How to apply radar level meter in feed processing industry

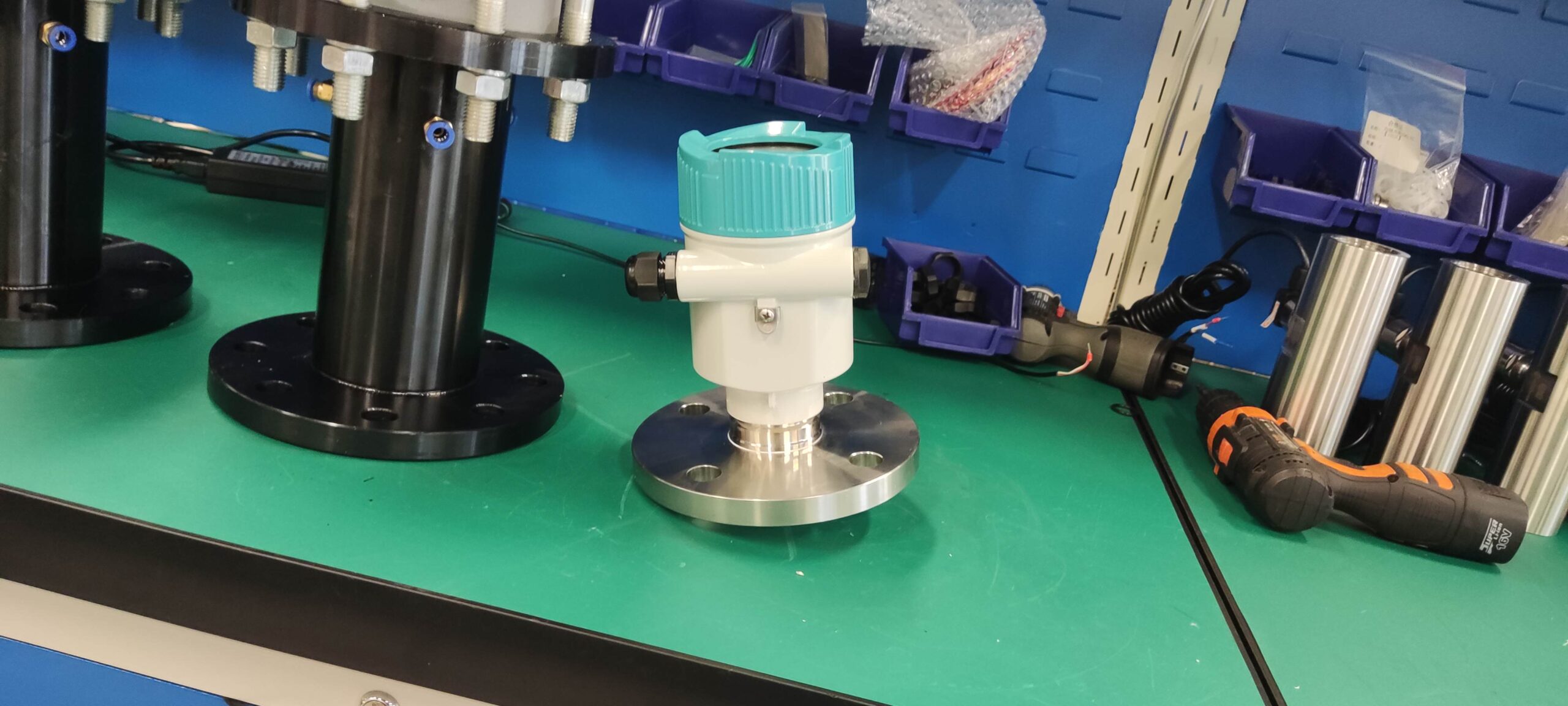

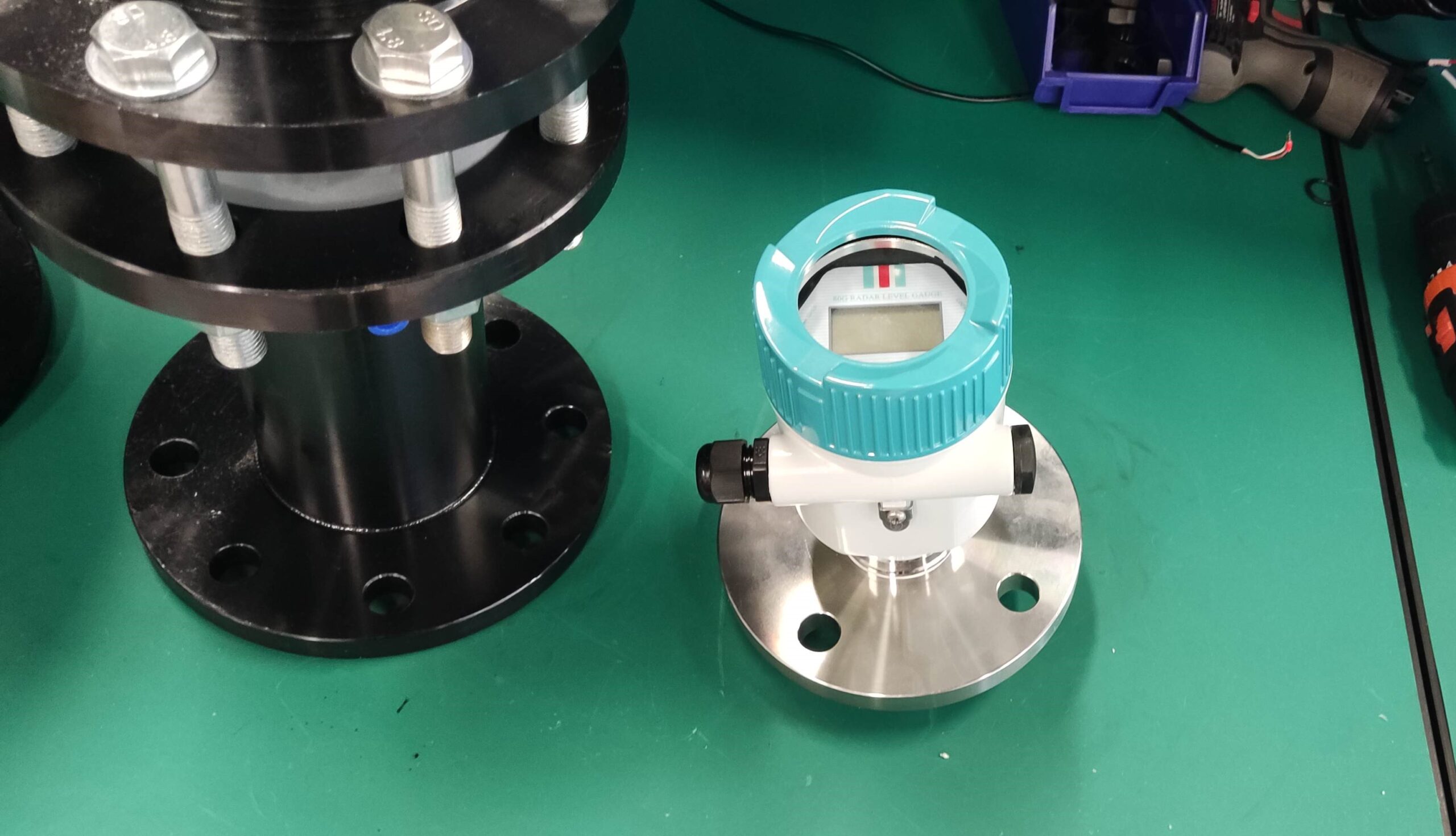

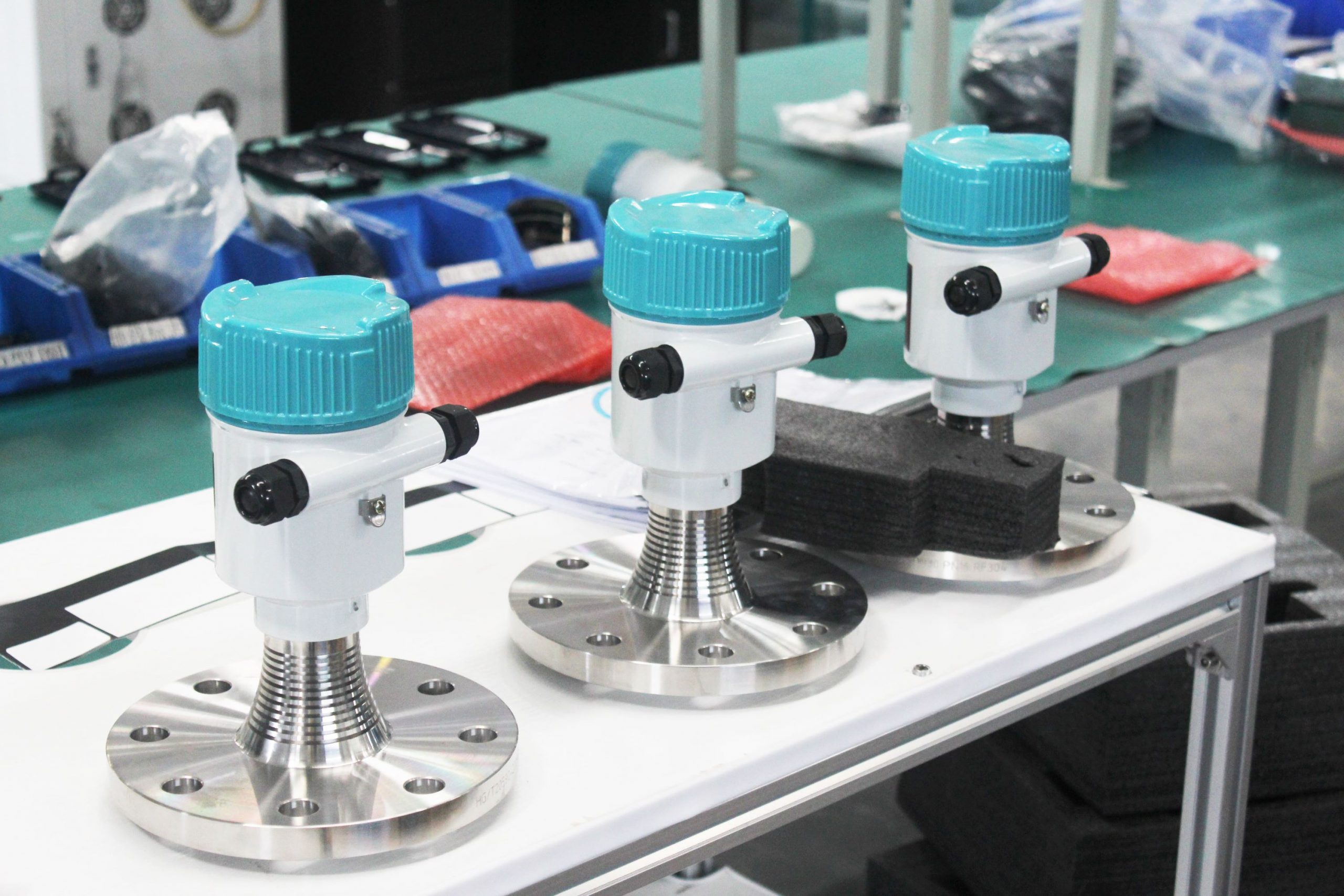

Radar level meter mainly uses the reflection principle of electromagnetic wave to work. It emits a microwave signal to the surface of the material, and when the signal meets the material, it reflects back, and determines the position of the material by calculating the time difference between the signal and the round trip. It can work stably in high temperature, high pressure, dust, steam and other harsh environments, which is very suitable for the environment of feed processing industry.

Radar level meter mainly uses the reflection principle of electromagnetic wave to work. It emits a microwave signal to the surface of the material, and when the signal meets the material, it reflects back, and determines the position of the material by calculating the time difference between the signal and the round trip. It can work stably in high temperature, high pressure, dust, steam and other harsh environments, which is very suitable for the environment of feed processing industry.

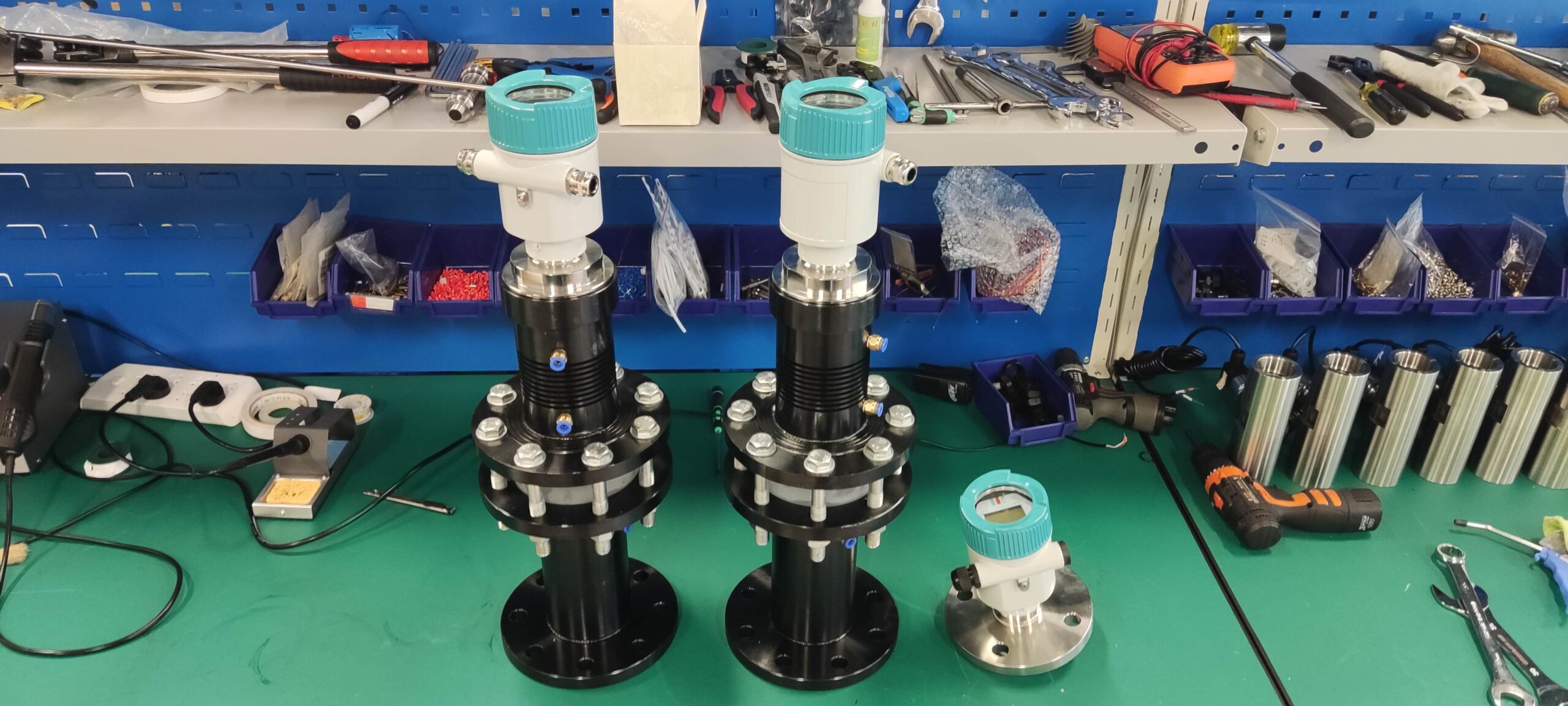

An important step in feed processing is often the storage of raw materials. Traditional level measurement methods such as heavy weight or ultrasonic level meter are often inadequate in the face of large amounts of dust and different material characteristics.

The radar level meter can ignore dust interference and accurately measure the storage capacity of various raw materials such as corn meal and soybean meal. This is of great significance for controlling inventory and optimizing purchasing plan.

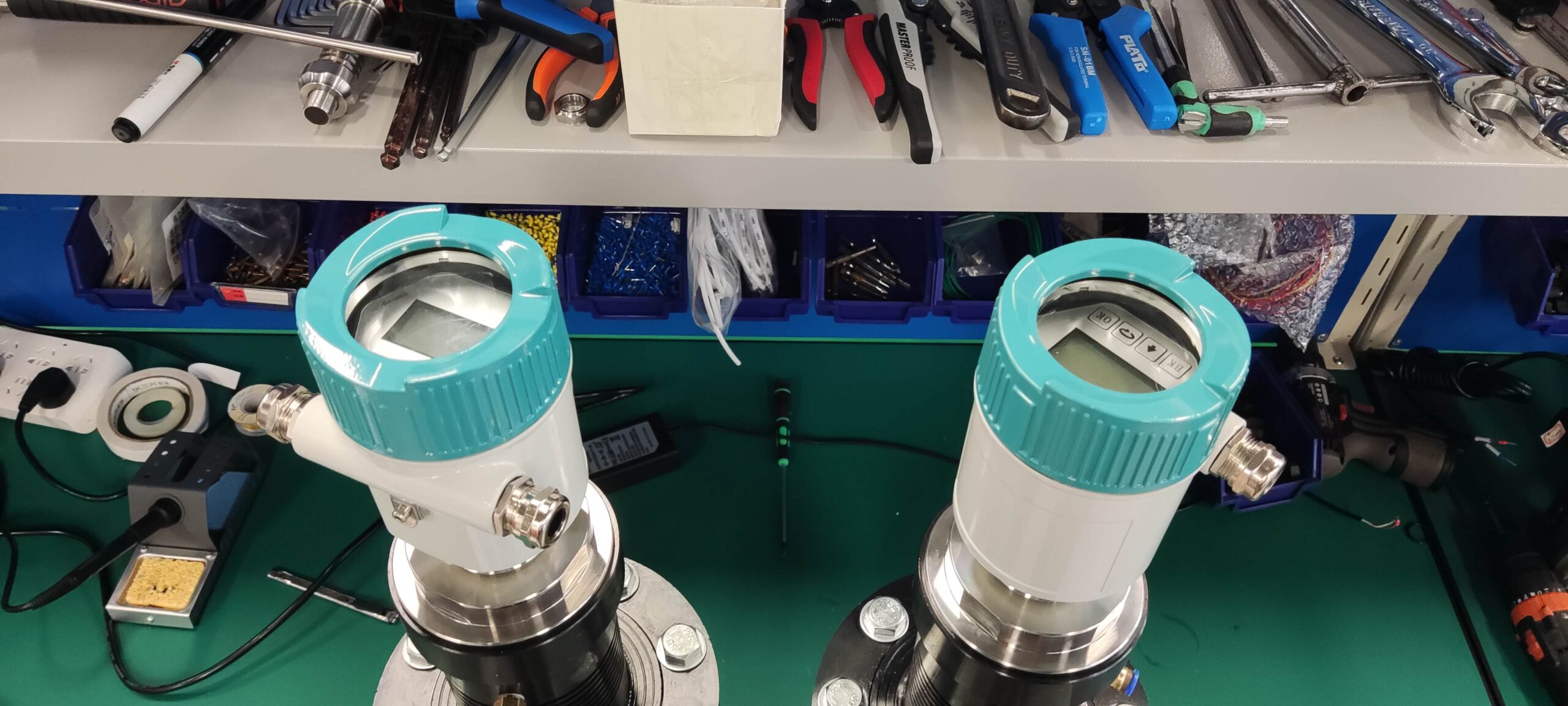

Precise ingredients are a key step in ensuring feed quality. The radar level meter can monitor the amount of various trace additives and bulk raw materials in real time to ensure the accuracy of the formulation.

Different from the delay and error that may occur in traditional methods, the real-time data feedback of radar level meter can greatly improve the efficiency and accuracy of batching. The storage and transportation of finished feed is also dependent on accurate level monitoring.

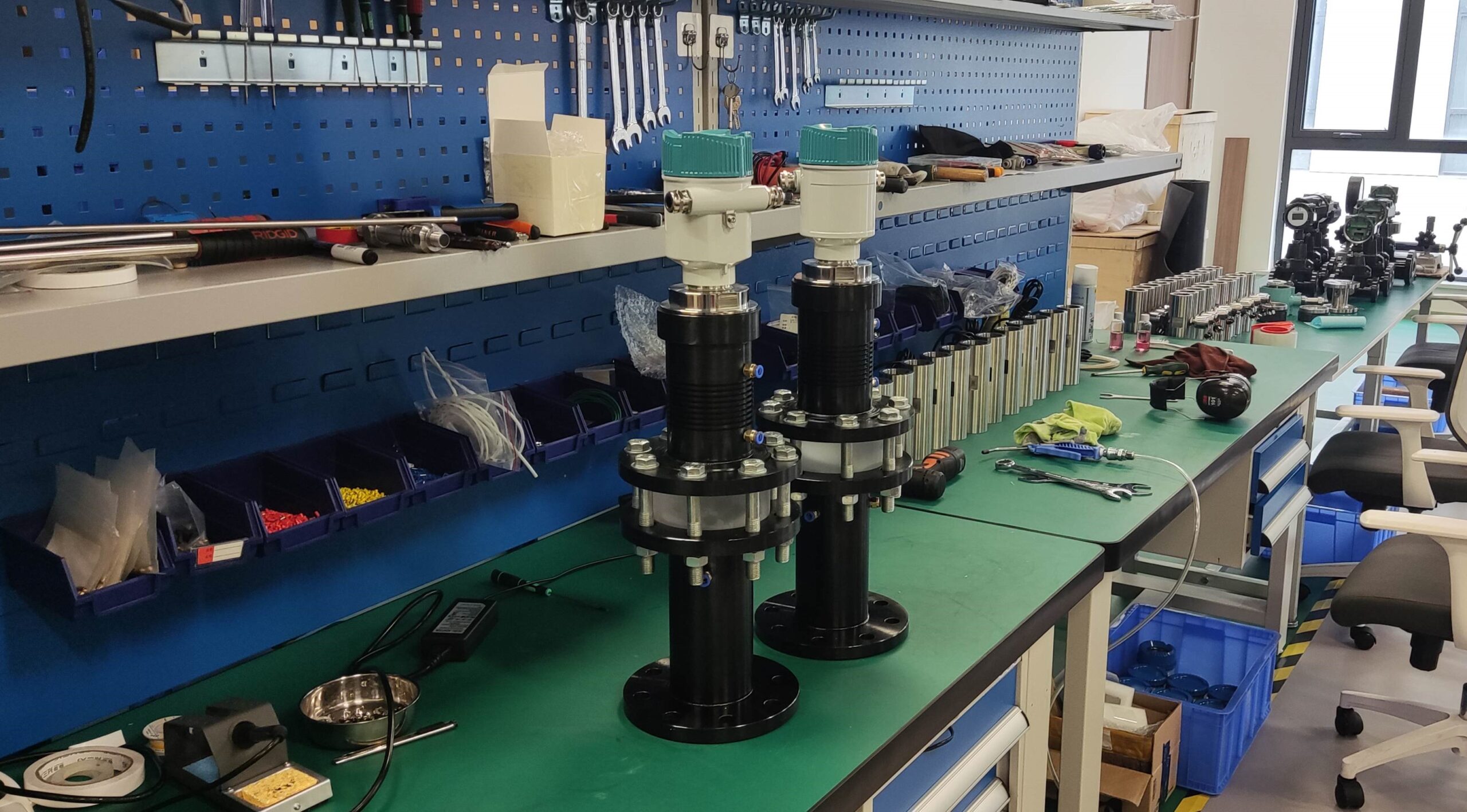

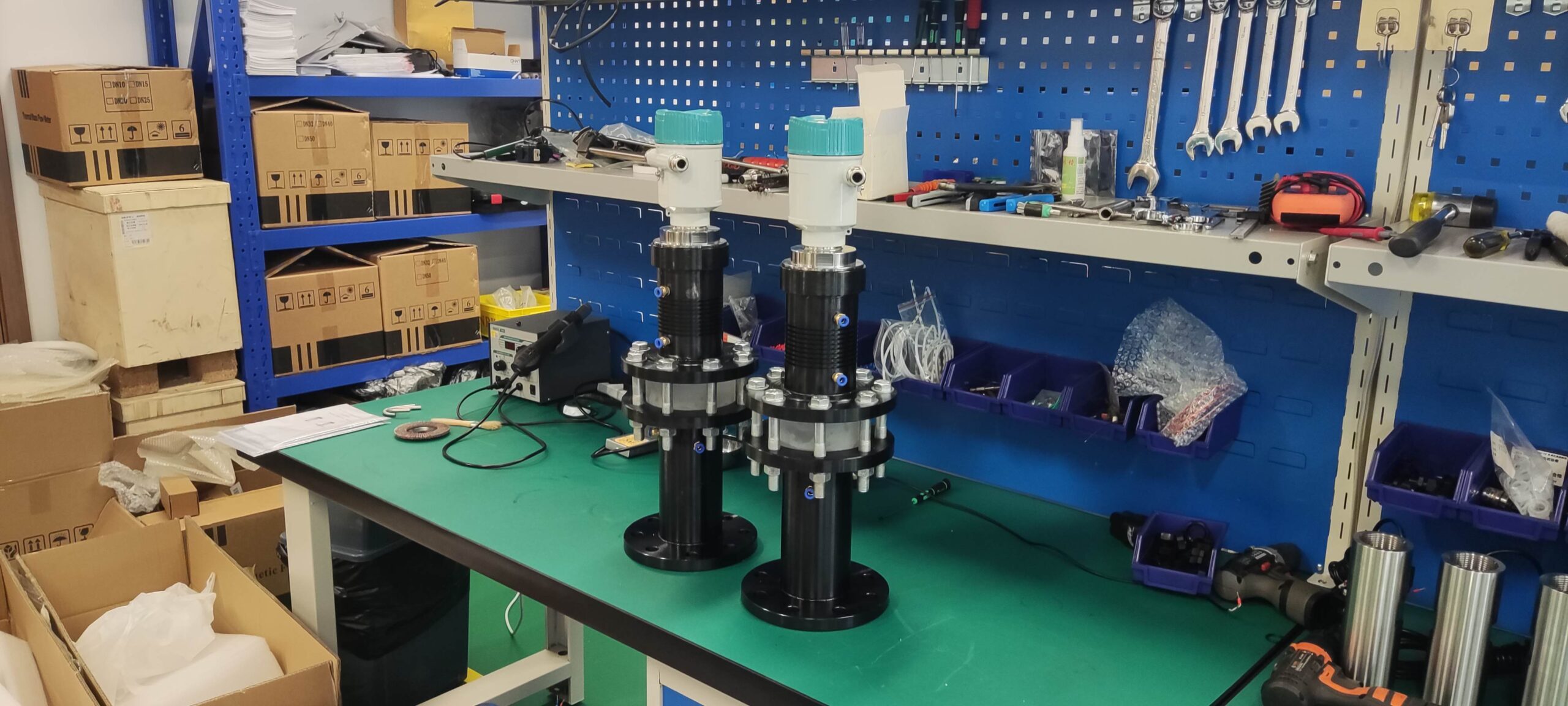

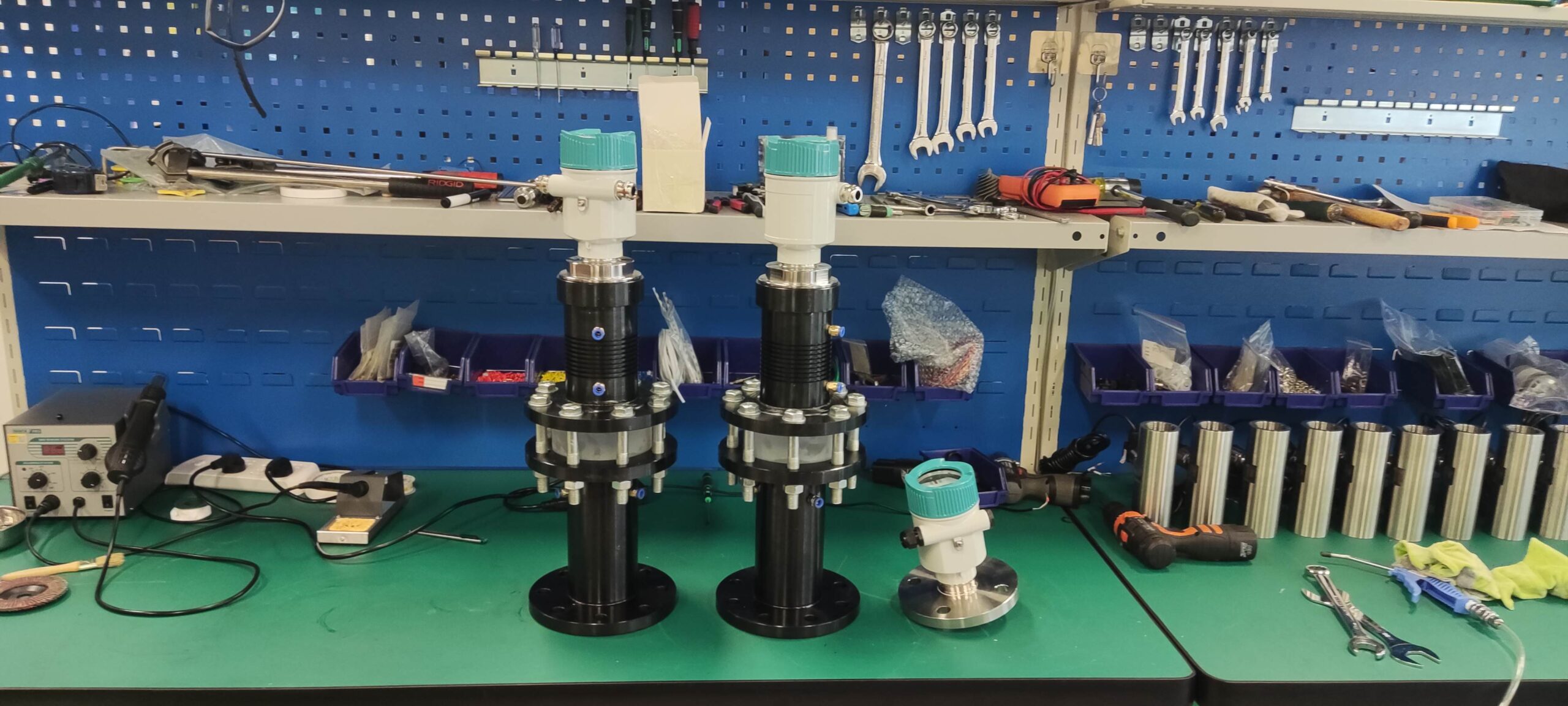

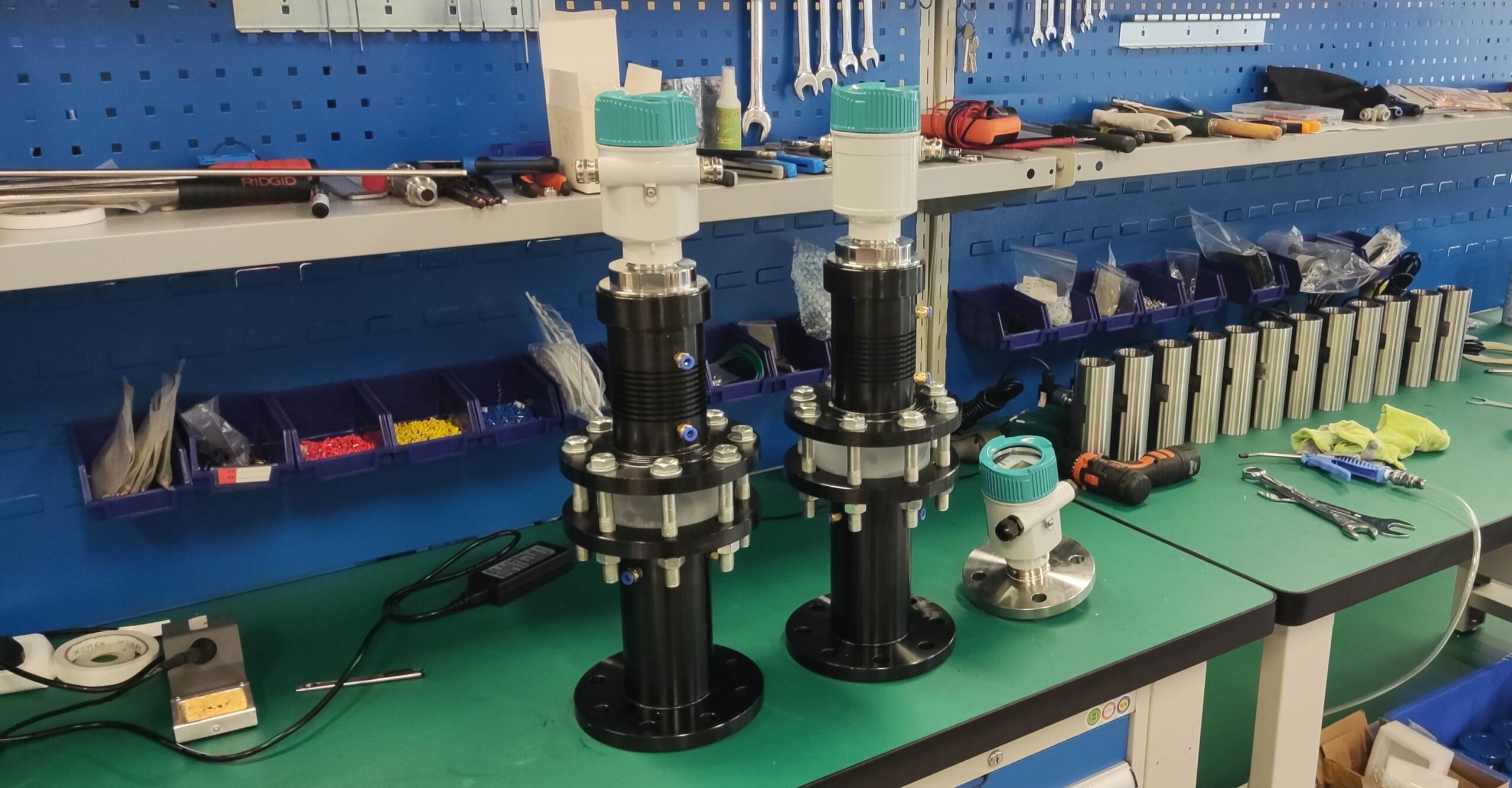

The radar level meter can be installed on the top of the feed warehouse to monitor the height of the bulk feed in real time, thereby optimizing the use of warehouse space and reducing excessive stacking or waste of space. In the logistics link, accurate material level information is helpful to plan the reasonable allocation of transportation resources.

Although the radar level meter has significant advantages in feed processing, it also faces some challenges in practical application, such as the uneven surface of the material can lead to measurement errors, or the change of the dielectric constant of the material can affect the measurement accuracy.

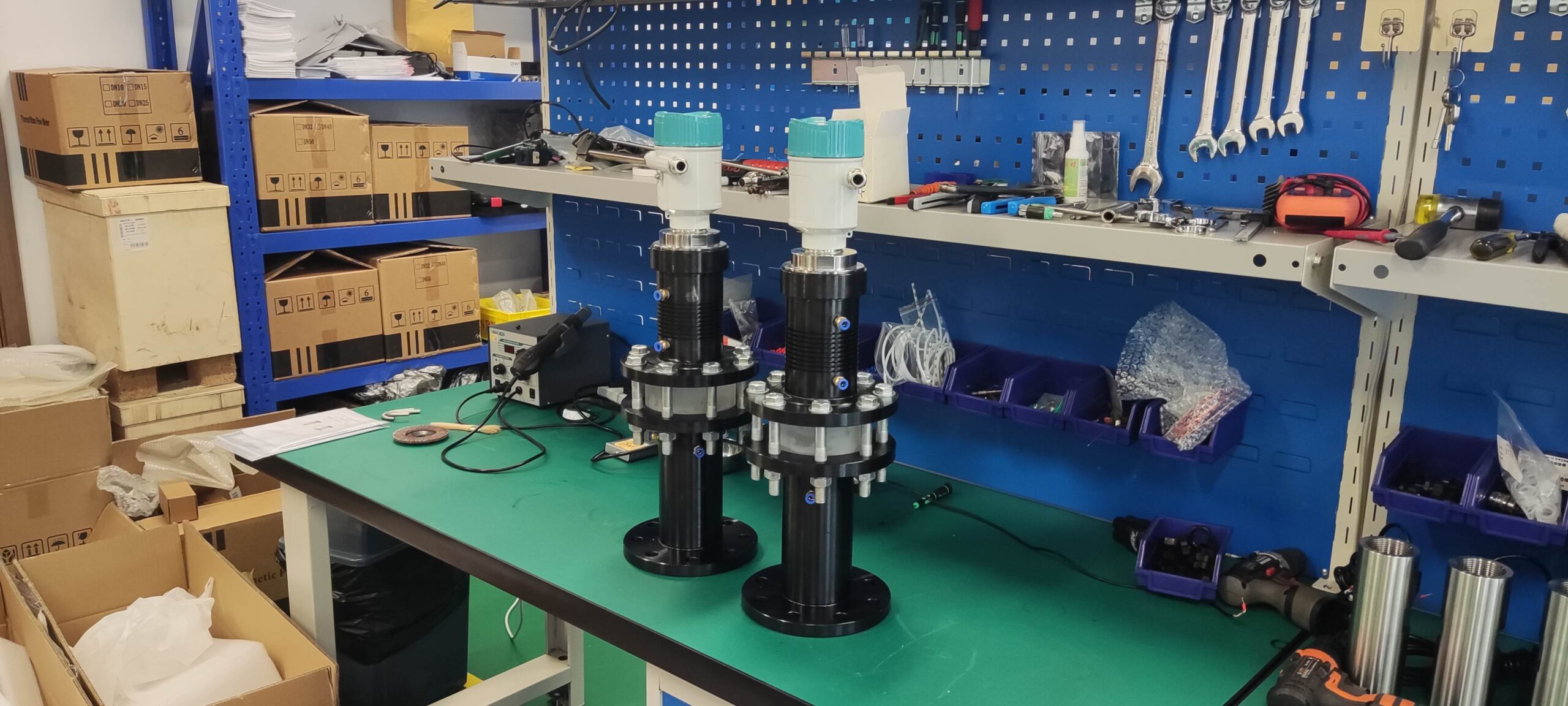

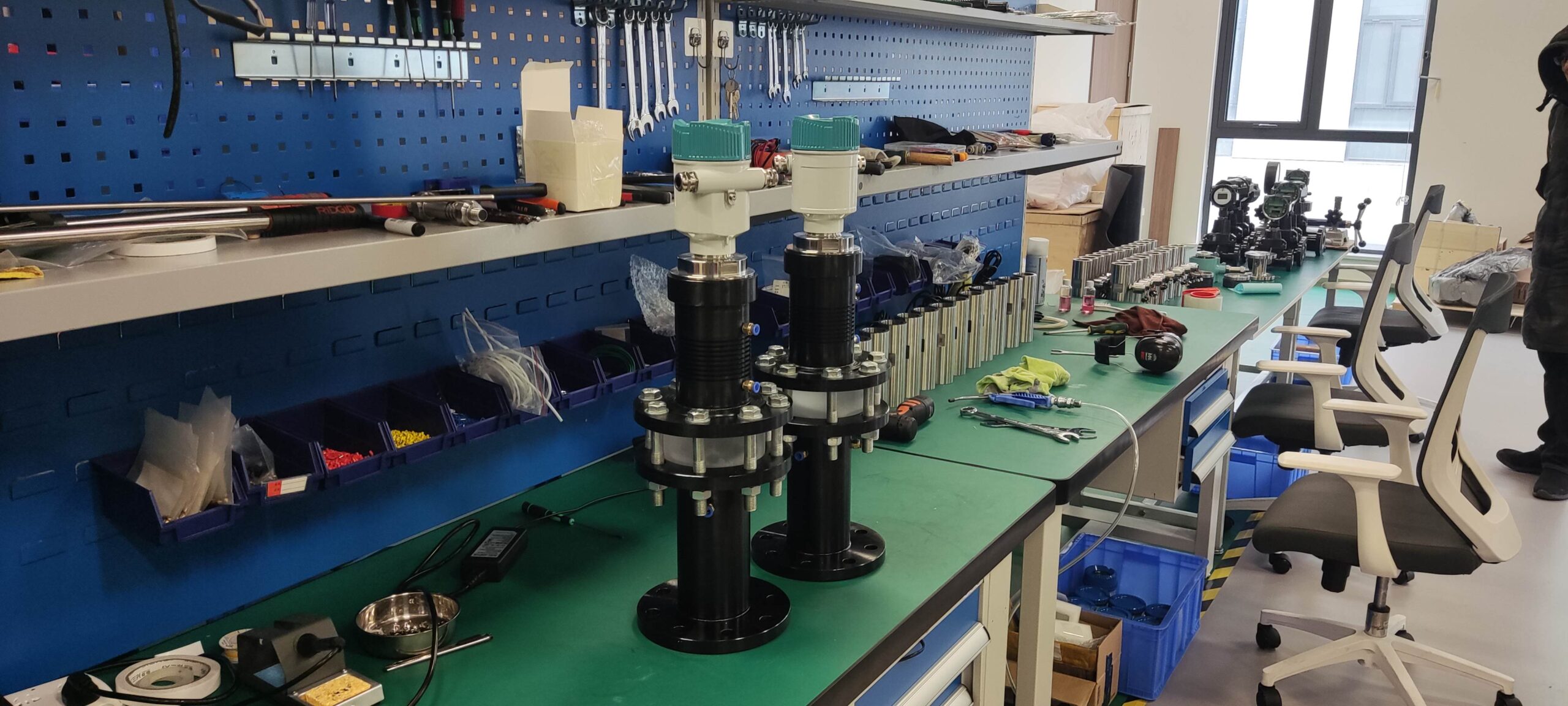

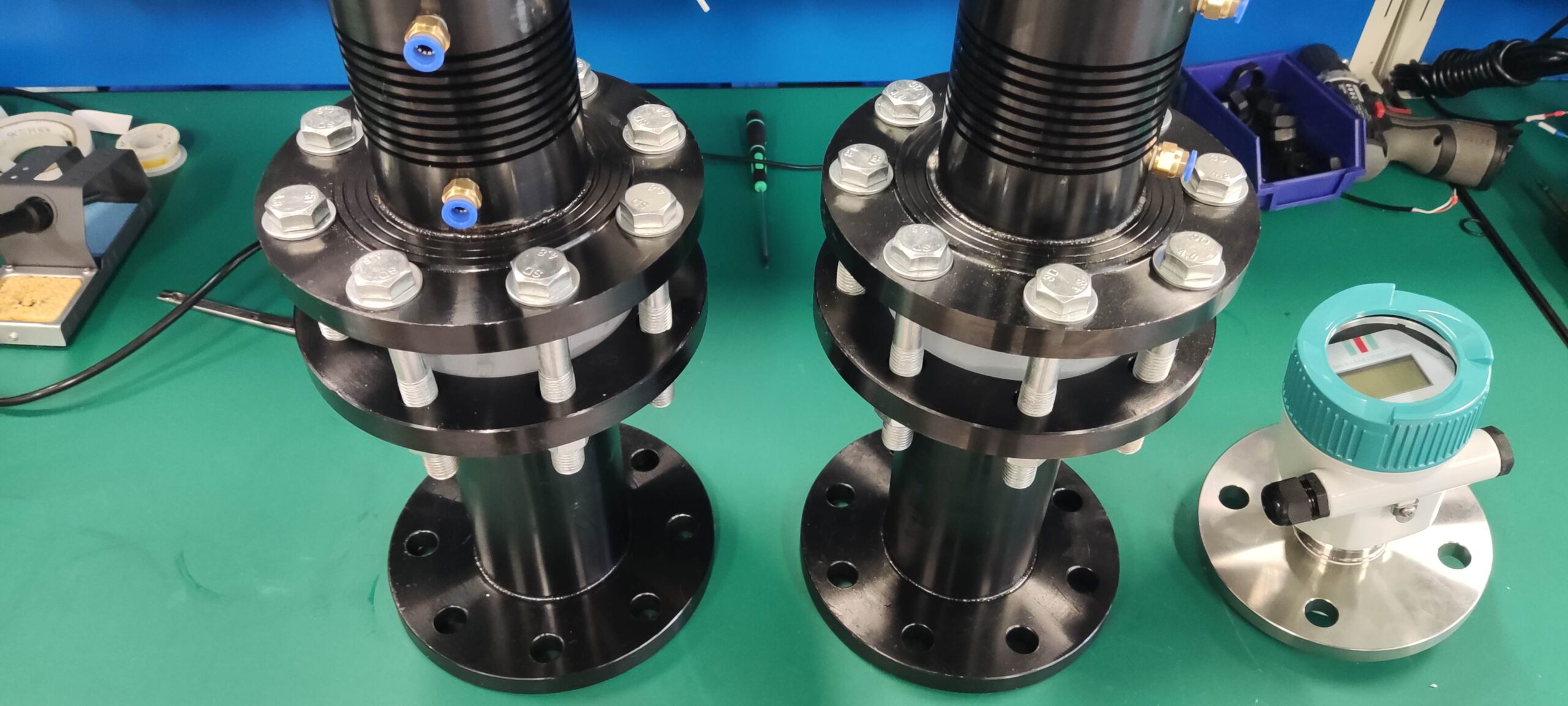

In response to these problems, modern radar level meters have been able to optimize measurement results by using higher frequency microwave signals, multi-angle measurement techniques, and intelligent algorithms to improve their adaptability and accuracy.

The application of radar level meter in feed processing industry not only improves the accuracy of measurement and production efficiency, but also reduces the production cost and maintenance difficulty.