How to select gas flow meter?

The selection of flue gas flowmeter is a complicated but critical process, which is directly related to the accuracy of measurement results and the reliability of equipment. Here are some of the main factors to consider in the selection process:

1. Measurement requirements

Measurement range: Determine the range of flue gas flow required to be measured in order to select the appropriate flue gas flowmeter model.

Measurement accuracy: According to the actual application requirements, choose the appropriate measurement accuracy. In general, the cost of high-precision gas flowmeters will also increase accordingly.

Temperature and pressure: Know the temperature and pressure range of the flue gas to choose a flue gas flowmeter that can withstand these conditions. For example, high temperature flue gas needs to choose a high temperature resistant flue gas flowmeter.

2. smoke composition

Different flue gas composition has a great influence on the selection of flue gas flowmeter. For example, smoke containing corrosive components needs to choose a gas flow meter made of corrosion resistant materials. At the same time, if the flue gas contains a large number of particles or high humidity, it is also necessary to consider the impact of these factors on the flue gas flowmeter.

3. Environmental conditions

Selection also needs to consider environmental conditions, such as vibration, noise, electromagnetic interference and so on. If there is a large vibration or noise in the measurement environment, it is necessary to choose a gas flowmeter with high stability and anti-interference ability.

4. Maintenance and operation

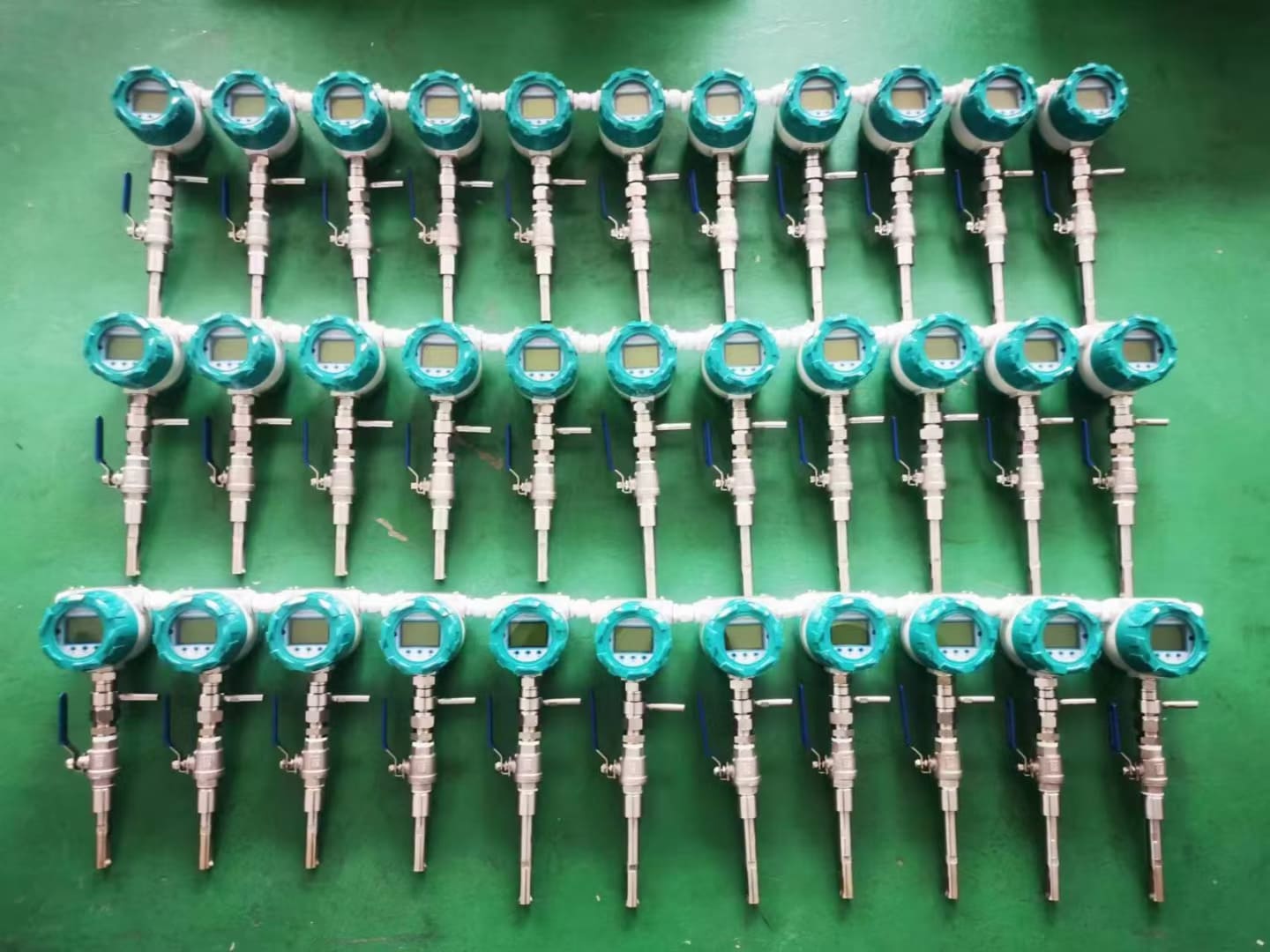

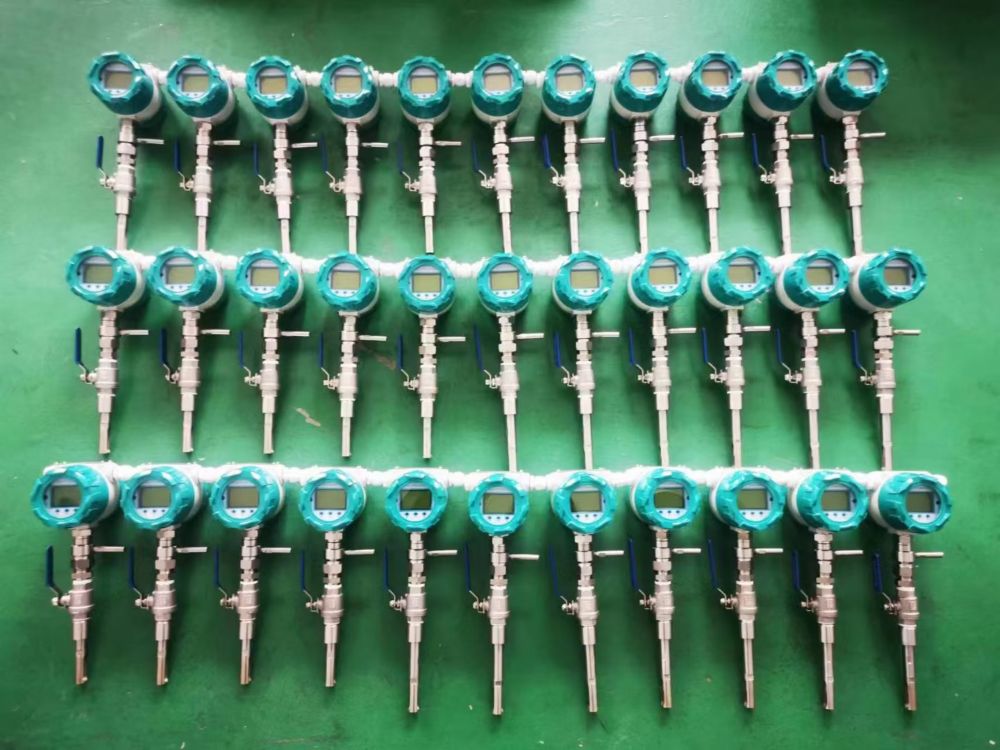

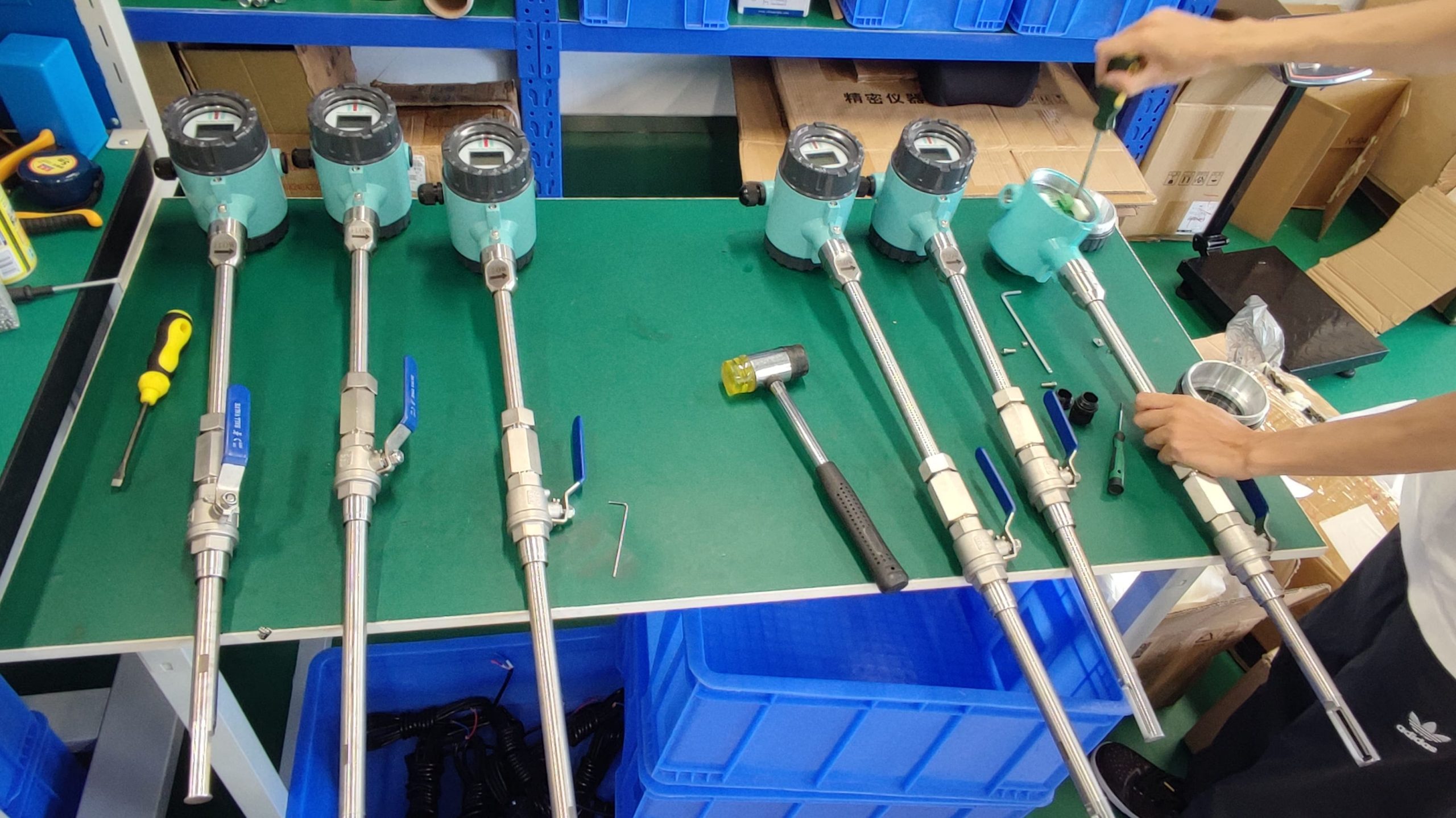

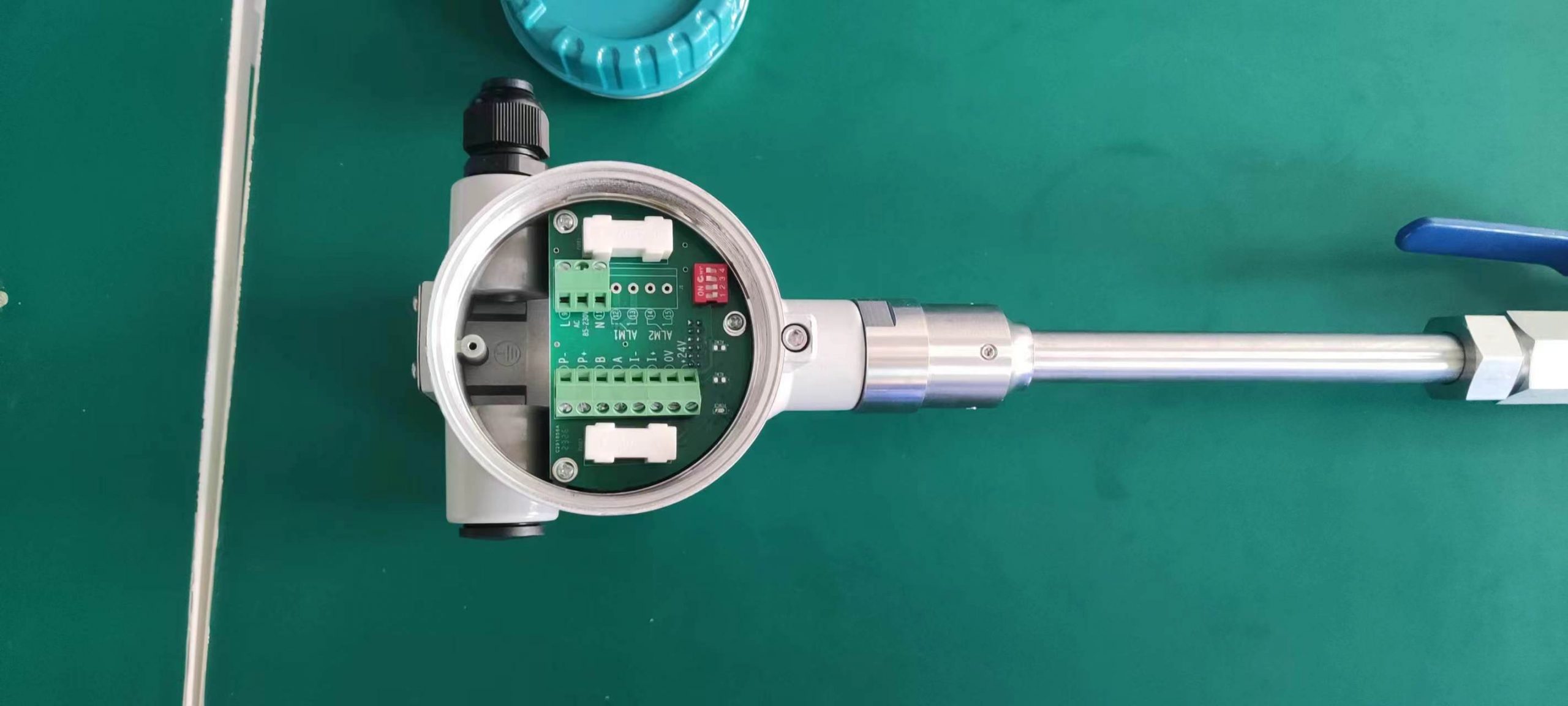

Easy installation and maintenance: Choose gas flow meters that are easy to install, use and maintain to reduce operating and labor costs.

Spare parts and repair services: Consider the availability of spare parts and repair service capabilities of the selected brand to ensure that equipment can be repaired in a timely manner in the event of a failure.

5. selection suggestions

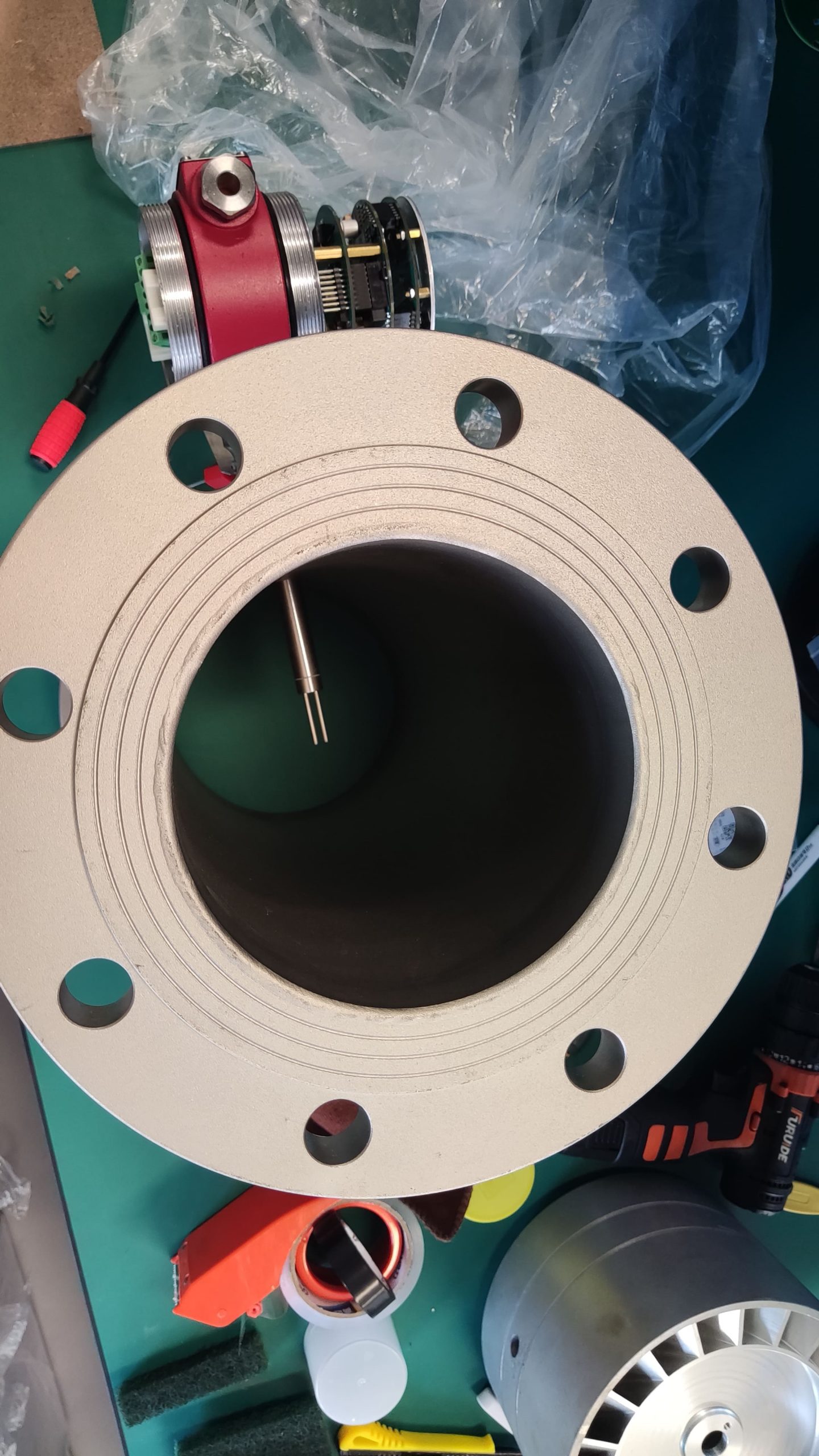

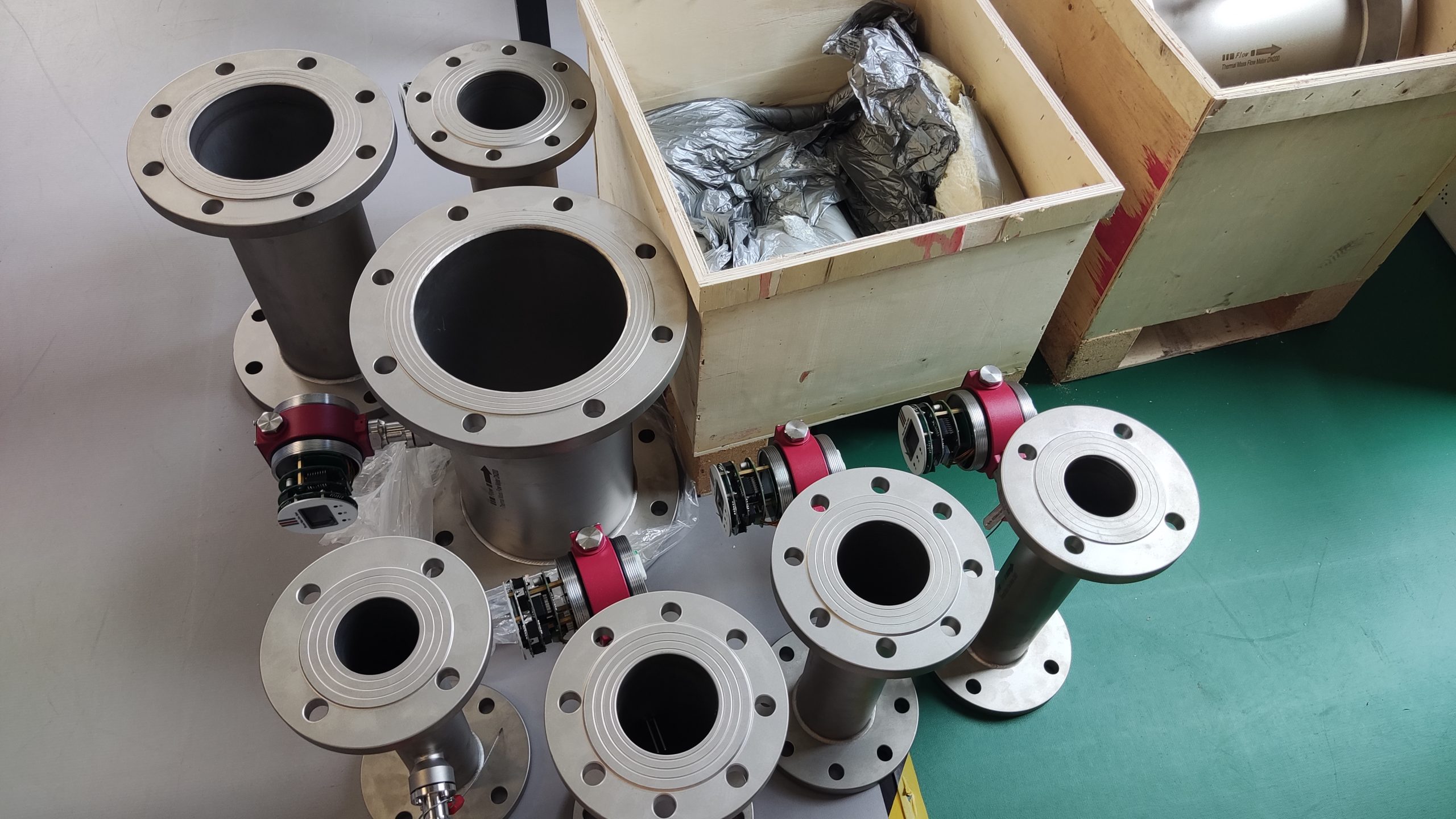

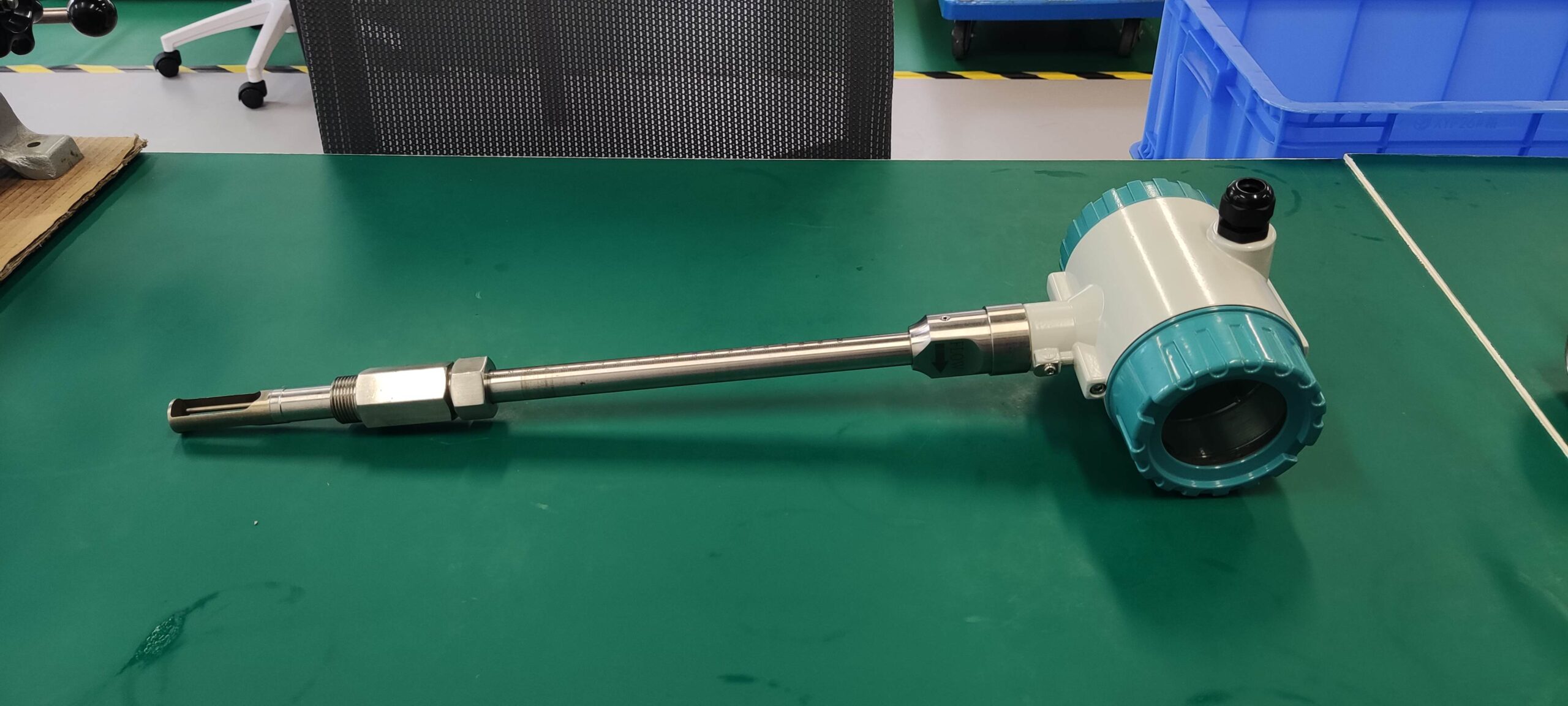

Technical principle: Select the appropriate technical principle according to the actual needs. For example, the differential pressure flowmeter is suitable for the measurement of the flow rate of a large cross-section of gas, and the thermal conductivity flowmeter has certain advantages in resistance, anti-blocking ash, wear resistance and installation convenience.

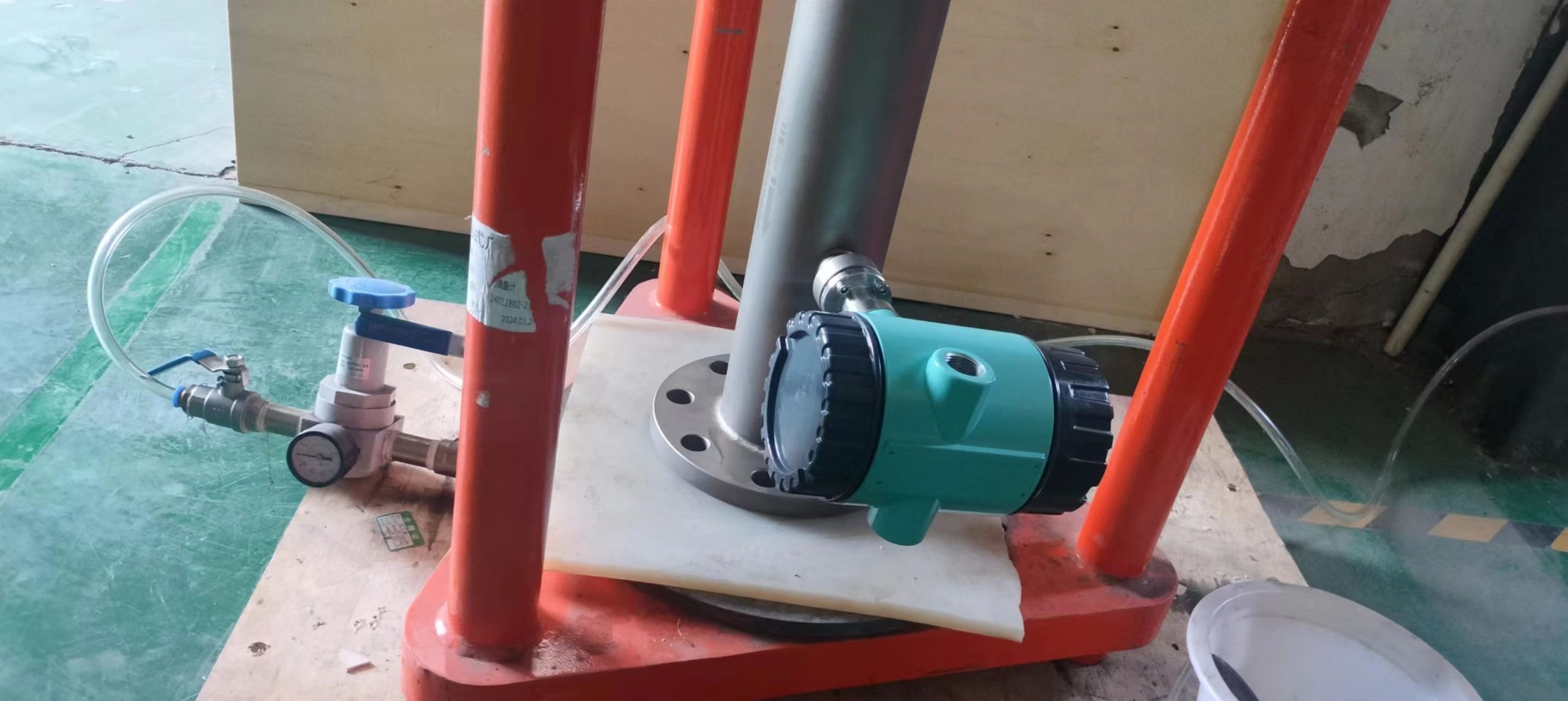

Installation mode: Select an appropriate installation mode based on site conditions, such as horizontal installation or vertical installation.

6. Precautions

Avoid mounting directly before and after valves, elbows and other components: these components can greatly change the fluid flow and affect the measurement accuracy.

Regular calibration and maintenance: Gas flow meters are calibrated and maintained regularly to ensure their measurement accuracy and stability.