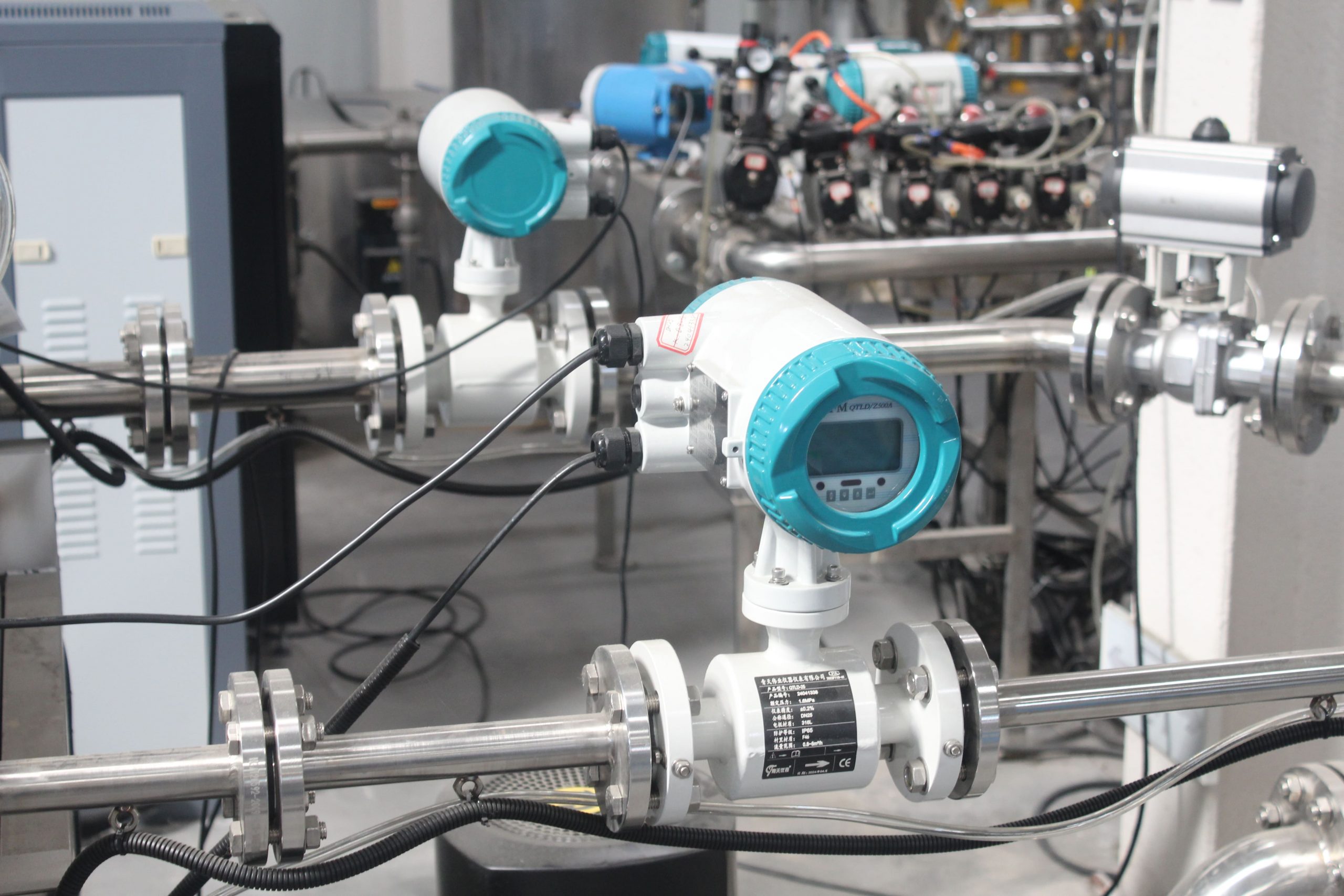

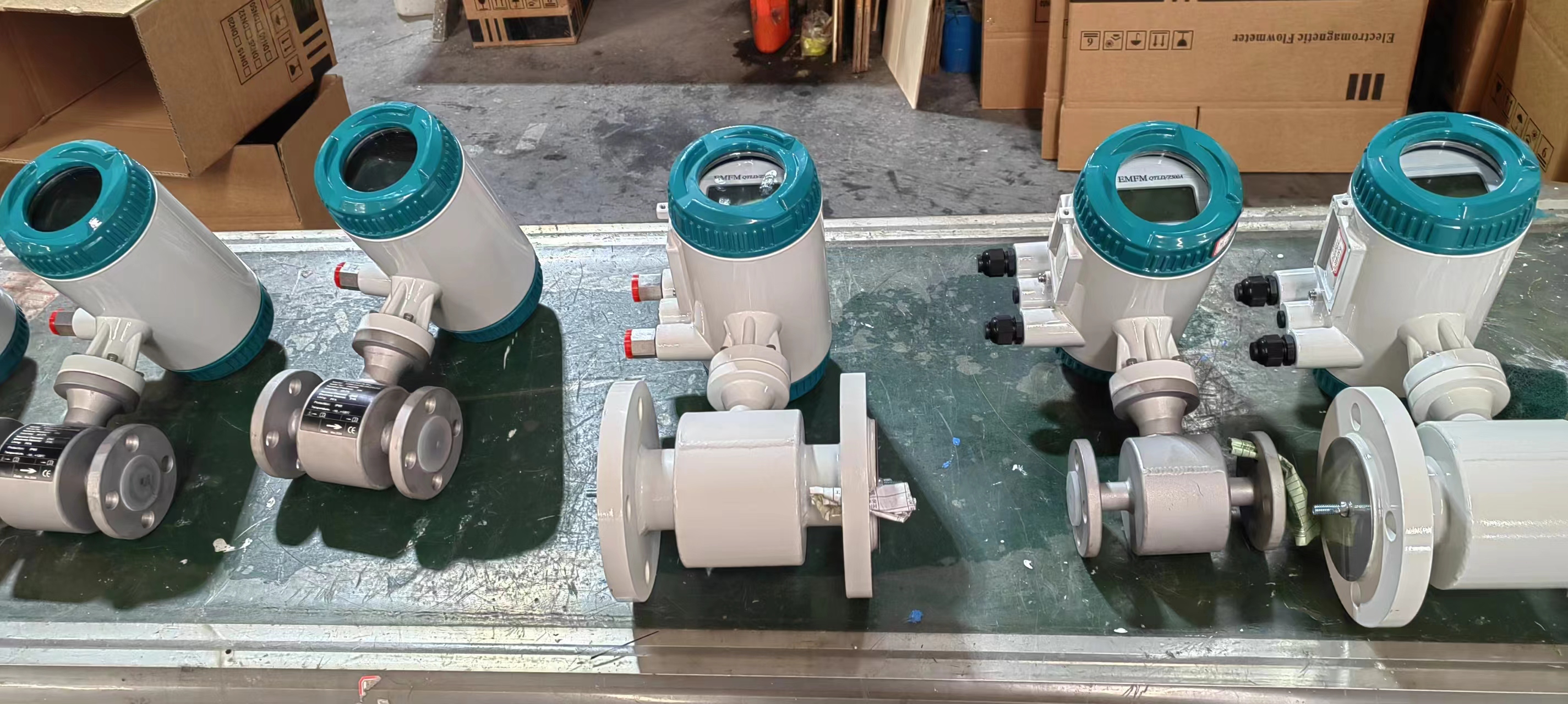

Electromagnetic flow meter selection

The correct selection of electromagnetic flowmeter is the prerequisite to ensure the good use of electromagnetic flowmeter. What kind of electromagnetic flowmeter should be selected should be determined according to the physical and chemical properties of the measured body medium, so that the diameter of the electromagnetic flowmeter, flow range, lining material, electrode material and output current, etc., can adapt to the nature and flow requirements of the measured body.

Fluid selection

According to the working principle of the electromagnetic flowmeter, the fluid that chooses the electromagnetic flowmeter to measure the flow must be conductive, in addition to the high-temperature fluid, as long as the conductivity is greater than 5μ/cm of any fluid, the corresponding electromagnetic flowmeter is selected to measure the flow, so the non-conductive gas, steam, oil, acetone and other substances can not choose the electromagnetic flowmeter to measure the flow.

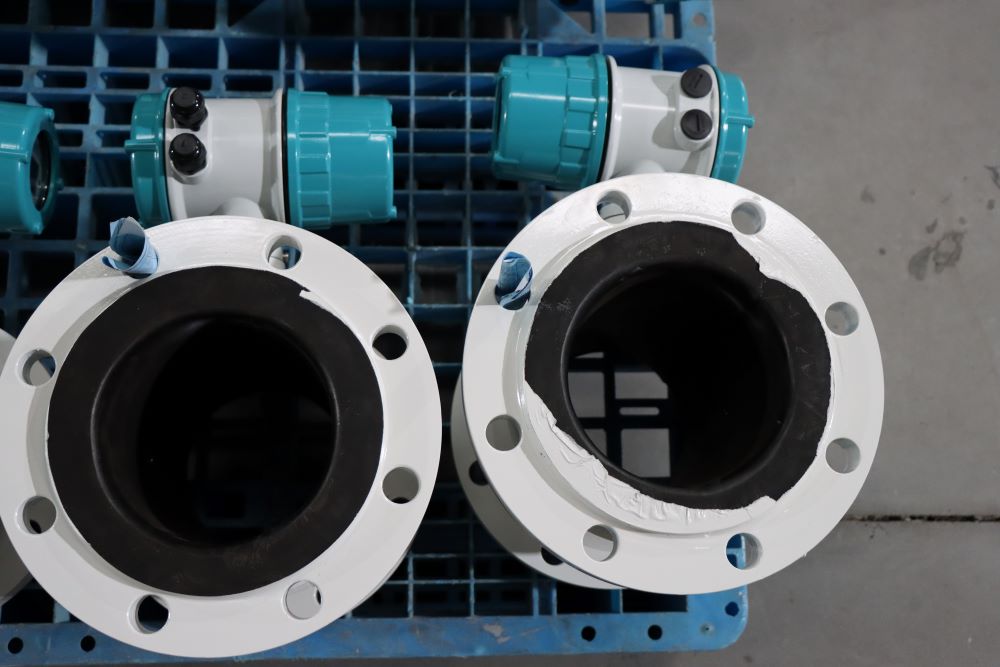

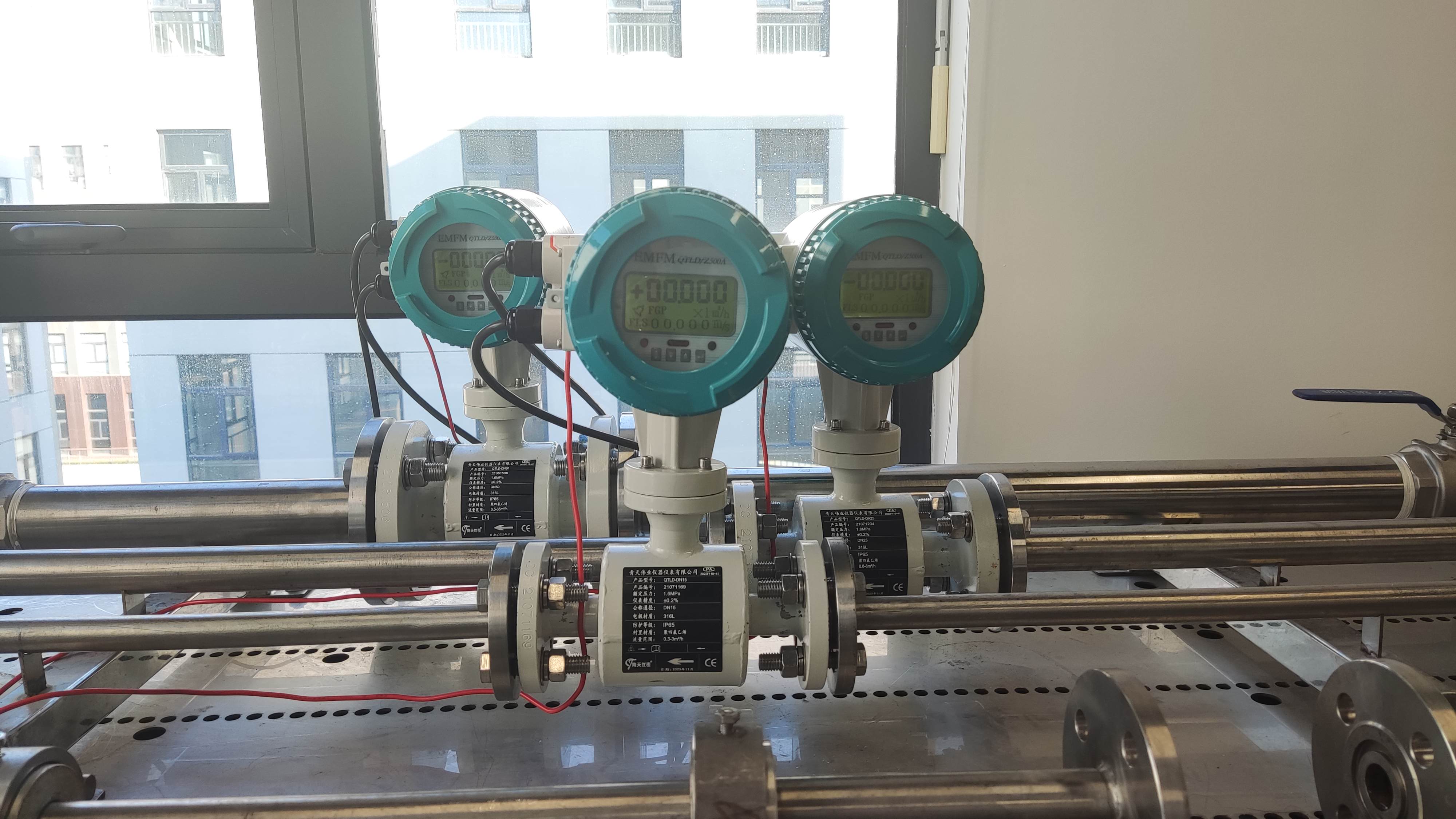

Determination of sensor caliber

The flow rate of the flowmeter is in the range of 0.3~15m/s, and the diameter of the flowmeter can be selected to be consistent with the diameter of the user’s pipeline. When the flow rate is lower than 0.3m/s, install shrinkage tubes on the upper and downstream straight pipe sections to increase the flow rate locally.