Flowmeter manufacturers analysis of precession vortex flowmeter need to pay attention to some matters

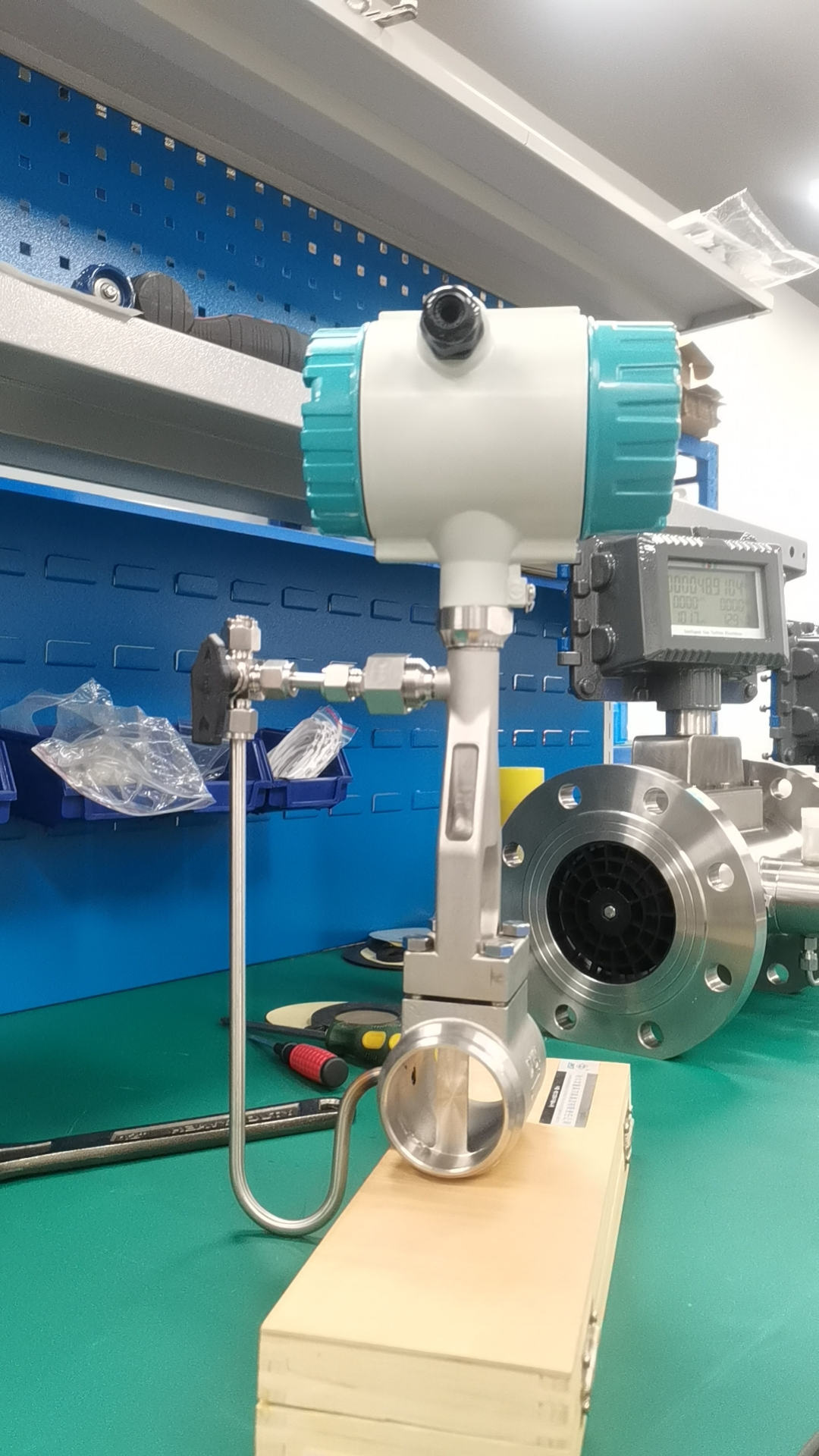

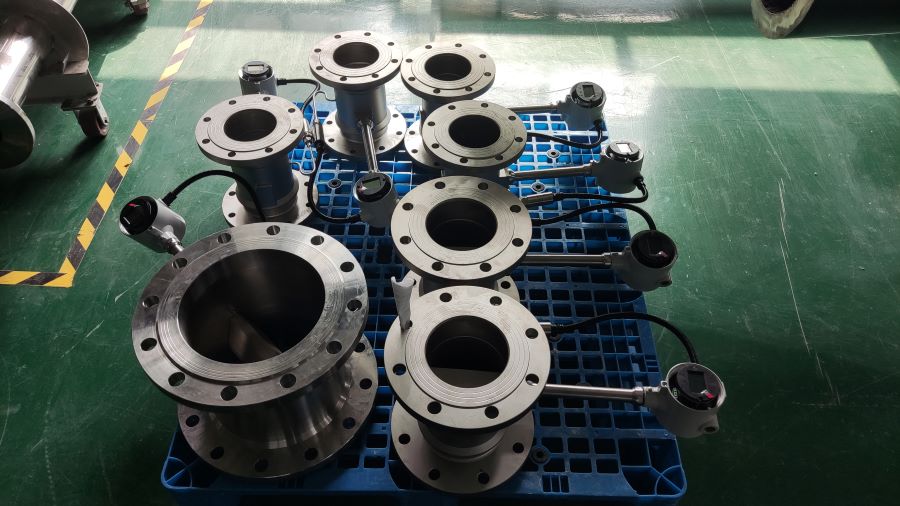

Precession vortex flowmeter without mechanical moving parts, small size, corrosion resistance, stable performance; It can directly display the working pressure, temperature, flow rate and gas volume under standard state of the medium; With the advantages of wide measuring range and small measuring error, the precession vortex flowmeter has been widely used in the production measurement of oil and gas Wells and the sales measurement of natural gas.

In the field application for many years, we believe that the flow meter is more suitable for relatively clean dry gas measurement, and gradually become a small and medium-sized gas measurement instrument.

To ensure accurate metering and reduce metering errors of the precession vortex flowmeter, please note the following:

1, the selection is reasonable, do not make the actual minimum flow QVmin lower than the lower limit of the flow range of the selected runoff meter.

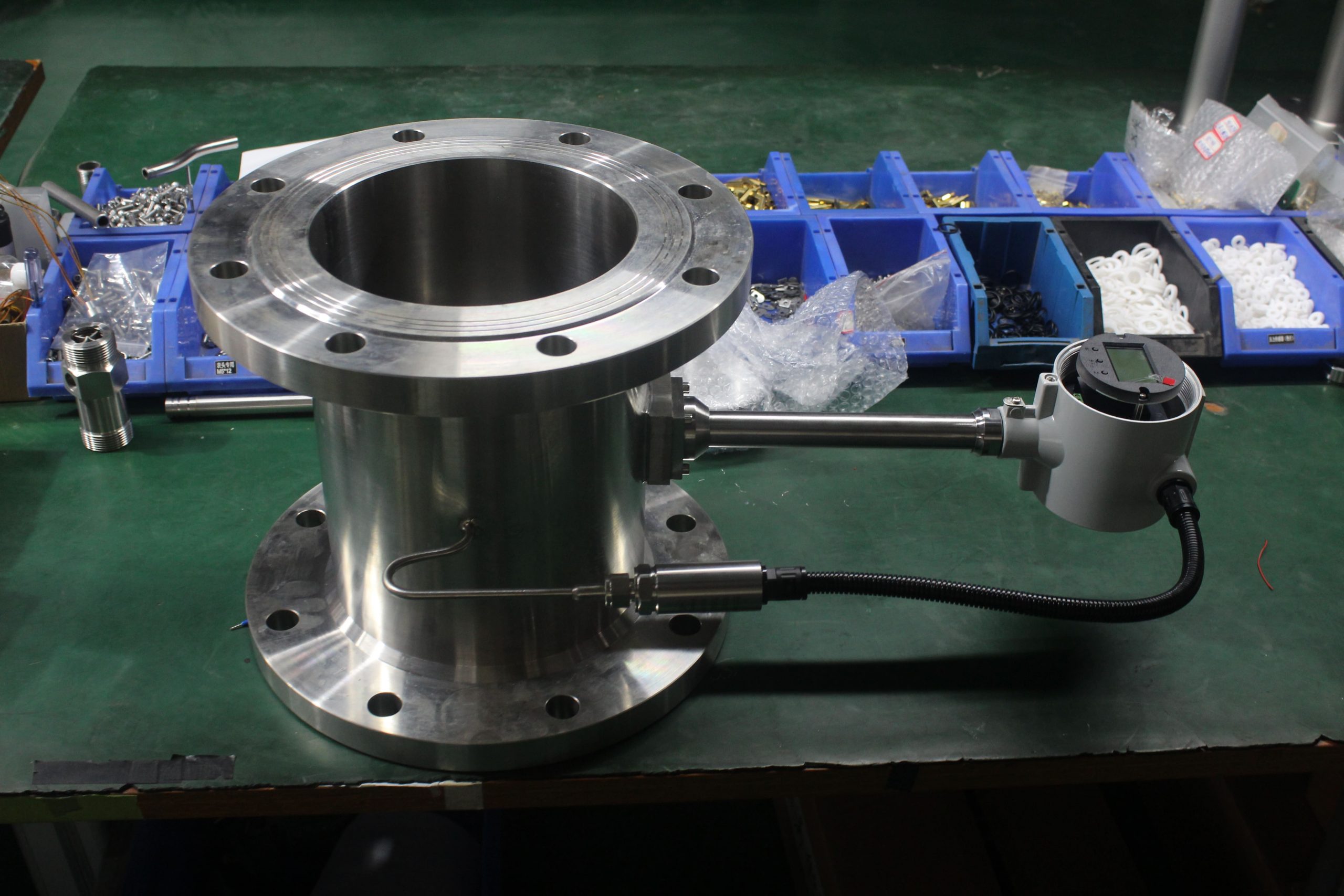

2, the installation of the correct upstream flow meter should be at least 10D length of the metering straight pipe section. The inner wall of the straight pipe section should be smooth, and there should be no steps, and the weld of the connecting flange should be smoothed, and the flange gasket should not burst into the pipeline. The installation direction of the flowmeter can not be reversed. The test proves that all unreasonable installation will lead to low metering value of the flowmeter.

3, away from the shock source, or on the flow meter, downstream installation pier to avoid the impact of pipeline vibration. Avoid the interference of strong magnetic field on the flowmeter chip.

4, the temperament is relatively clean, especially can not appear liquid gas two-phase flow; When the temperament is dirty, the flowmeter should be cleaned immediately.

5, reduce the impact of air pulsation can be installed in front of the flow meter buffer tank, or extend the length of the metering straight pipe section upstream of the flow meter.

6. Timely measurement verification of the flowmeter to ensure accurate and reliable quantity value.