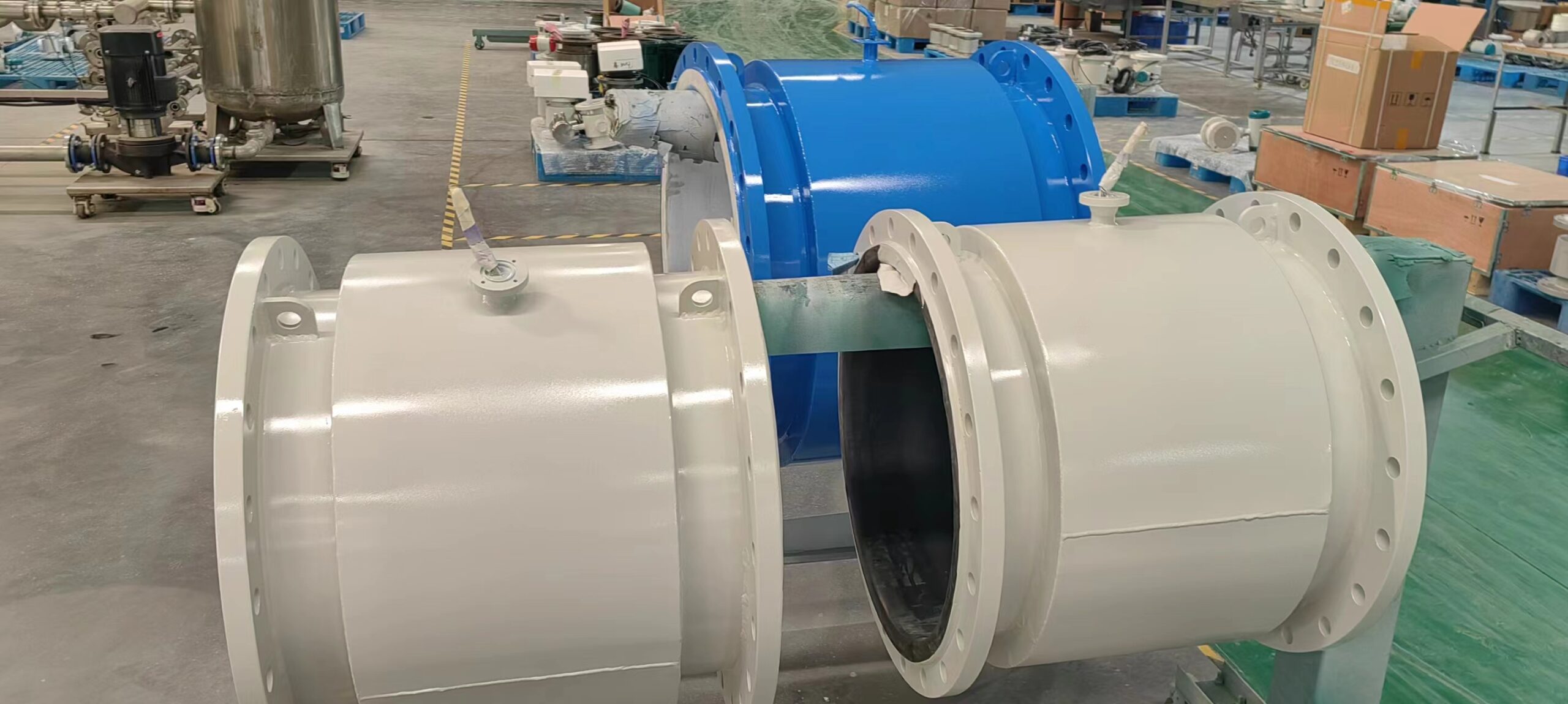

Industrial Type Digital Electromagnetic Flowmeter Water Pump Liquid Magnetic Flow Meter

Several factors can contribute to the inaccurate measurement of flow by electromagnetic flowmeters. These factors can vary depending on the specific application, installation conditions, and characteristics of the fluid being measured. Here are some common reasons for inaccurate flow measurement with electromagnetic flowmeters:

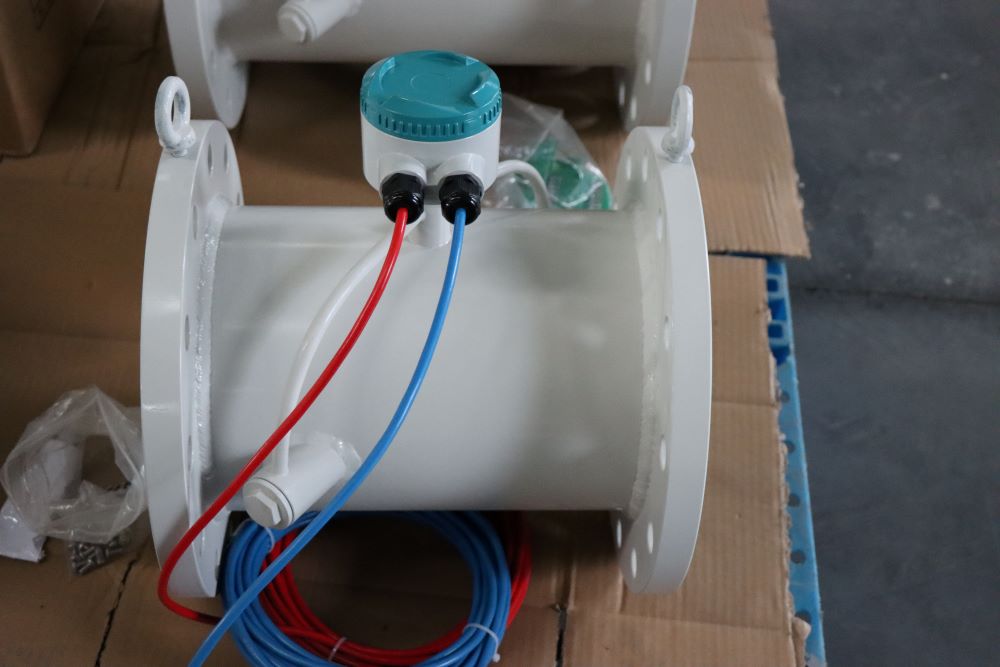

Improper Installation: Incorrect installation, such as improper alignment of the flowmeter, inadequate grounding, or insufficient straight pipe lengths upstream and downstream of the flowmeter, can lead to inaccurate measurements.

Air Bubbles or Gas Entrapment: Air bubbles or gas entrapped in the fluid can distort the magnetic field, leading to inaccurate measurements. Proper degassing or air elimination devices should be installed upstream of the flowmeter to minimize this effect.

Electrode Fouling or Coating: Accumulation of deposits, scaling, or coating on the electrodes can interfere with the electromagnetic signal and disrupt flow measurement accuracy. Regular maintenance and cleaning of electrodes are necessary to prevent this issue.

Flow Profile Disturbances: Non-uniform flow profiles, such as swirl, turbulence, or flow disturbances caused by valves, pumps, or fittings, can affect the accuracy of flow measurement. Adequate upstream and downstream straight pipe lengths help to establish a stable flow profile.

Incorrect Fluid Properties: Variations in fluid conductivity, temperature, viscosity, or composition beyond the specified range of the flowmeter can lead to inaccurate measurements. Calibration adjustments may be necessary to compensate for changes in fluid properties.

Electromagnetic Interference (EMI): External electromagnetic interference from nearby power lines, motors, or other electronic equipment can disrupt the electromagnetic signal and cause measurement errors. Proper shielding and grounding techniques should be employed to minimize EMI effects.

Wear and Tear: Degradation or damage to flowmeter components, such as electrodes, liners, or cables, over time can lead to measurement inaccuracies. Regular inspection, maintenance, and replacement of worn parts are essential to ensure reliable performance.

Flow Velocity Limitations: Electromagnetic flowmeters may have limitations on the minimum and maximum flow velocities they can accurately measure. Operating outside of these velocity limits can result in inaccurate measurements.

Calibration Drift: Over time, electromagnetic flowmeters may experience calibration drift due to factors such as sensor aging, environmental changes, or mechanical wear. Regular calibration checks and adjustments are necessary to maintain measurement accuracy.

Incorrect Sizing or Selection: Choosing a flowmeter that is not properly sized or selected for the specific flow rate, pipe size, or fluid characteristics of the application can result in inaccurate measurements. It’s essential to consider the flow range, pipe diameter, and fluid properties when selecting a flowmeter.

Addressing these factors through proper installation, maintenance, calibration, and selection of electromagnetic flowmeters can help minimize inaccuracies and ensure reliable flow measurement in various industrial applications.

-.jpg)