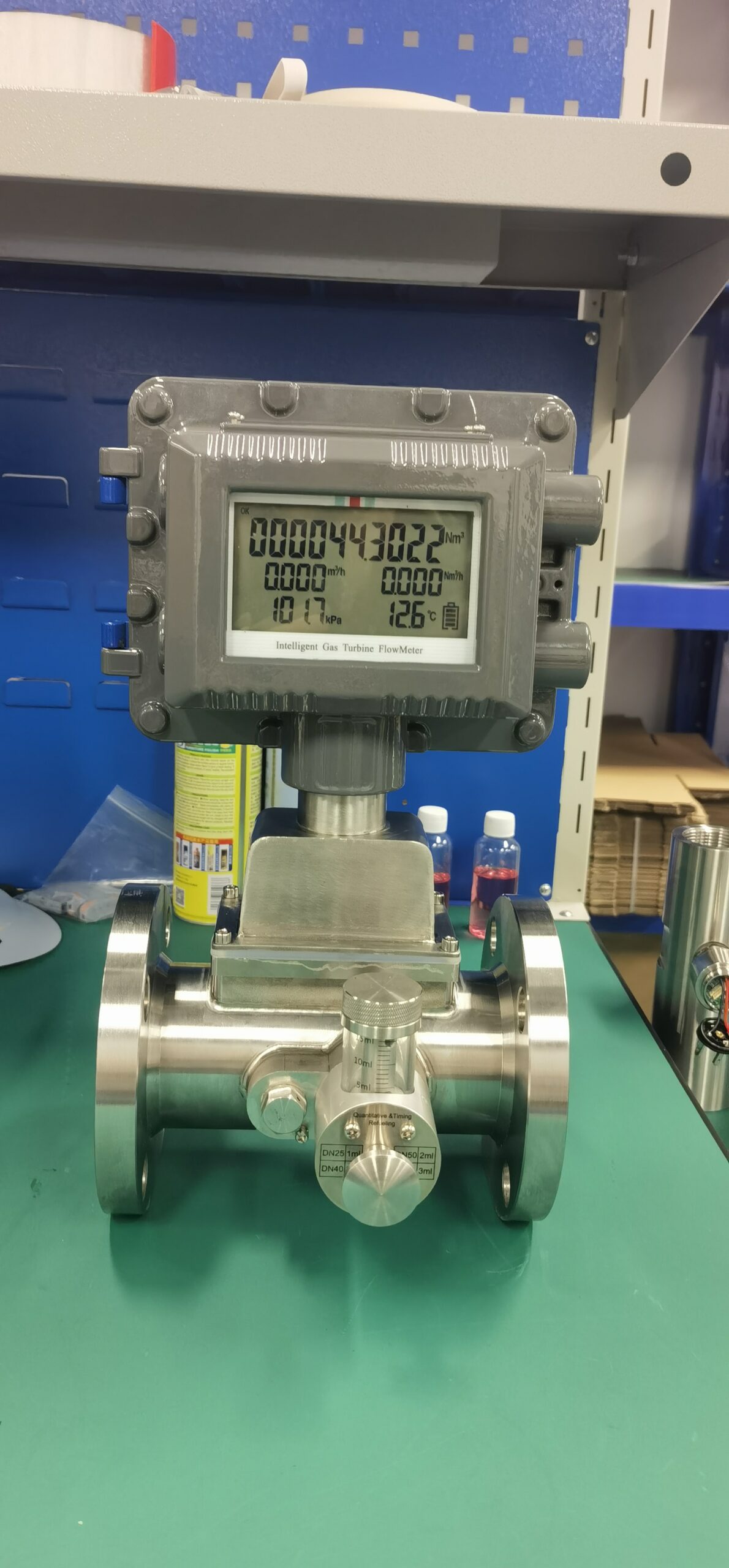

Gas turbine flow meter installation precautions

Gas turbine flow meter installation precautions

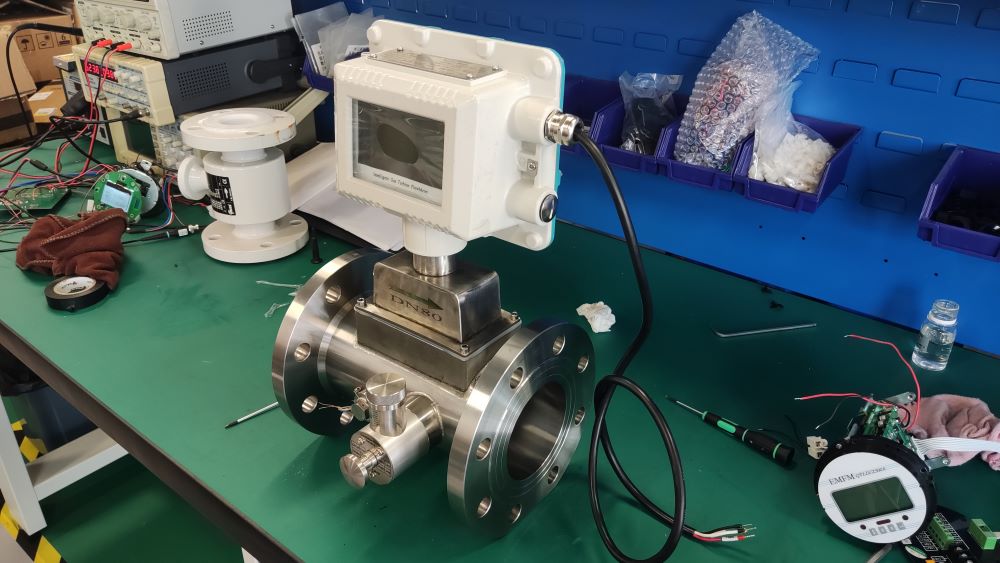

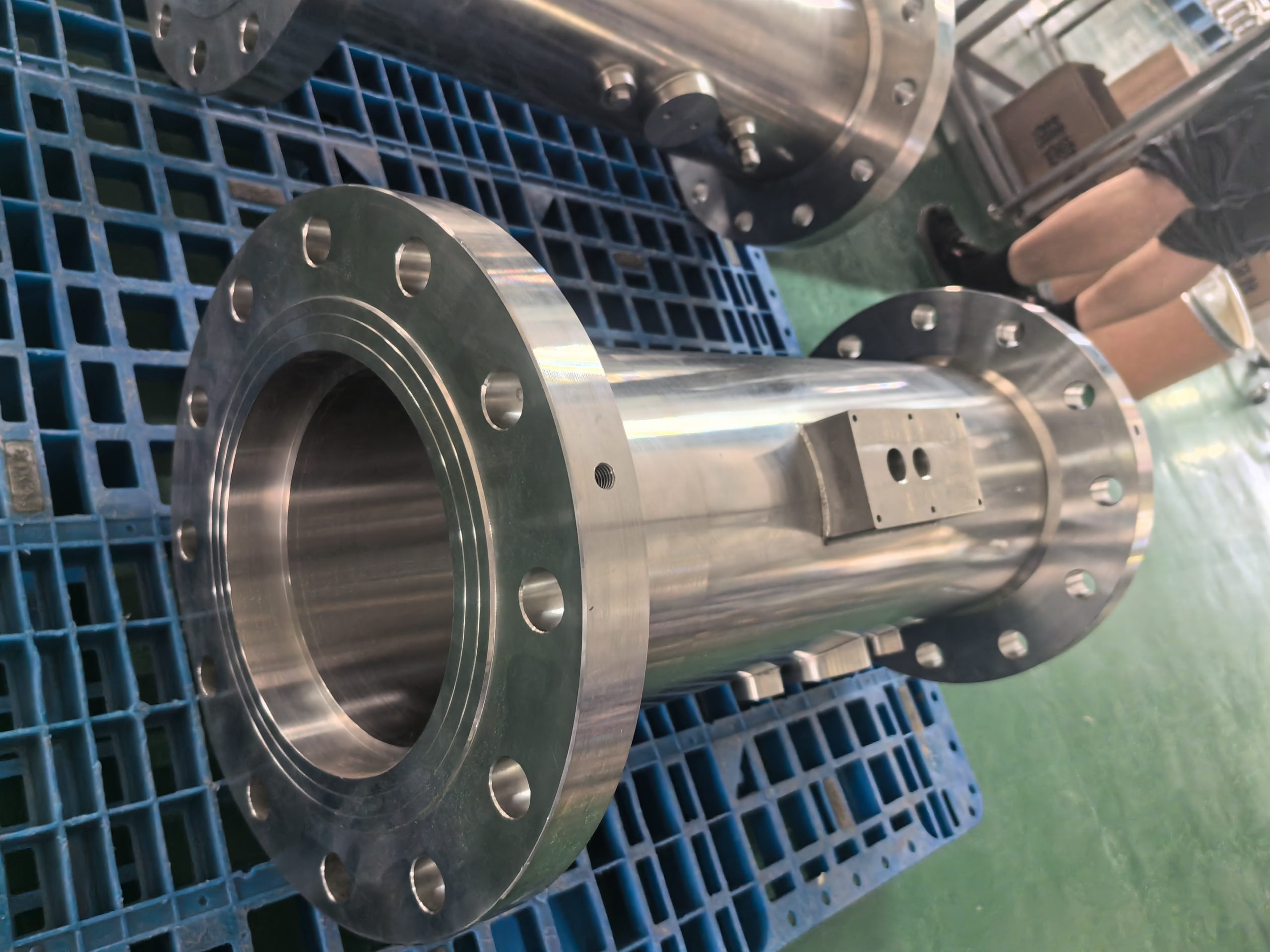

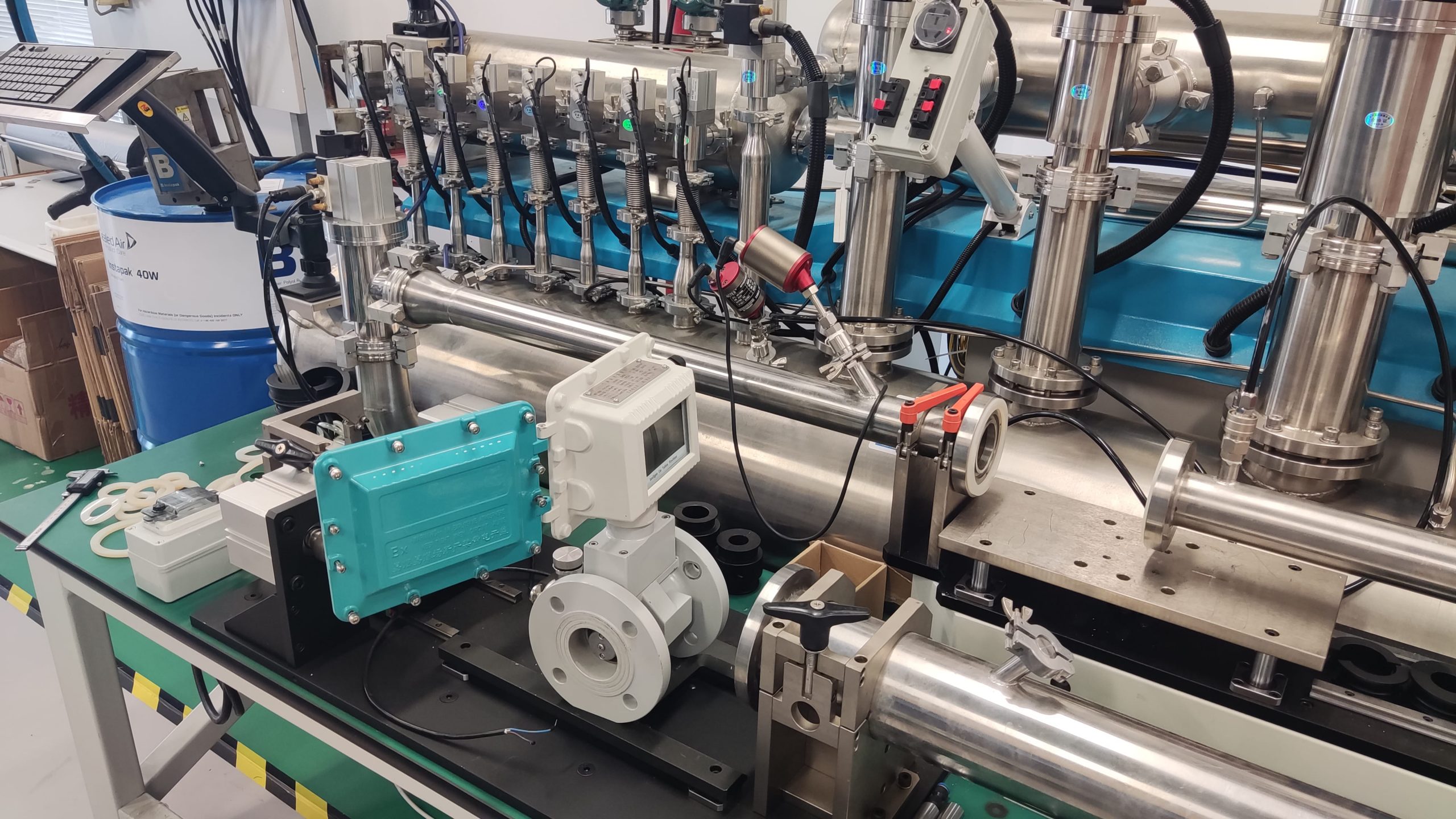

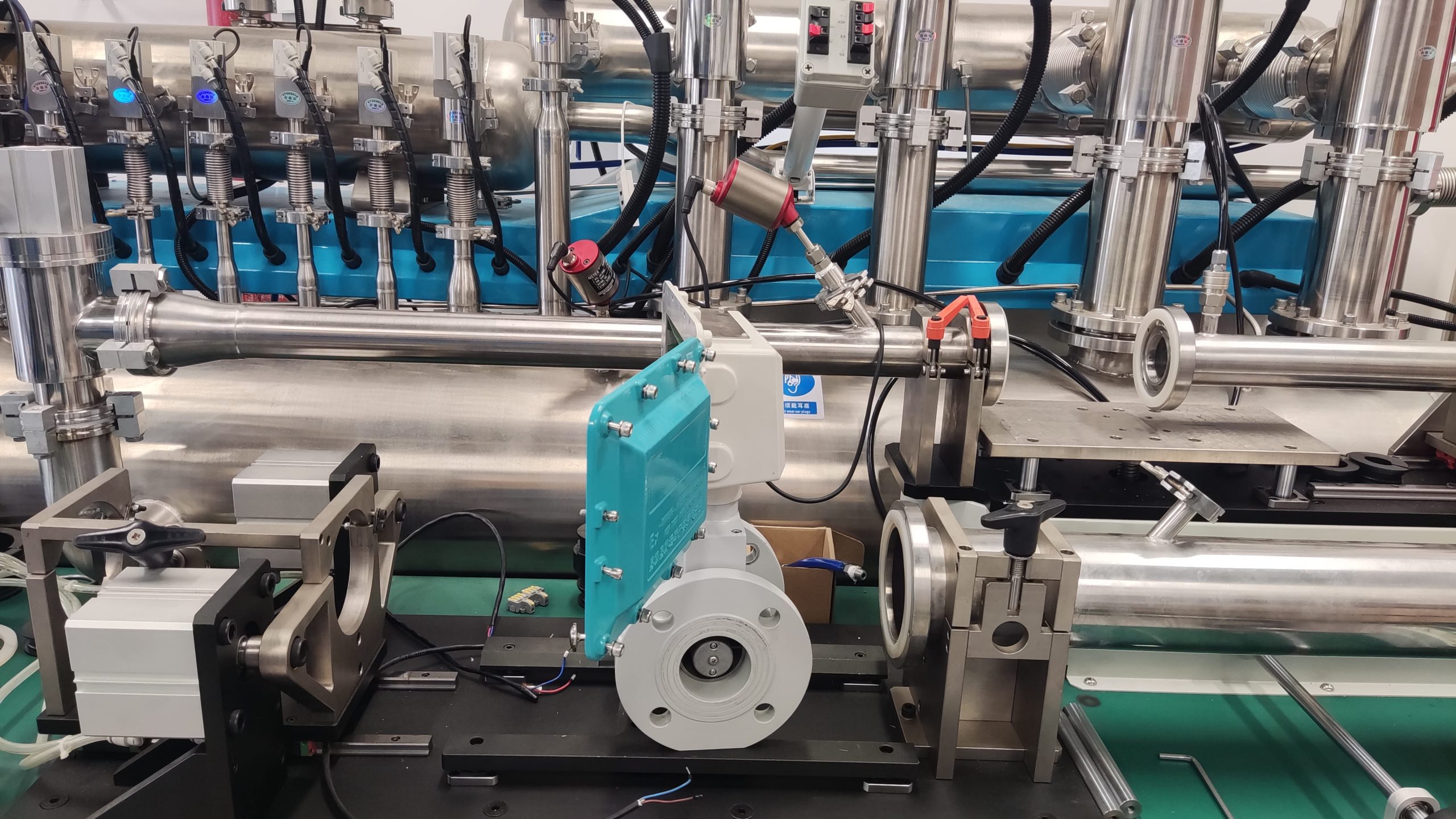

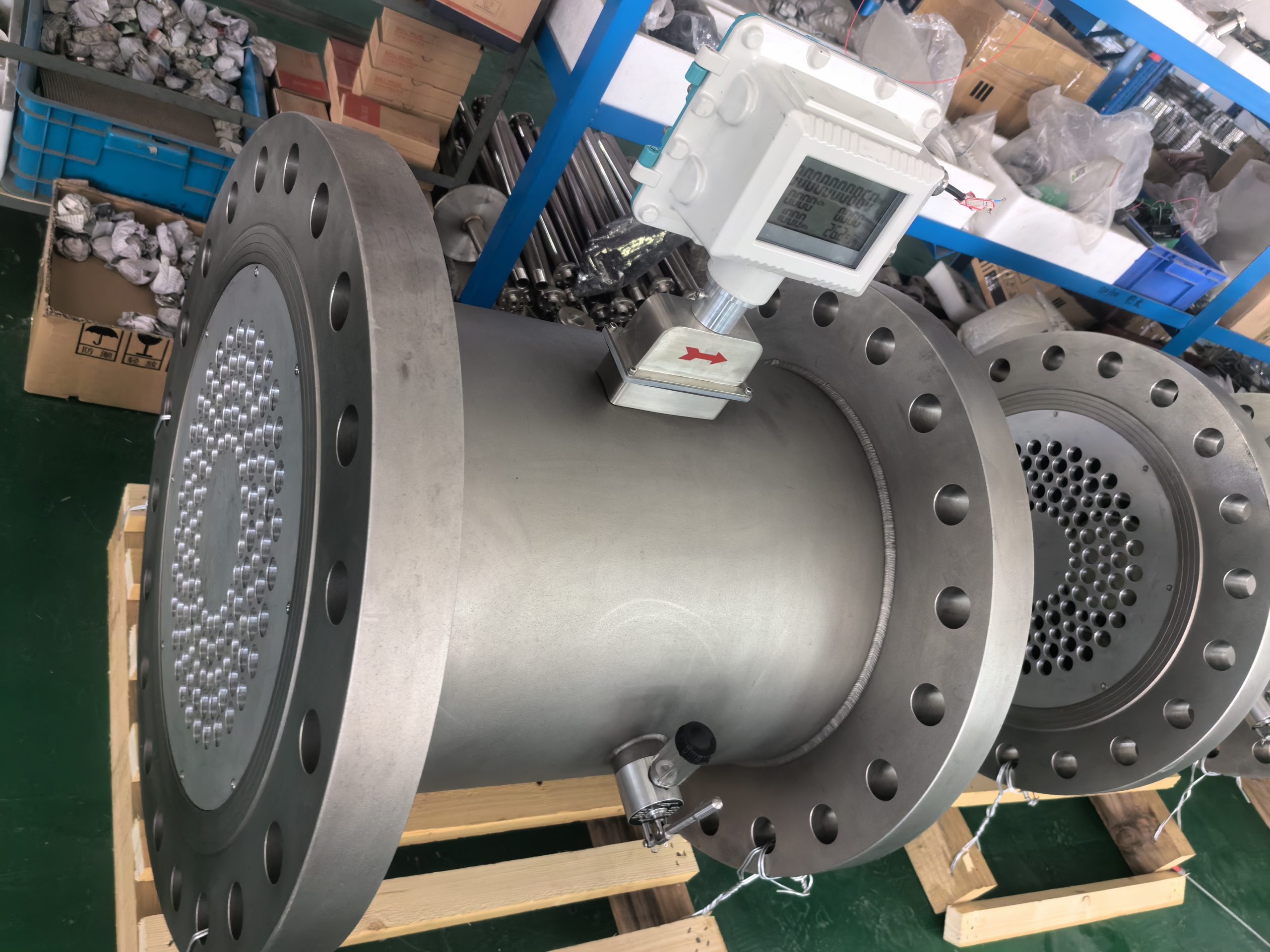

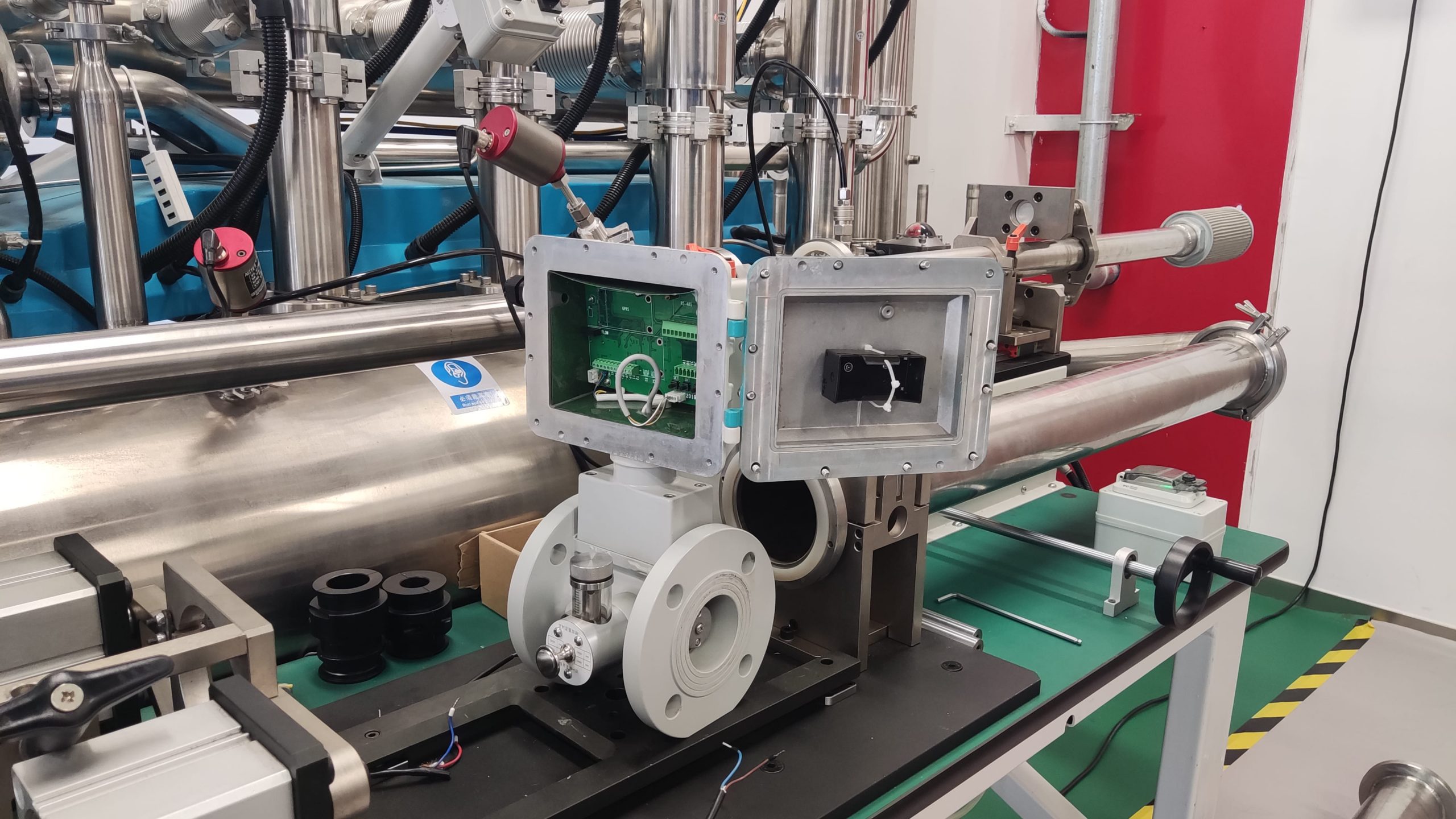

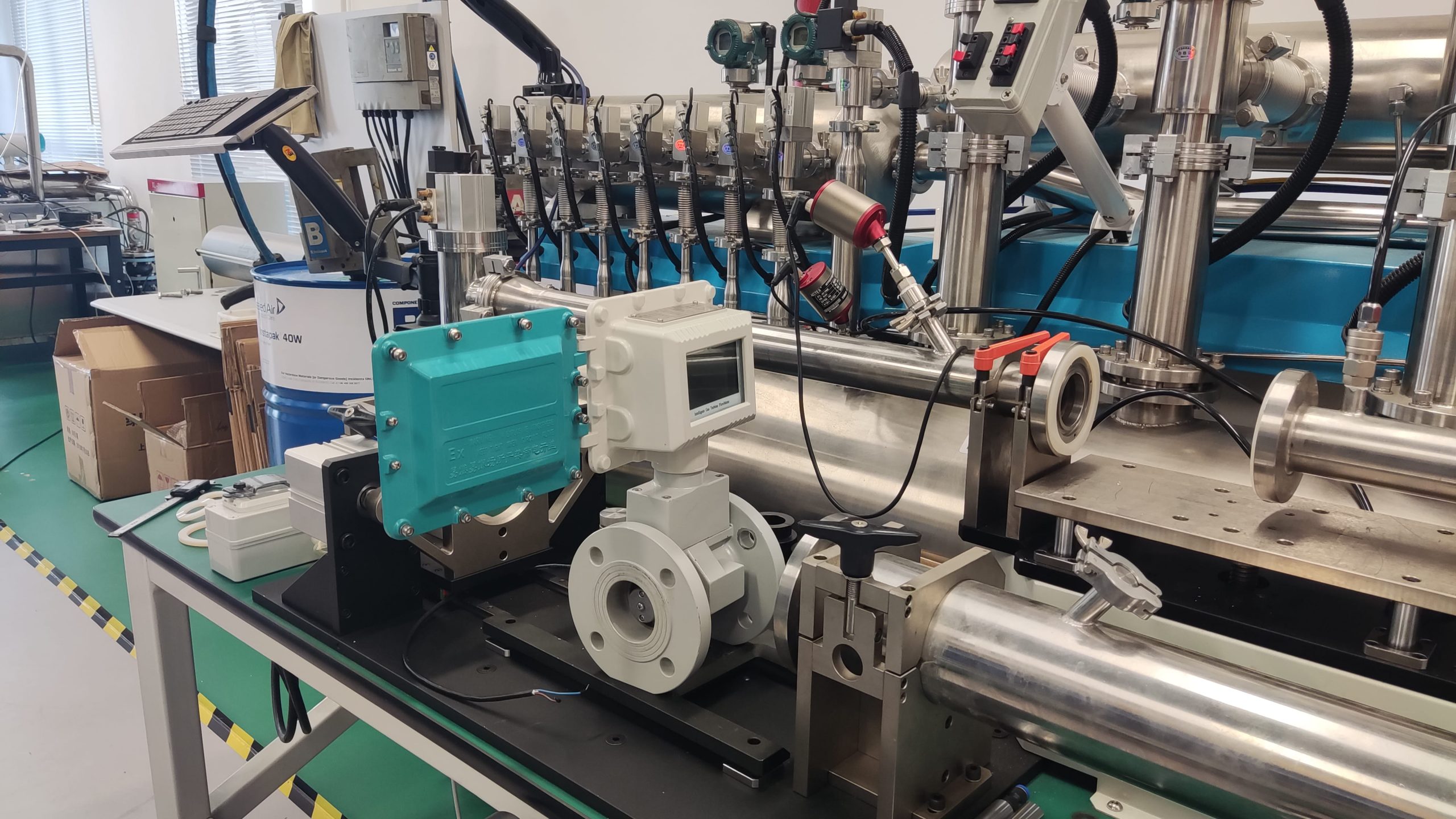

1. The installation of gas turbine flowmeter generally still uses the three-valve and two-branch pipeline installation mode. The bypass design is mainly for the convenience of maintenance and verification, and the straight pipe section is left in front of the gas turbine flowmeter to meet the requirements of the first 5D and the second 2D. The front and rear pipe flanges should be installed horizontally without pipe stress.

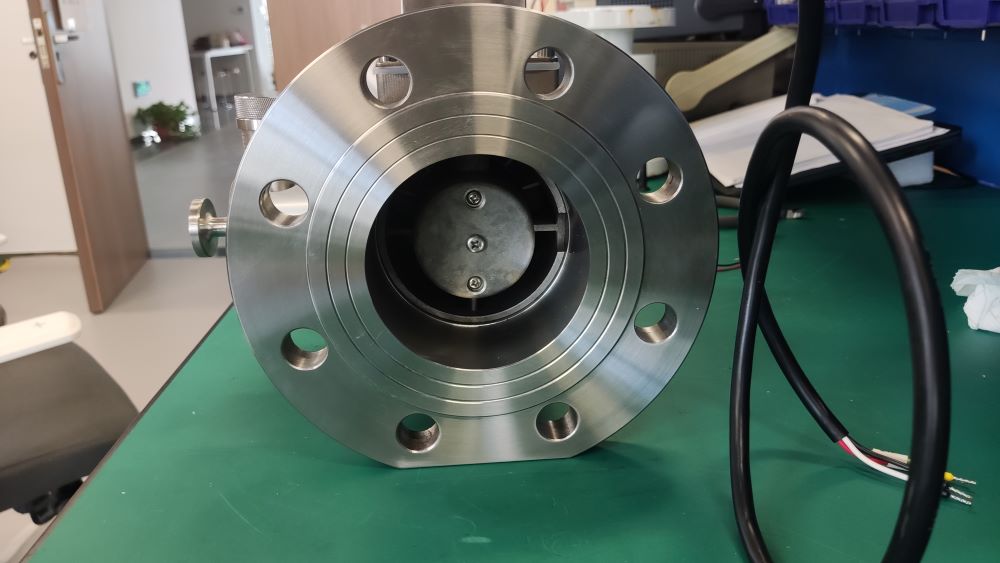

2. The gas medium is required to be a clean gas without corrosion, and the pipeline should be thoroughly cleaned before installing the gas turbine flowmeter.

3. In order to ensure the service life of the gas turbine flowmeter, the filter must be installed before the gas turbine flowmeter, which can be purchased together with the order. When using the filter, a regular cleaning system should be developed to prevent impurities in natural gas dust from entering the bearing of the turbine, and the phenomenon of sticking shaft does not turn.

4. When installing the gas turbine flowmeter and measuring pipe, the installation of telescopic tube or bellows should be considered, and the upper and lower pipelines should be laid reasonably according to the actual size of the gas turbine flowmeter, so that the flowmeter deformation caused by pipeline stress is smaller.

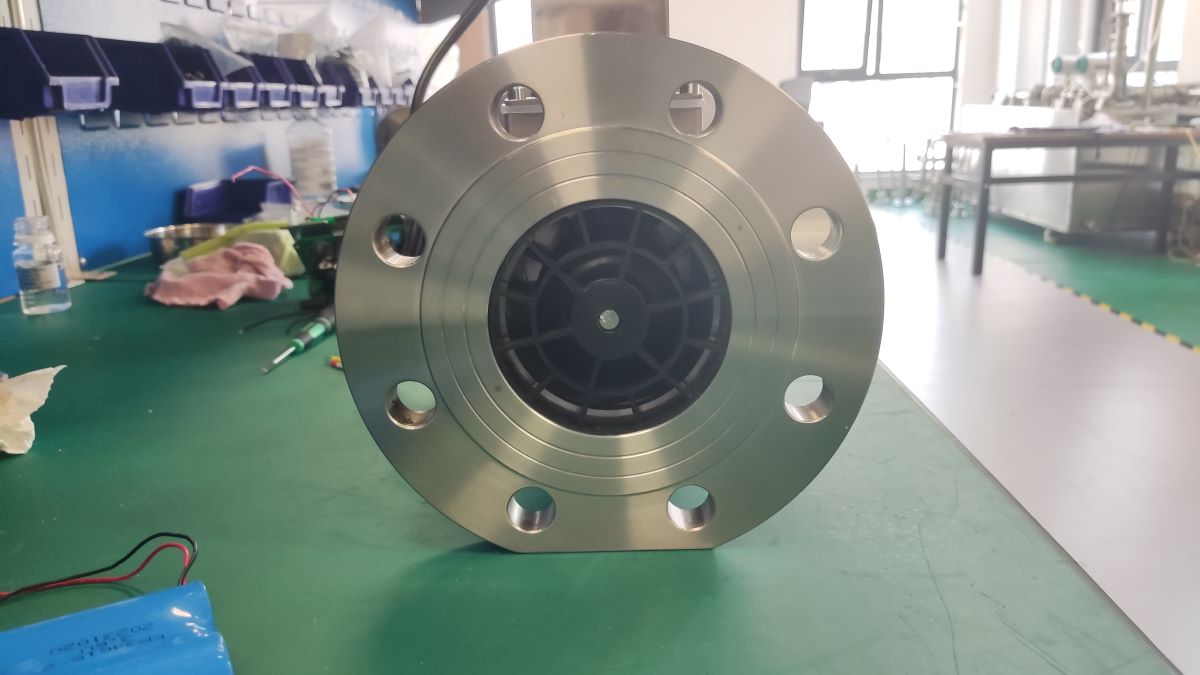

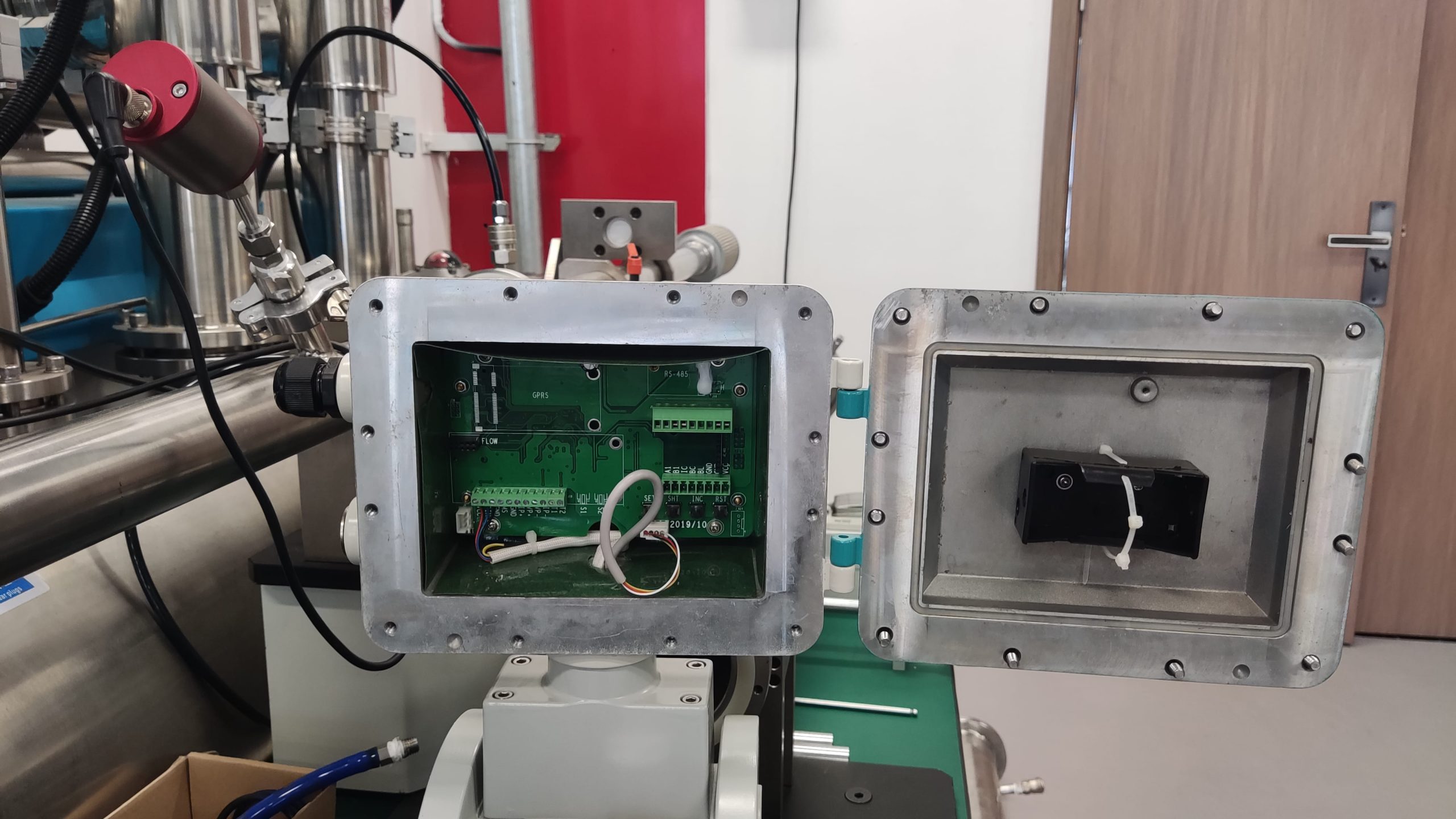

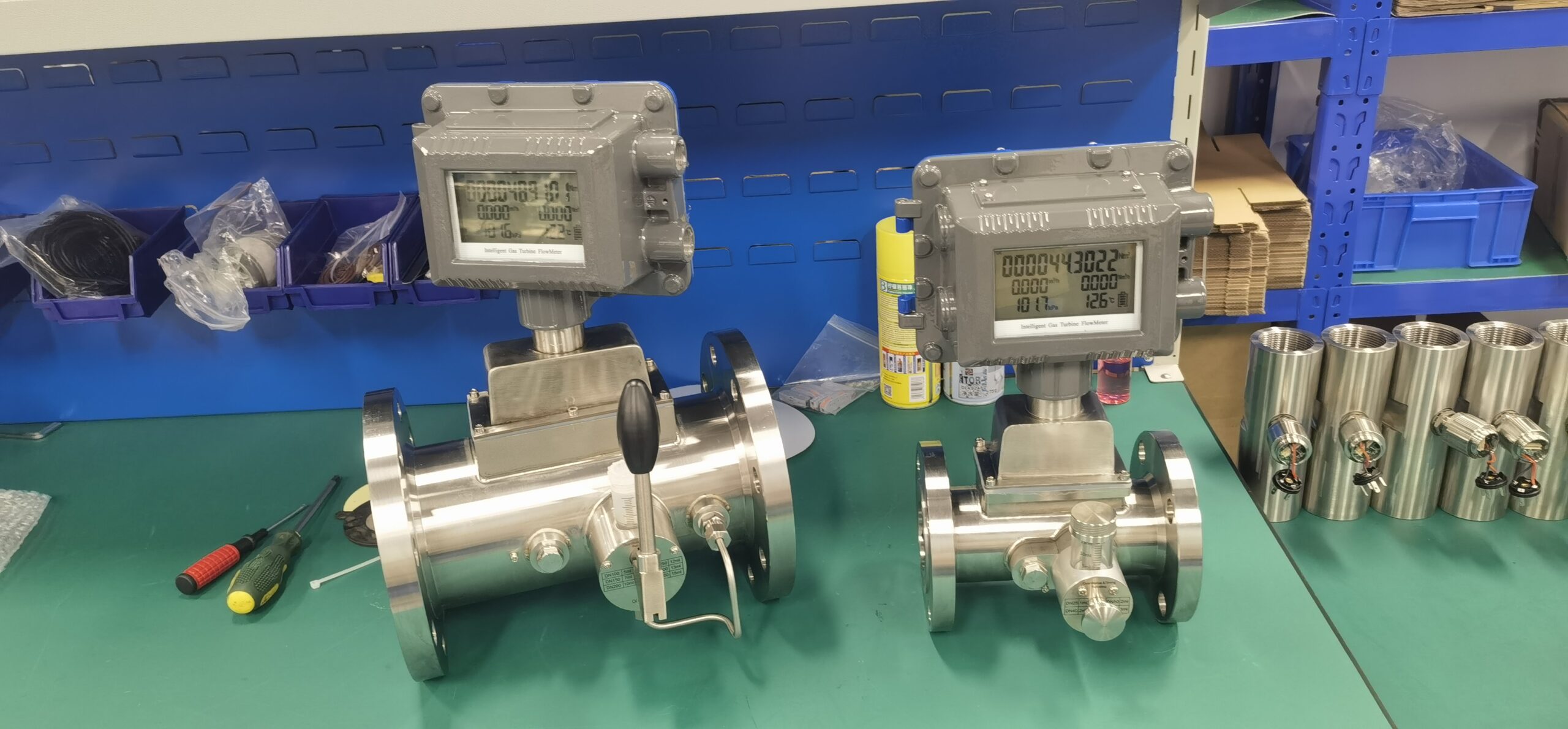

5. The gas turbine flowmeter detector power line should use a shielded wire, the ground should be good and reliable, and the magnetic induction part should not be collided during installation.