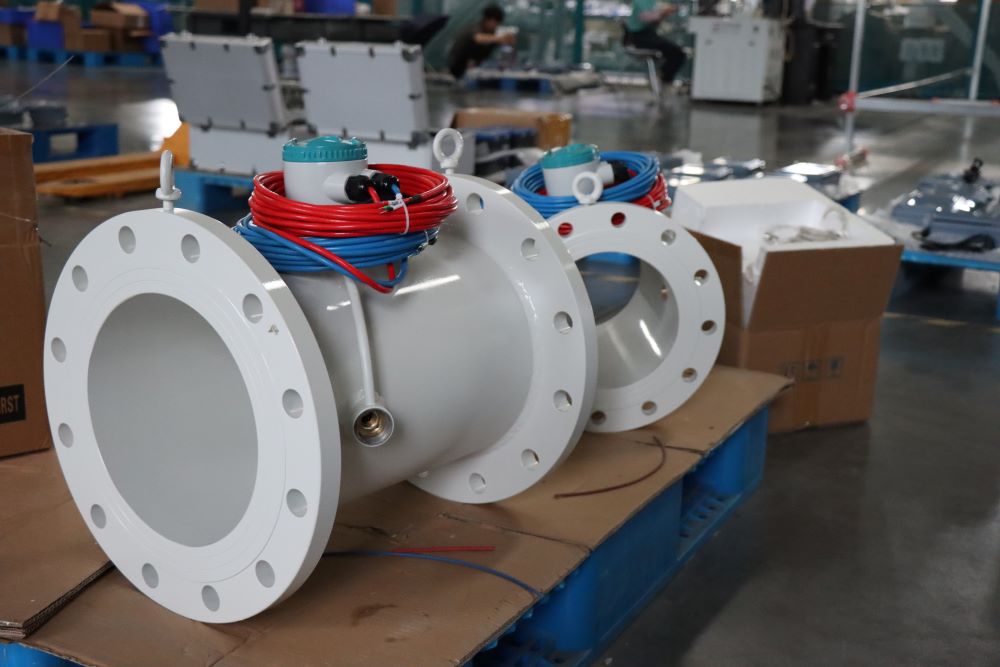

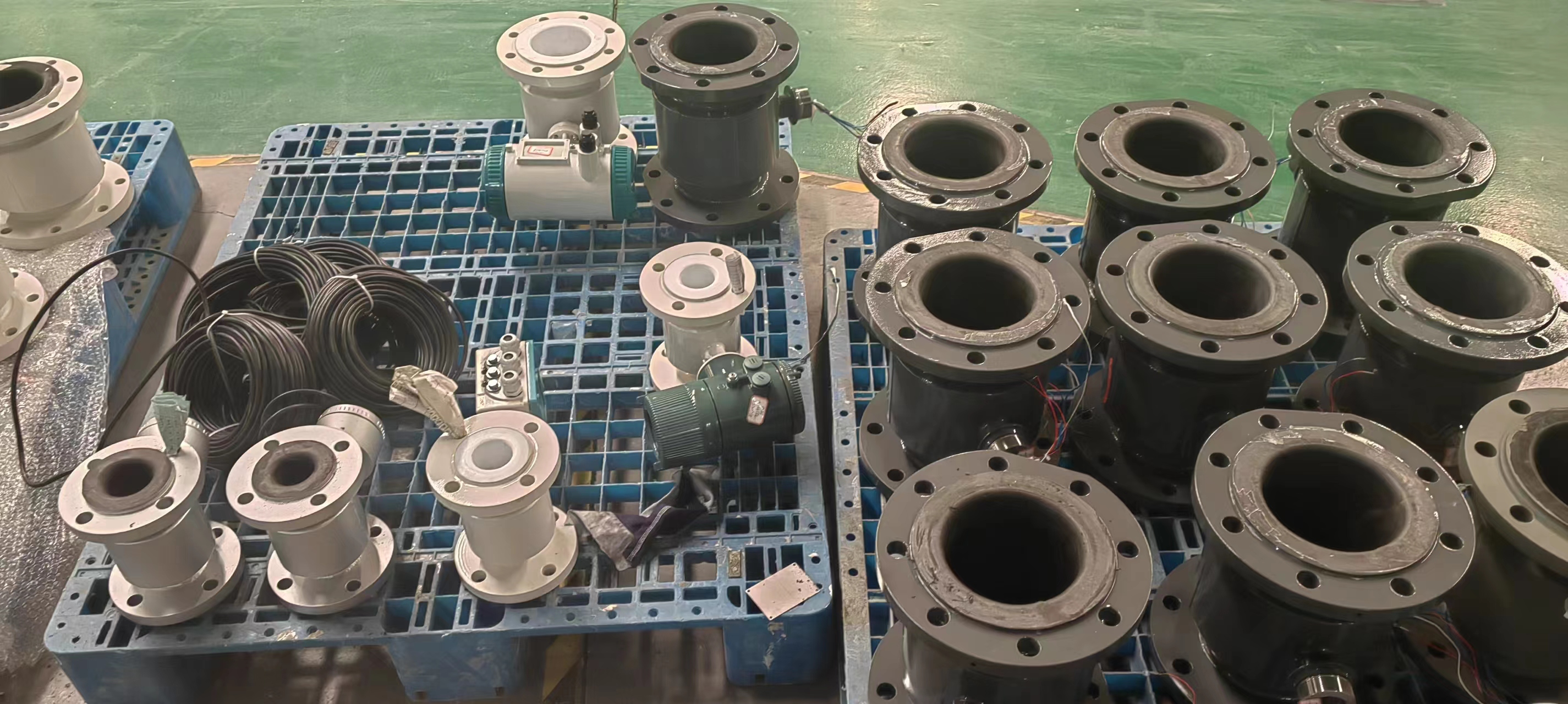

Flange Connection Waste Water Liquid Electromagnetic Flowmeter Magnetic Flowmeter

When measuring waste acid using an electromagnetic flowmeter, it’s crucial to choose electrodes that are suitable for the corrosive nature of the acid and that can withstand the specific conditions of the application. Common electrode materials for electromagnetic flowmeters used in corrosive environments include:

Hastelloy:

Hastelloy is a family of corrosion-resistant alloys known for their excellent resistance to a wide range of corrosive media, including acids. Hastelloy C-276 and Hastelloy C-22 are popular choices for acidic environments. These alloys provide high corrosion resistance and are suitable for measuring waste acids.

Platinum/Iridium:

Platinum or platinum/iridium-coated electrodes are often used in applications involving corrosive fluids. Platinum is known for its corrosion resistance, and the addition of iridium further enhances durability. These electrodes are suitable for measuring acids with moderate corrosivity.

Tantalum:

Tantalum is a corrosion-resistant metal that can withstand highly aggressive acids. Tantalum electrodes are suitable for applications involving concentrated and aggressive acids, making them a good choice for measuring waste acids.

Titanium:

Titanium is another corrosion-resistant material that can be used for electrodes in acidic environments. Titanium electrodes are suitable for a wide range of acids, including those found in waste streams.

Ceramic Coatings:

Some electromagnetic flowmeter electrodes may have ceramic coatings, providing an additional layer of protection against corrosion. These coatings can enhance the electrode’s resistance to aggressive acids.

The selection of electrode material depends on factors such as the concentration and type of acid in the waste, temperature, and other specific application conditions. Always refer to the manufacturer’s guidelines and specifications for the electromagnetic flowmeter being used, as they will provide recommendations on suitable electrode materials for different environments.