Electromagnetic flow meter maintenance

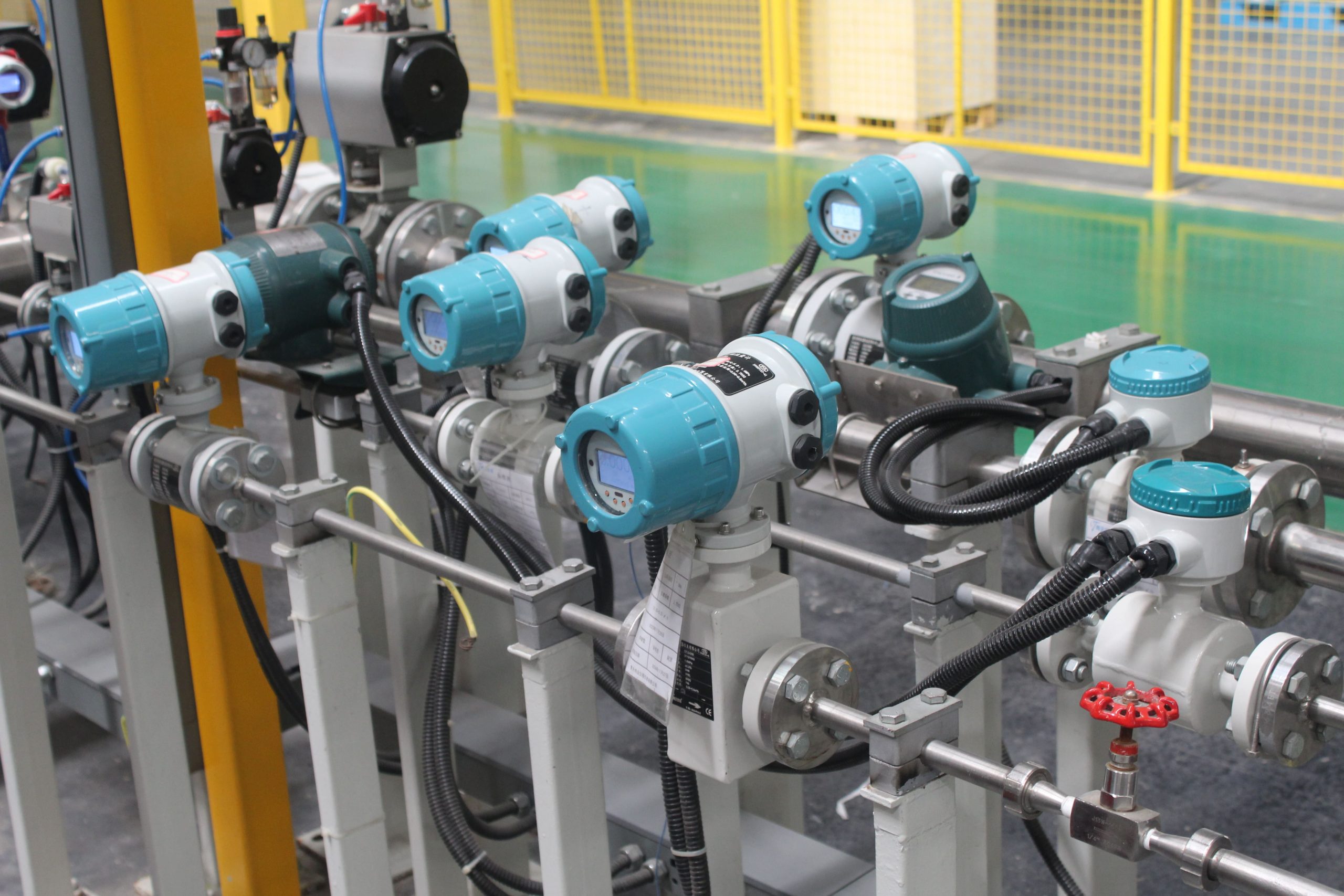

Fixed the electromagnetic flowmeter for periodic visual inspection, check the environment around the instrument, clean dirt, ensure that no water and other substances, check whether the wiring is good, check whether the electromagnetic flowmeter near the new installation of strong electromagnetic field equipment or a new wire across the instrument.

1. Daily maintenance

Fixed the electromagnetic flowmeter for periodic visual inspection, check the environment around the instrument, clean dirt, ensure that no water and other substances, check whether the wiring is good, check whether the electromagnetic flowmeter near the new installation of strong electromagnetic field equipment or a new wire across the instrument. If the measuring medium is easy to stain the electrode or precipitate and scale in the measuring tube wall, it should be cleaned and cleaned regularly.

2. Fault search

After the electromagnetic flowmeter is put into operation or normal operation for a period of time, it is found that the meter is not working normally, you should first check the external situation of the flow electromagnetic flowmeter, such as whether the power supply is good, whether the pipeline leaks or is in a non-full tube state, whether there are bubbles in the pipeline, whether the signal cable is damaged, and whether the output signal of the converter (that is, the input loop of the meter in the back) is open. Remember to dismantle flowmeters blindly.

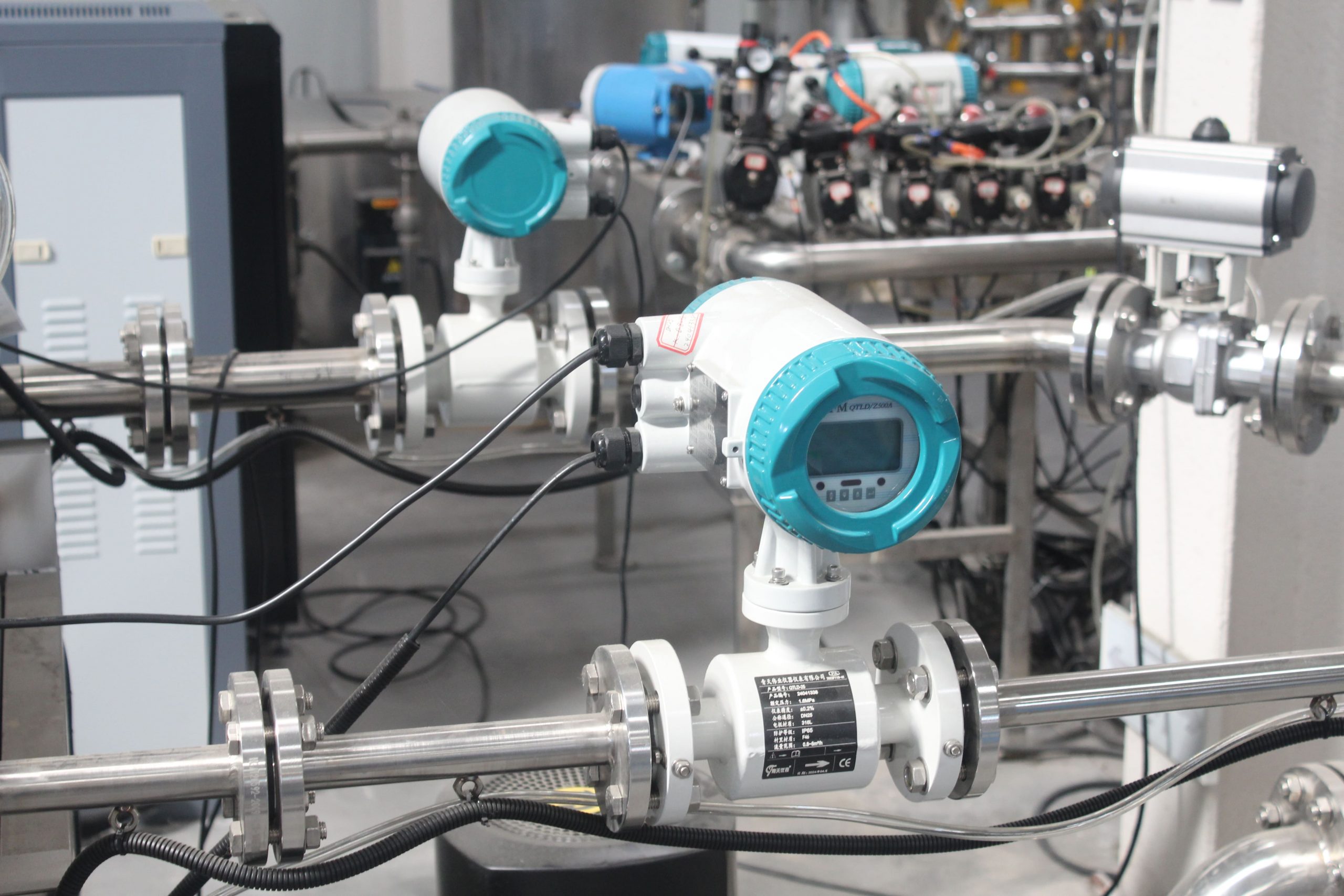

3, sensor inspection

Test equipment: one 500MΩ insulation resistance tester, one multimeter.

Test steps:

(1) In the case that the pipeline is full of media, use A multimeter to measure the resistance value between the terminal A, B and C, and the resistance value between A-C and B-C should be equal. If the difference is more than 1 times, there may be leakage of the electrode, condensate adsorption in the outer wall of the measuring tube or the junction box.

(2) When the lining is dry, use the MΩ meter to measure the insulation resistance between A-C and B-C (should be greater than 200MΩ). Then use A multimeter to measure the resistance between terminals A and B and the two electrodes in the measuring tube (the connection should be short circuit). If the insulation resistance is small, it indicates that the electrode is leaking, and the whole flowmeter should be returned to the factory for maintenance. If the insulation has decreased but is still more than 50MΩ and the inspection result of step (1) is normal, the outer wall of the measuring tube may be damp, and the inside of the housing can be dried by a hot fan.

(3) Use a multimeter to measure the resistance between X and Y, if more than 200Ω, the excitation coil and its lead line may be open or poor contact. Remove the terminal board and check.

(4) Check the insulation resistance between X, Y and C, should be more than 200MΩ, if it drops, use hot air to dry the inside of the shell. In actual operation, the decrease of coil insulation will lead to the increase of measurement error and the instability of instrument output signal.

-.jpg)

-.jpg)