Electromagnetic flow meter installation should be noted

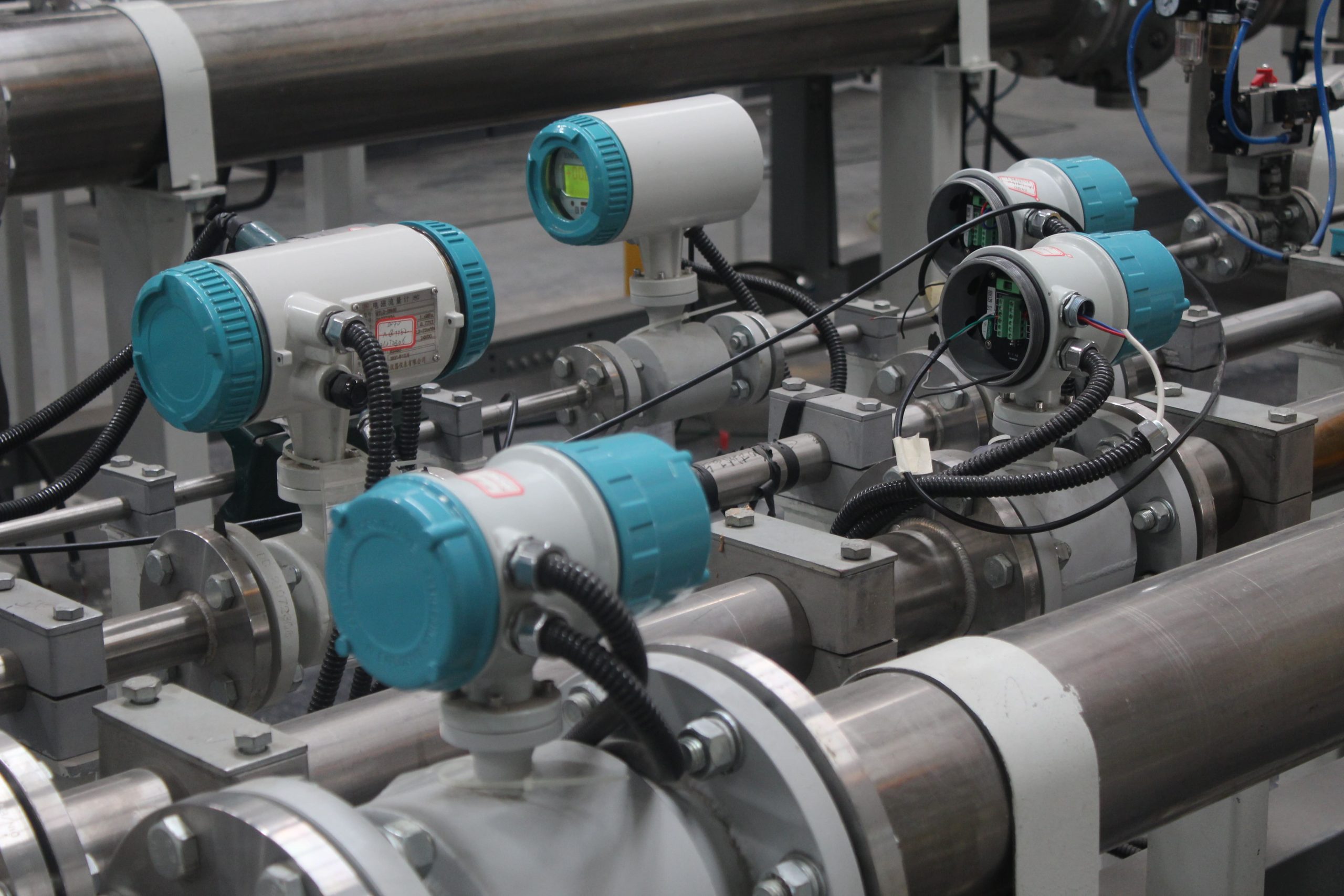

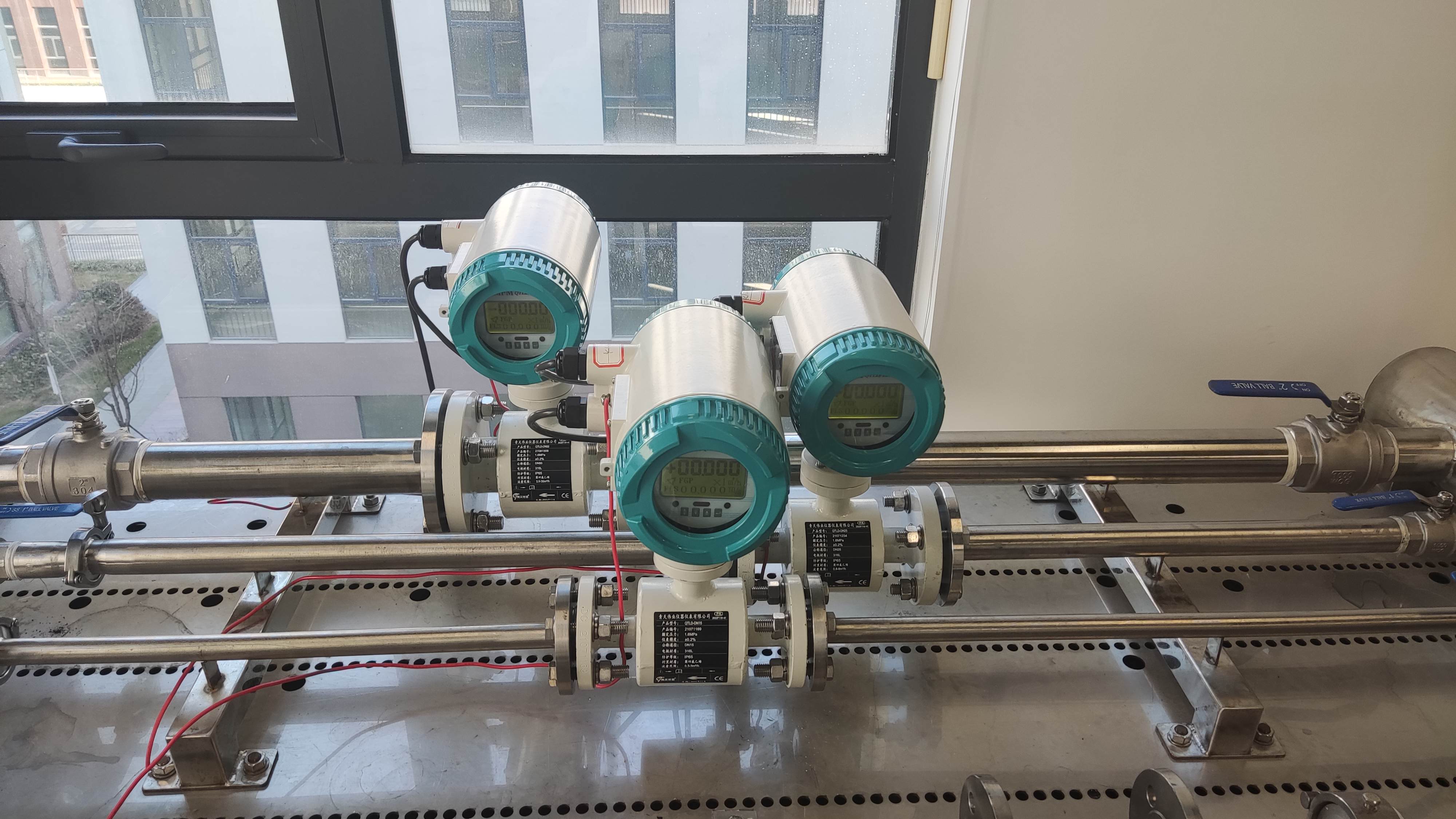

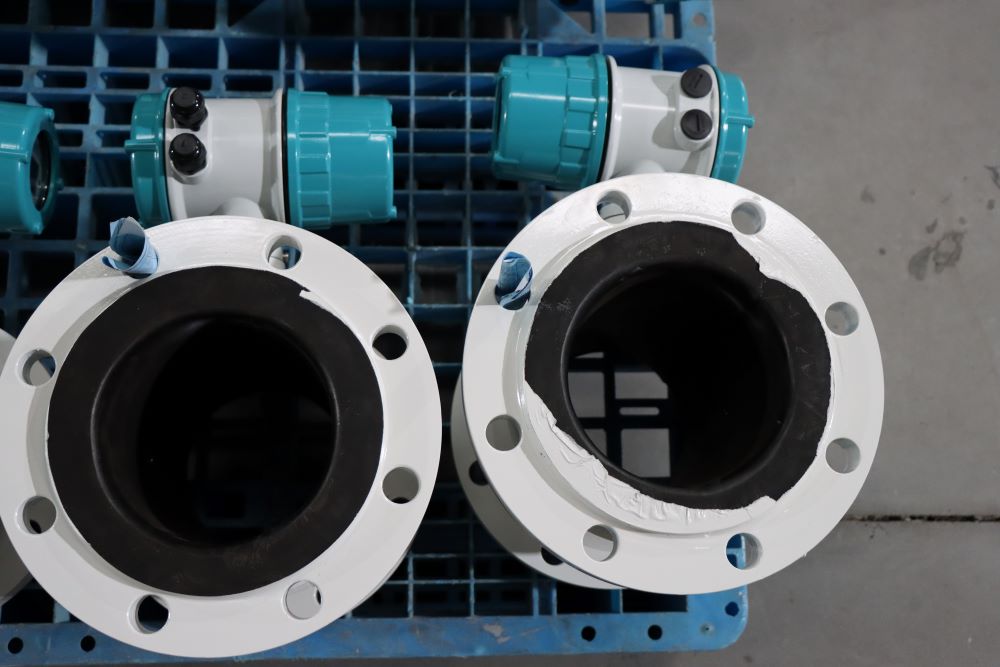

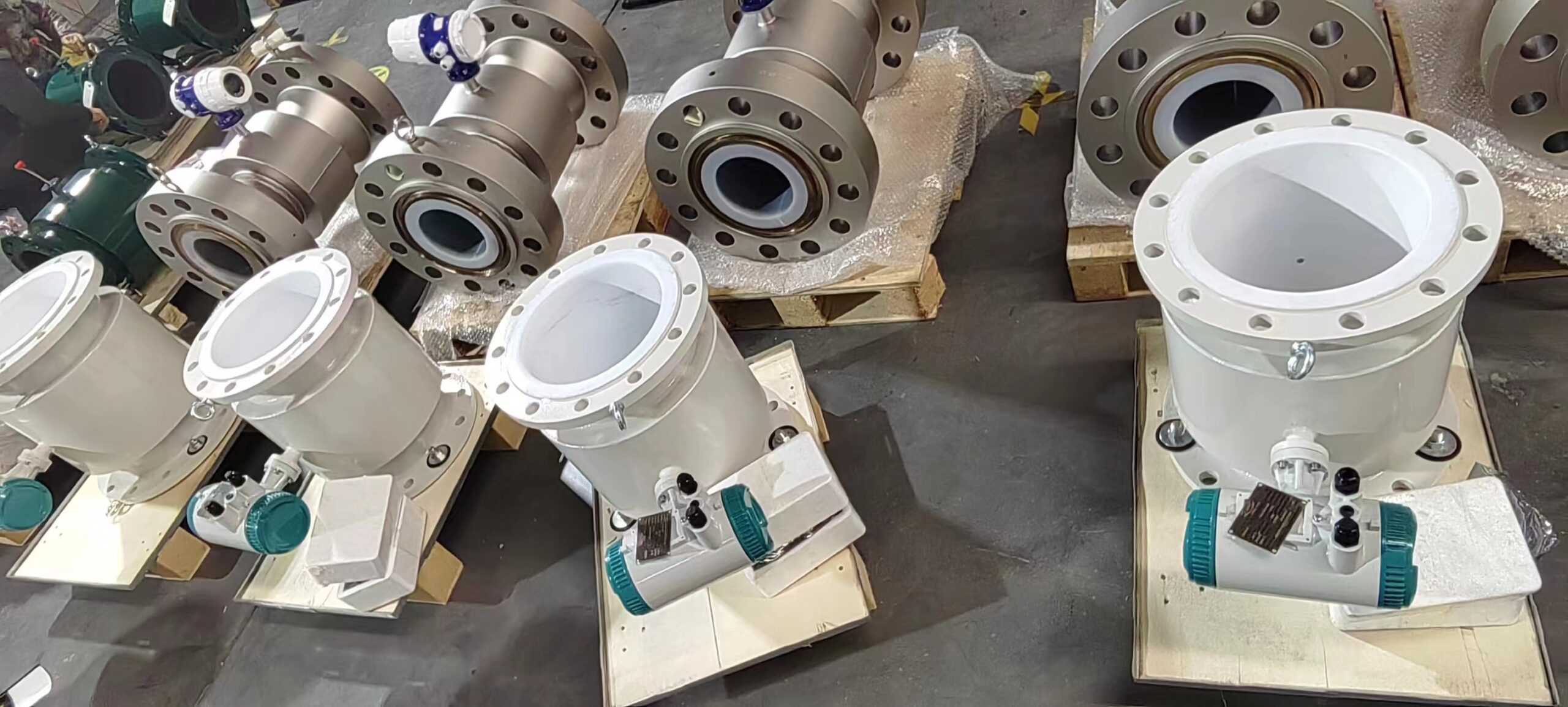

The shell protection level of the ordinary electromagnetic flowmeter sensor is IP65 (the dustproof and anti-splash level stipulated by GB4208), and the requirements for the installation site are:

1. When measuring mixed phase fluid, a place that will not cause phase separation should be selected;

2. Select a place where there is no negative pressure in the measuring tube;

3. Avoid installation near strong electric equipment such as motors and transformers to avoid electromagnetic field interference;

4. Avoid installation in places with strong corrosive gases around;

5. The ambient temperature should generally be in the range of -25~60 ° C, as far as possible to avoid direct sunlight;

6. Install in a place with no vibration or small vibration. If the vibration is too large, a fixed support should be added to the pipe before and after the sensor.

7. The relative humidity of the environment should generally be in the range of 10% to 90%;

8. Avoid installation in places that can be directly flooded by rain or submerged by water. If the shell protection level of the electromagnetic flowmeter sensor is IP67 (dustproof and waterproof) or IP68 (dustproof and waterproof), the latter two items can not be required.

-.jpg)

-.jpg)

-.jpg)