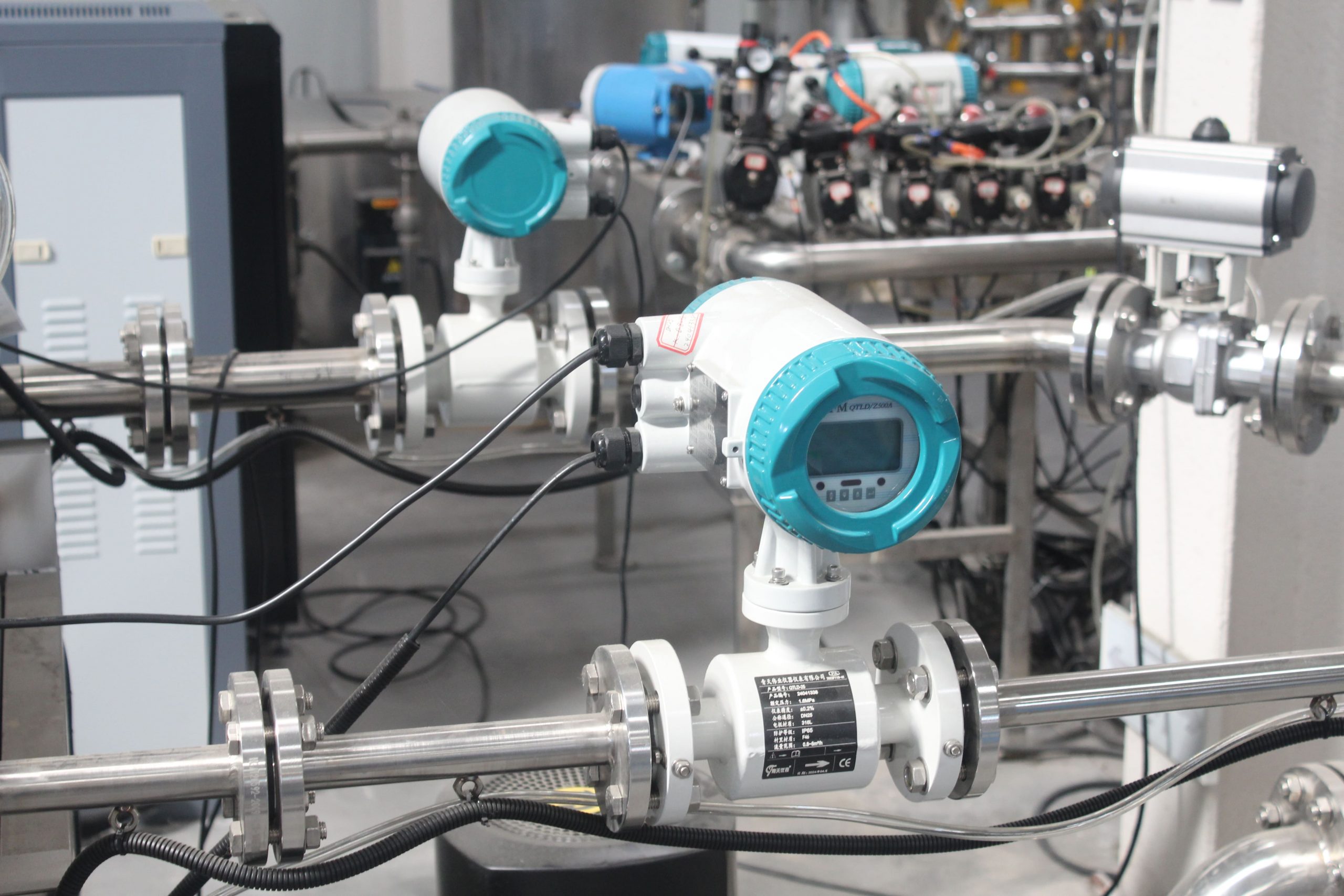

Influence of liquid conductivity on electromagnetic flow meter measurement

According to the principle formula of the electromagnetic flowmeter, the induced signal potential is not affected by the change of conductivity and temperature, pressure, density and viscosity when the liquid conductivity is uniform. However, in the actual measurement, due to the following reasons, the electrical conductivity will also have some impact on the measurement.

1. Slurry noise and low conductivity flow noise cause the electromagnetic flowmeter output signal to swing.

2. The length of the electromagnetic flowmeter measuring tube insulation village is limited, and the metal tube connected with it shorted out part of the flow signal and reduced the signal. In this case, with the decrease of the liquid conductivity, the signal internal resistance increases, so that the output of the electromagnetic flowmeter is reduced.

3. Electromagnetic flowmeter will produce a finite length magnetic field end effect The length of the magnetic field is limited, so that the magnetic flux at the end changes with time, so that the eddy current and secondary magnetic flux are generated in the metal tube and fluid, thereby offsetting the main magnetic flux and reducing the amplitude of the electromagnetic flowmeter signal. In general, the end effect will cause an increase in differential interference. Since the converter uses synchronous sampling and excizes differential interference, the measurement is not affected. However, the excessive conductivity causes the skin effect of the conductive fluid, increases the internal resistance of the signal, reduces the measurement signal of the electromagnetic flowmeter, and forms a negative measurement error. It is generally believed that the upper limit of the measurement conductivity of the industrial electromagnetic flowmeter is 1 S/cm, in fact, the conductivity experiment with saturated salt water, so that the conductivity is 0.2S /cm has been obviously wrong. For liquid metals with very high electrical conductivity, electromagnetic flowmeters with AC excitation cannot be used, and electromagnetic flowmeters with DC magnetic fields need to be used to avoid the impact of skin effects.

-.jpg)

-.jpg)