Industrial High Pressure Digital Liquid Control Electromagnetic Flow Meter Water Magnetic Flowmeter

The grounding ring is a crucial component in the installation of an electromagnetic flowmeter as it helps establish proper grounding and ensures accurate and reliable measurements. Here’s a general guide on how to install an electromagnetic flowmeter grounding ring:

Materials Needed:

Electromagnetic flowmeter grounding ring (provided by the manufacturer).

Appropriate tools (e.g., wrenches, screwdrivers).

Grounding cable.

Installation Steps:

Select the Installation Location:

Choose an appropriate location for installing the grounding ring. Typically, this is near the electromagnetic flowmeter. The ring should be installed on the pipe between the flowmeter flanges.

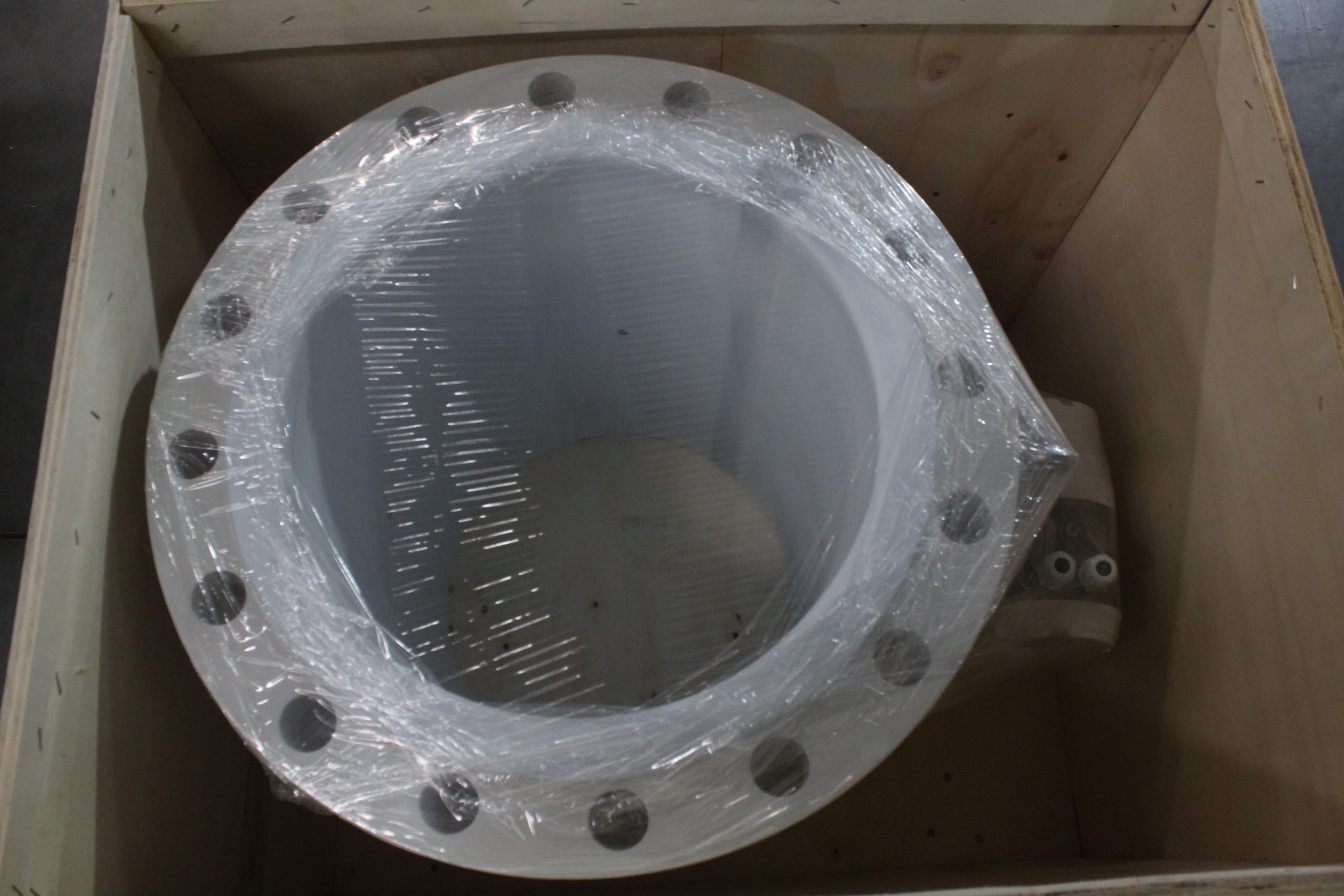

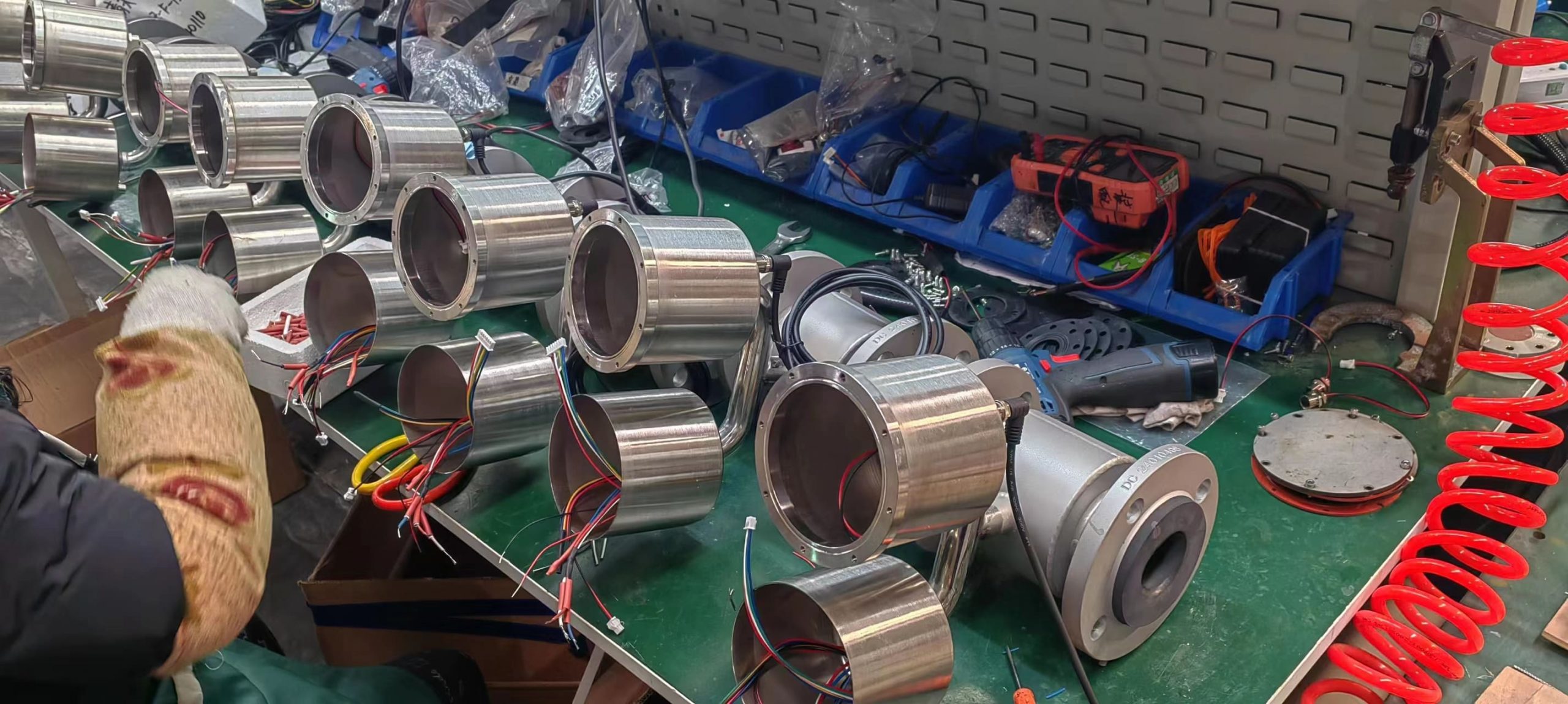

Prepare the Grounding Ring:

Inspect the grounding ring to ensure it is free from any defects or damage. Check that the ring is of the correct size and material specified by the flowmeter manufacturer.

Prepare the Pipe Surface:

Ensure that the surface of the pipe where the grounding ring will be installed is clean and free from any corrosion, paint, or other contaminants. Use a wire brush or other suitable tools to clean the pipe surface.

Install the Grounding Ring:

Slide the grounding ring onto the pipe between the flowmeter flanges. Make sure it is positioned correctly and aligned with the flowmeter electrodes. The grounding ring should make good contact with the pipe surface.

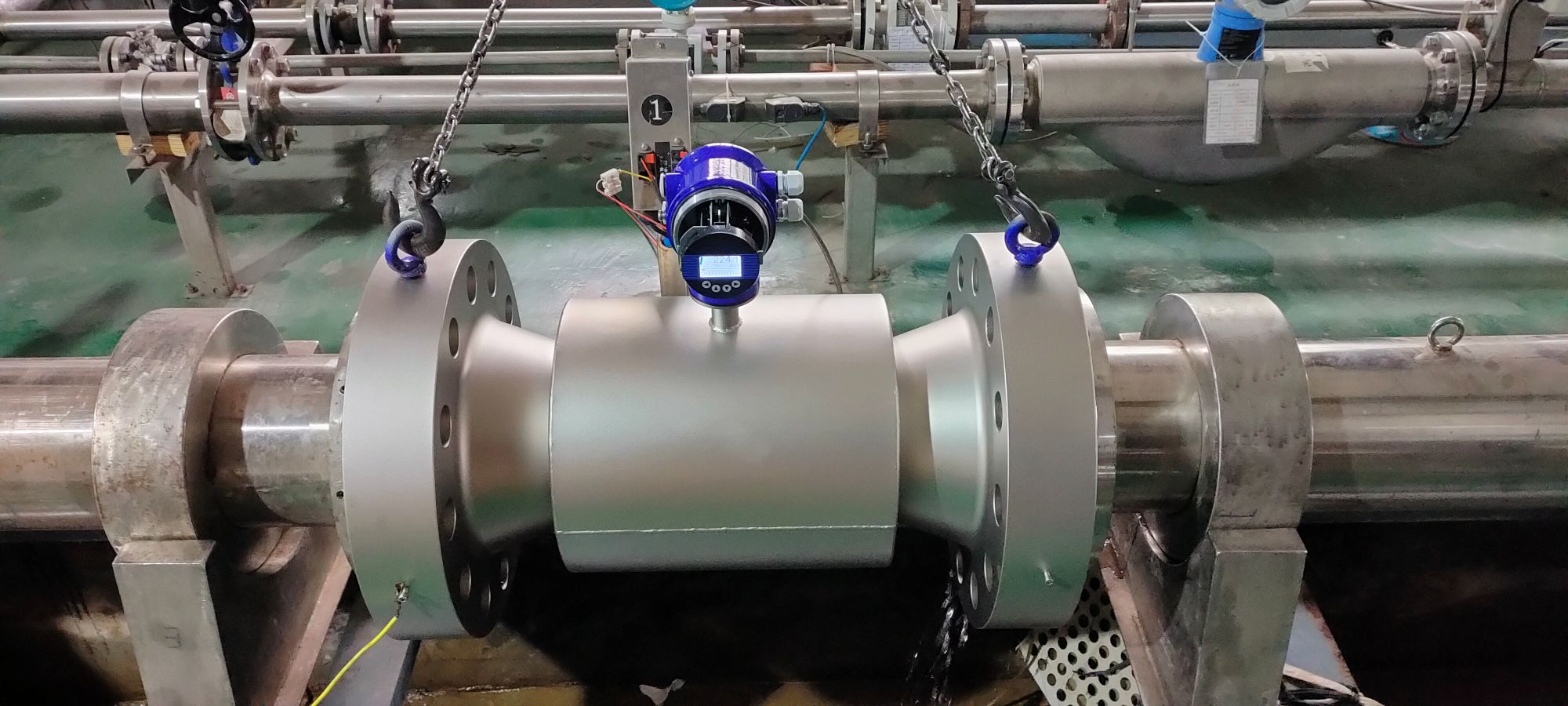

Tighten Flange Bolts:

Securely tighten the flange bolts to ensure the grounding ring is firmly in place. Follow the specified torque values provided by the flowmeter manufacturer. Tightening the bolts evenly helps maintain a uniform contact between the grounding ring and the pipe.

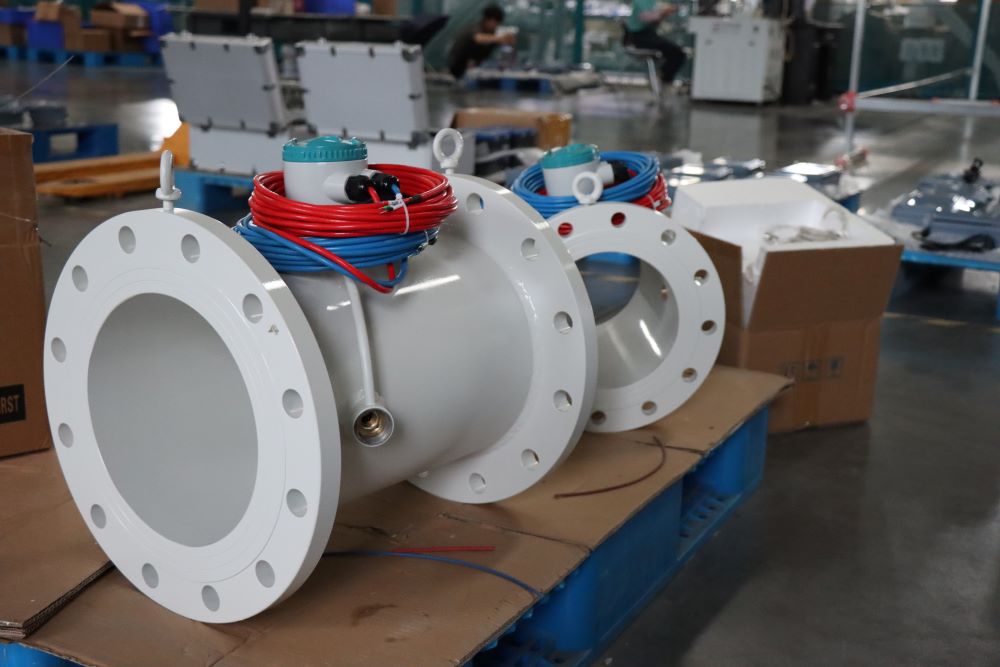

Attach Grounding Cable:

Connect the grounding cable to the grounding ring. Ensure a secure and tight connection to establish a good electrical bond. The other end of the grounding cable should be connected to a reliable earth ground, such as a grounding rod or a suitable grounding system as per local electrical codes.

Verify Electrical Continuity:

Check for electrical continuity between the grounding ring, the pipe, and the grounding system. Use a multimeter or other suitable testing equipment to verify that the grounding connection is effective.

Follow Manufacturer Guidelines:

Always follow the specific installation instructions provided by the electromagnetic flowmeter manufacturer. Different models may have variations in grounding requirements, and adherence to the manufacturer’s guidelines is crucial for proper operation.

Inspect Regularly:

Periodically inspect the grounding ring and the associated connections for any signs of wear, corrosion, or damage. Ensure that the grounding system remains effective over time.

-.jpg)

-.jpg)