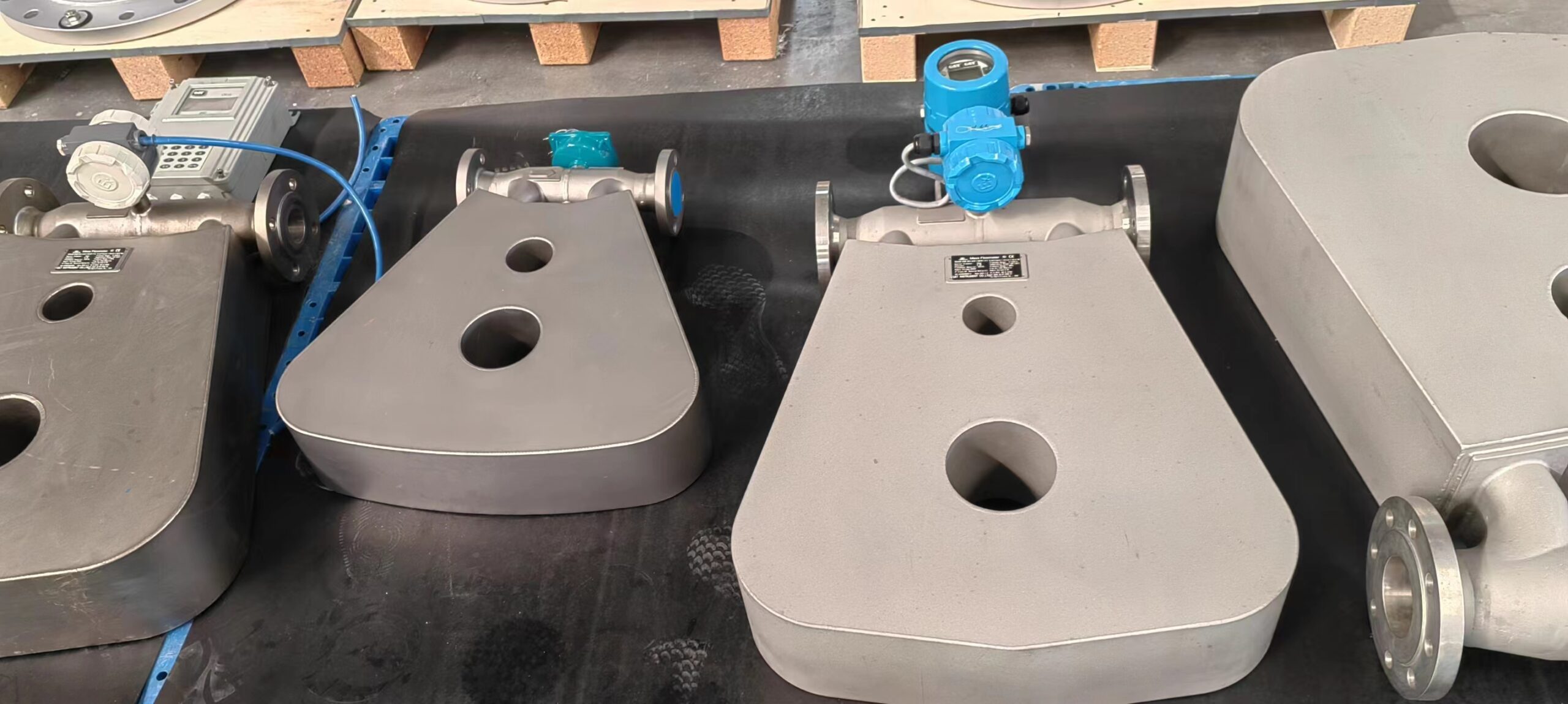

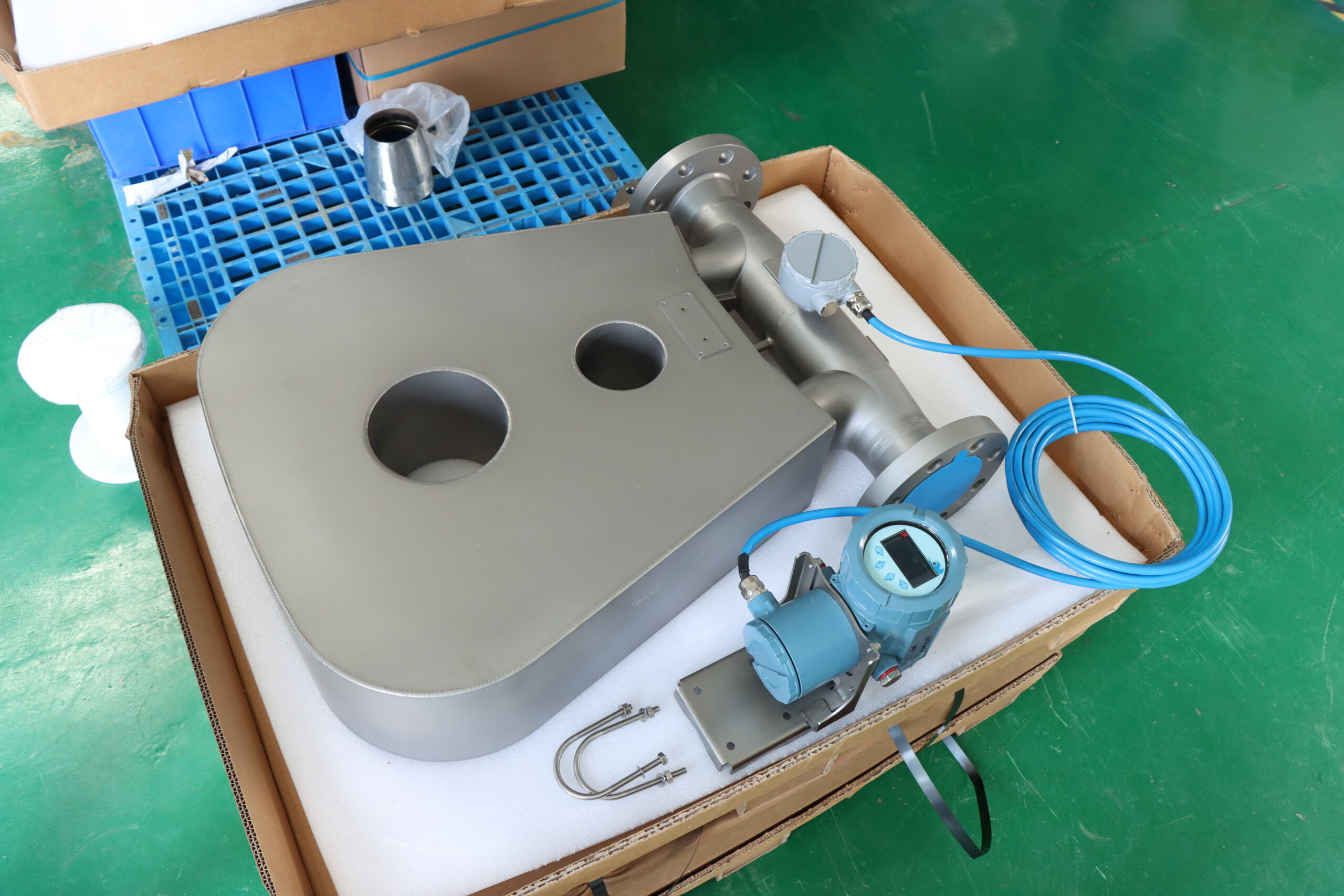

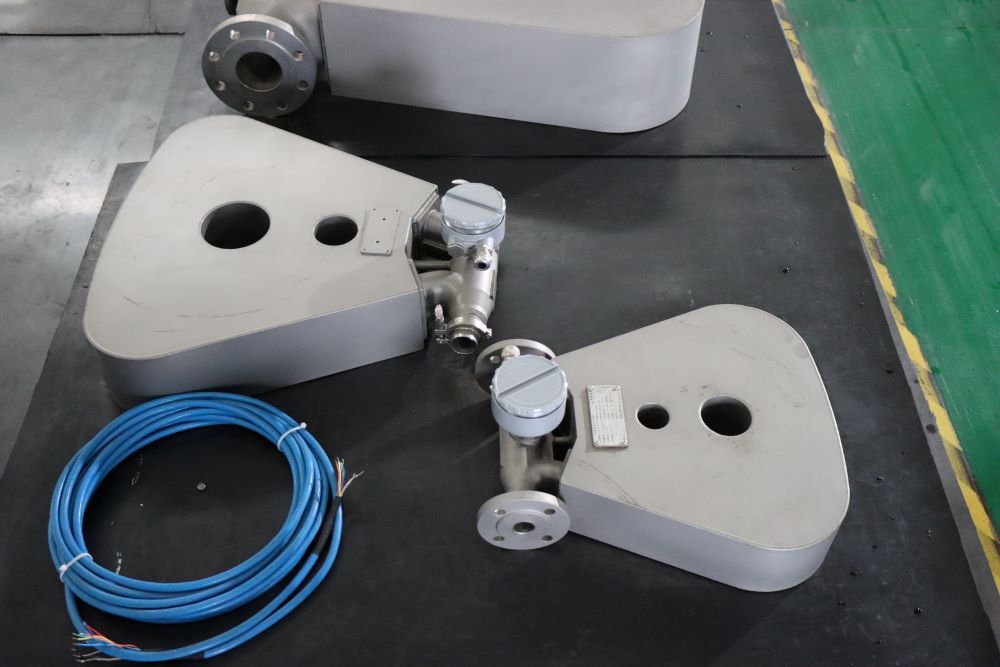

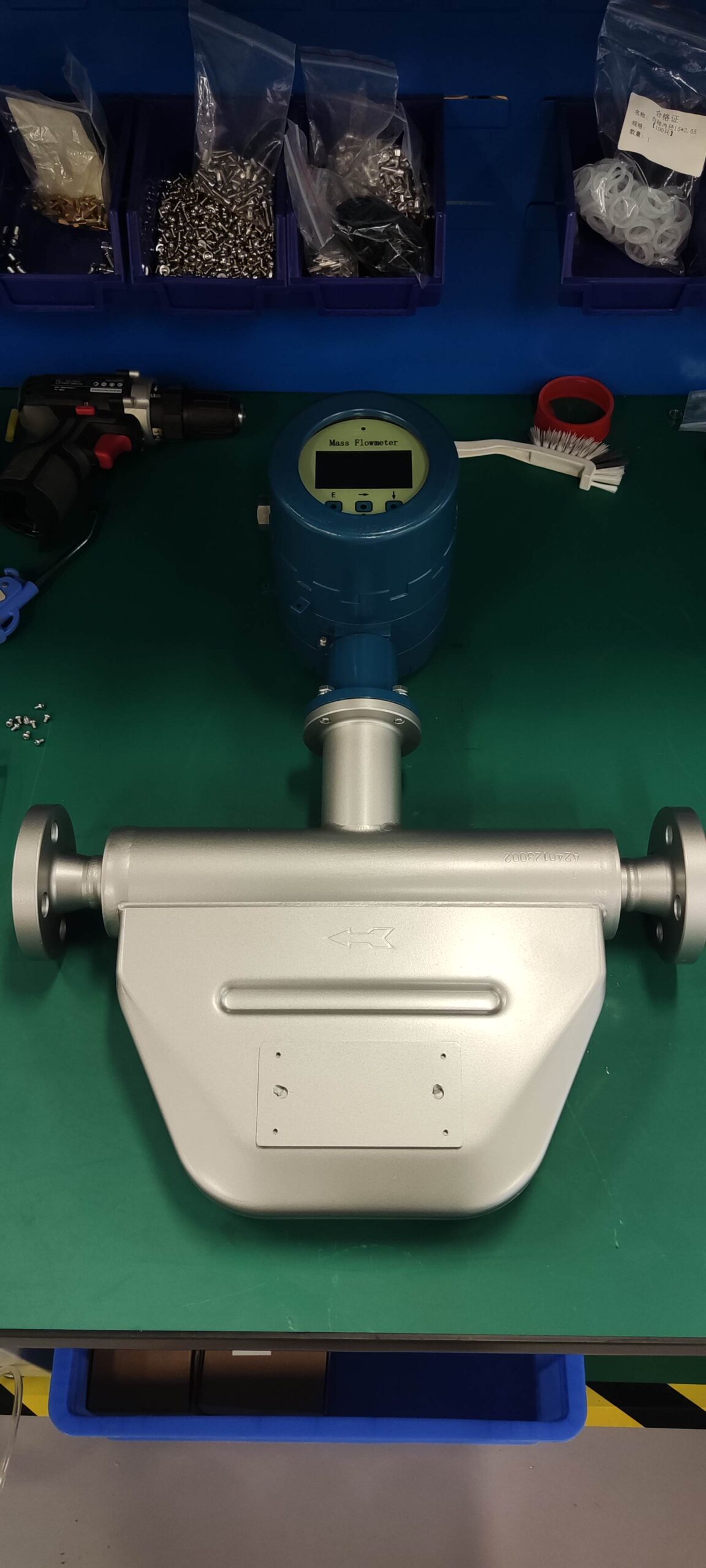

High Temperature Resistance Coriolis Mass Flowmeter with Remote Flow Transmitter

The working principle of a Coriolis mass flowmeter is based on the Coriolis effect, which describes the apparent deflection of an object’s path due to rotation. In the case of a Coriolis flowmeter, this effect is utilized to measure mass flow rates of fluids. Here’s how it works:

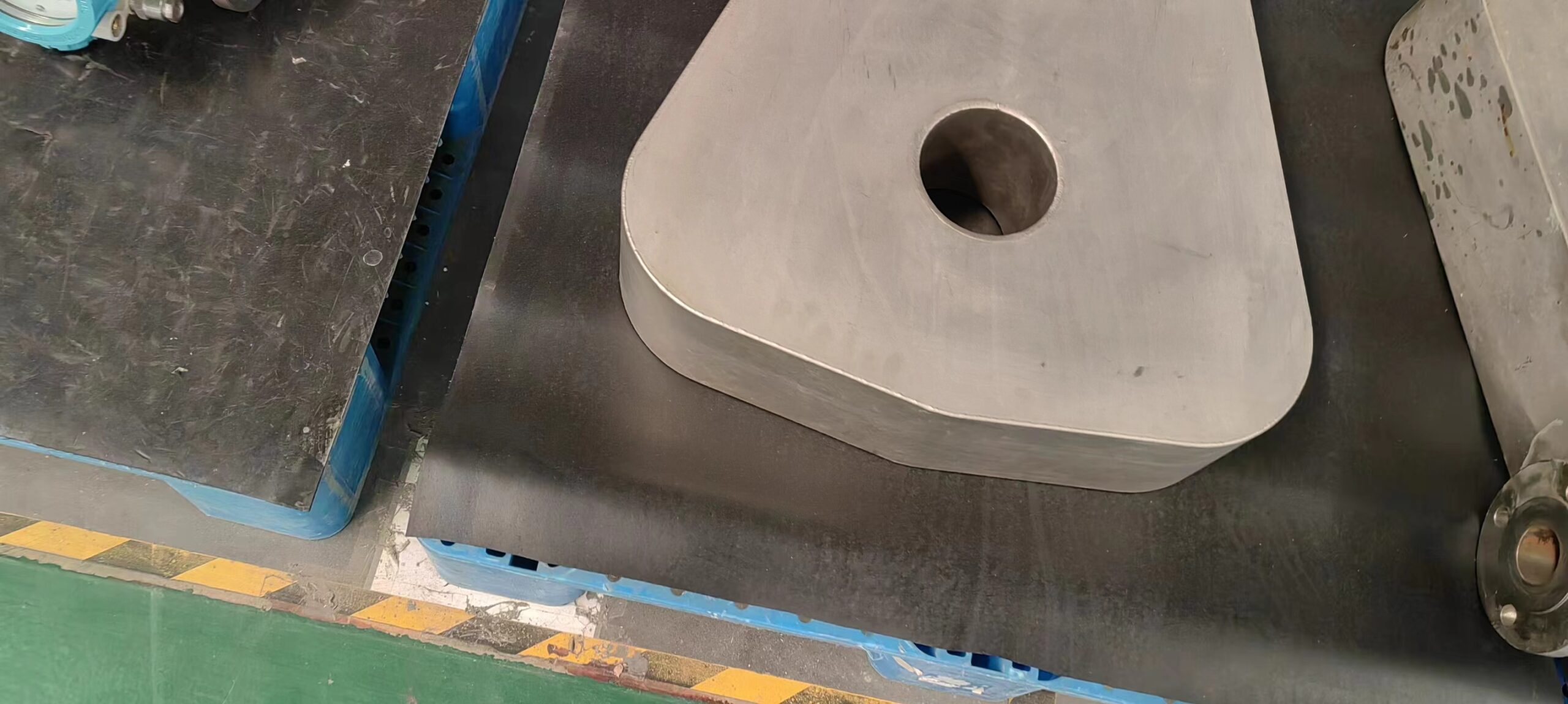

Tube Structure: The primary component of a Coriolis mass flowmeter is a set of vibrating tubes arranged in a specific configuration. These tubes are typically made of metal and are connected to the flowmeter’s inlet and outlet.

Fluid Flow: When fluid flows through the vibrating tubes, it causes them to move in a characteristic pattern. The fluid flow introduces inertia, which induces the tubes to deform slightly in the direction perpendicular to both the flow direction and the direction of vibration.

Vibration: The vibrating tubes are excited by an external force, typically generated by a piezoelectric device or electromagnetic drive mechanism. This vibration can occur in various modes, such as torsional, bending, or both.

Coriolis Effect: As the fluid flows through the vibrating tubes, the Coriolis effect causes the tubes to twist or oscillate in proportion to the mass flow rate of the fluid. This twisting or oscillation is directly related to the mass flow rate of the fluid passing through the tubes.

Measurement: Sensors located at strategic points along the vibrating tubes detect the extent of deformation or twisting caused by the Coriolis effect. By measuring the phase shift or frequency difference between the input and output signals of the vibrating tubes, the flowmeter determines the mass flow rate of the fluid.

Output: The flowmeter’s electronics process the signals from the sensors and convert them into a mass flow rate value, which is typically displayed on a digital readout or transmitted to a control system for further processing or recording.

Compensation: To ensure accurate measurement, Coriolis flowmeters often incorporate temperature sensors to compensate for variations in fluid density due to temperature changes. Additionally, some models may include pressure sensors to account for changes in fluid density caused by pressure fluctuations.

In summary, a Coriolis mass flowmeter measures mass flow rates by exploiting the Coriolis effect, which causes vibrating tubes to deform in response to fluid flow. By detecting and analyzing the deformation of the tubes, the flowmeter accurately determines the mass flow rate of the fluid passing through it.