How to properly install a insertion vortex flow meter?

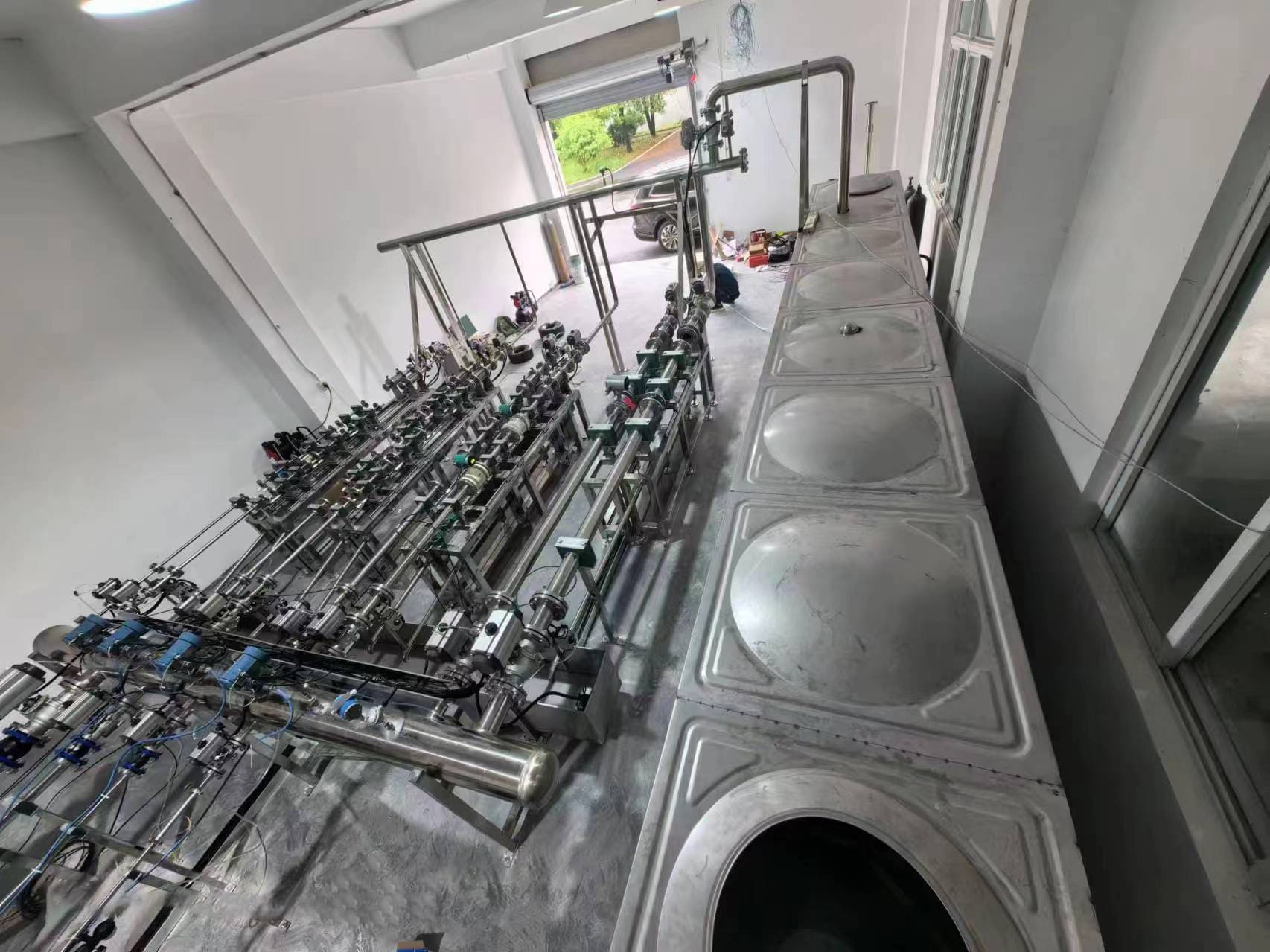

The insertion vortex flowmeter is mainly used for the flow measurement of large-diameter gas, liquid and steam medium in industrial pipelines. In order to ensure the accuracy of its measurement, the following points should be noted when installing:

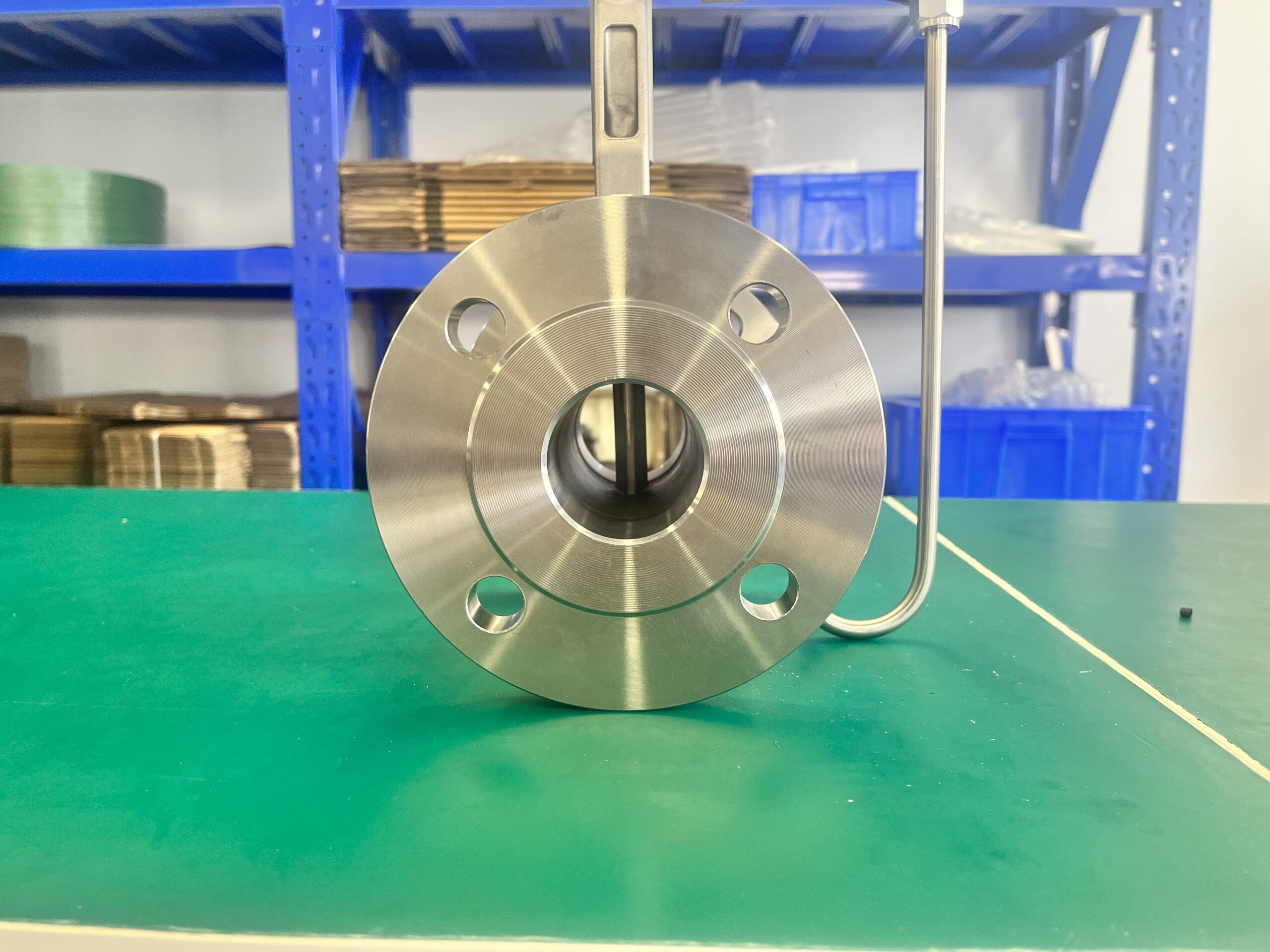

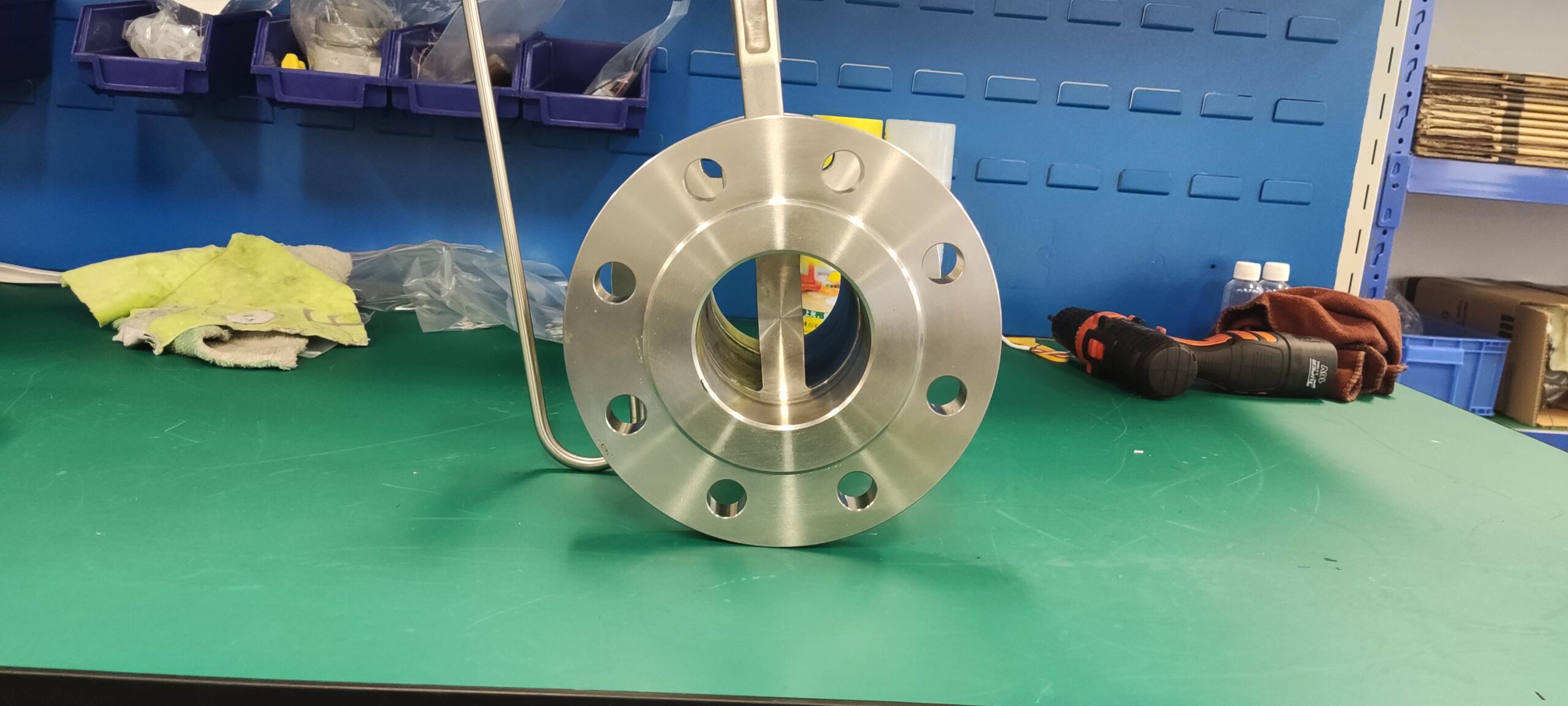

1. A round hole with a diameter of 100 must be cut on the horizontal pipe directly above the pipe that needs to be installed with the plug-in vortex flowmeter, and the surrounding burrs and welding slag must be removed.

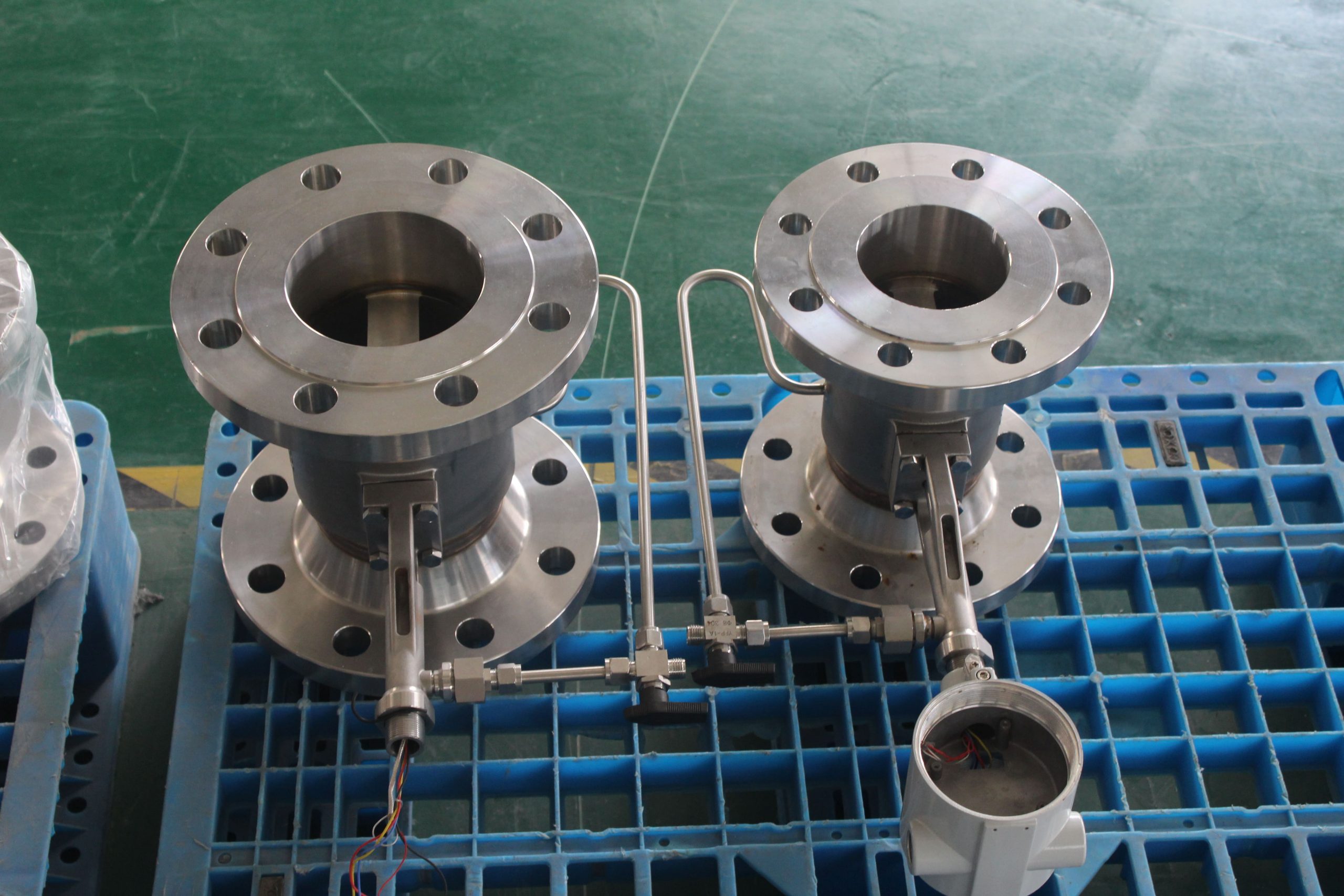

2, the matching end, that is, the short pipe with flange on the hole above, to keep the short pipe and the pipe perpendicular, must be welded firmly.

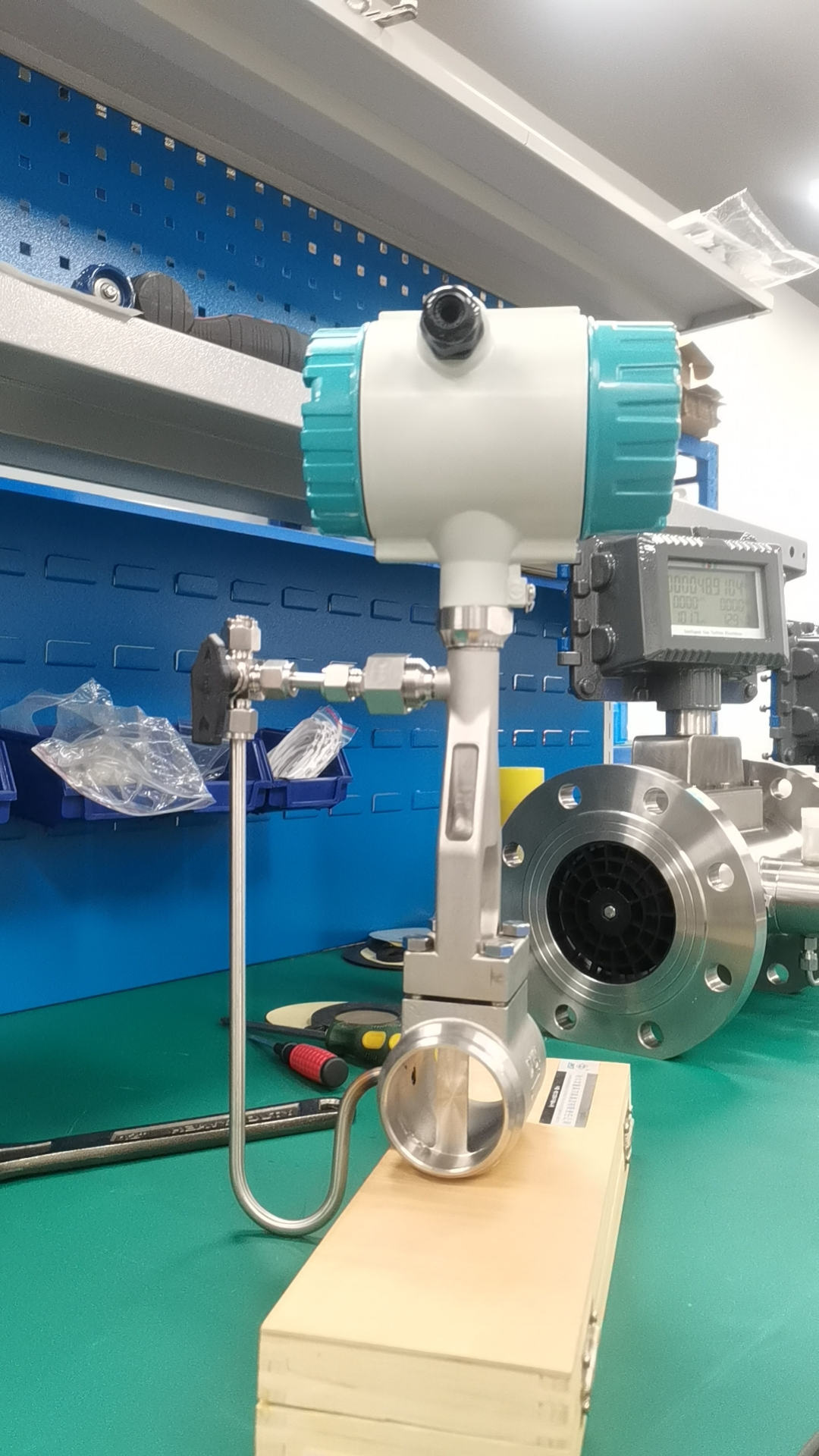

3, after completing the above steps, put the gasket at the round hole, and then insert the flowmeter, the flange is connected, if there is a ball valve, first put the ball valve on the short pipe connection and then open the ball valve, and then run the flowmeter.

4. Ensure that the flow direction of the medium is consistent with the flow indicator rod, and it is strictly prohibited to pull the flow indicator rod.

5, ensure that the flow meter has a range of more than 15D, and ensure that there is a 5D straight pipe section behind.

6, the inner diameter of the straight pipe section is consistent with the sensor diameter as far as possible, if it is not consistent, a pipe slightly larger than the sensor diameter should be used.

7. When the measured medium contains more impurities, a filter should be installed outside the required length of the upstream straight pipe section of the sensor.