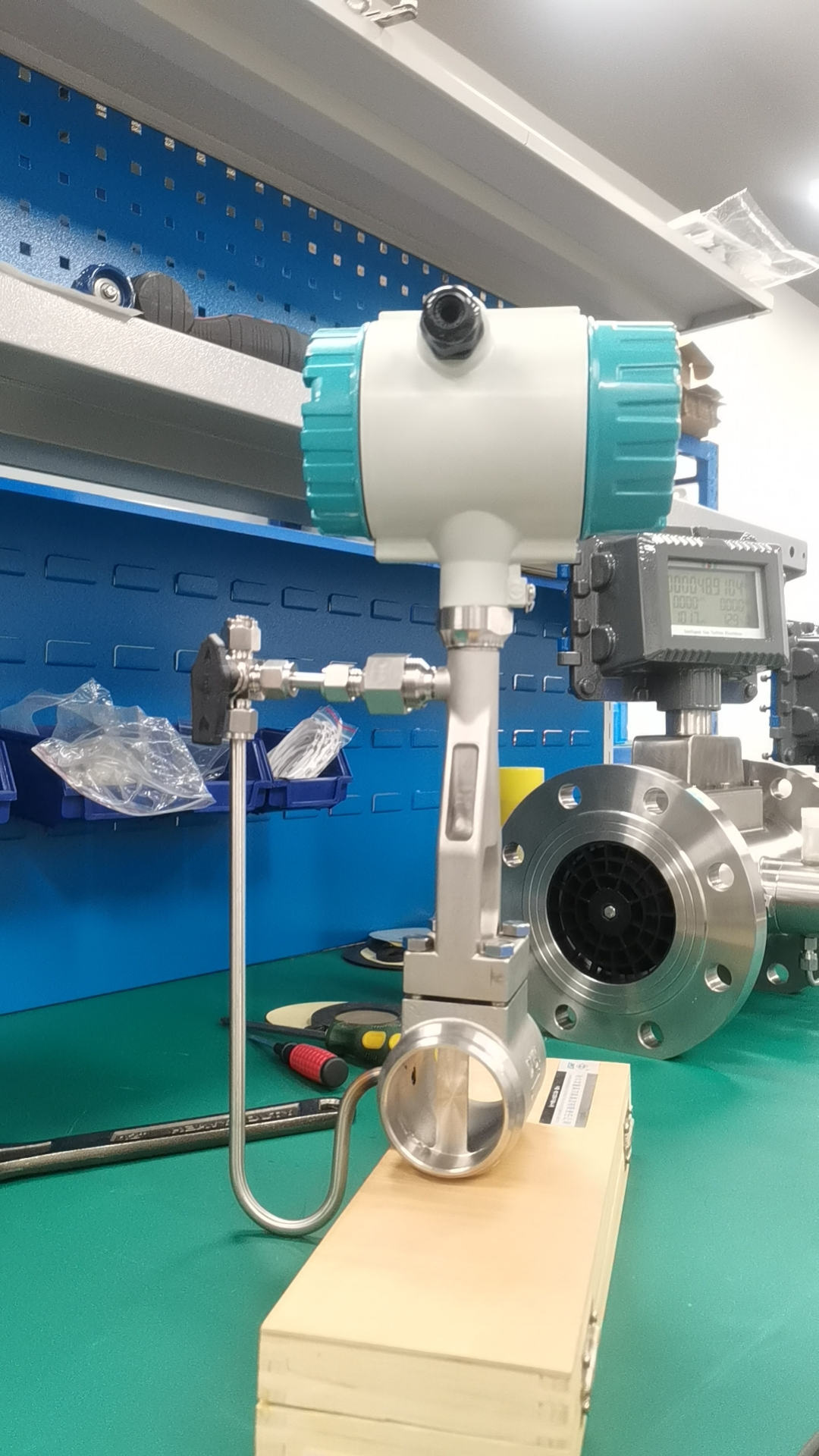

Integrated intelligent vortex flowmeter troubleshooting and daily maintenance

Integrated intelligent vortex flowmeter troubleshooting

In the production process, each of the intelligent vortex flowmeters has passed a strict quality inspection, and each flow real flow calibration. If the meter does not work properly during use, please follow these steps to check.

1. Check the electrical connection

Check whether the power terminal of the instrument is connected correctly and whether there is voltage. Is the line connected correctly? Check loop load and power polarity.

2. Check the installation status

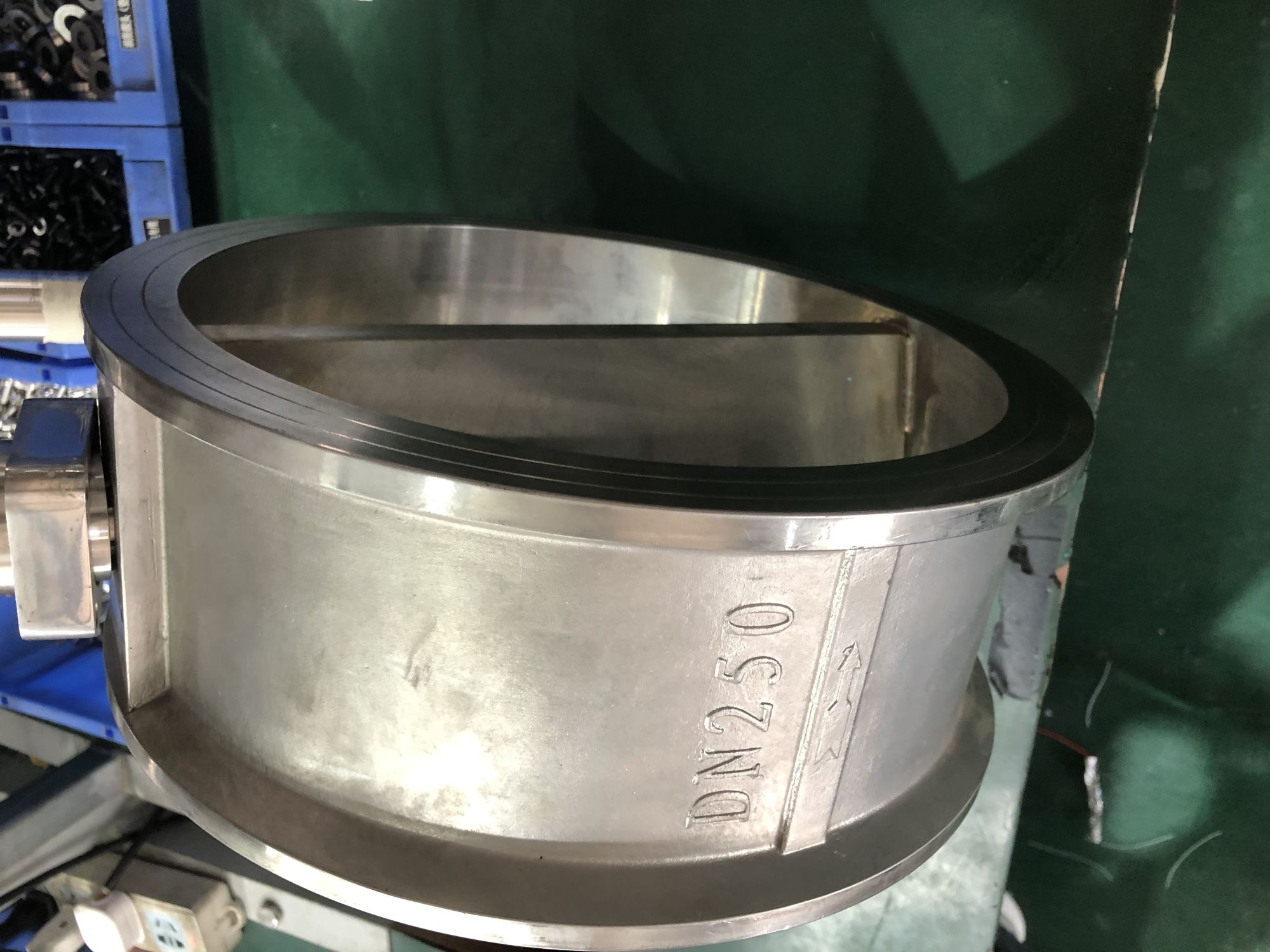

Were the installation requirements followed when installing instrumentation on pipes? Is the flow below the normal operating range? Is the gasket diameter the same as the pipe diameter? Is the grounding good? Are there any parts that protrude into the pipe? Is there scaling in the pipe? Is the meter far from the vibration source?

In strong vibration applications, if there is no flow in the pipe and the meter still has an output display, the sensitivity of the signal amplifier can be adjusted to become smaller. However, it should be noted that the rotation should not be excessive, otherwise the small flow signal will be lost, so that the lower limit of the measurement flow will be increased, affecting the accuracy of the measurement.

Daily maintenance of integrated intelligent vortex flowmeter

Vortex flow meter has no moving parts, the maintenance amount is small, under normal circumstances no maintenance, but when the measured medium is dirty or easy to scale, the inner wall of the flow meter should be cleaned regularly, and the vortex generator and detection probe should be protected during cleaning, taking care not to hurt its surface and corners.