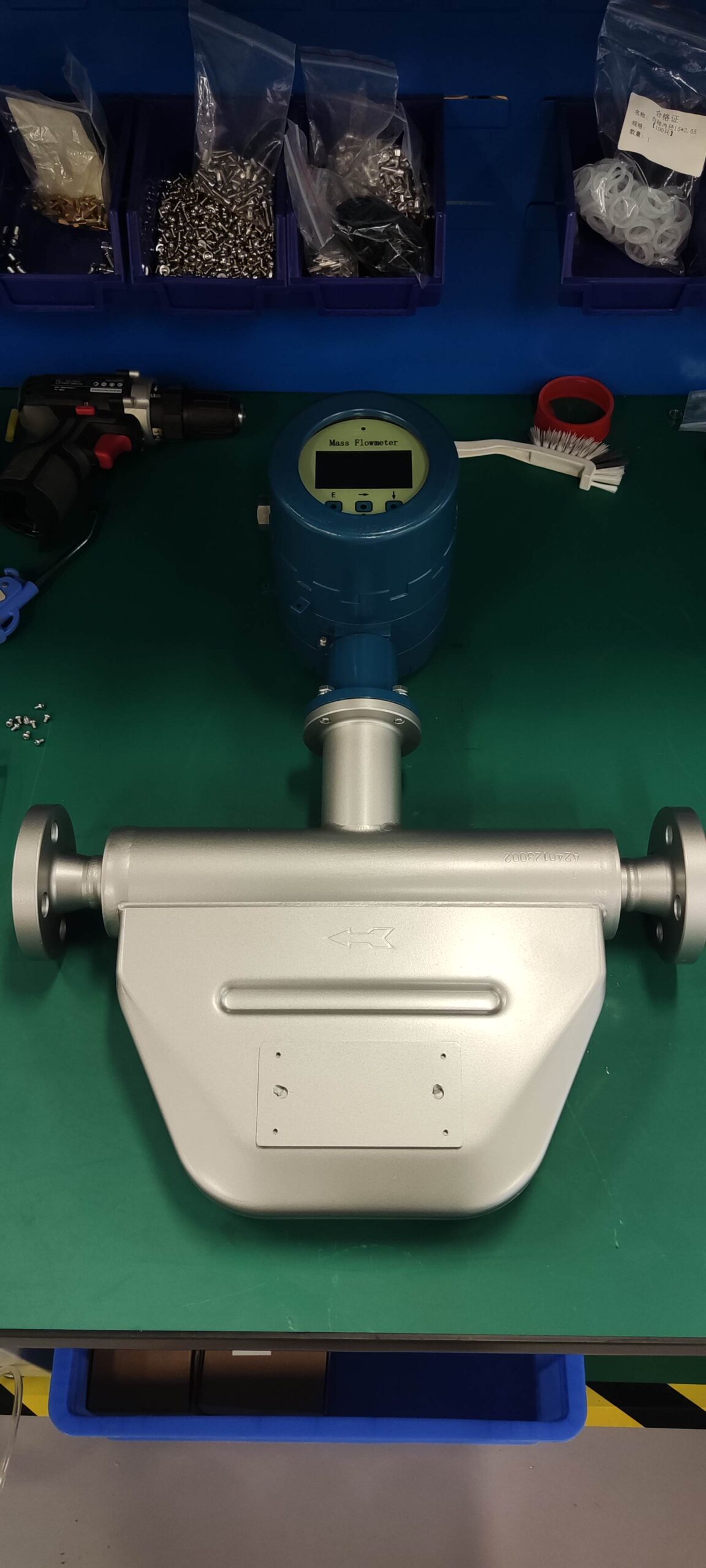

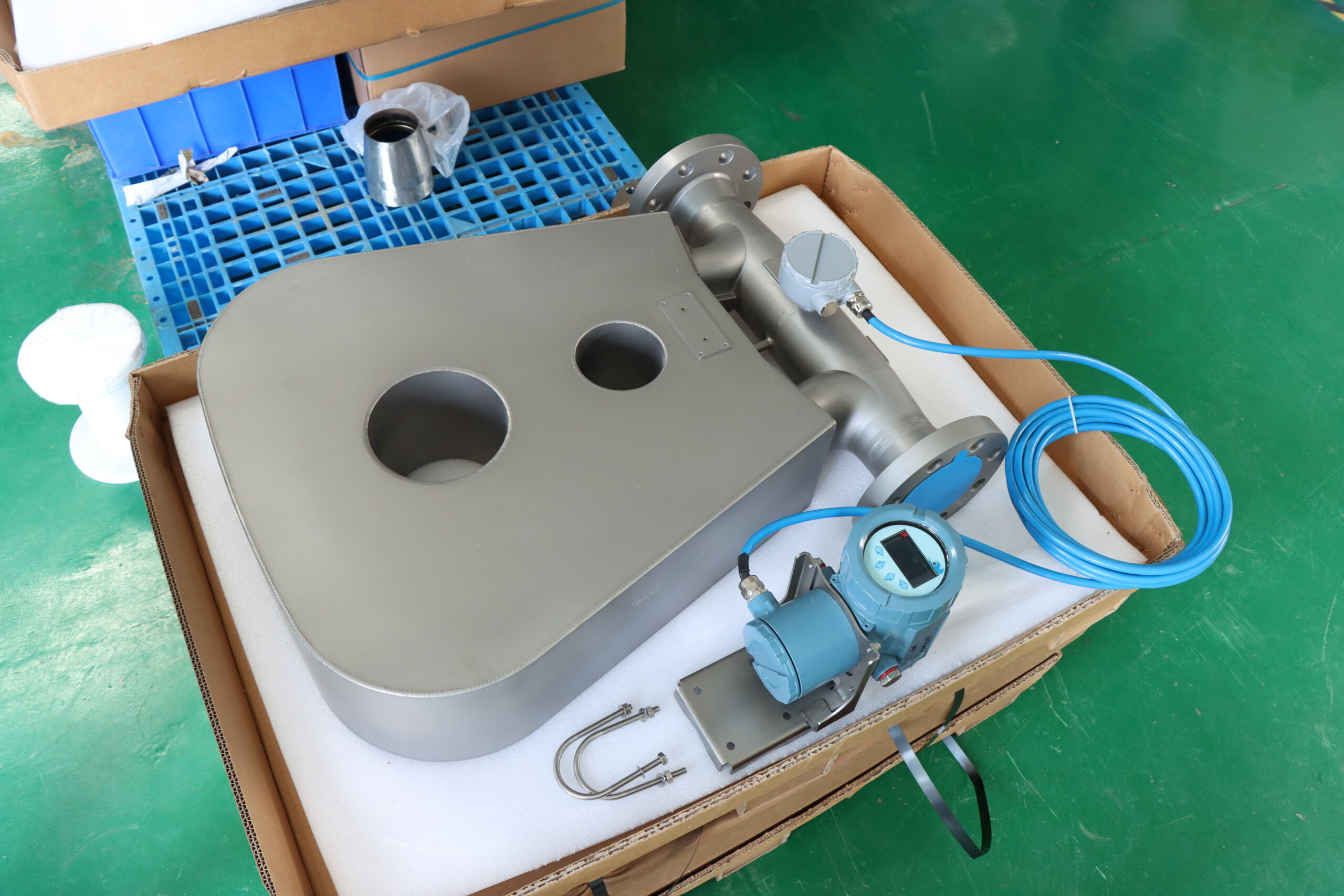

High Accuracy 0.1 Grade Mass Ciriolis Fluid Flow Meter

Coriolis mass flowmeters are sophisticated instruments used for measuring the mass flow rate of fluids flowing through a pipe. They utilize the principle of Coriolis force, which occurs when a fluid is set in motion within a vibrating tube. Here are some common uses of Coriolis mass flowmeters:

Fluids with varying densities: Coriolis mass flowmeters are particularly useful for measuring fluids with varying densities, such as slurries, liquids with suspended solids, or multiphase fluids (e.g., oil and water mixtures). Unlike volumetric flowmeters, which require density compensation, Coriolis flowmeters directly measure mass flow rate and are unaffected by changes in fluid density.

Accurate measurement of liquids and gases: Coriolis mass flowmeters can accurately measure the mass flow rates of both liquids and gases. They are widely used in industries such as oil and gas, chemical processing, food and beverage, pharmaceuticals, and water and wastewater treatment.

Batching and blending: Coriolis mass flowmeters are commonly used in batching and blending processes where precise control of fluid flow rates is essential for achieving desired product quality and consistency. They enable accurate measurement and control of the flow of ingredients or components in mixing, blending, and batching operations.

Process control and optimization: Coriolis mass flowmeters play a critical role in process control and optimization by providing real-time measurement data that can be used to monitor and adjust process parameters. They help industries improve efficiency, reduce waste, and ensure compliance with regulatory requirements.

Custody transfer applications: Coriolis mass flowmeters are widely accepted for custody transfer applications where accurate measurement of fluid flow rates is required for billing and financial transactions. They are used in industries such as oil and gas production, refining, and distribution, as well as in chemical and petrochemical industries.

High-pressure and high-temperature environments: Coriolis mass flowmeters are suitable for use in challenging operating conditions, including high-pressure and high-temperature environments. They offer robust performance and reliability even in harsh industrial settings.

Hygienic applications: Coriolis mass flowmeters with sanitary designs are used in hygienic applications in the food and beverage, pharmaceutical, and biotechnology industries. They meet stringent sanitary standards and regulations, making them suitable for measuring flow rates of sensitive or sterile fluids.

Overall, Coriolis mass flowmeters are versatile instruments that offer accurate, reliable, and direct measurement of mass flow rates across a wide range of industries and applications. Their ability to provide simultaneous measurement of mass flow, density, and temperature makes them valuable tools for process control, optimization, and quality assurance.