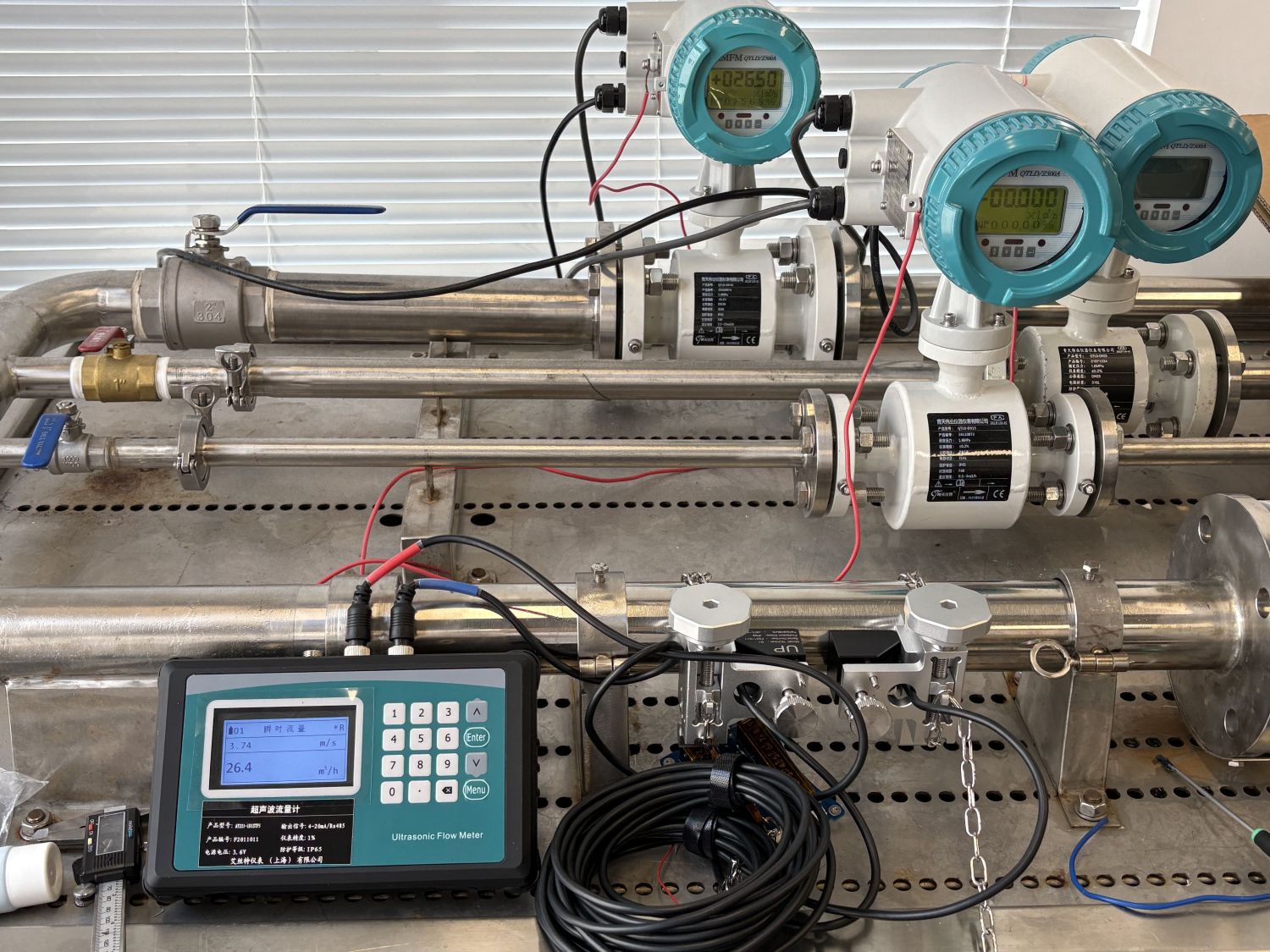

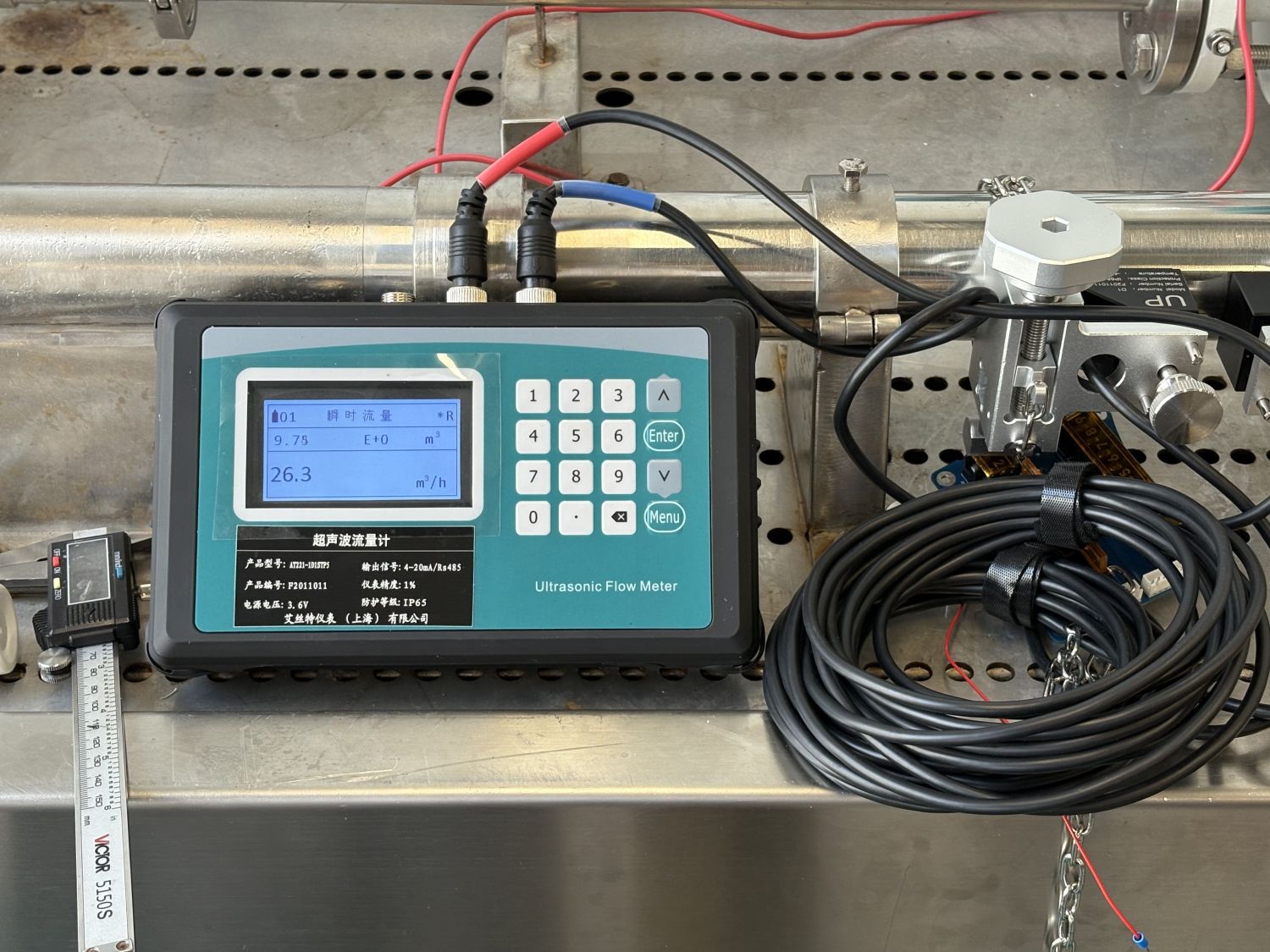

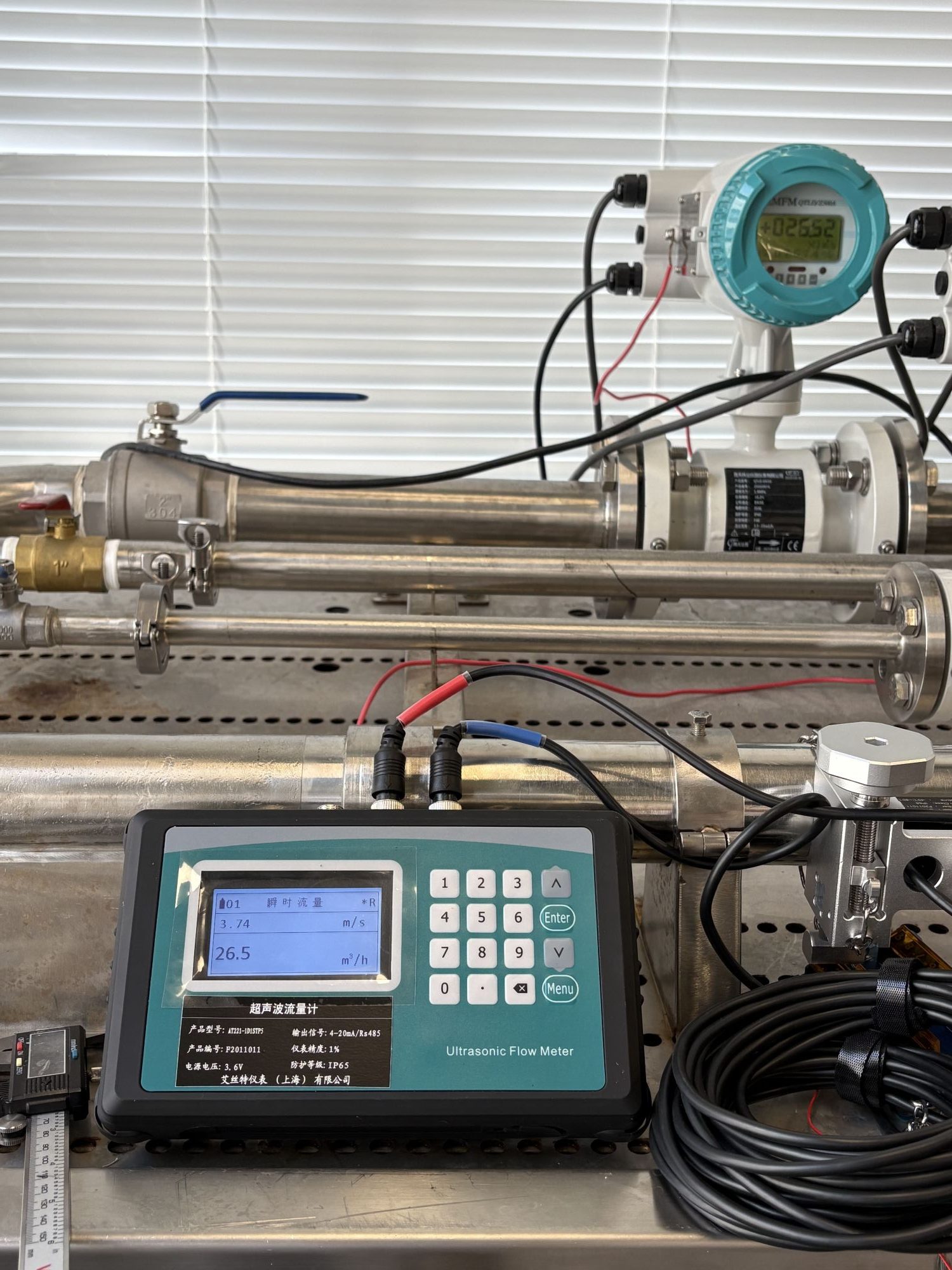

Installation and measurement of ultrasonic flow meter

Ultrasonic flowmeters are instruments that measure flow by detecting the effect of fluid flow on an ultrasonic beam (or ultrasonic pulse). The ultrasonic flowmeter is mainly composed of an ultrasonic transducer (or an ultrasonic flow sensor composed of a transducer and a measuring tube) and a transducer mounted on the measuring pipe.

Ultrasonic flowmeter installation flow sensors generally follow the following steps:

1. Select the appropriate installation measuring point;

2. Select the appropriate installation method according to the site situation or the type of sensor purchased;

(1) Plug-in flow sensor type selection: plug-in type B, installation Z method

(2) Pipe segment flow sensor: parameters have been set before the factory, directly break the pipe installation.

3. Enter the pipe parameters and calculate the installation distance between the two flow sensors.

4. Install the sensor onsite

5. Signal check

Select the flow measurement point

In order to ensure measurement accuracy and stability, the installation point of the ultrasonic flowmeter sensor should be selected in the lower pipe section with uniform flow field distribution (the pipe must be filled with liquid during normal use), and the following principles must be followed:

1. Select a full pipe location, such as a vertical pipe section (fluid flows upward) or a horizontal pipe section.

2. The installation point should be a straight pipe section that is more than 10 times the upstream straight pipe diameter and less than 5 times the downstream straight pipe diameter without any uniform valves, elbows, and diameters, and the installation point should be fully away from interference sources such as valves, pumps, high voltage and frequency converters.

3. Avoid installation at the high point of the pipe system or vertical pipe with free outlet (fluid flow down)

4. For open or half-full pipes, the flow meter should be installed in the U-shaped pipe section.

5. The two sensors must be installed in the horizontal direction of the axial surface of the pipeline and installed within the range of ±45° of the horizontal position of the axis to prevent phenomena such as unsatisfactory pipes, bubbles or precipitation at the bottom from affecting the normal measurement of the sensor. If it is not possible to install horizontally and symmetrically due to the space limitation of the installation site, the sensor can be installed vertically or at an Angle under the condition that the upper part of the tube is free of bubbles.

Ultrasonic flow meter well construction requirements:

If the field sensor needs to be installed in the instrument well, it must have a certain installation space so that people can work upright, that is, the distance between the pipe wall and the wall is at least 600mm, that is, the width W > (D+600*2)mm, the cement pipe W > (D+700*2)mm, the axial width of the instrument well L > D+1200mm. When installing the sensor, avoid flanges, welds, and diameter reduction, and try to install the sensor within the horizontal position of the pipeline axis ±45°.