Electromagnetic flow meter on the choice of lining

Another important requirement of the electromagnetic flowmeter: how to accurately select the lining material, the lining material of the electromagnetic flowmeter should be selected according to the erosion, wear and temperature of the measured medium.

Natural rubber (soft rubber)

1, good elasticity, wear resistance and tearing force

2, resistance to general weak acid, weak alkali erosion

Measuring water, sewage

Acid-resistant rubber (hard rubber) can withstand the attack of hydrochloric acid, acetic acid, oxalic acid, ammonia, phosphoric acid and 50% sulfuric acid, sodium hydroxide, potassium hydroxide at room temperature, but it is not resistant to the attack of strong oxidants in general acid, alkali and salt solutions

Neoprene rubber 1, excellent elasticity, high tearing force, good wear resistance

2, resistant to general low concentration of acid, alkali, salt solution erosion, but not resistant to oxidation of the medium < 80℃;

Measuring water, sewage, mud and pulp

Polyamine rubber

1, excellent wear resistance

2, acid resistance, alkali function poor < 40℃ test neutral strong wear coal slurry, mud and pulp

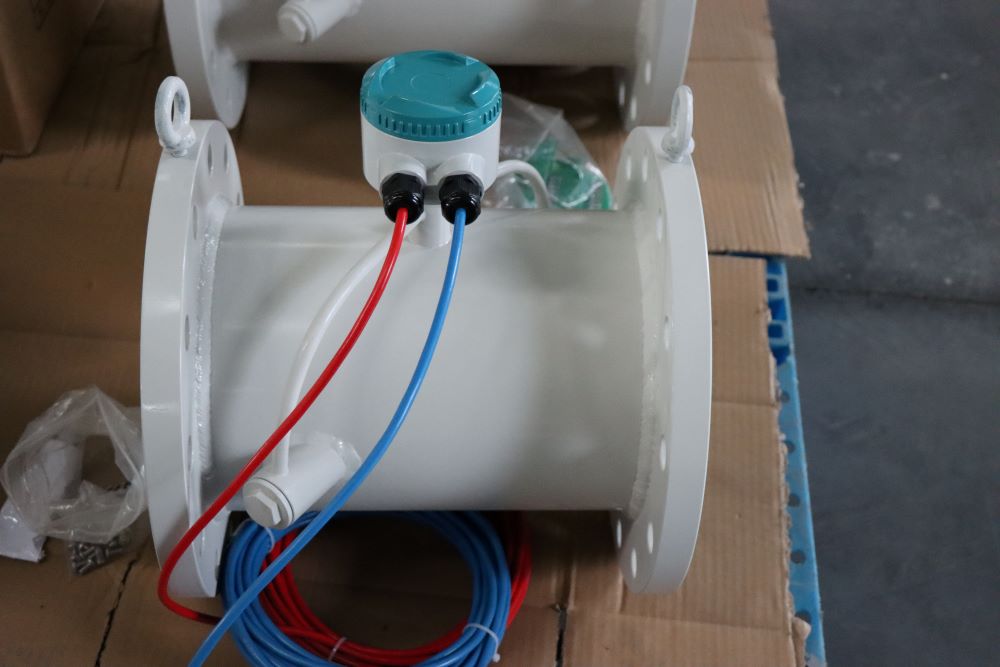

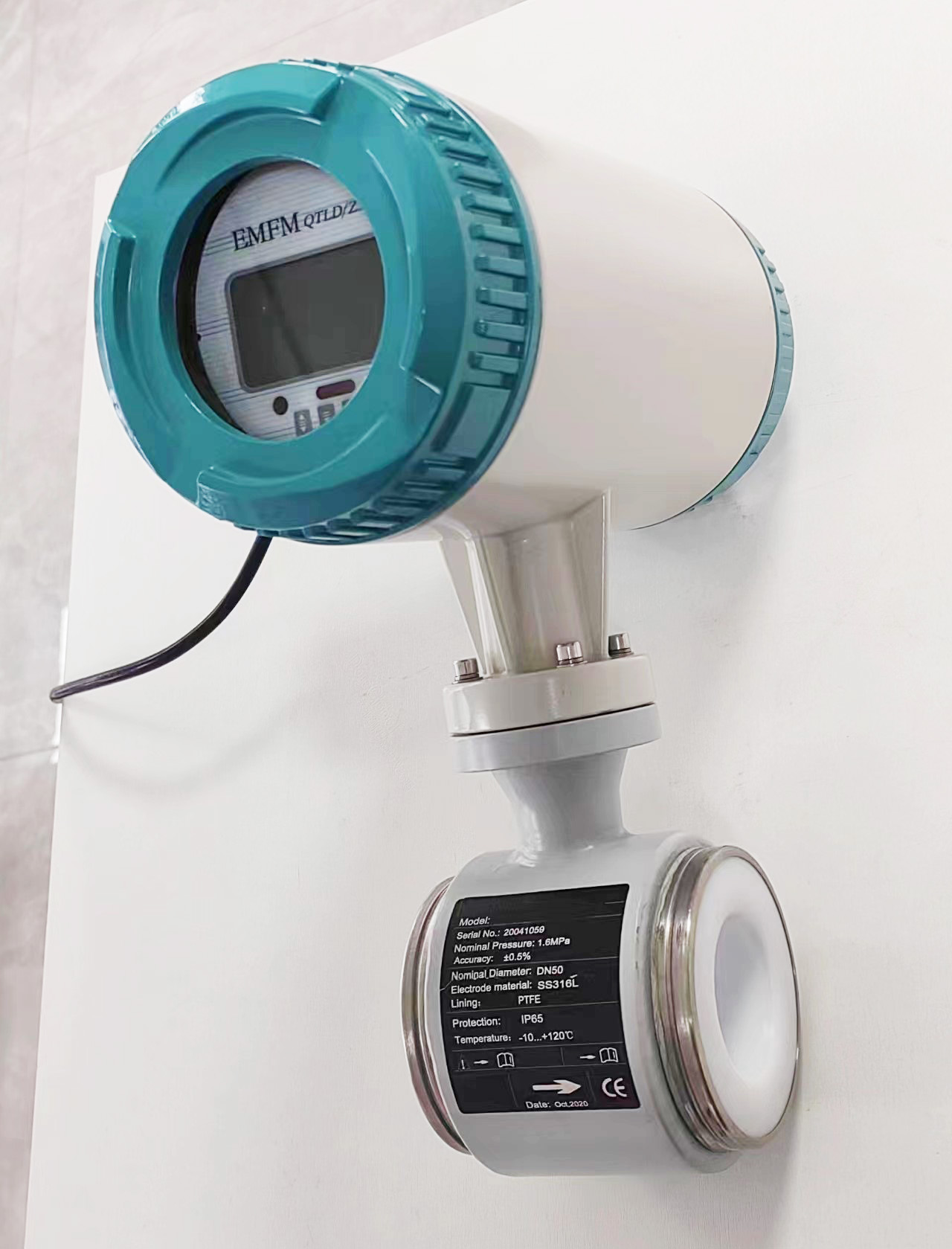

Polytetrafluoroethylene (PTFE)

1, resistant to boiling hydrochloric acid, sulfuric acid, nitric acid, aqua Regis, concentrated alkali and various organic solvents

2, good wear resistance, poor bonding function -80 ~ +180℃;

Measuring concentration, strong corrosive solution of concentrated alkali and sanitary medium

-.jpg)

-.jpg)