Gas Flow Meter Buying Guide: How to choose the right ammonia flow meter for you

When choosing the right ammonia flow meter for you, several factors need to be considered to ensure the accuracy of the measurement results and the reliability of the equipment. Here’s a detailed buying guide:

1. Understand the characteristics of ammonia

Ammonia has a certain toxicity and corrosion, so these characteristics must be taken into account when choosing flow timing. Ammonia density, viscosity, temperature and pressure and other parameters will change with the change of working conditions, these factors will directly affect the choice of flowmeter and measurement accuracy.

2. Determine measurement requirements

Flow range: Specify the ammonia flow range to be measured, that is, the minimum flow rate and the maximum flow rate. Choosing the right measuring range can ensure the accuracy and stability of the flowmeter.

Accuracy requirements: Determine the required accuracy level based on the application scenario. For example, for high-precision applications such as refrigeration systems, high precision flowmeters need to be selected.

Environmental conditions: Consider the environmental conditions in which the flowmeter will be installed, including temperature, humidity, vibration, and pressure. Make sure the flow meter can adapt to these environmental conditions.

3. Select the right flowmeter type

Mass flowmeter:

Features: Directly measure the mass flow of gas, not affected by pressure and temperature changes.

Application scenario: High precision measurement, such as chemical industry, metallurgy and other industrial fields.

Recommended models: thermal mass flowmeter, vibrating mass flowmeter, etc.

Volume flowmeter:

Features: To measure the volume flow of gas, the influence of pressure and temperature should be considered.

Application scenario: General industrial measurement, such as gas pipeline transportation.

Recommended models: turbine flowmeter, fluid oscillator, float flowmeter, etc.

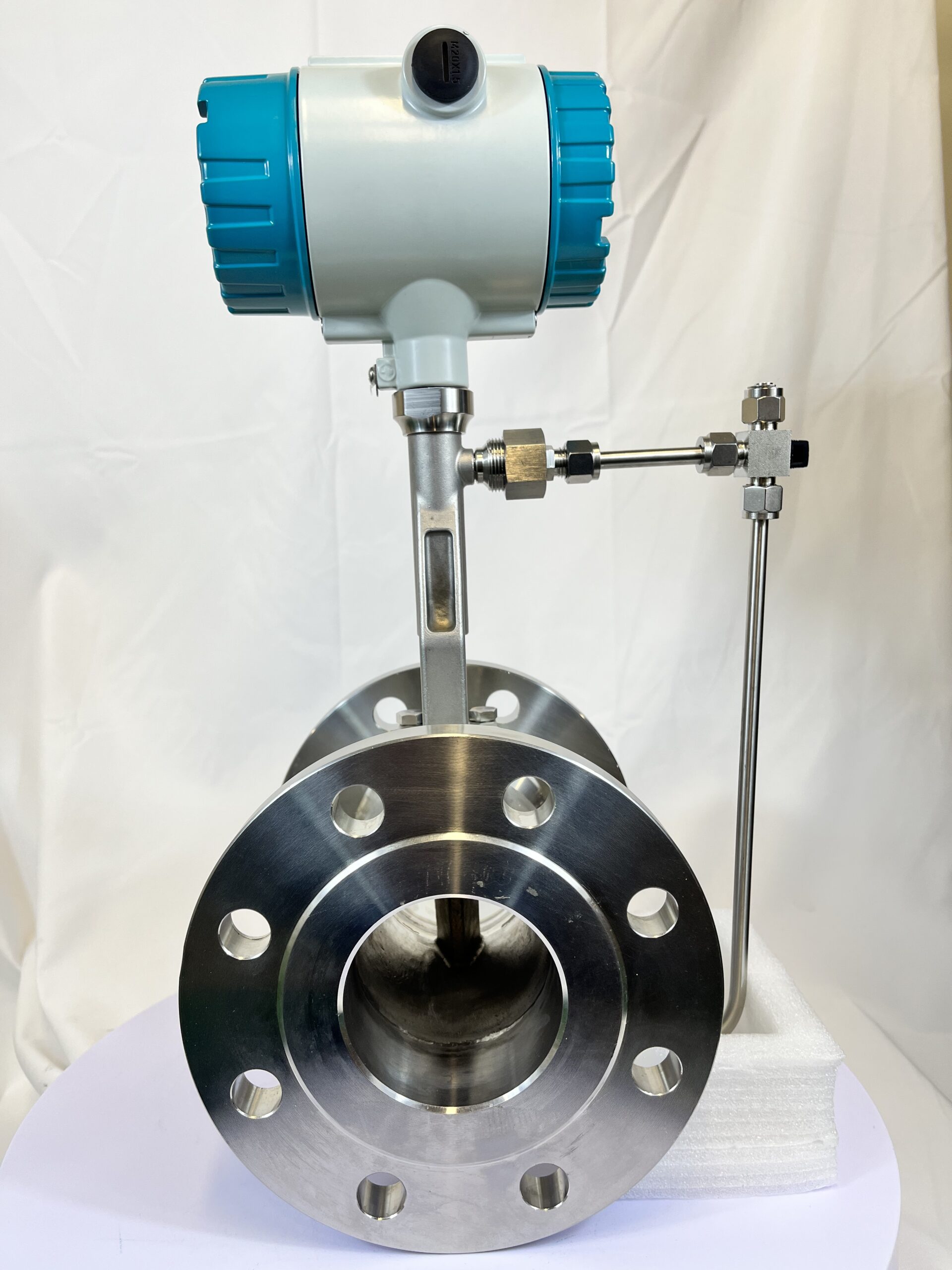

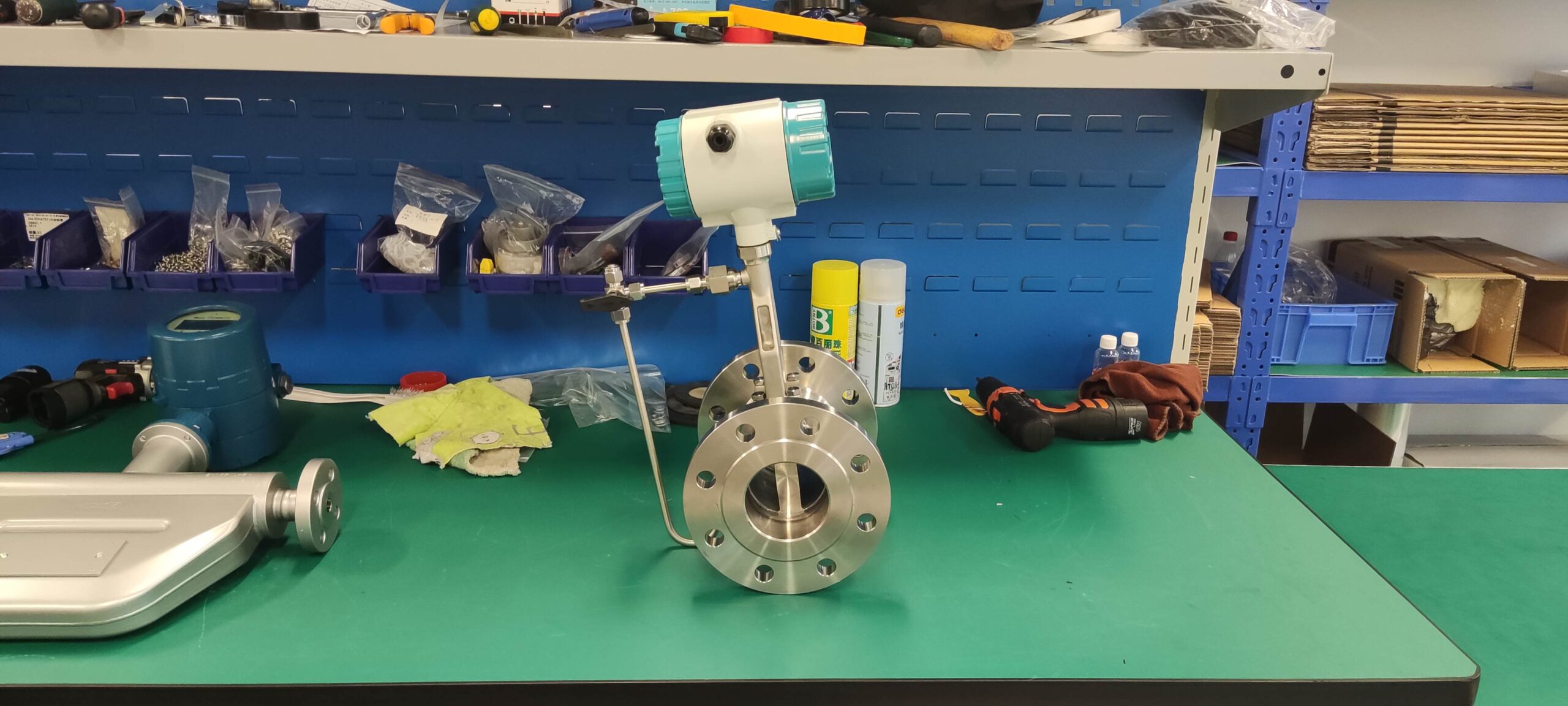

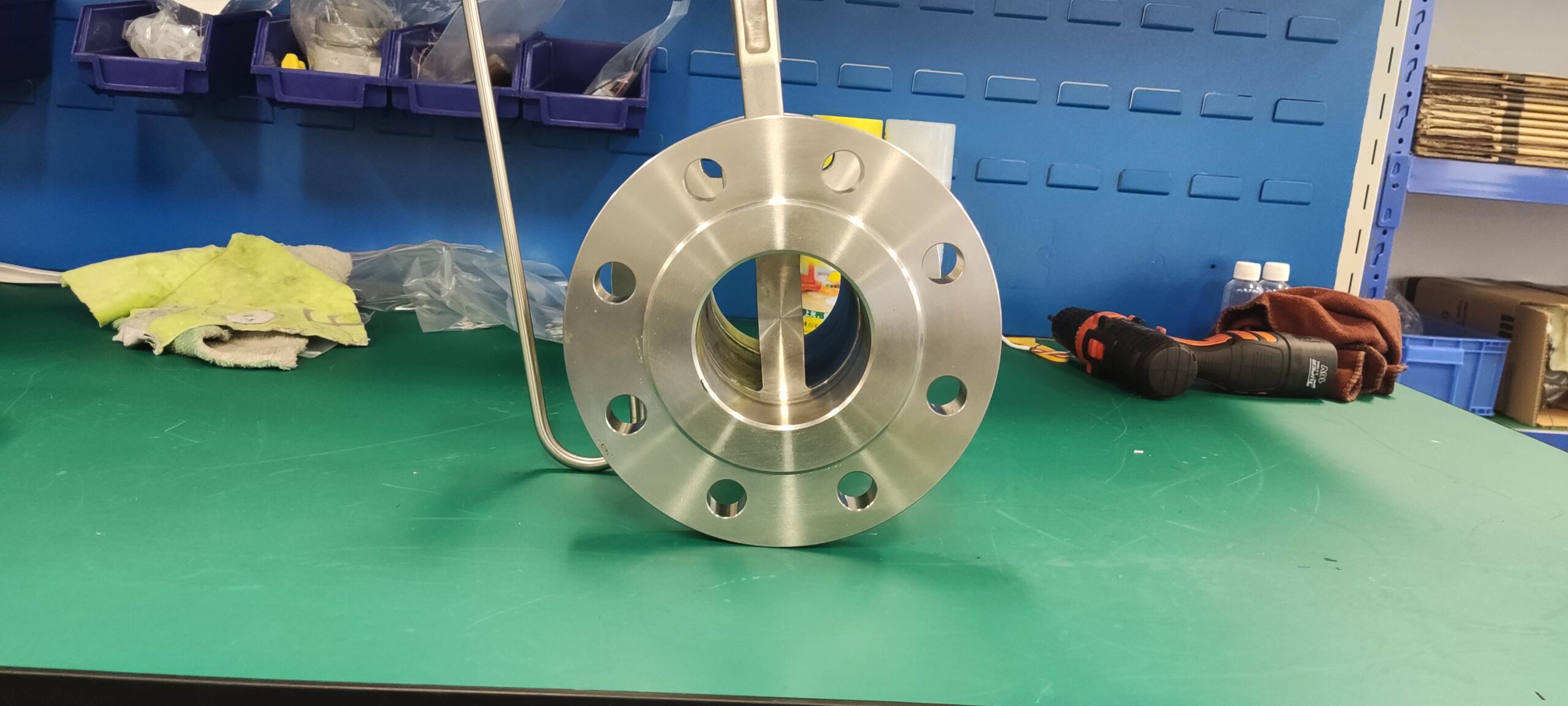

Differential pressure flowmeter:

Features: Flow rate is inferred by measuring the pressure difference in the pipe.

Application scenario: large flow measurement, such as industrial waste gas treatment.

Recommended models: orifice flowmeter, nozzle flowmeter, flow tube, etc.

Ultrasonic flowmeter:

Features: Non-invasive, no pressure loss, high precision.

Application scenario: Measurement of various gases, including ammonia.

Thermistor flowmeter:

Features: Flow rate can be inferred by measuring the cooling effect of gas flow when superheating wire, suitable for small flow range.

4. Consider other key factors

Material: Choose a flow meter made of corrosion-resistant materials to cope with the corrosiveness of ammonia.

Maintenance and calibration: Consider the maintenance and calibration requirements of the flow meter to ensure long-term stability and accuracy.

Cost: Choose the right flowmeter type according to your budget, taking into account cost performance.

Manufacturer reputation and support: Choose the flow meter produced by well-known manufacturers to ensure product quality and after-sales support.