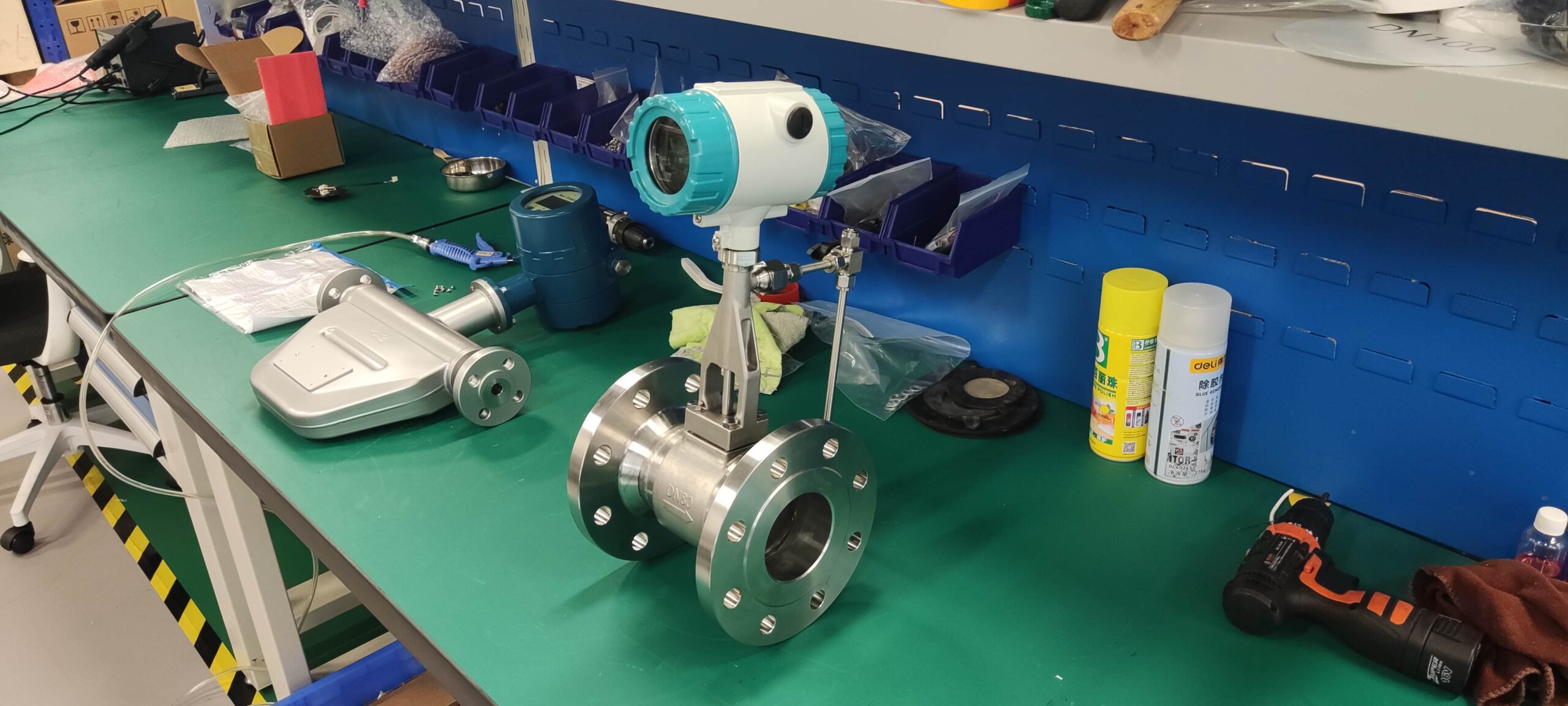

How is the vortex flow meter compensated

Vortex flowmeter is mainly used for the flow measurement of industrial pipeline medium fluids, such as gas, liquid, steam and other media. There are special phenomena and problems in the process of measurement. One of the key problems is that the vapor density value deviates too much from the design value, which brings significant measurement errors to the measurement results. At present, the density measurement instrument with mature technology has not been successfully applied, which brings certain difficulties to the steam flow measurement.

Vortex flowmeter compensation description:

1, one-time compensation implementation method

First determine the working parameters of the steam – temperature and pressure, flowmeter according to the working parameters to determine the density of the steam working state, the density as the future flow measurement process of steam density for hole plate calculation.

If in operation, the working parameters of the steam are consistent with the set value at the time of design, the accuracy of the steam flow measurement can be guaranteed. If the parameters deviate from the actual working conditions, or even deviate greatly, the deviation of the measurement results may be large.

One-time compensation method, the measurement method adopted in the early development of automatic detection technology, the measurement error is large, can be used as a rough measurement. This design method is still in use in the current widely popular flow throttling device design manual.

2, online density compensation implementation method

With the wide application of microelectronic technology in instrument. The calculation function, compensation correction function, cumulative function, historical data storage function, digital filtering function, output function, digital communication function and so on can be easily realized.

1, saturated steam online density compensation.

The flowmeter can realize integrated temperature and pressure compensation, and there is a strict one-to-one correspondence between the temperature and pressure of saturated steam. The density of a saturated vapor can be a single function of its temperature or its pressure. According to the temperature value or pressure value of the saturated steam, the real-time density value can be obtained by looking up the table method or formula calculation method (IFC1967 or IAPW-1997).

In flow measurement, the flowmeter can be selected to achieve temperature compensation or pressure compensation flowmeter. To select a flowmeter with temperature compensation function. Turn on the temperature sensor of the flowmeter to detect the measured steam temperature in real time, so as to obtain the corresponding density value.

2, superheated steam online density compensation

Superheated steam is a kind of steam with special quality obtained by reheating saturated steam. It breaks the strict one-to-one relationship between temperature and pressure inherent in saturated steam. The flowmeter can treat superheated steam as a single medium in the flow measurement process. The density of superheated steam is a function of its temperature and pressure. When ordering the flowmeter, the temperature and pressure compensation type should be selected. In actual use, the temperature and pressure sensors are opened at the same time to measure the steam temperature and pressure value in real time, and the density value can be accurately calculated according to the superheated steam density table or density calculation formula.