How to judge the quality of vortex flow meter?

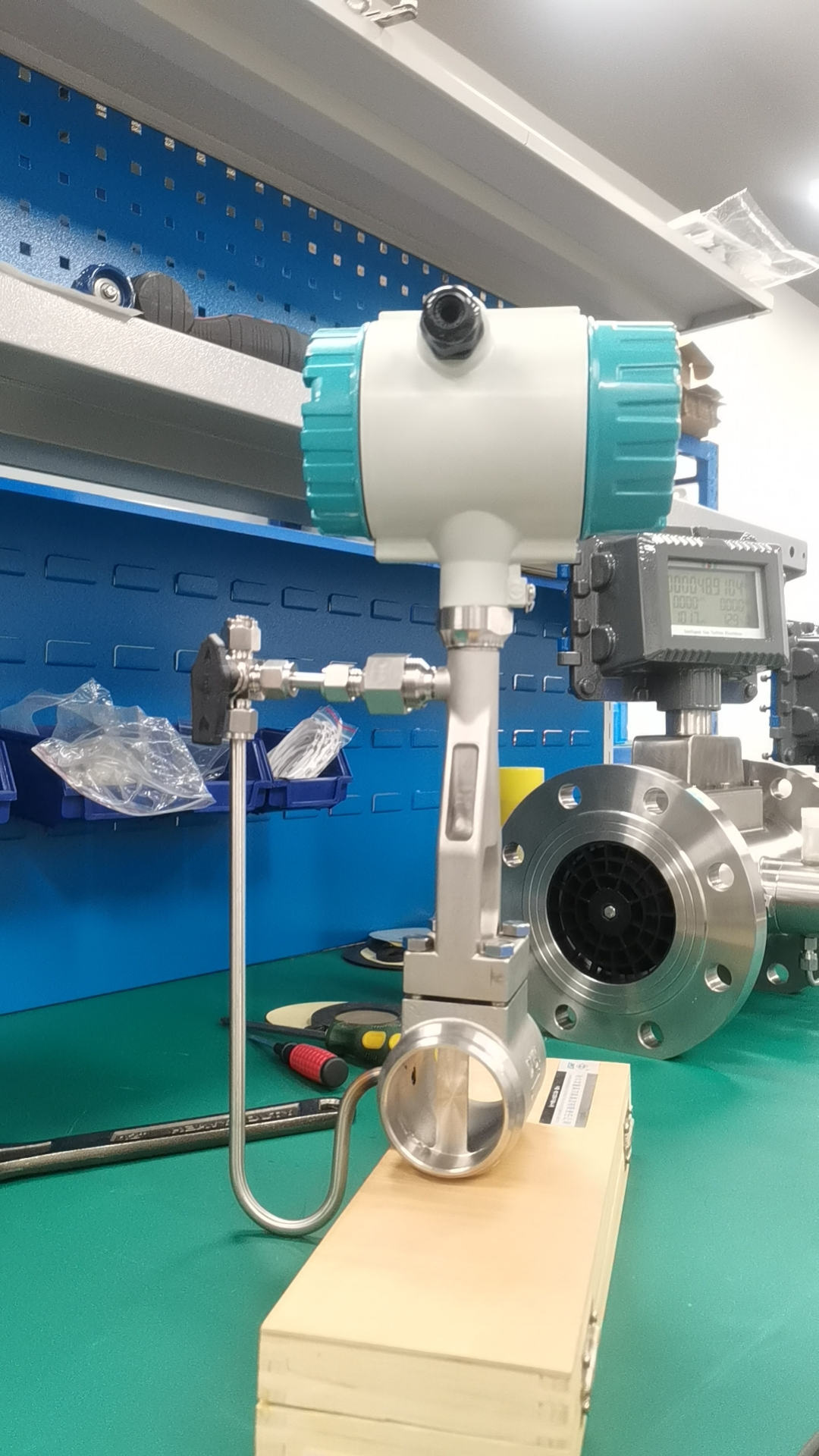

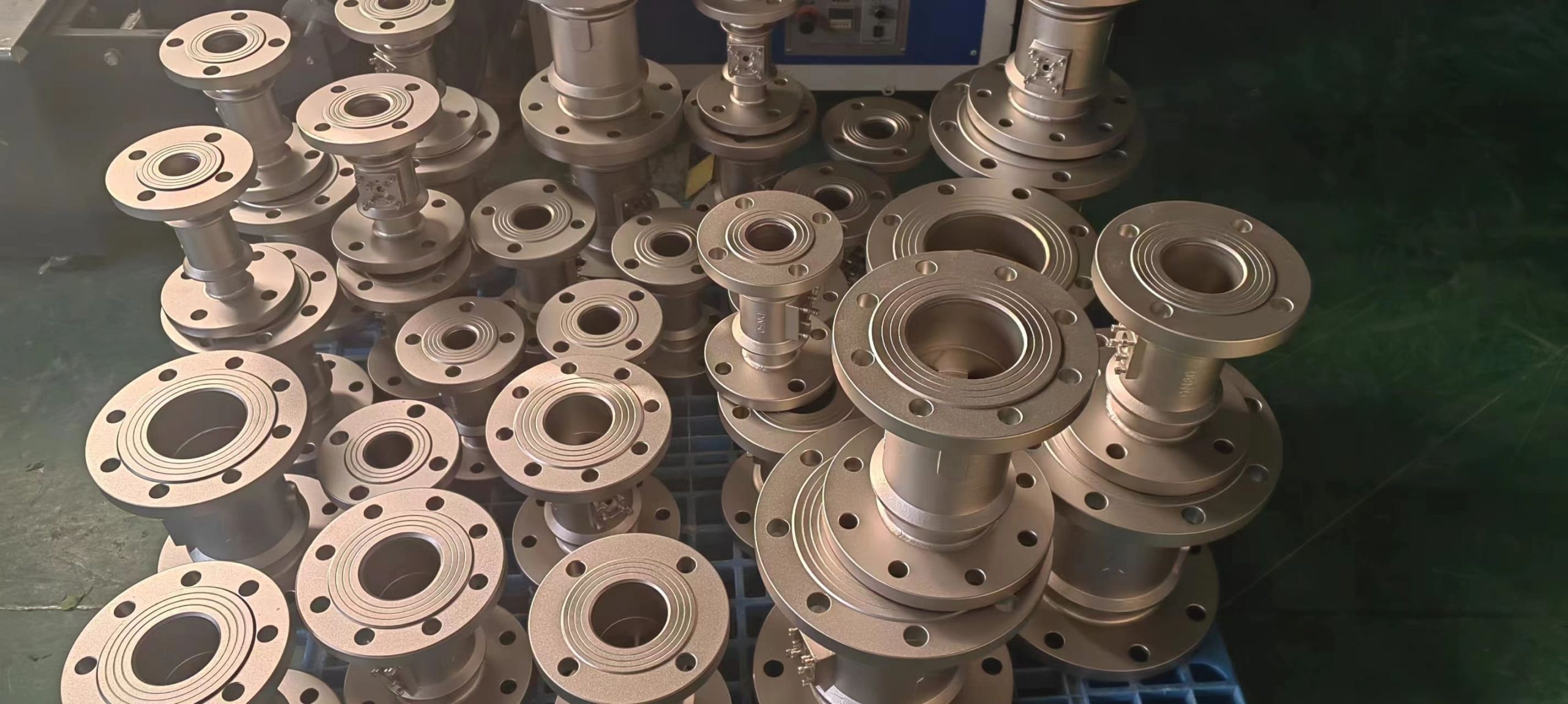

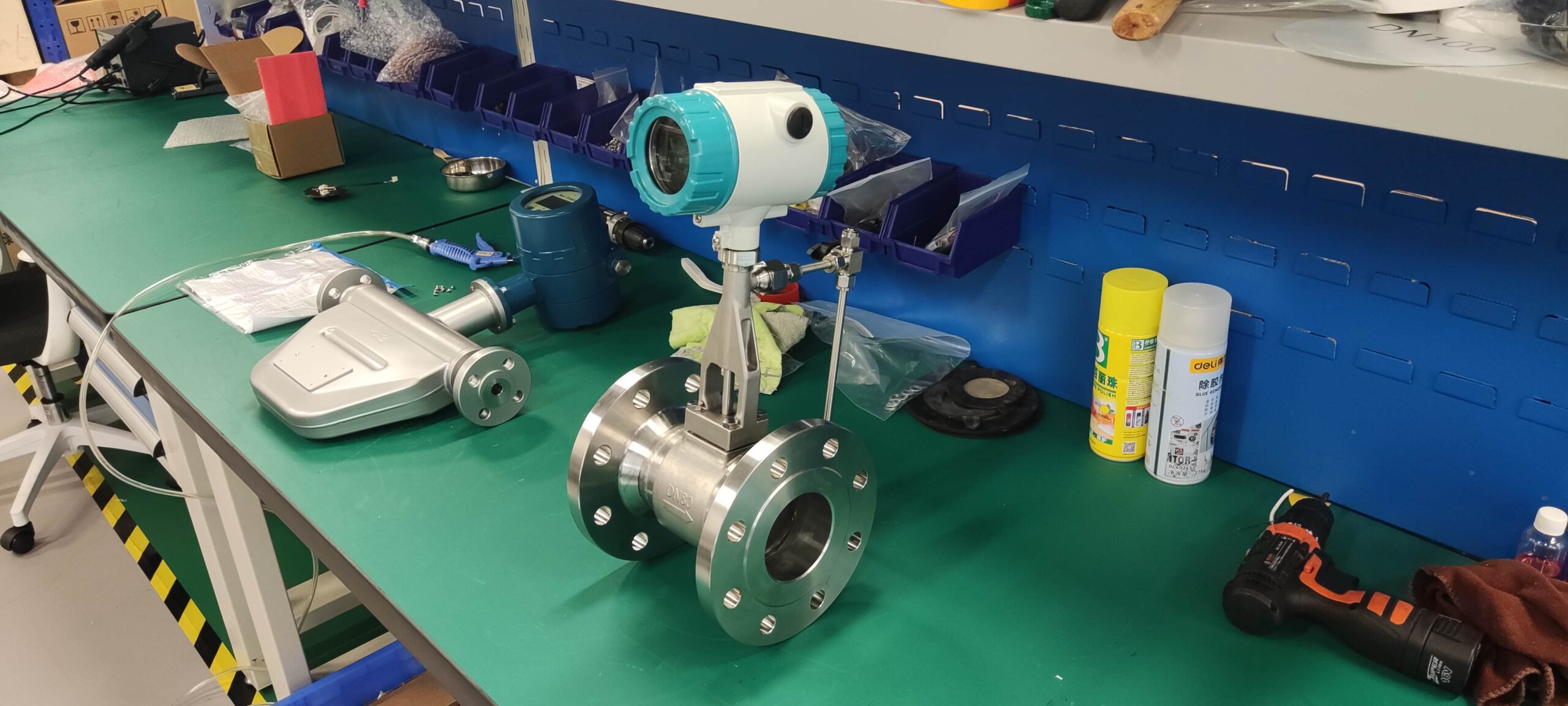

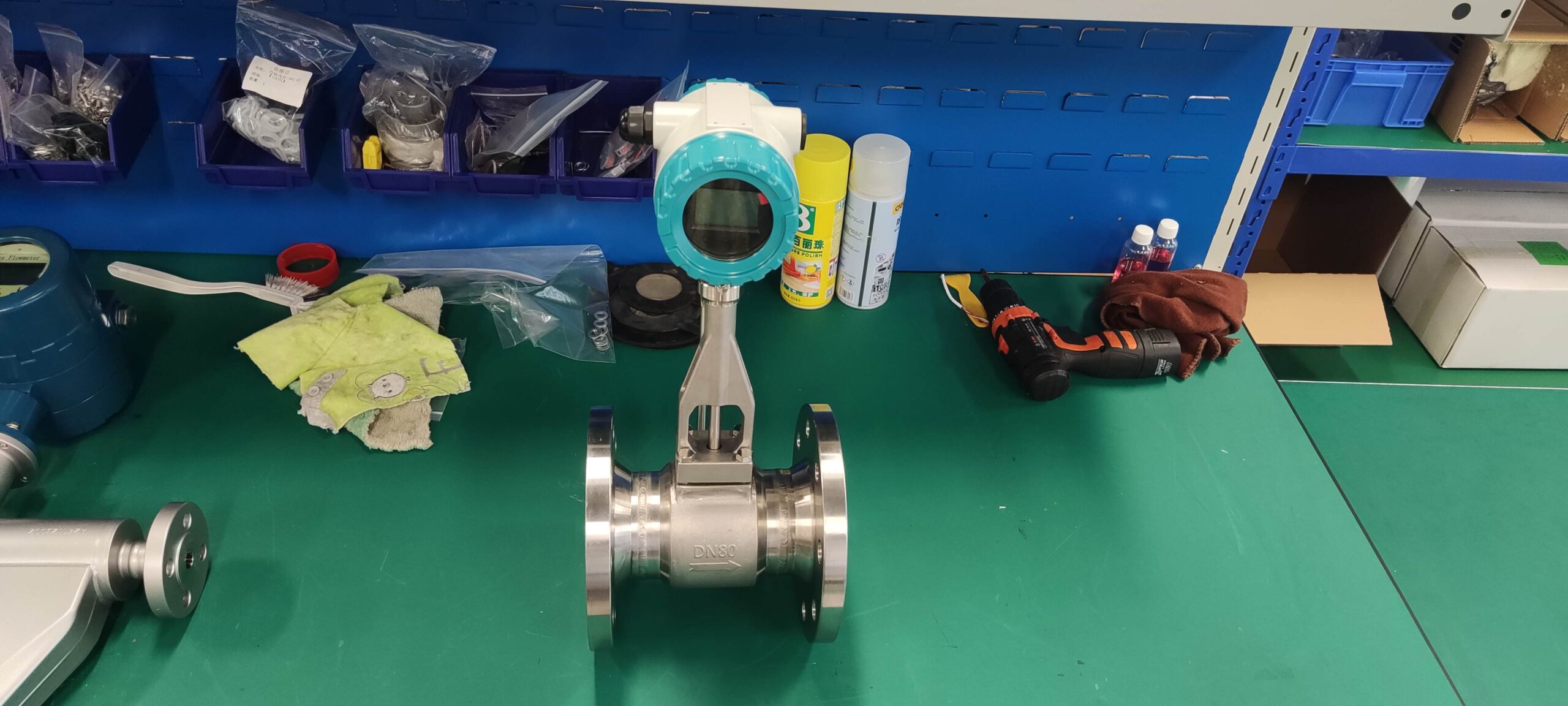

The structure of the vortex flowmeter is relatively simple, only the sensor and the display instrument are composed of two parts, and the measurement accuracy and stability are also relatively stable.

Due to the outstanding advantages of vortex flowmeters, especially in recent years, the development is extremely rapid, and the market share is also increasing year by year, especially in the flow measurement of steam. But how should the widely quoted users identify the quality of a vortex flowmeter? You can look down now.

The technical design of vortex flowmeter sensor lies in three aspects:

a. Design of sensor vortex generator. It should be ensured that a stable Karman vortex street signal can be generated when the fluid is passing by.

b. Design of sensor discussion. The piezoelectric crystal is precisely encapsulated in the probe to receive Karman vortex signal, and the piezoelectric crystal in the probe will automatically convert the vortex signal into a vortex electrical signal.

c. Amplifier circuit design. The function is to amplify the vortex signal and convert it into the corresponding pulse signal.

Understand the three technical keys of the sensor, then how to judge the quality?

1. Look at the two piezoelectric crystals inside the probe

One for anti-vibration interference, one for detection. The probe leads are two leads of the detection piece, and the probe shell is inserted by the wall of the vortex body and fixed on the wall of the vortex body through a fixed flange. The probe can work normally below 300 ° C and can resist 350 ° C. If the temperature is higher, it will destroy the sealed porcelain body, reduce the probe performance, and even damage the probe. We can use a multimeter to check the probe two leads, should be infinite, if there is a resistance value, the probe performance decline; If it is below tens of thousands of ohms, the probe is damaged.

2. Check the circuit board

a. The quality of the circuit board will directly affect the correctness of the signal generated by the vortex flowmeter, which can be used to view the waveform generated by the instrument in the work of the oscilloscope.

b. In addition, the sealing of the sensor and the surface body in the production process of the vortex flowmeter is also very important, if the sealing is not good, it will directly lead to the leakage phenomenon of the surface body.

c. When the instrument leaves the factory, it should also go through strict pressure test, and carry out flow calibration through the calibration device.

d. If the flow of the vortex flow meter in the work project is unstable, then the voltage of the vortex flow meter should be checked first is stable at about 12V, if it is, continue to measure the neutral line and pulse signal to see whether it is stable, and then measure the diagonal circuit board to see whether the voltage is about 3V.

e. In measuring the signal of the two lines of the vortex flowmeter sensor, this can be used to view the waveform generated by the instrument when it is working with the usual oscilloscope.

Summary: The above is to determine the quality of the vortex flow meter by detecting the corresponding components, especially in the detection of the circuit board, the circuit board of the vortex flow meter is like the CPU of the computer that dominates the entire process of the instrument.