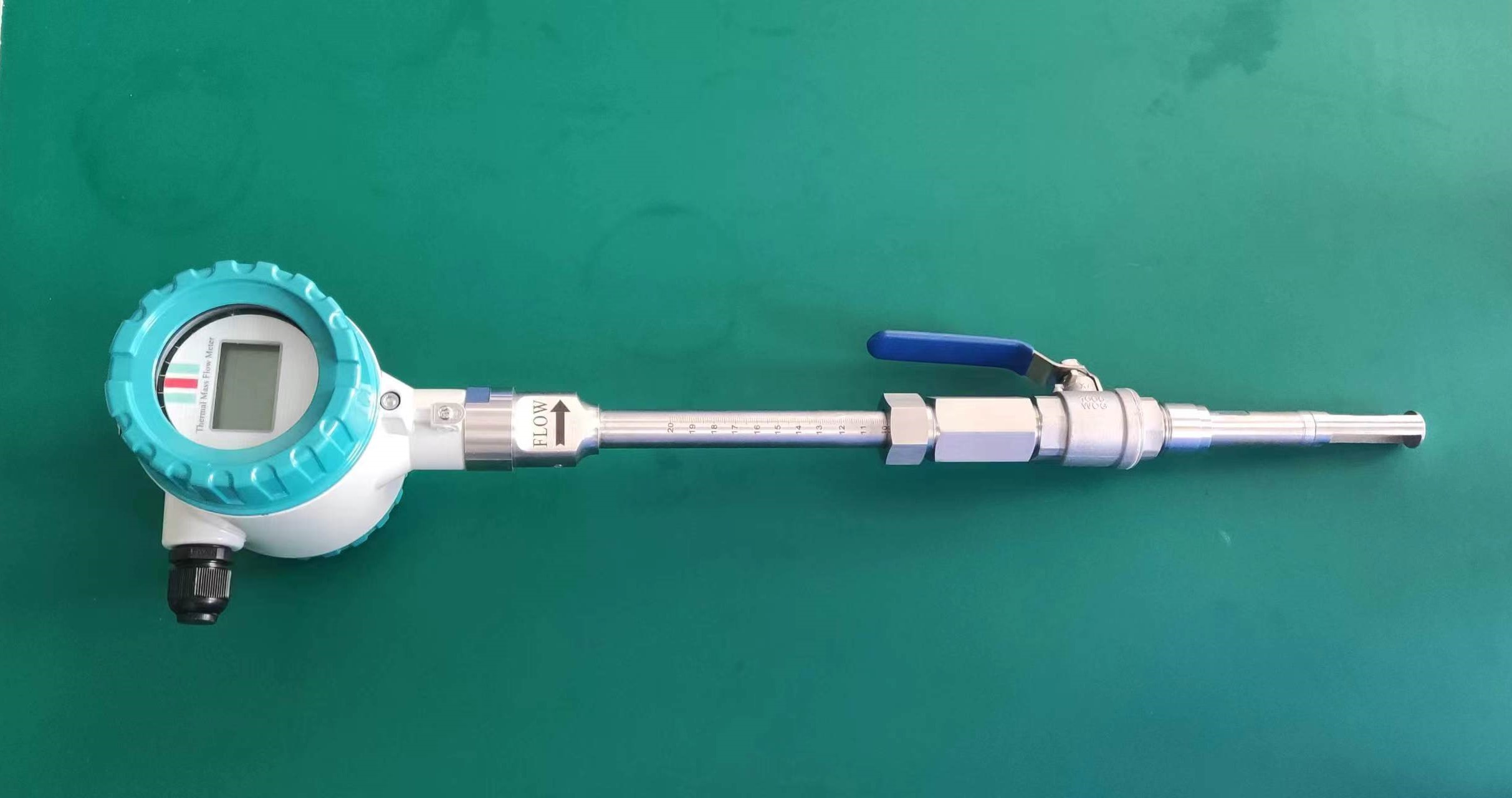

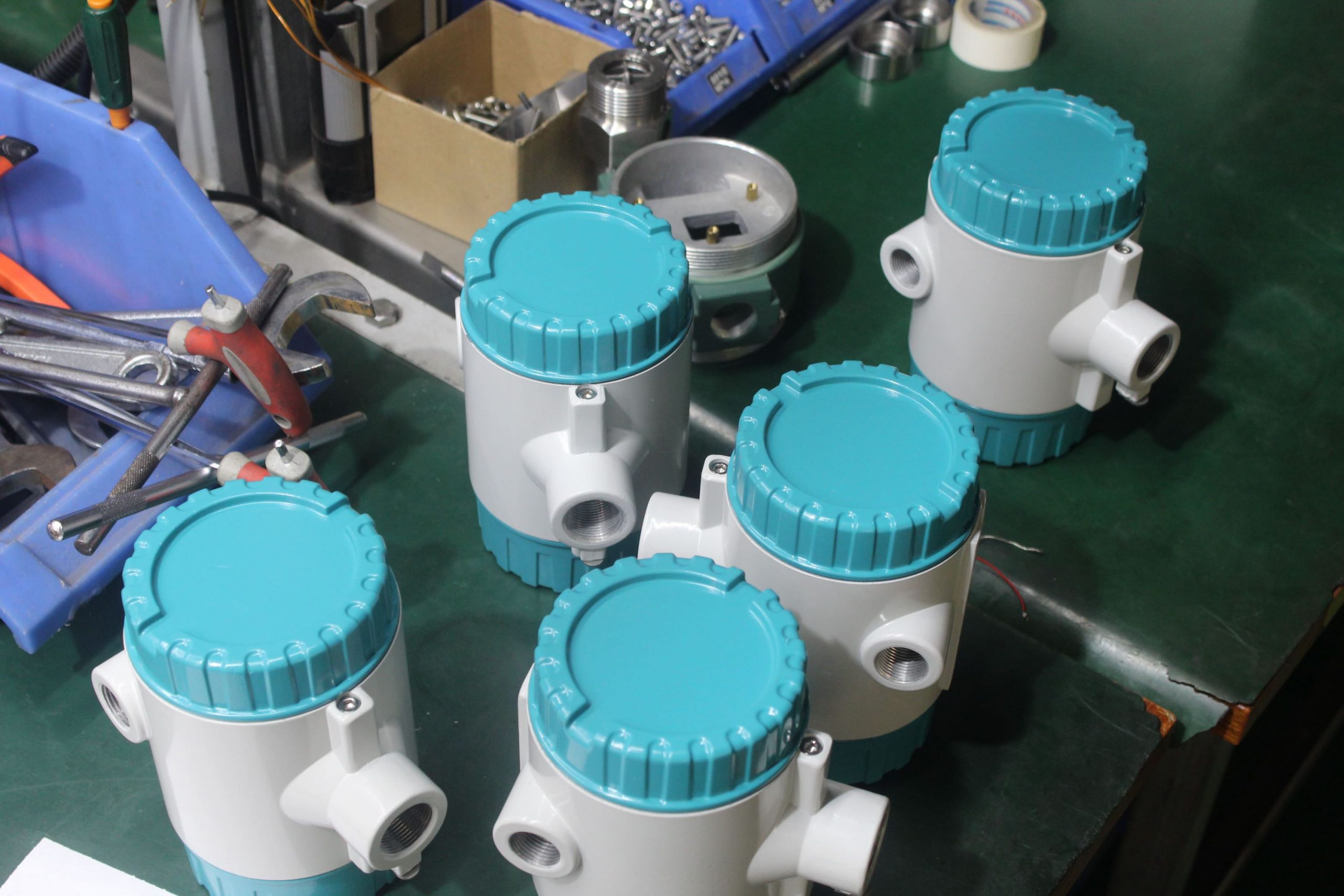

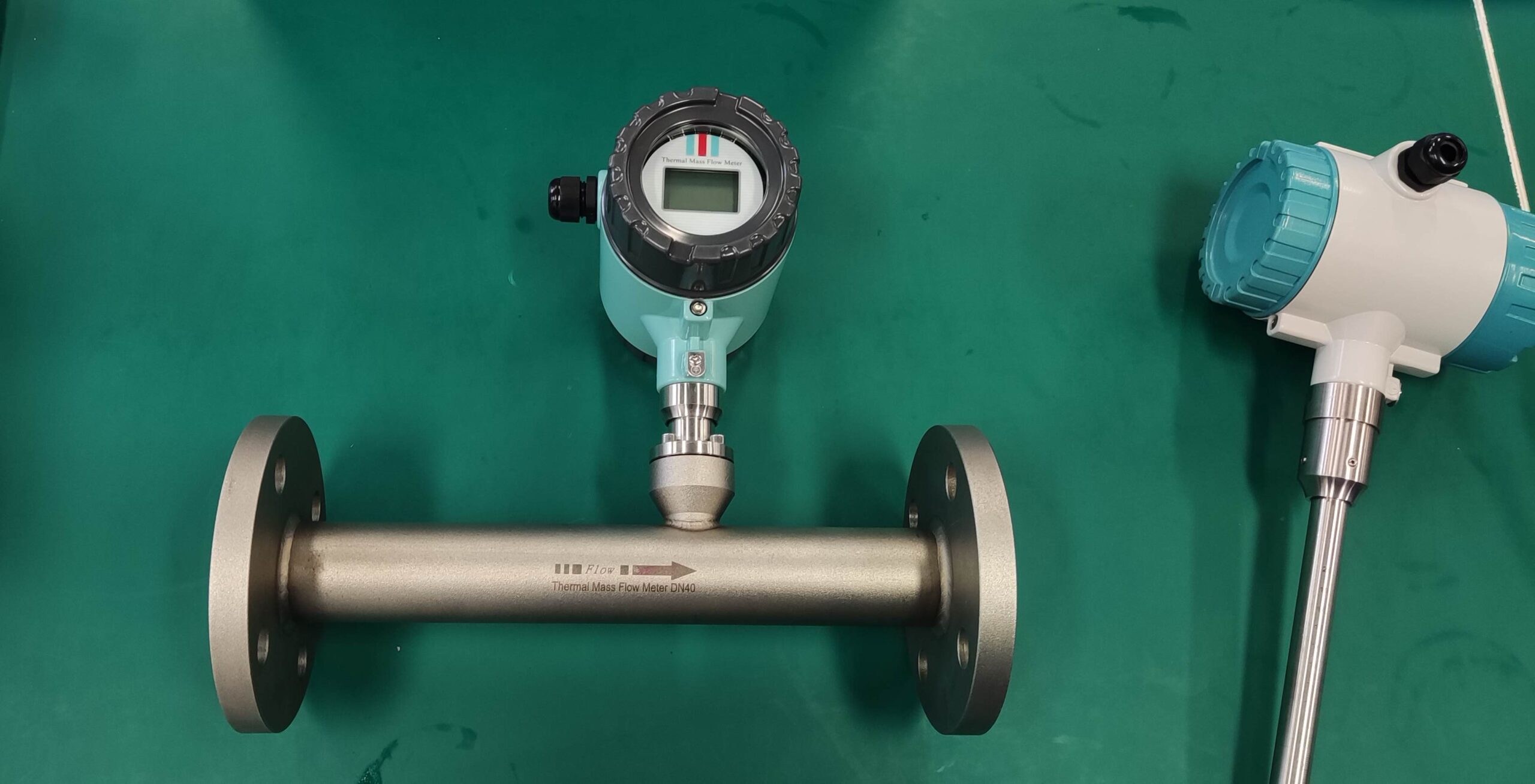

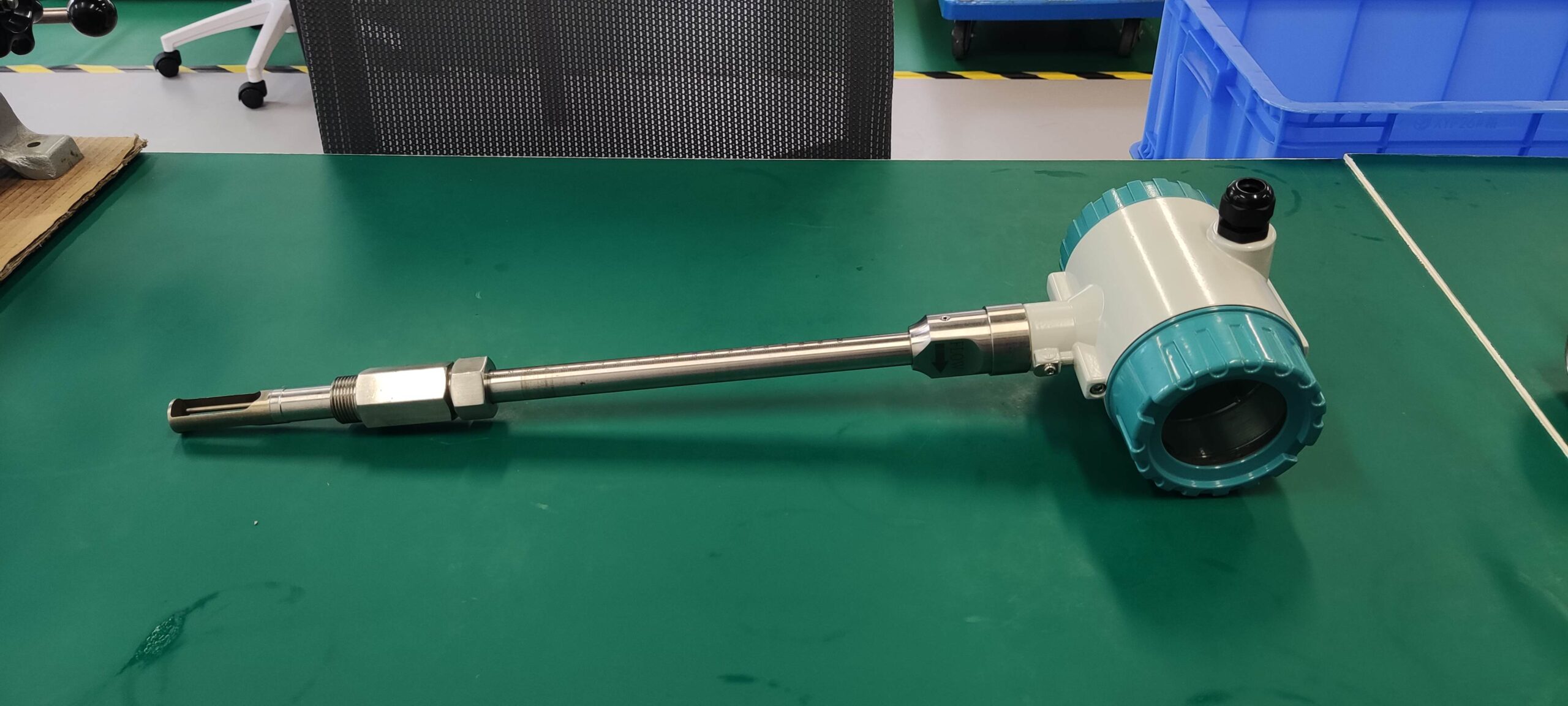

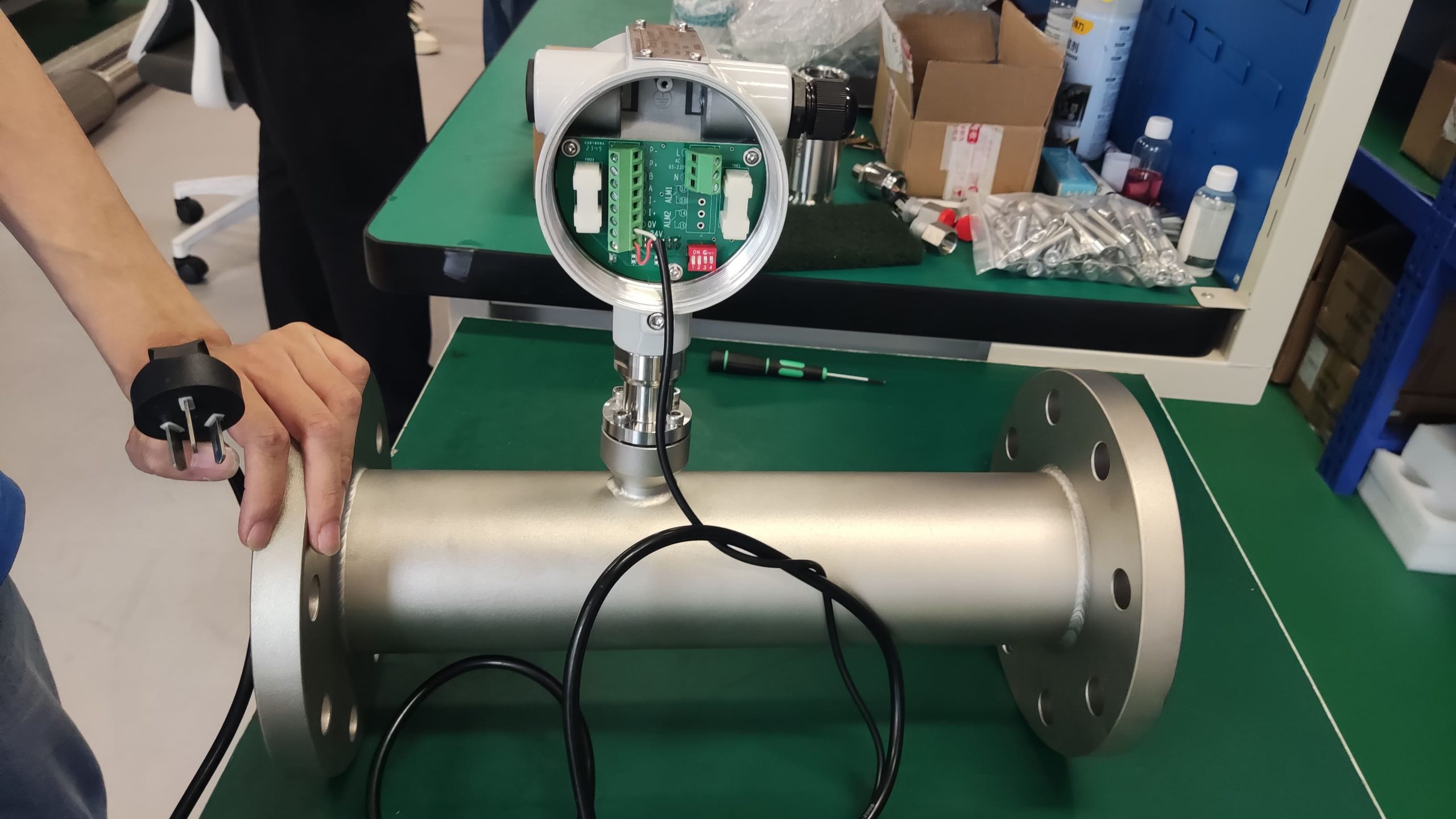

IP65 Industrial RS485 Insertion Thermal Gas Mass Flow Meter DN80 Flowmeter

When selecting a thermal mass flowmeter, several important factors should be taken into consideration to ensure it meets the requirements of the application and provides accurate and reliable measurements. Here are key points to pay attention to:

Flow Measurement Range: Choose a flowmeter with a measurement range that covers the anticipated flow rates of the application. Ensure that the selected flowmeter can accurately measure both low and high flow rates within the desired range.

Fluid Compatibility: Verify that the flowmeter is compatible with the fluid being measured in terms of its chemical composition, temperature, pressure, and viscosity. Some flowmeters may be specifically designed for certain types of fluids or applications.

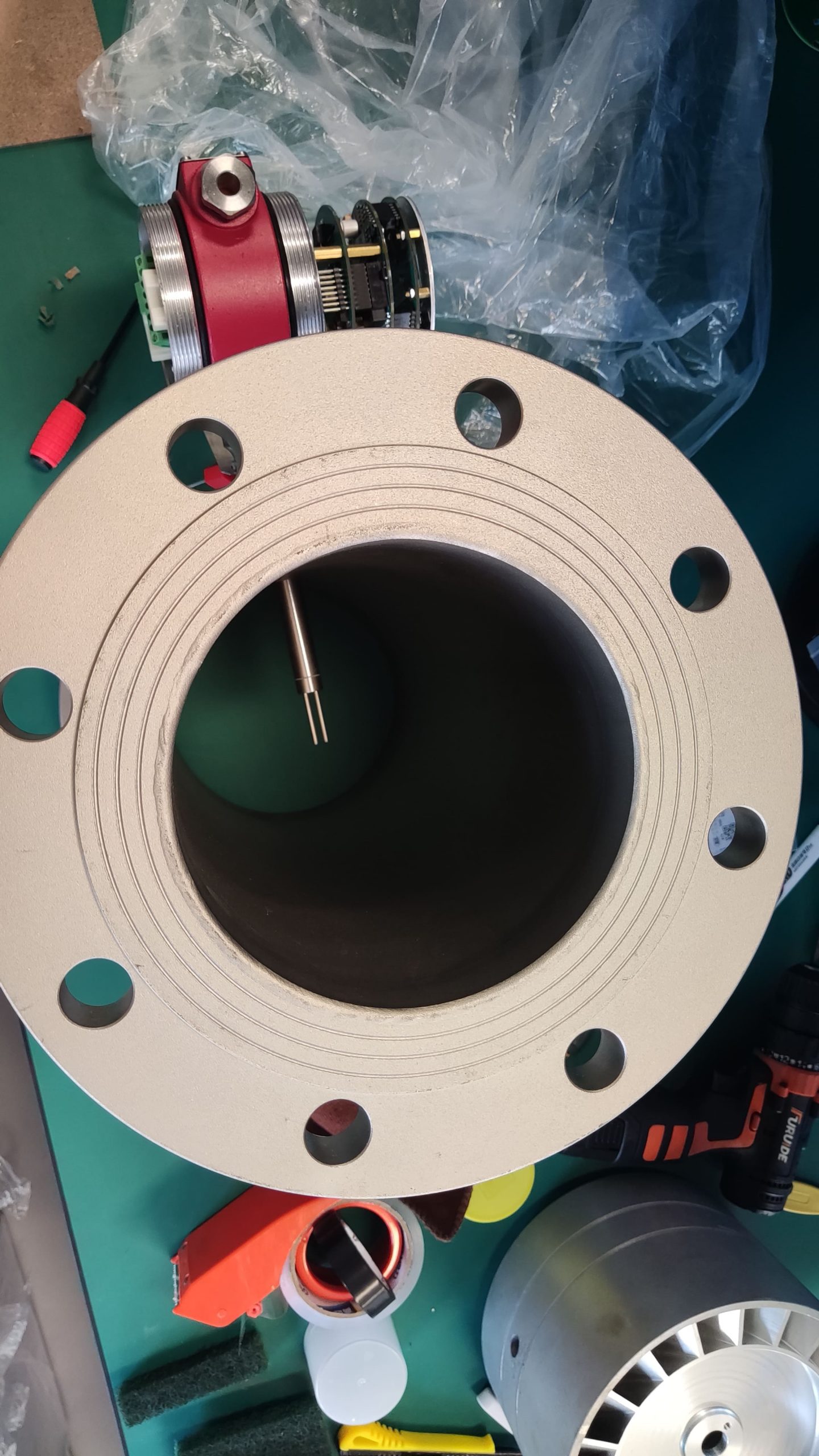

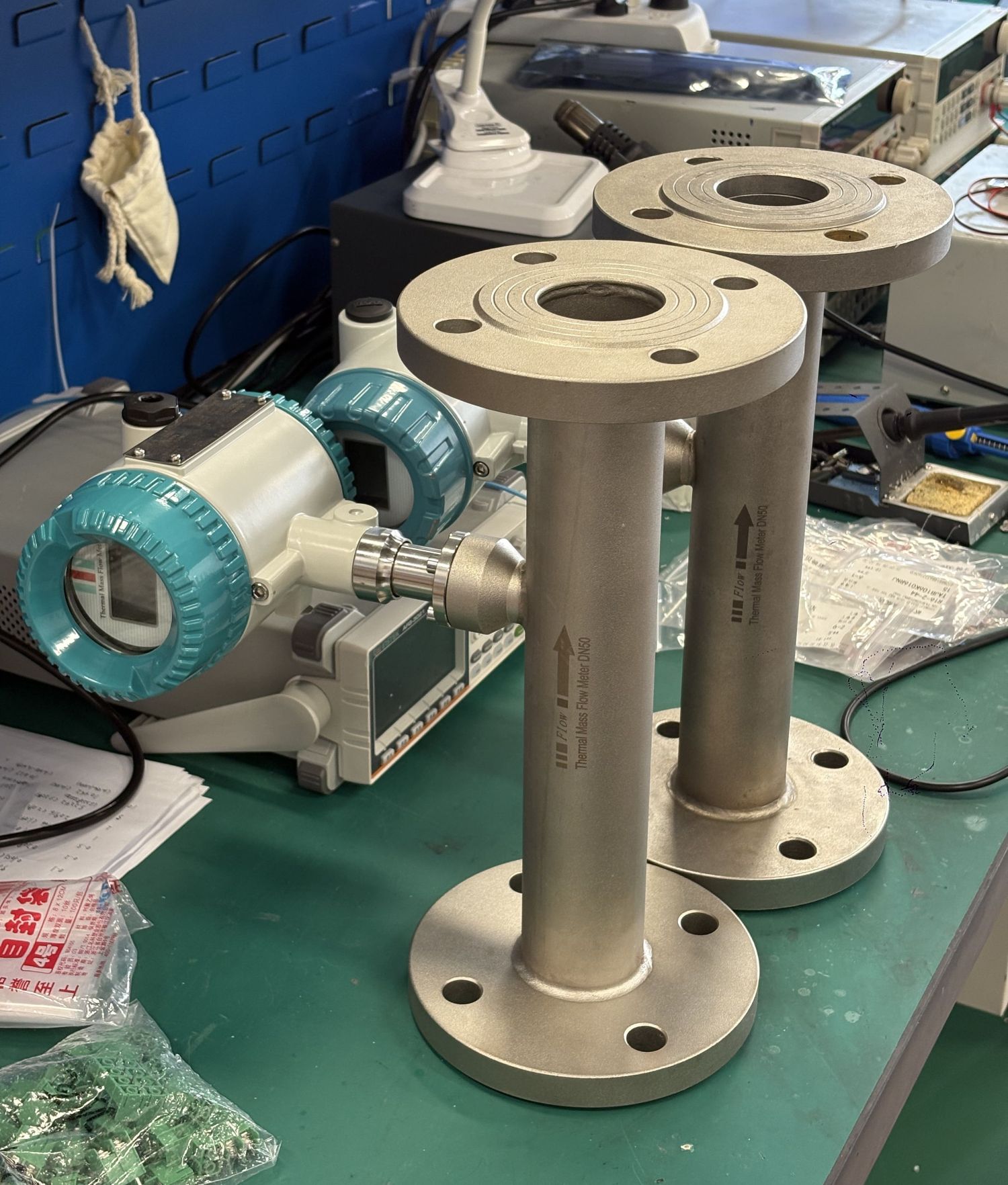

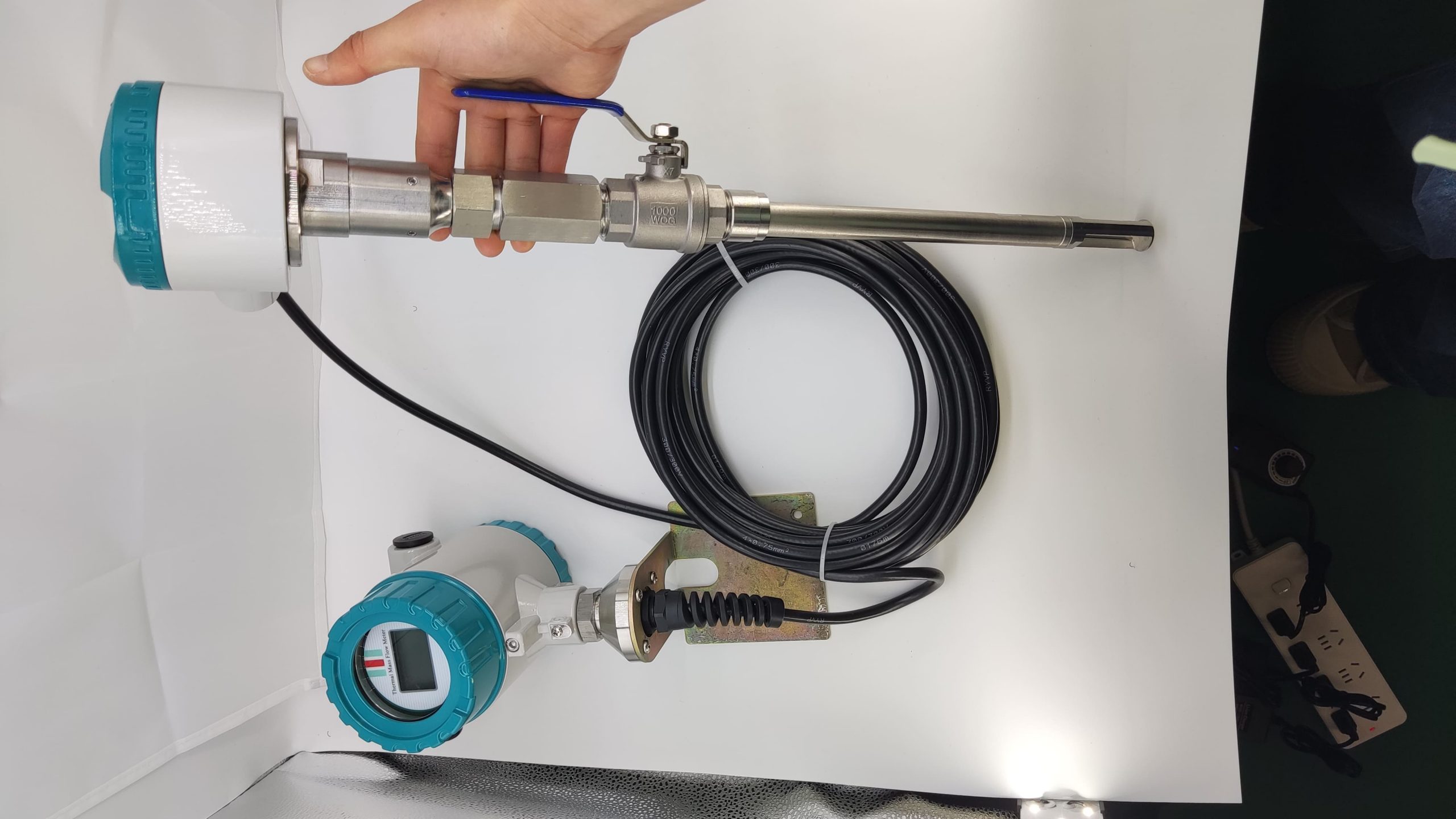

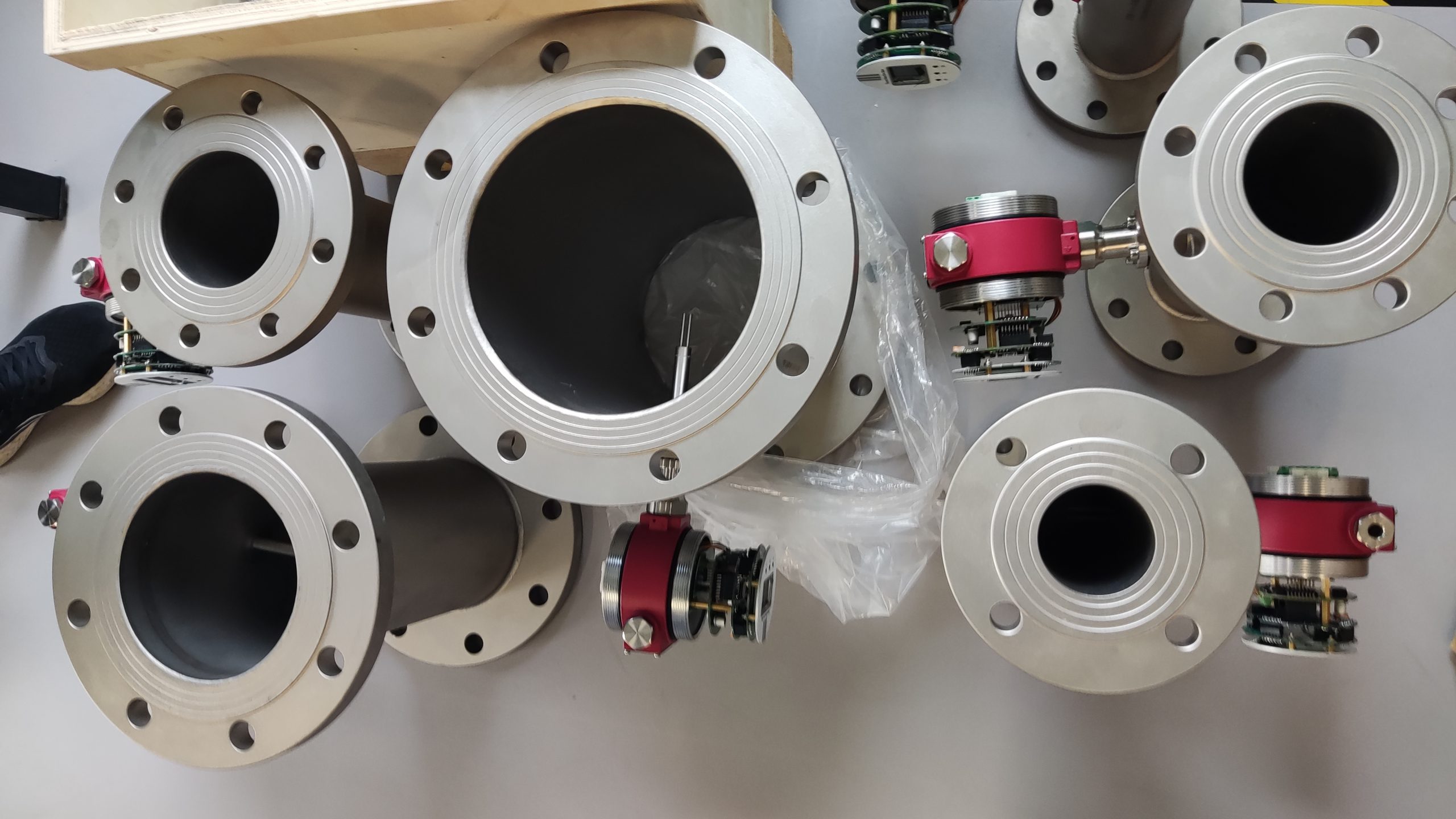

Pipe Size Compatibility: Select a flowmeter with a sensor size that matches the diameter of the pipe in which it will be installed. Ensure that the flowmeter can be properly inserted into the pipeline without causing obstructions or flow disturbances.

Accuracy and Precision: Consider the required level of accuracy and precision for the application. Choose a flowmeter that offers the necessary level of accuracy to meet measurement requirements, taking into account factors such as flow profile, calibration, and environmental conditions.

Response Time: Evaluate the response time of the flowmeter, which refers to the time it takes to detect changes in flow rate and provide a corresponding output. Select a flowmeter with a response time suitable for the dynamics of the application, ensuring timely measurement updates.

Temperature and Pressure Ratings: Ensure that the flowmeter can withstand the temperature and pressure conditions present in the application environment. Choose a flowmeter with appropriate temperature and pressure ratings to prevent damage or performance issues.

Environmental Conditions: Consider the ambient conditions surrounding the flowmeter, such as temperature, humidity, vibration, and potential exposure to corrosive or hazardous substances. Select a flowmeter with suitable environmental protection features to ensure reliable operation in challenging conditions.

Mounting Options and Installation Requirements: Determine the available mounting options and installation requirements for the flowmeter. Choose a flowmeter that can be easily integrated into the existing system and installed in the desired location with proper orientation and alignment.

Output and Communication Interfaces: Verify the available output signals and communication interfaces supported by the flowmeter, such as analog outputs, digital communication protocols (e.g., Modbus, HART), and compatibility with control systems or data acquisition systems.

Cost and Lifecycle Considerations: Evaluate the upfront cost, as well as the long-term maintenance and lifecycle costs associated with the flowmeter. Consider factors such as reliability, durability, and the availability of spare parts and support services from the manufacturer.

By carefully considering these factors during the selection process, you can choose a thermal mass flowmeter that best suits the specific requirements and conditions of your application, ensuring accurate and reliable measurement of fluid flow.