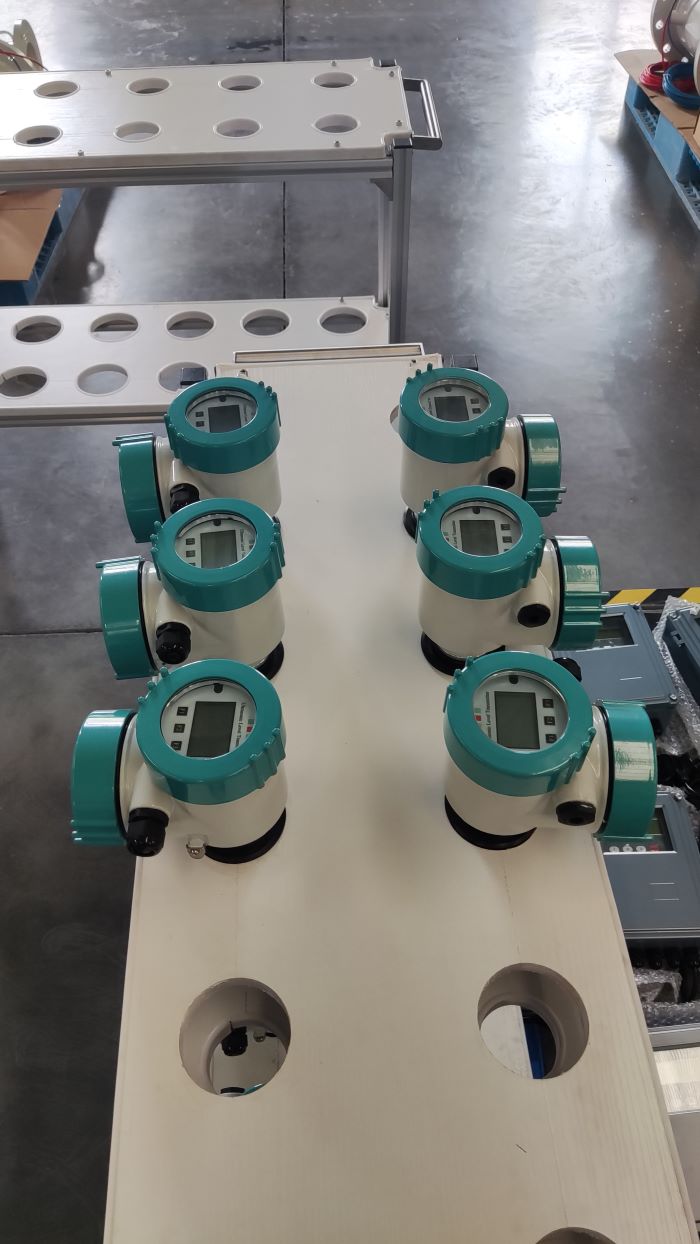

High Tank Level Meter LCD Display Ultrasonic Level Meters for Water

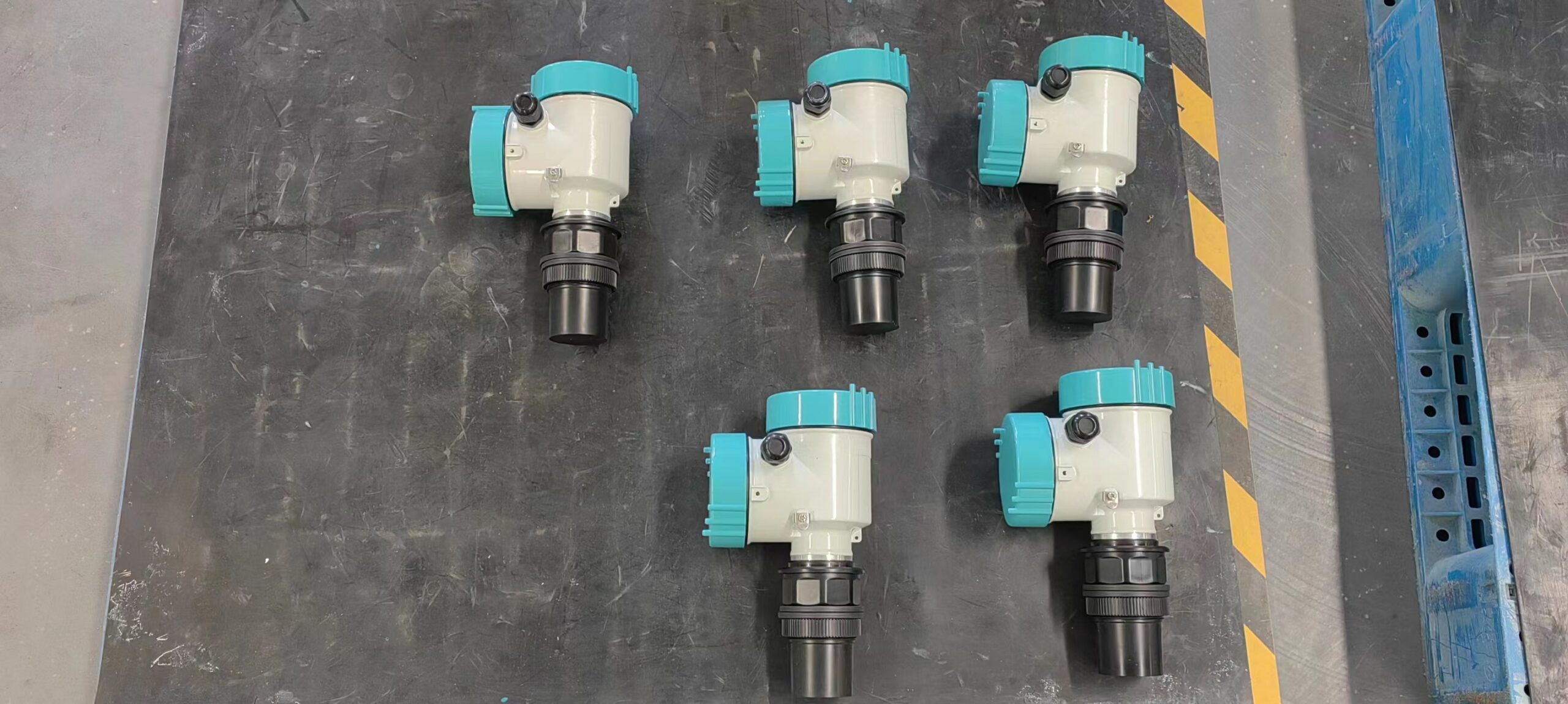

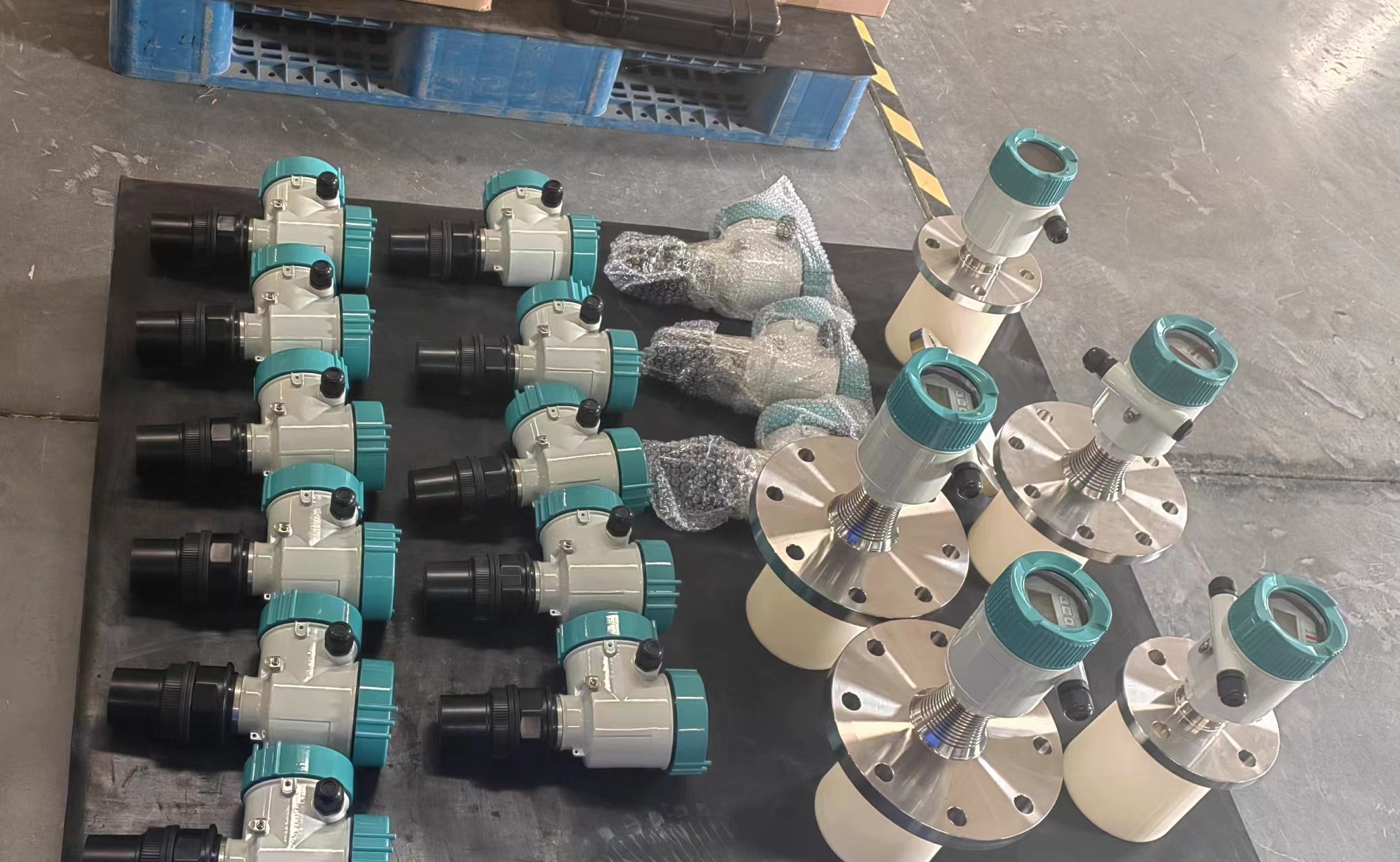

Ultrasonic level meter are usually widely used in industrial fields, such as chemical, pharmaceutical, water treatment, food and beverage production. Their non-contact measurement characteristics make them suitable for use in environments where corrosive or hazardous liquid media may be present, as well as where remote monitoring is required. This level measuring device provides accurate measurements while avoiding direct contact with the medium, reducing the risk of contamination and maintenance.

Ultrasonic level meter is based on the Time-of-Flight principle. A sensor emits ultrasonic pulses, the surface of the media reflects the signal and the sensor detects it again. The Time-of-Flight of the reflected ultrasonic signal is directly proportional to the distance traveled. With the known tank geometry the level can be calculated.

Ultrasonic level meter for continuous level measurement of liquids or bulk solids. Typical applications are the measurement of liquids in storage tanks or open basins. The sensor is also suitable for the detection of bulk solids in small vessels or open containers. The non-contact measuring principle is independent of product features and allows a setup without medium.

The ultrasonic level meter is mainly used to measure the liquid level of the liquid medium, but it can also be applied to the level measurement of some solid media. These liquid media can include water, oil, chemical liquids, solutions, etc. The working principle of the ultrasonic level meter is to determine the distance between the liquid surface and the sensor by transmitting the ultrasonic pulse and measuring the time of its echo, so as to calculate the liquid level.

Ultrasonic level meters are usually widely used in industrial fields, such as chemical, pharmaceutical, water treatment, food and beverage production. Their non-contact measurement characteristics make them suitable for use in environments where corrosive or hazardous liquid media may be present, as well as where remote monitoring is required. This level measuring device provides accurate measurements while avoiding direct contact with the medium, reducing the risk of contamination and maintenance.